Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-31-300-012 HPC Front Cases - Repair Loose Or Damaged Pin(s), Repair-012 (VRS6321)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

01-400 | 6A3462 | Assembly A |

01-400 | 6A3675 | Assembly A |

DELETED | ||

DELETED | ||

01-400 | 6A5470 | Assembly B |

01-400 | 6A4439 | Assembly C |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor Front Case Assembly | TEG | 4 per cent Aluminium, 6 percent Vanadium Titanium Alloy |

Pin | QAL or QAK | Nickel chromium heat resisting alloy |

Retaining ring | Nickel chromium steel |

General

This repair must only be done when the instruction to do so is given in 72-41-31 Inspection/Check.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Price and availability

Refer to International Aero Engines

Related repairs - none

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Workshop Inspection equipment | LOCAL | Workshop Inspection equipment | ||

| Jig boring machine | LOCAL | Jig boring machine | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Ring, retaining | AS20762 | 3 AR | ||

| Pin, grooved, Headless, | AS20742 | 3 AR | (standard) | |

| Pin, grooved, Headless, 0.005 in. | 6A5954 | 3 AR | (0,127 mm), (oversize) | |

| Pin, grooved, Headless, 0.010 in. | 6A5955 | 3 AR | (0,254 mm), (oversize) | |

| Ring, Retaining | AS20763 | 3 AR | ||

| Pin, grooved, Headless | AS20745 | 2 AR | (standard) | |

| Pin, grooved, Headless 0.005 in. | 6A5956 | 2 AR | (0,127 mm) , (oversize) | |

| Pin, grooved, Headless, 0.010 in. | 6A5957 | 2 AR | (0,254 mm), (oversize) | |

| Pin, grooved, Headless | AS20744 | 1 AR | (standard) | |

| Pin, grooved, Headless 0.005 in. | 6A5958 | 1 AR | (0,127 mm), (oversize) | |

| Pin, grooved, Headless, 0.010 in. | 6A5959 | 1 AR | (0,254 mm), (oversize) |

Safety Requirements

NONEProcedure

Refer to TASK 72-41-31-200-000 (INSPECTION/CHECK-000).

Use penetrant crack test equipment.

Cracks are not permitted.

Do a penetrant crack test.

SUBTASK 72-41-31-230-106 Do a Crack Test

Refer to Figure.

SUBTASK 72-41-31-350-093-A00 Remove Loose or Damaged Pin(s) and Retaining Ring(s), Assembly A

Refer to Figure.

SUBTASK 72-41-31-350-093-B00 Remove Loose or Damaged Pin(s) and Retaining Ring(s) Assembly B

Refer to Figure.

SUBTASK 72-41-31-350-093-C00 Remove Loose or Damaged Pin(s) and Retaining Ring(s), Assembly C

Refer to the SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) with penetrant crack test equipment.

Cracks not permitted.

Do a penetrant crack test.

SUBTASK 72-41-31-230-107 Do a Crack Test

SUBTASK 72-41-31-322-052-A00 Machine the Pin Hole(s), Assembly A

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.SUBTASK 72-41-31-322-052-B00 Machine the Pin Hole(s), Assembly B

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.SUBTASK 72-41-31-322-052-C00 Machine the Pin Hole(s), Assembly C

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Refer to the SPM TASK 70-23-05-230-501.

Use Co Mat 06-022 fluorescent penetrant with penetrant crack test equipment.

Cracks are not permitted.

Do a penetrant crack test.

SUBTASK 72-41-31-230-110 Do a Crack Test

Use CoMat 03-026 LIQUID NITROGEN and standard workshop equipment.

Freeze the pin(s).

SUBTASK 72-41-31-350-095-A00 Install the Pin(s) and Retaining ring(s) into the HP Compressor Front Case Assembly, Assembly A

Use CoMat 03-026 LIQUID NITROGEN and standard workshop equipment.

Freeze the pin(s).

SUBTASK 72-41-31-350-095-B00 Install the Pin(s) and Retaining ring(s) into the HP Compressor Front Case Assembly, Assembly B

Use CoMat 03-026 LIQUID NITROGEN and standard workshop equipment.

Freeze the pin(s).

SUBTASK 72-41-31-350-095-C00 Install the Pin(s) and Retaining ring(s) into the HP Compressor Front Case Assembly, Assembly C

