Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-31-300-024 HPC Front Cases - Repair Worn Or Damaged Stage 6 Bush Holes By The Installation Of Steel Liner(s),Repair-024 (VRS6618)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor Front Case Assembly | TEG | 6 percent, Aluminum 4 percent Vanadium alloy |

Liner | EAF | Chromium - Nickel (18/8) - |

Stabilised Steel |

General

This Repair must only be done when the instruction to do so is given in 72-41-31 Inspection/Check.

This Repair, repairs worn or damaged Stage 6 VSV Bush Locations, in the HP Compressor Front Case Assembly, by the Installation of Steel Liner(s).

The Practises and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines

Related repairs - none

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Boring machine | LOCAL | Boring machine | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Heat protection gloves | LOCAL | Heat protection gloves | ||

| Drift | LOCAL | Drift | Non-metallic | |

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Liner | 6A6576 | 84 AR. |

Safety Requirements

NONEProcedure

SUBTASK 72-41-31-323-051 Machine the Worn or Damaged HP Compressor Front Case Assembly

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Use 6A6576 liner, 01-480, 84 off, as necessary.

Freeze the liner to minus 30 degrees F, with CoMat 03-026 LIQUID NITROGEN.

Use standard workshop equipment, with heat protective gloves.

Freeze the liner.

SUBTASK 72-41-31-350-086 Install the Liner(s)