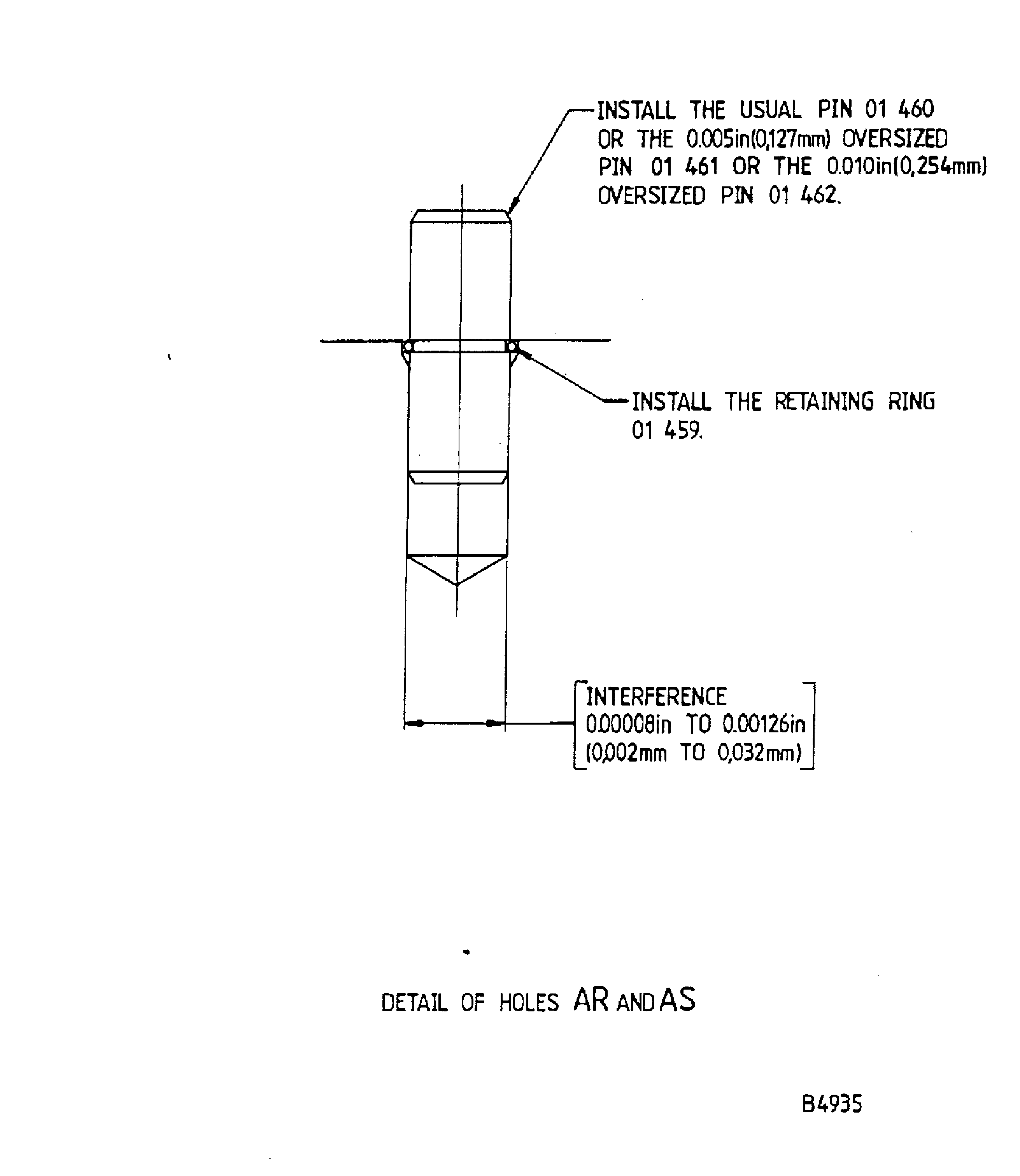

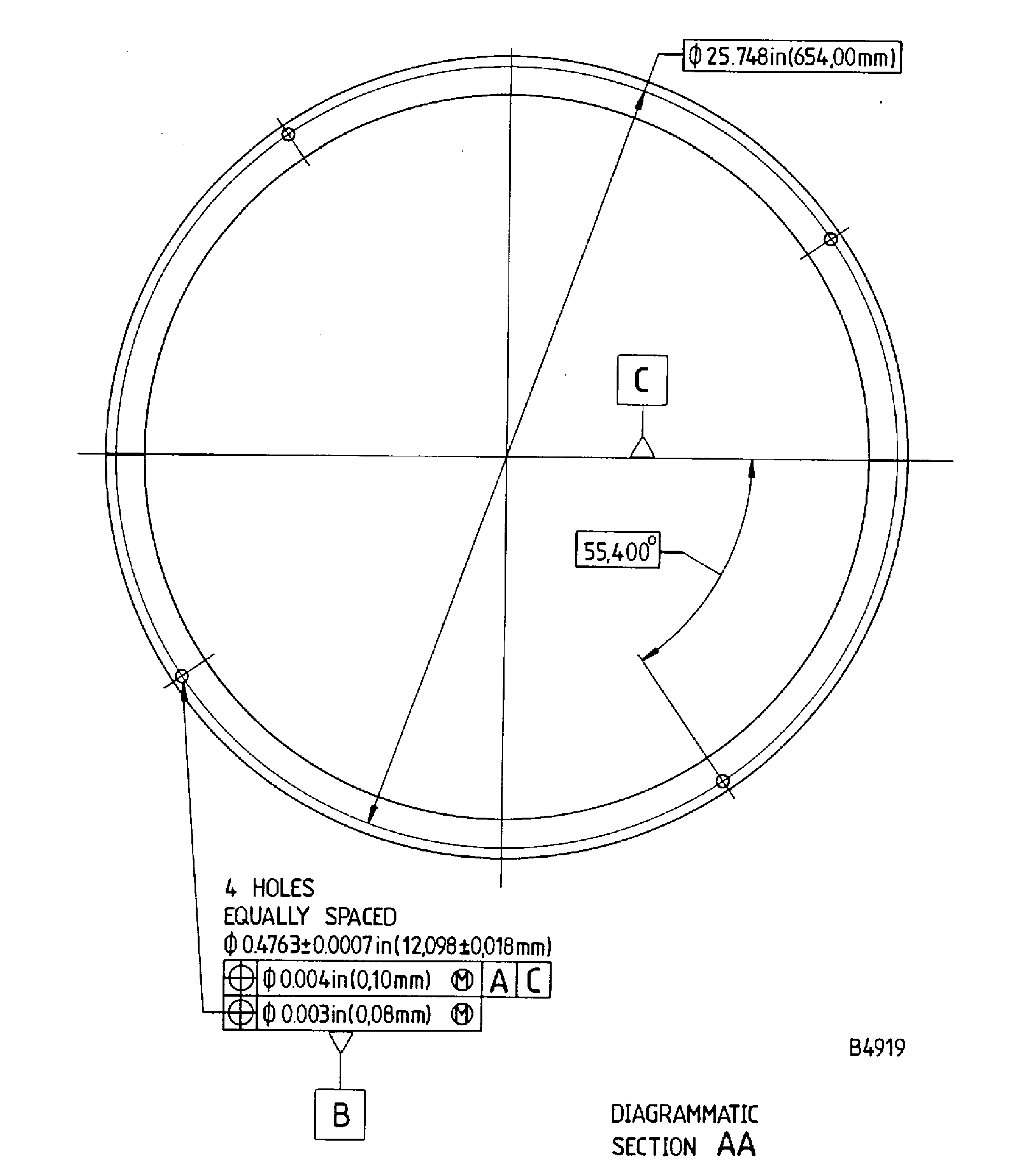

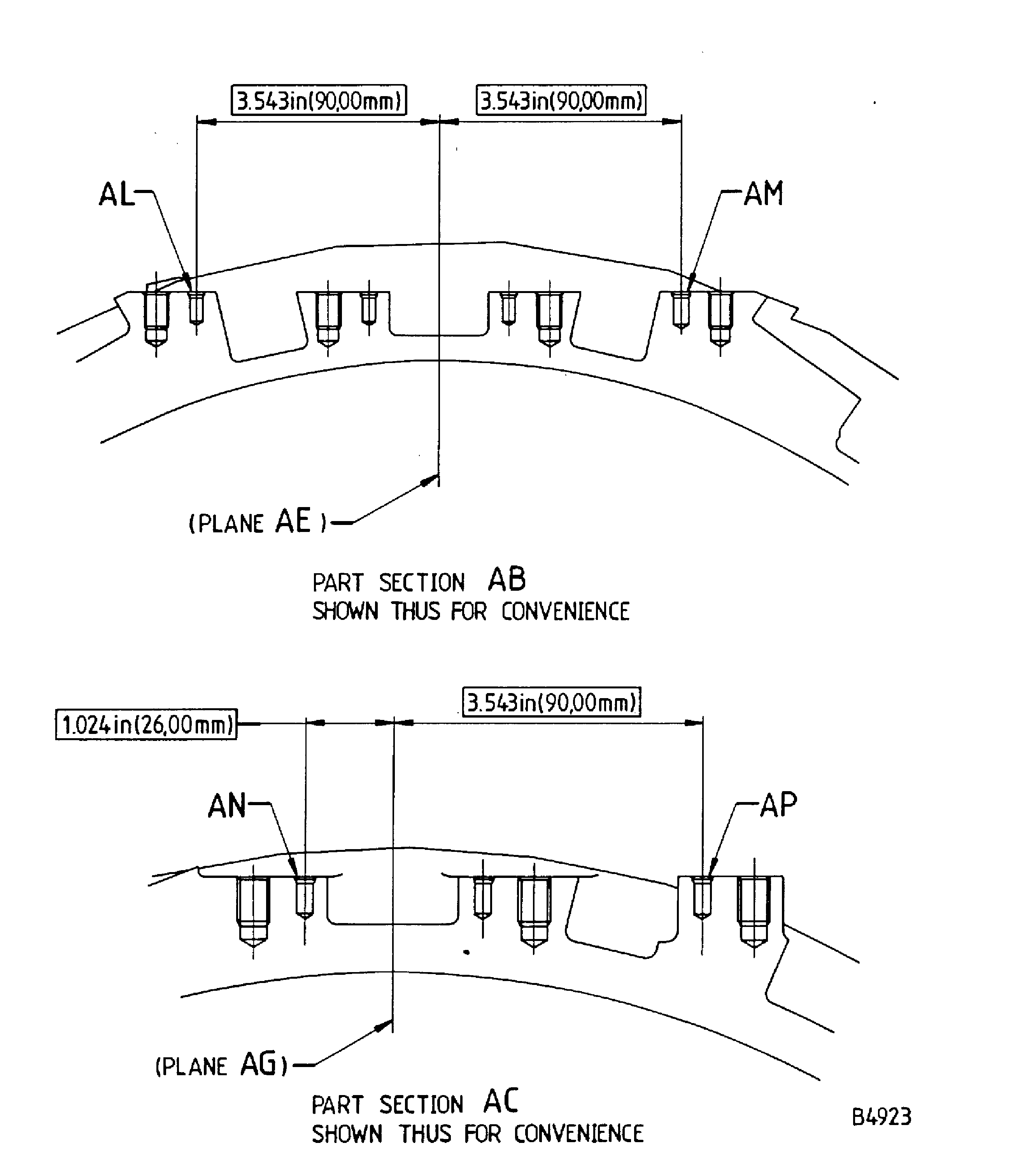

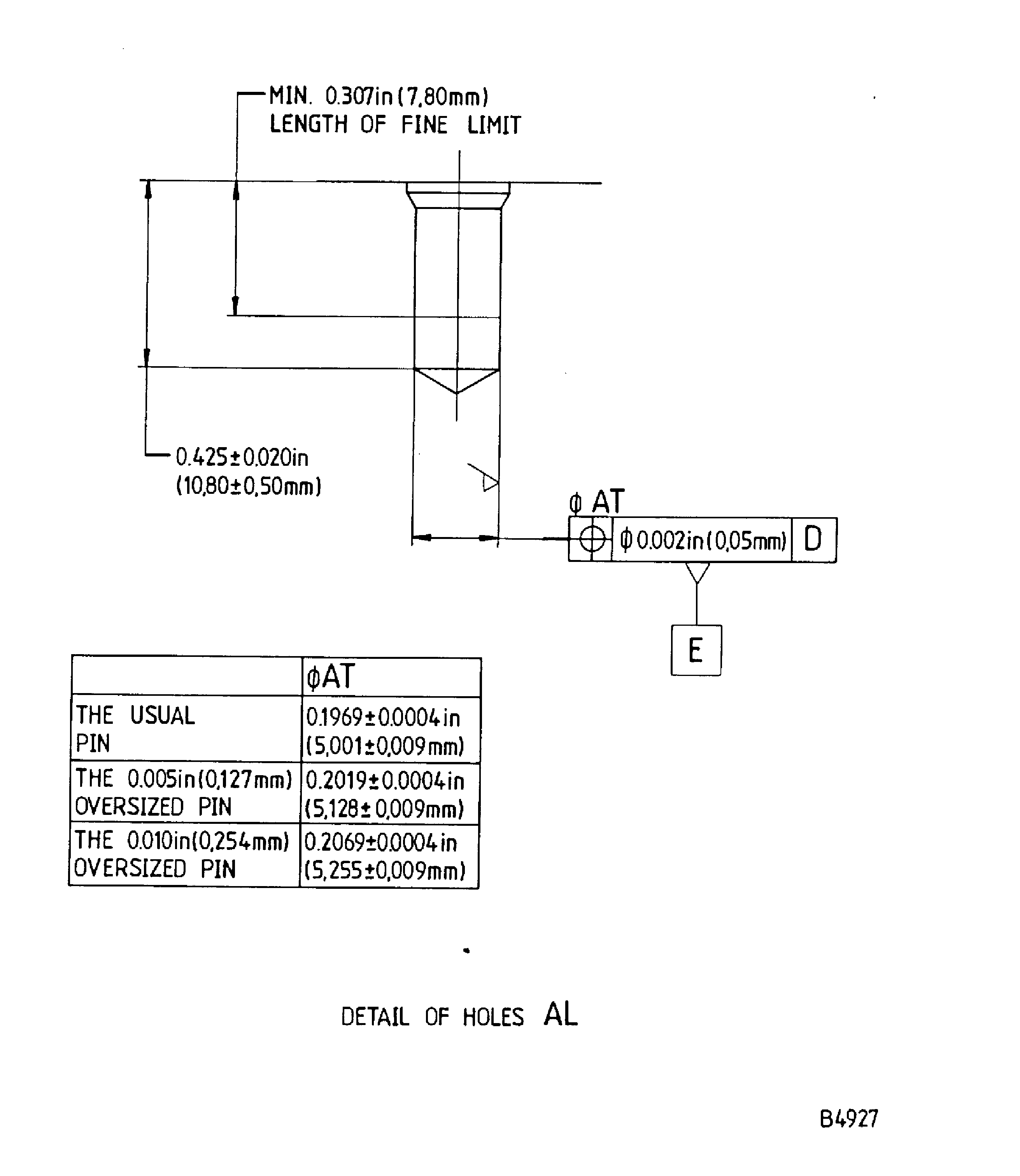

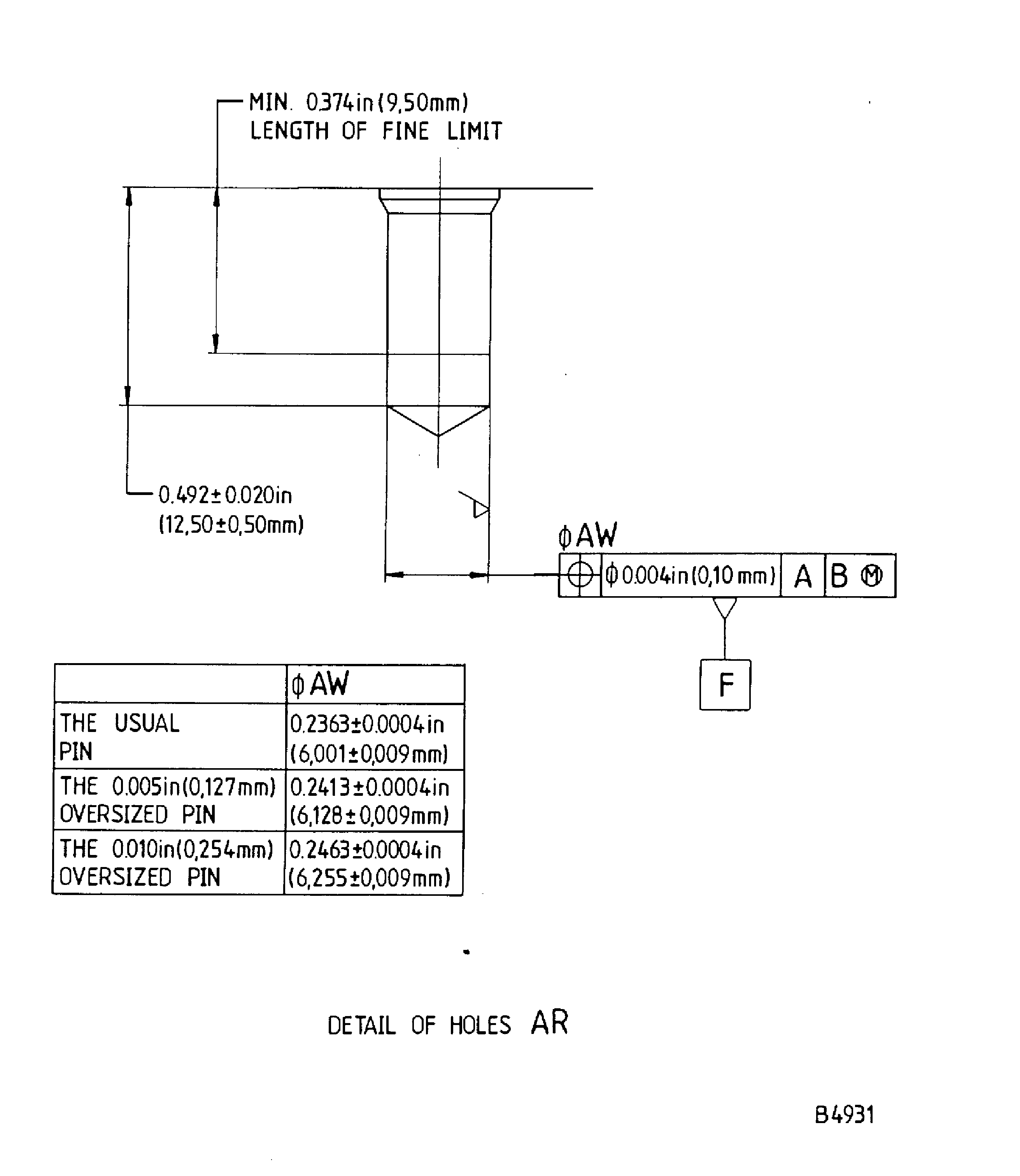

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

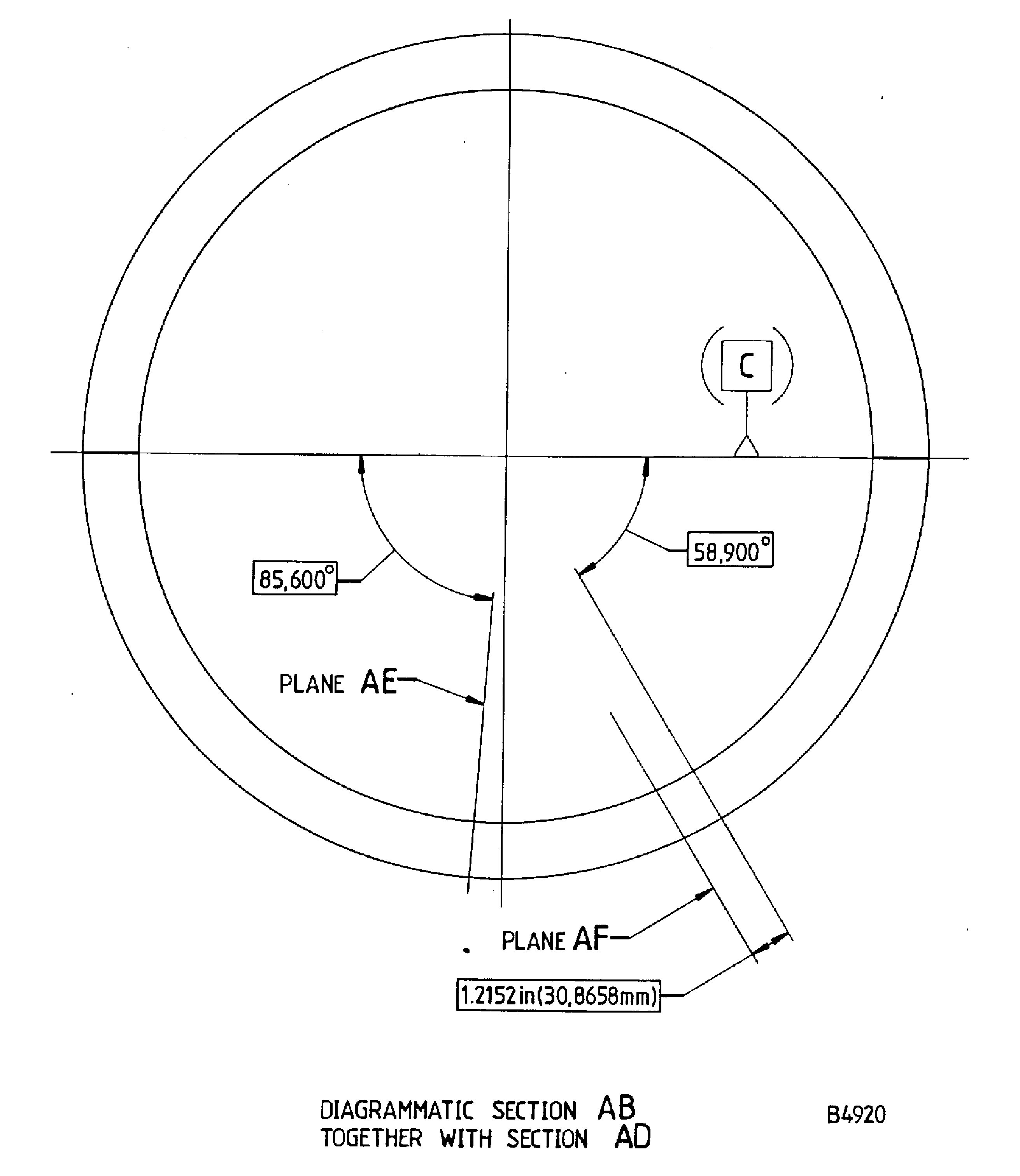

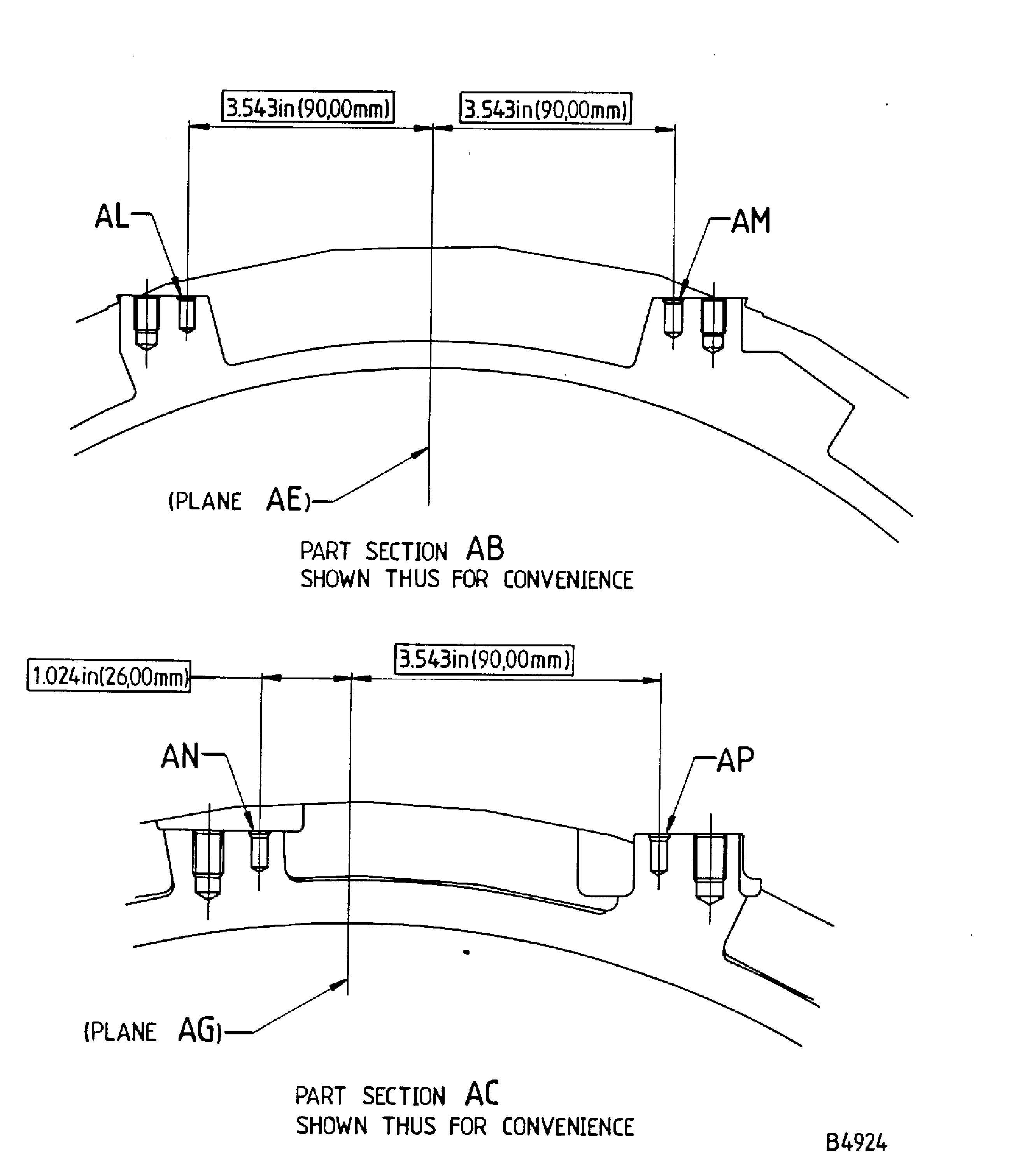

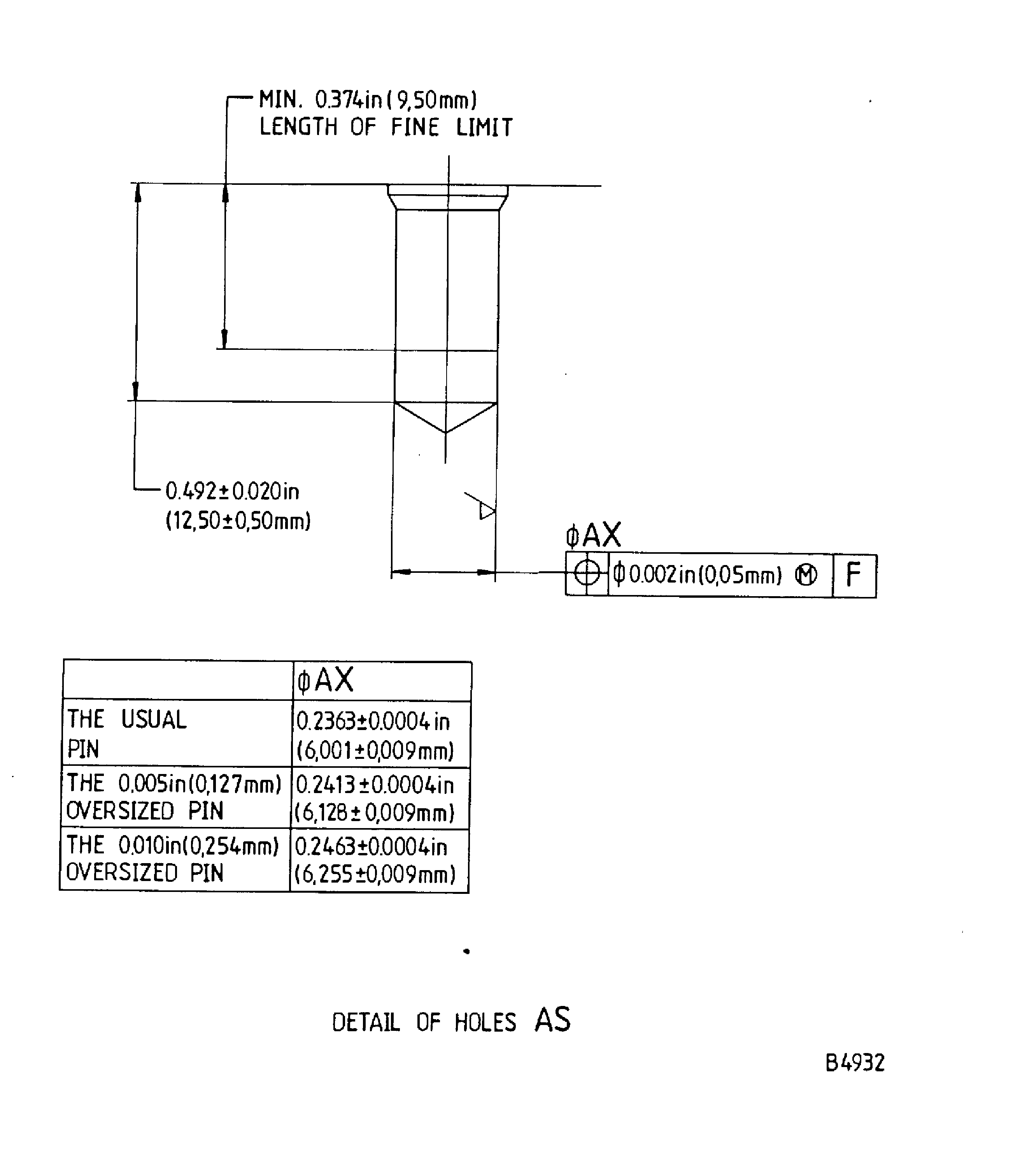

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

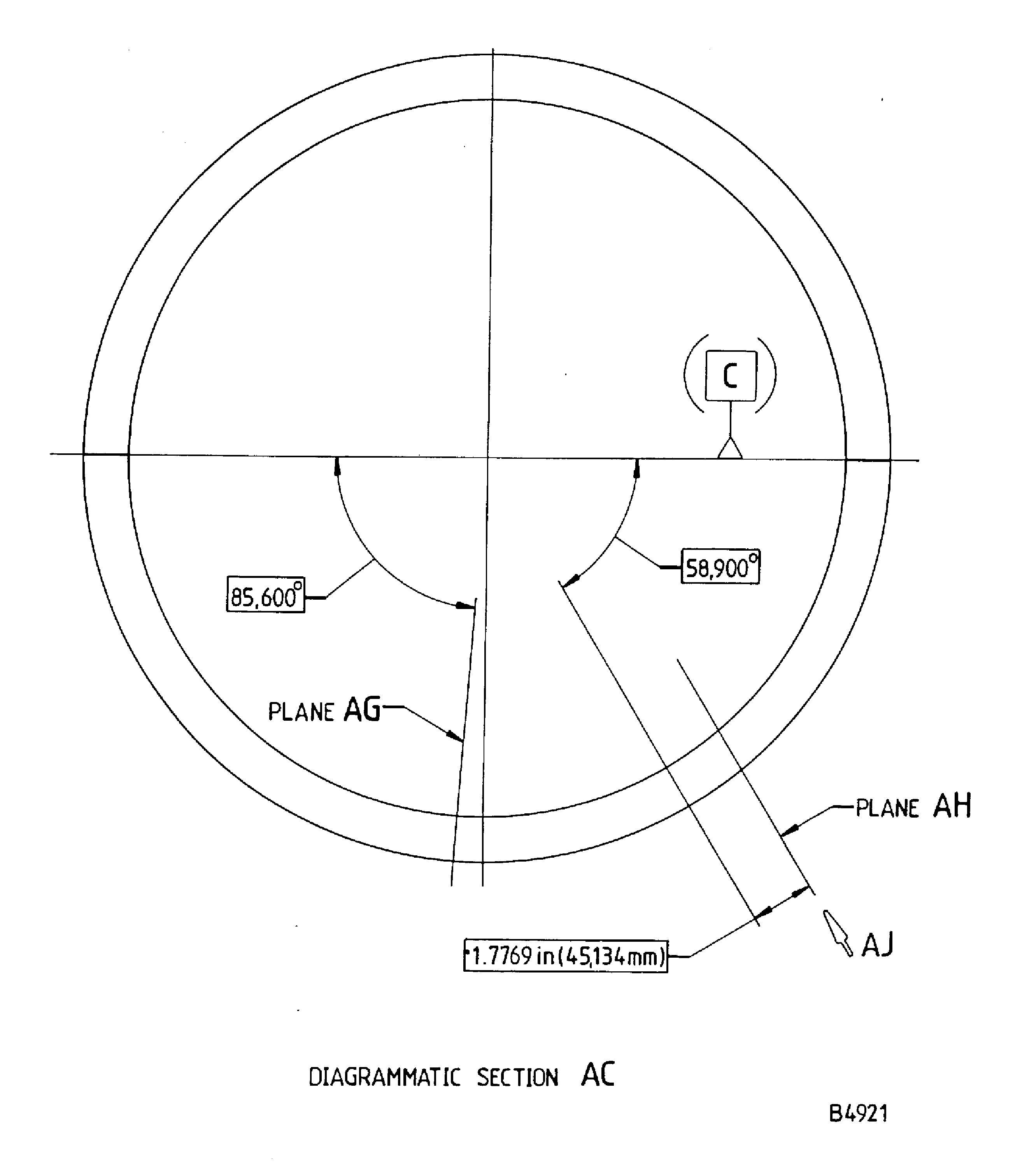

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

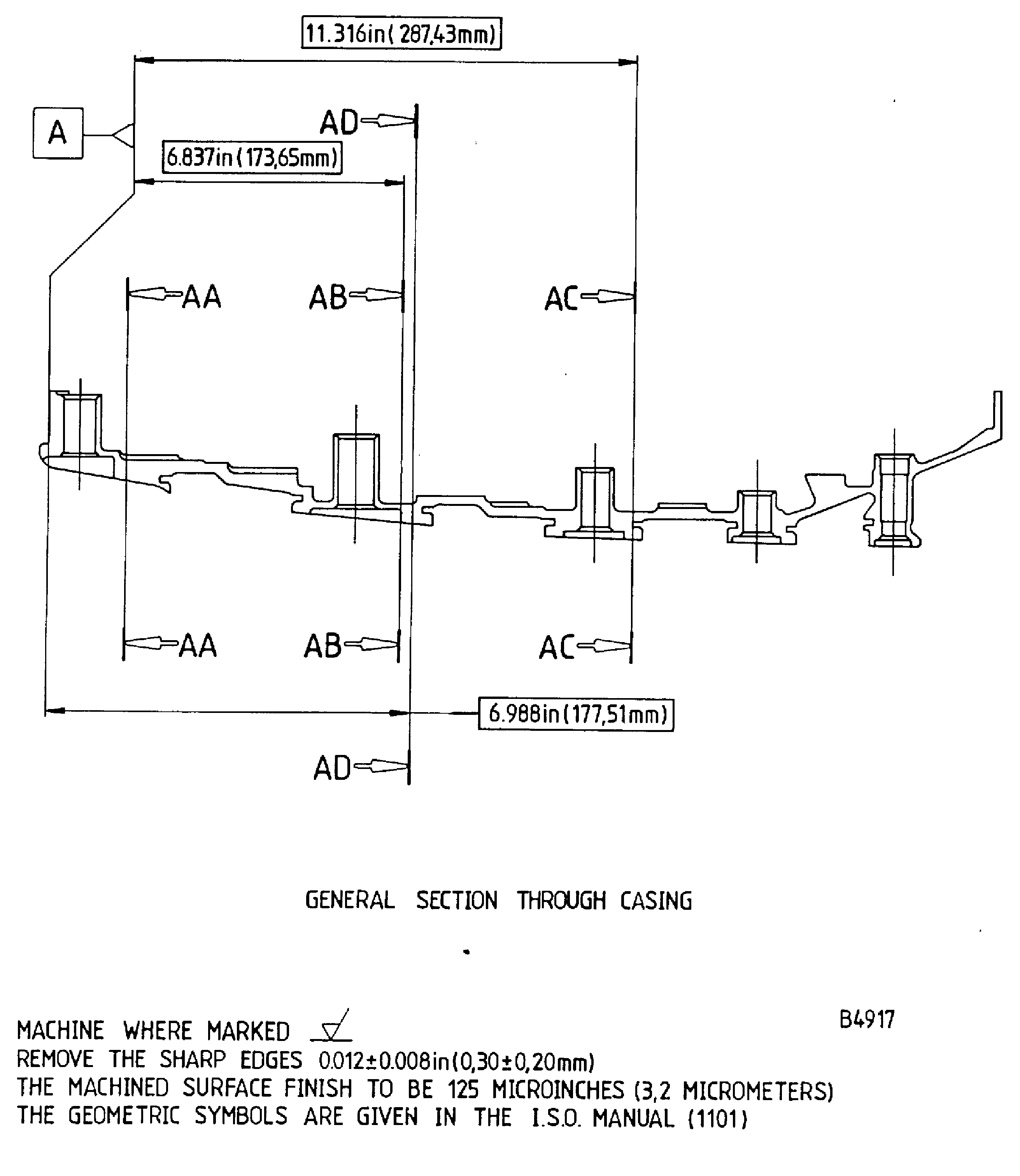

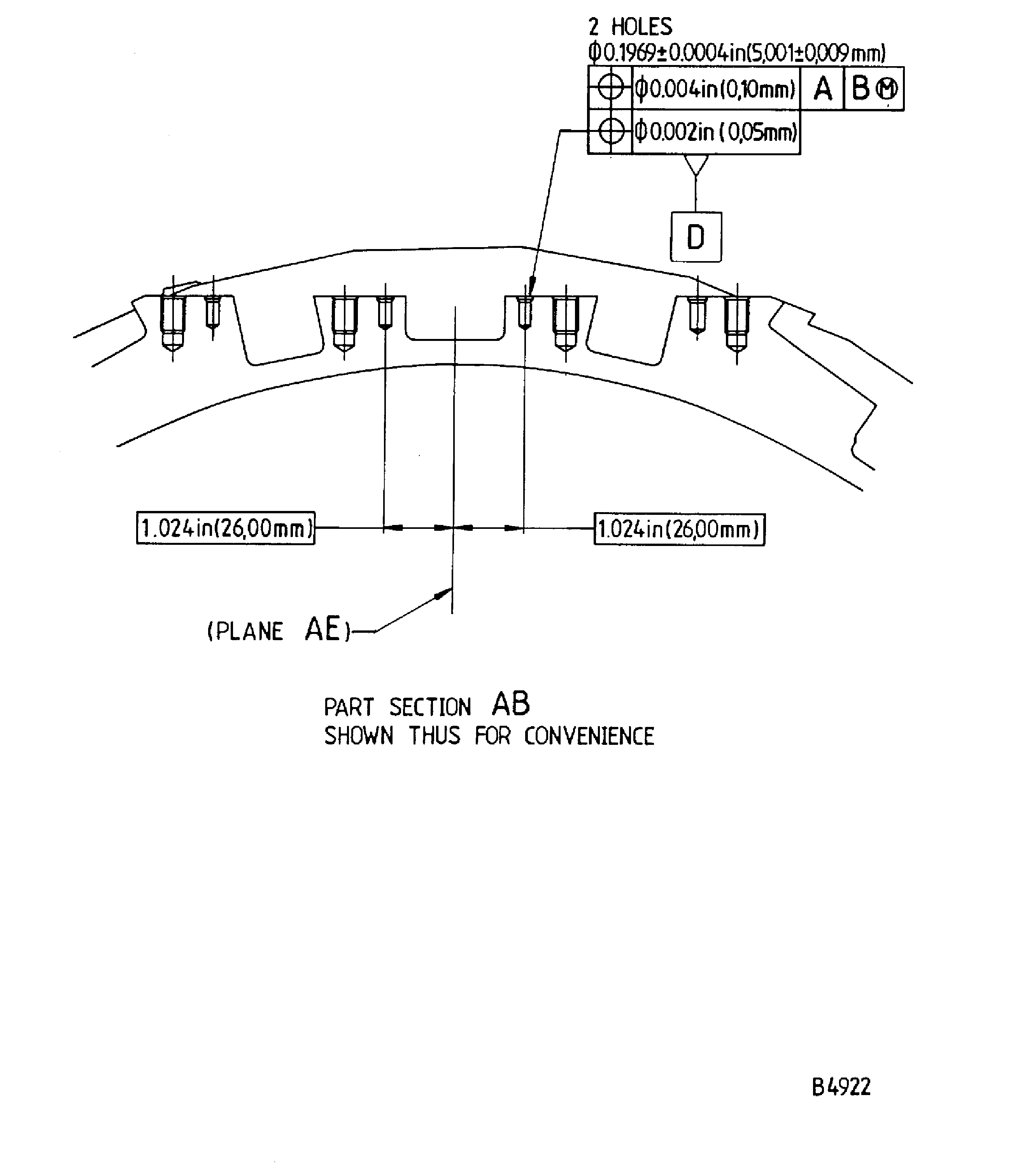

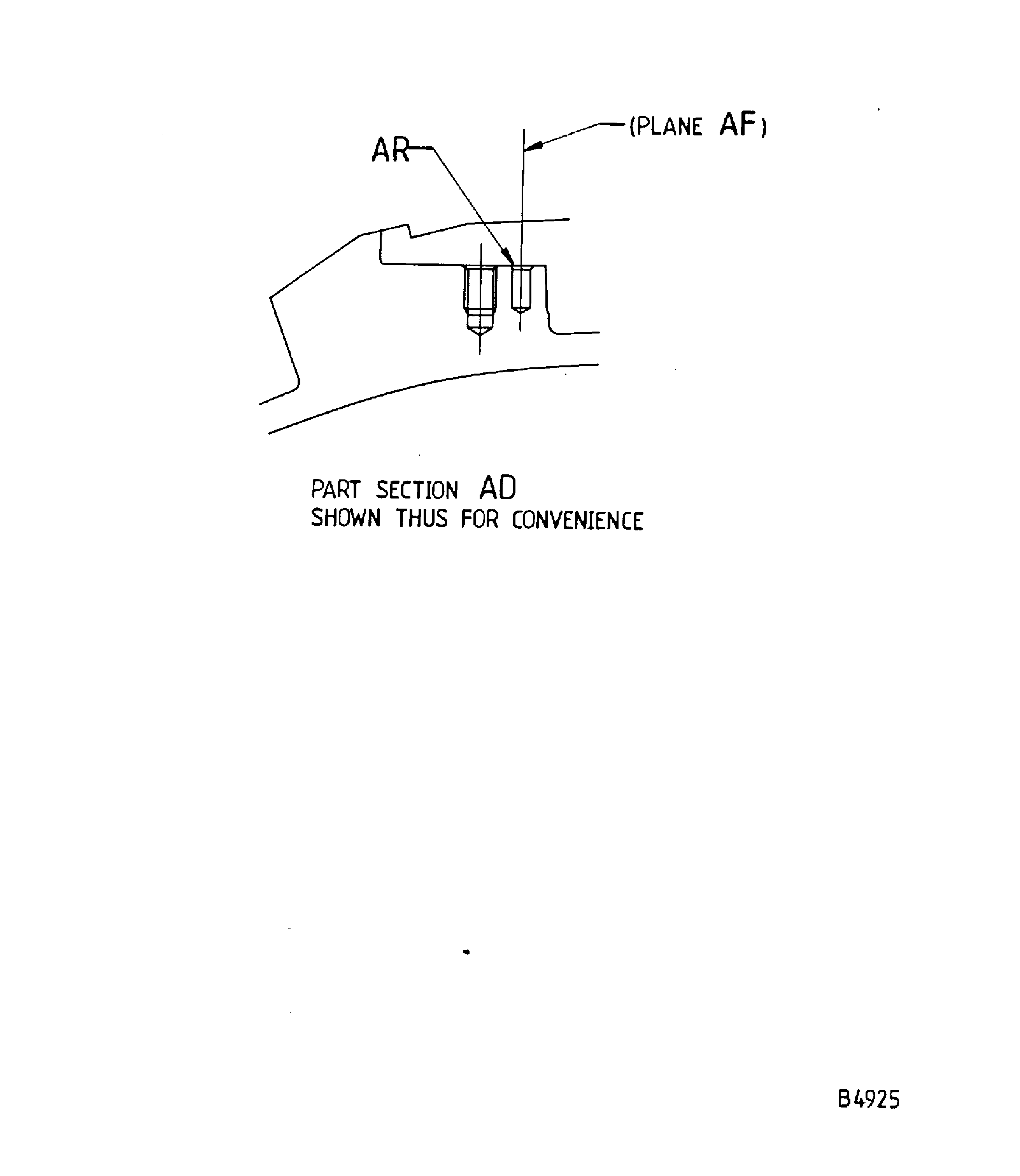

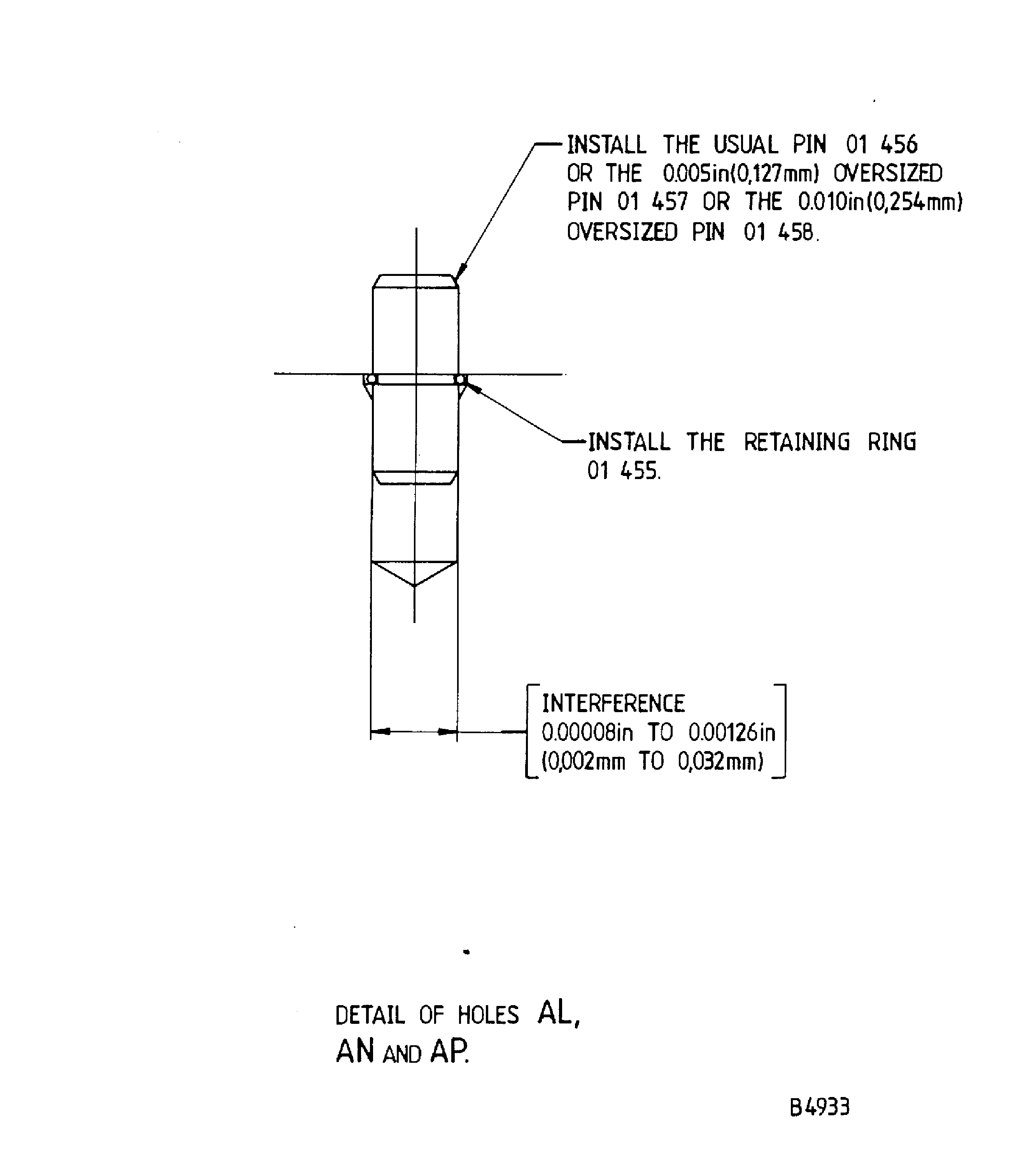

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C

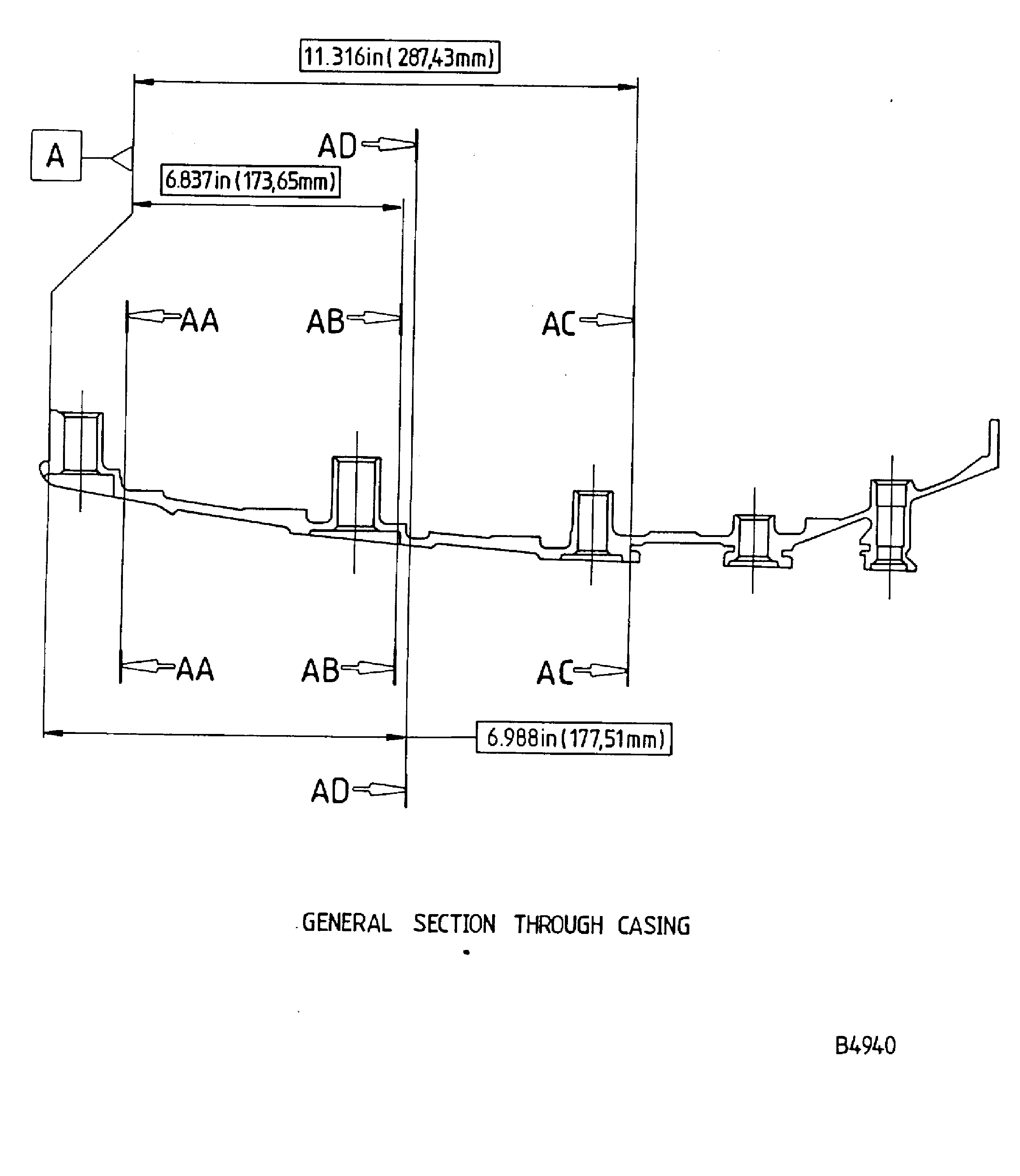

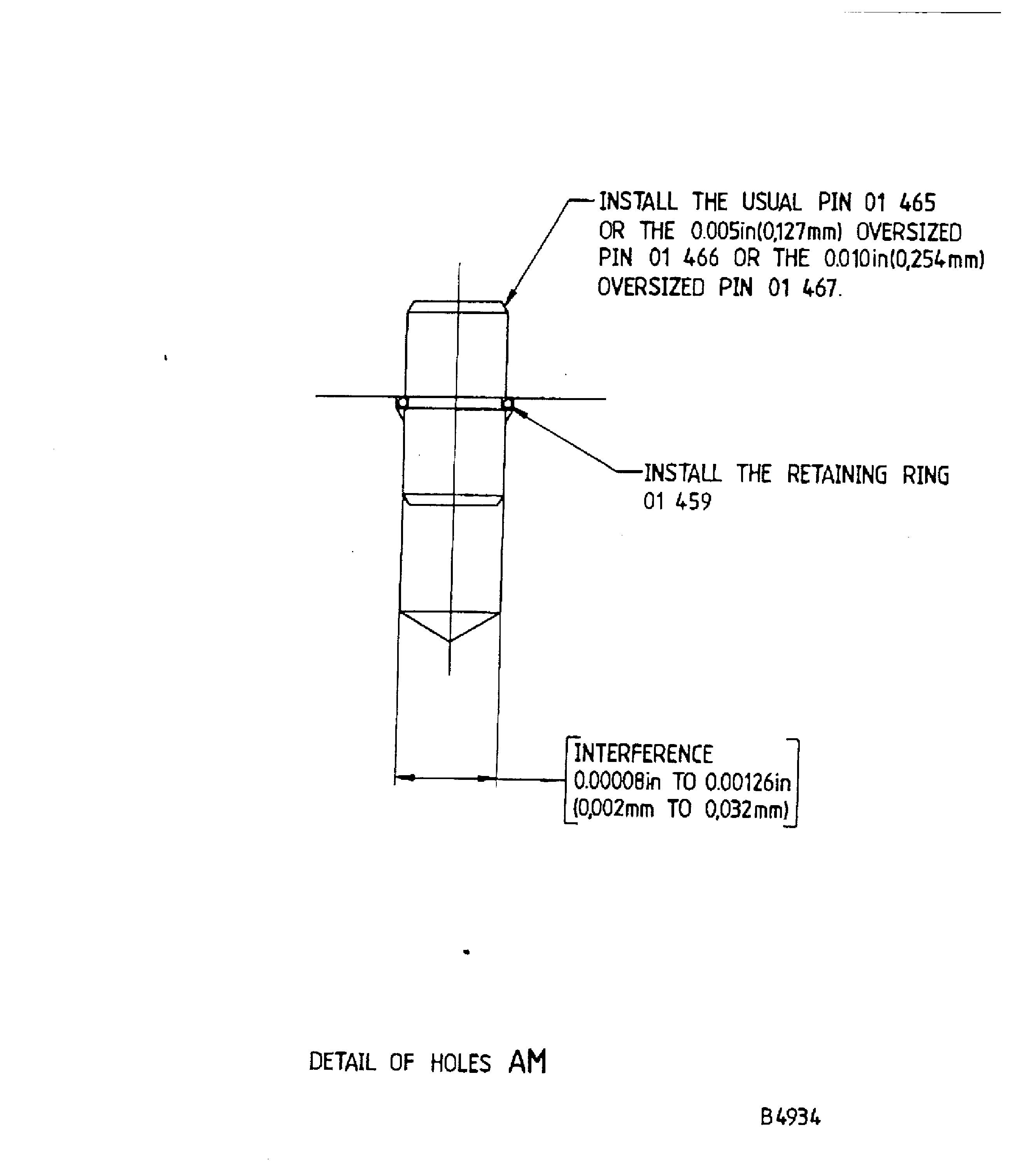

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C

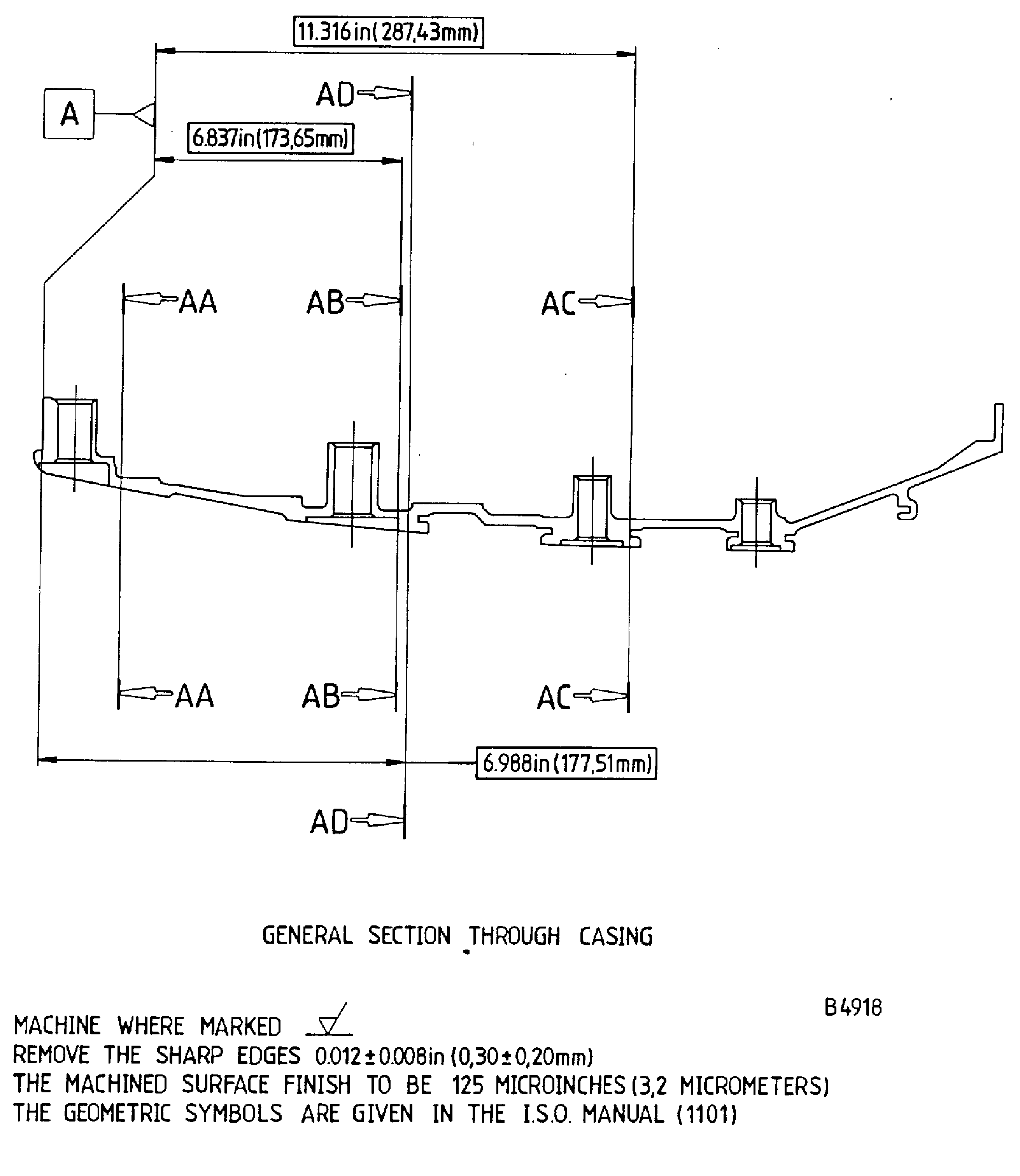

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

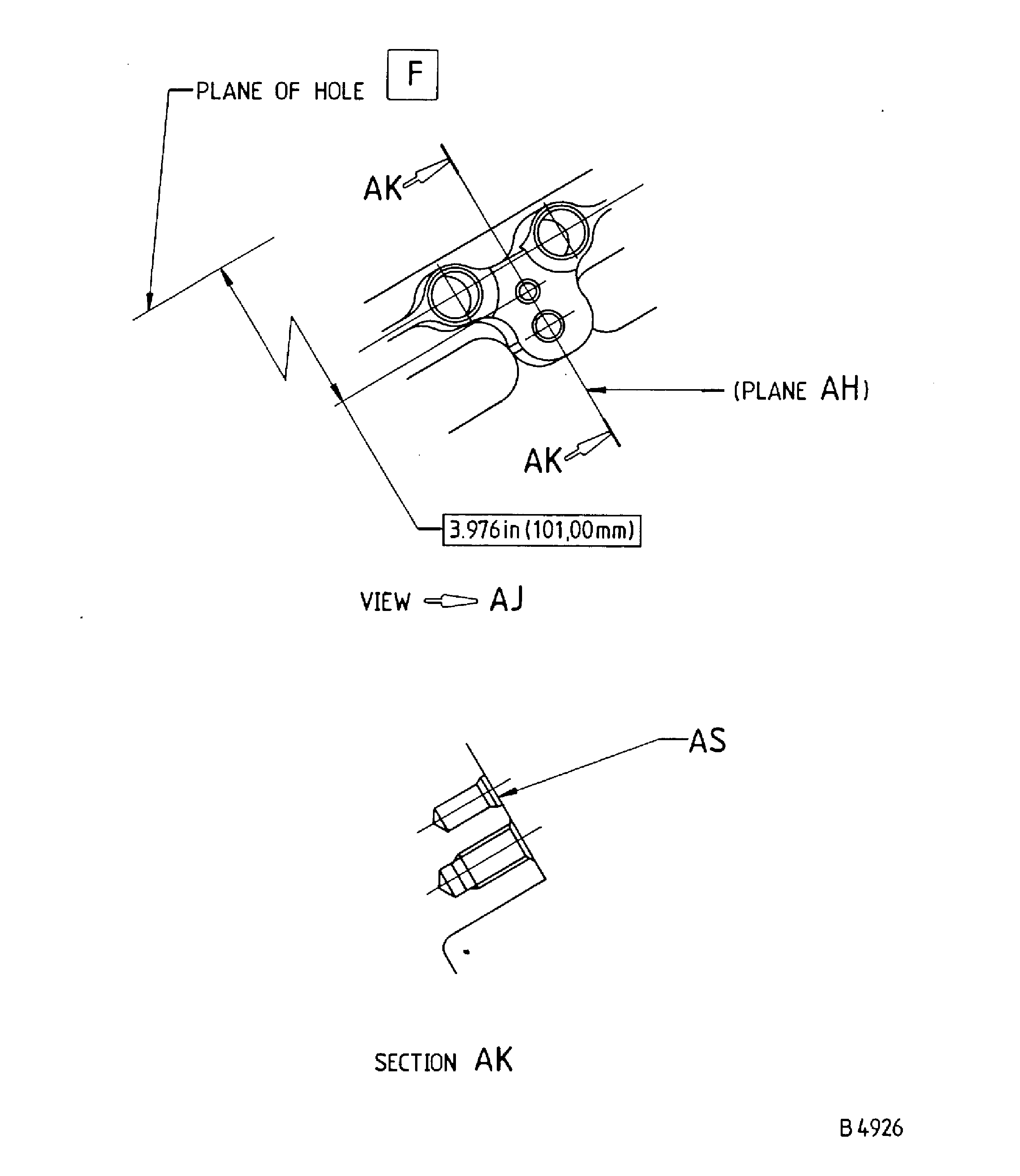

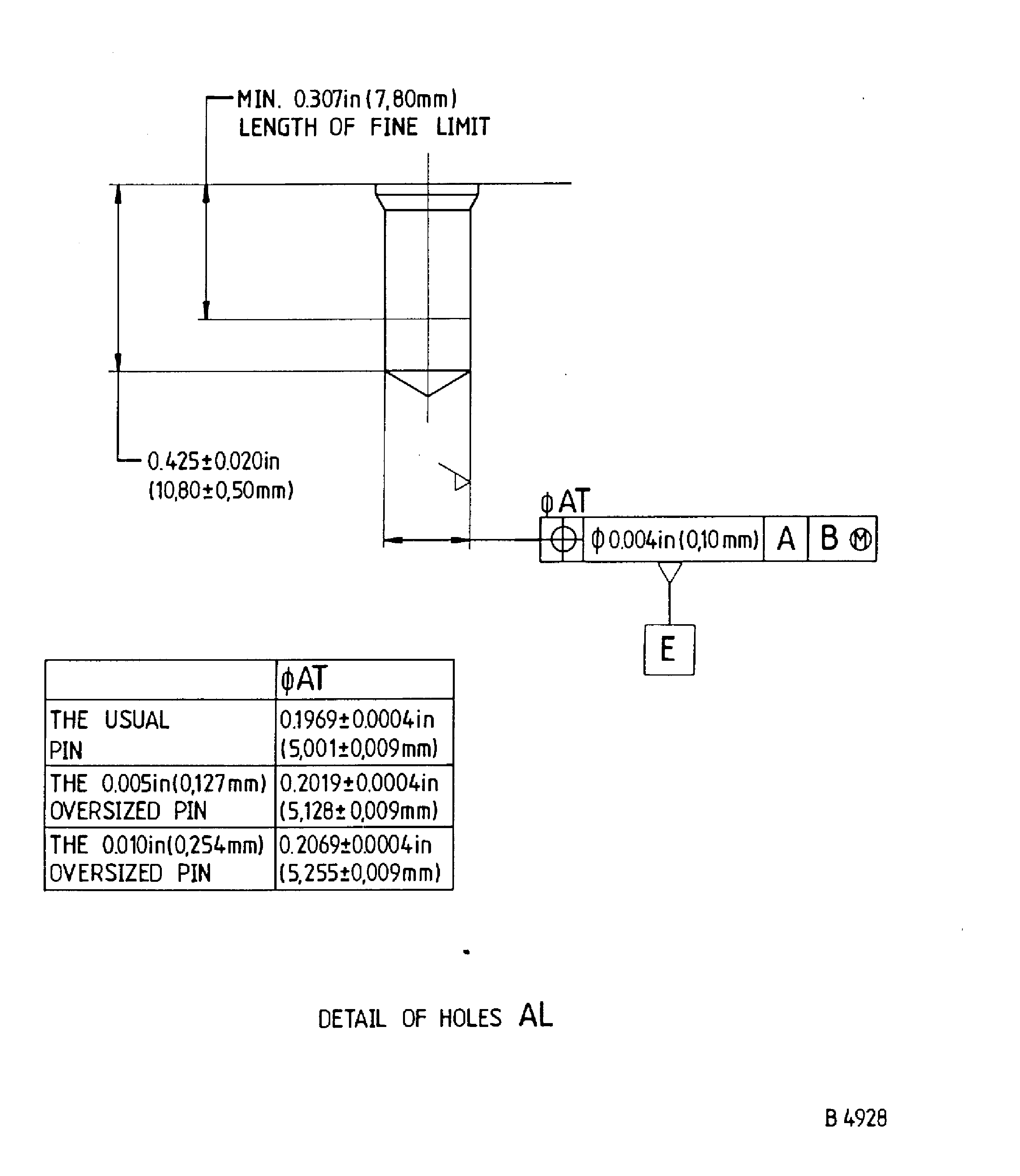

Figure: Repair details and dimensions - Assembly A and Assembly B

Repair details and dimensions - Assembly A and Assembly B

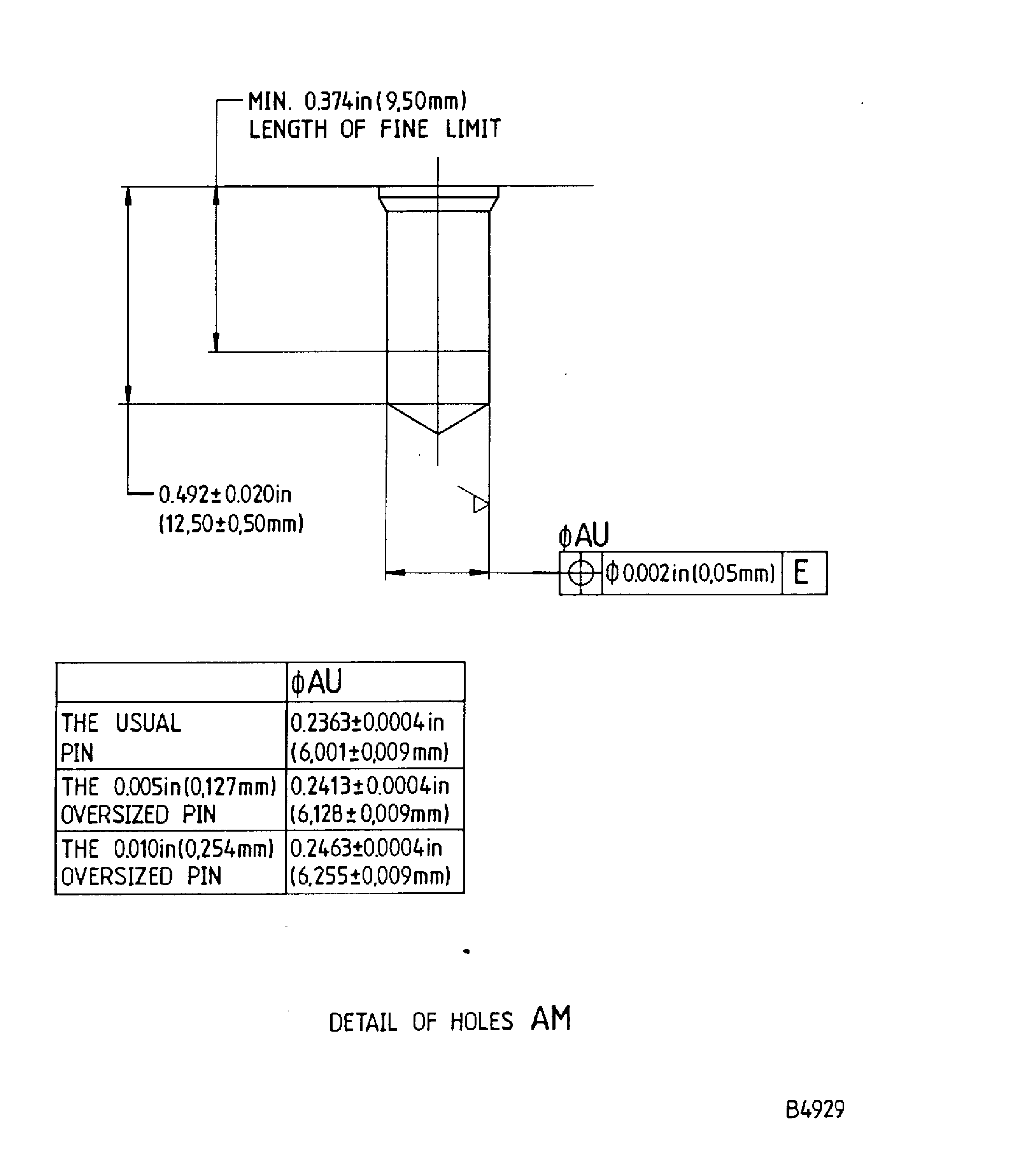

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C

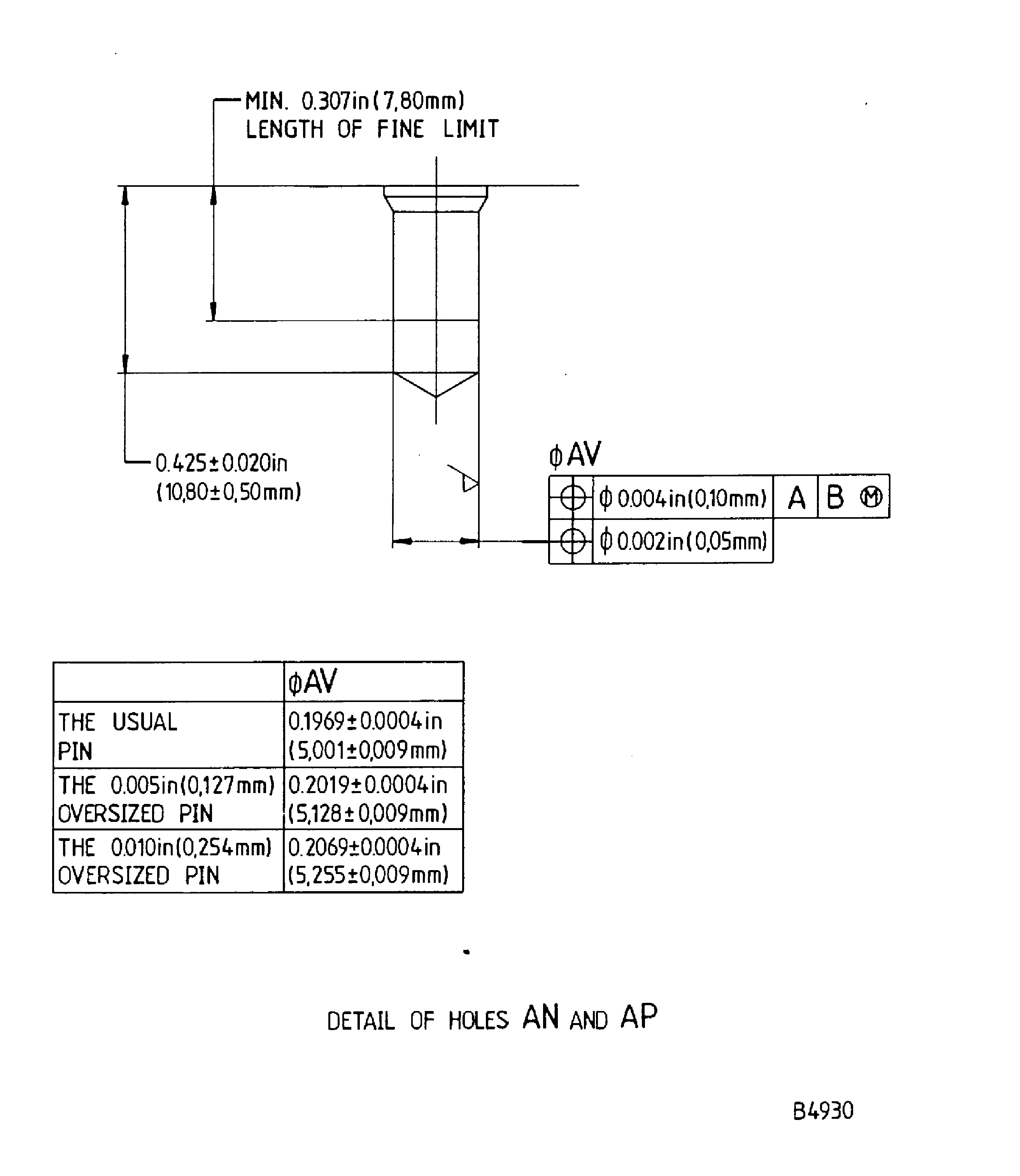

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C