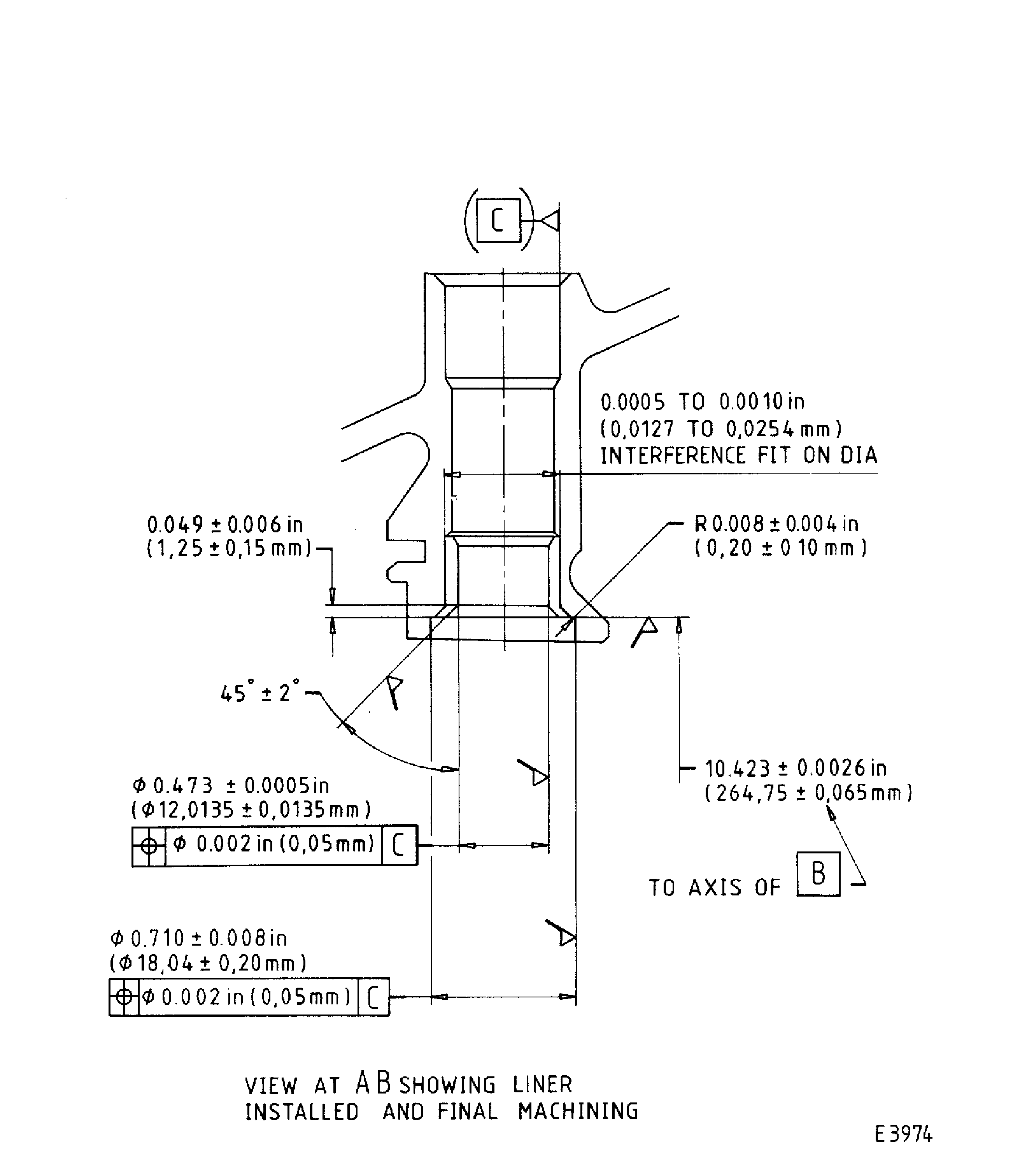

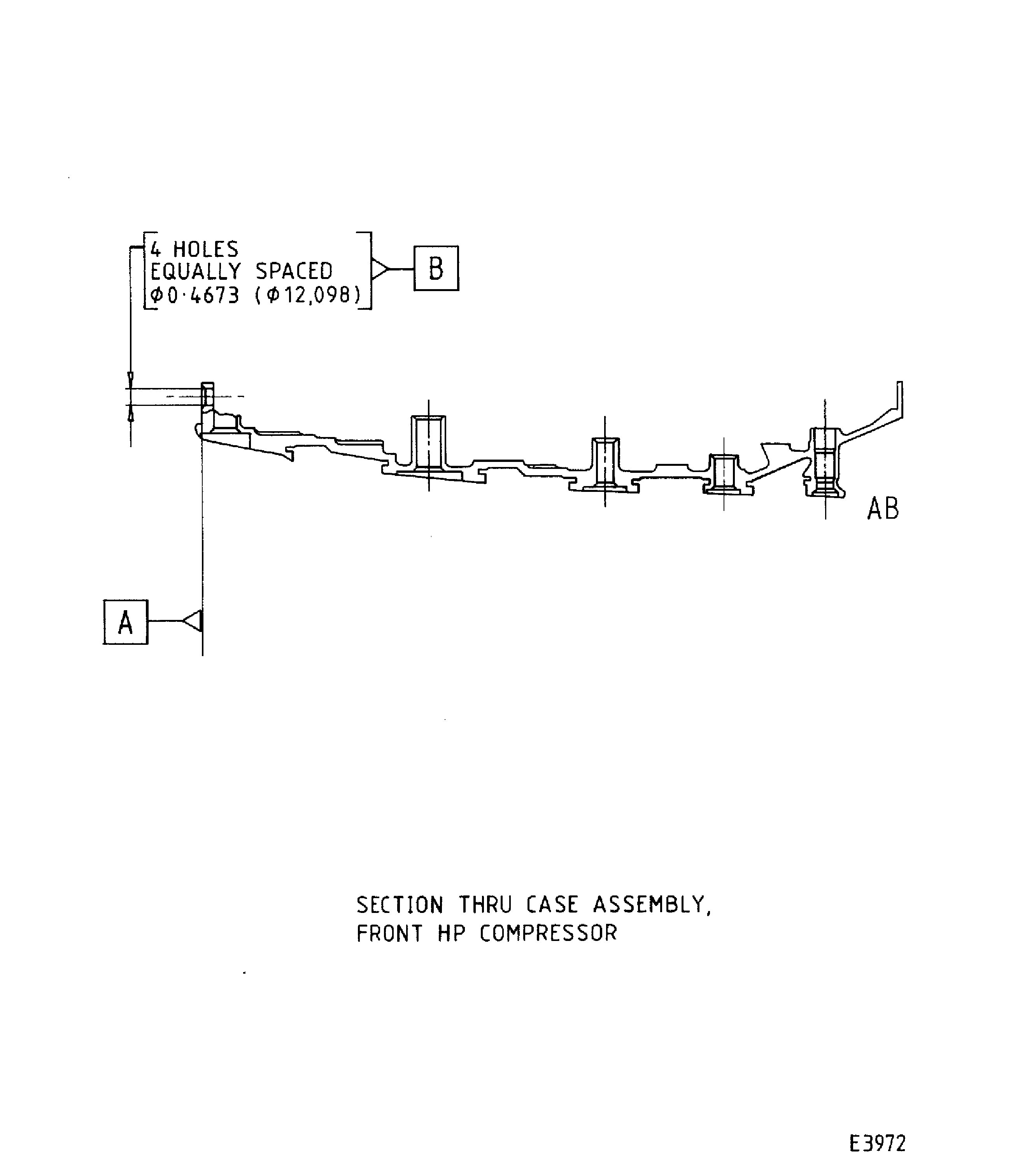

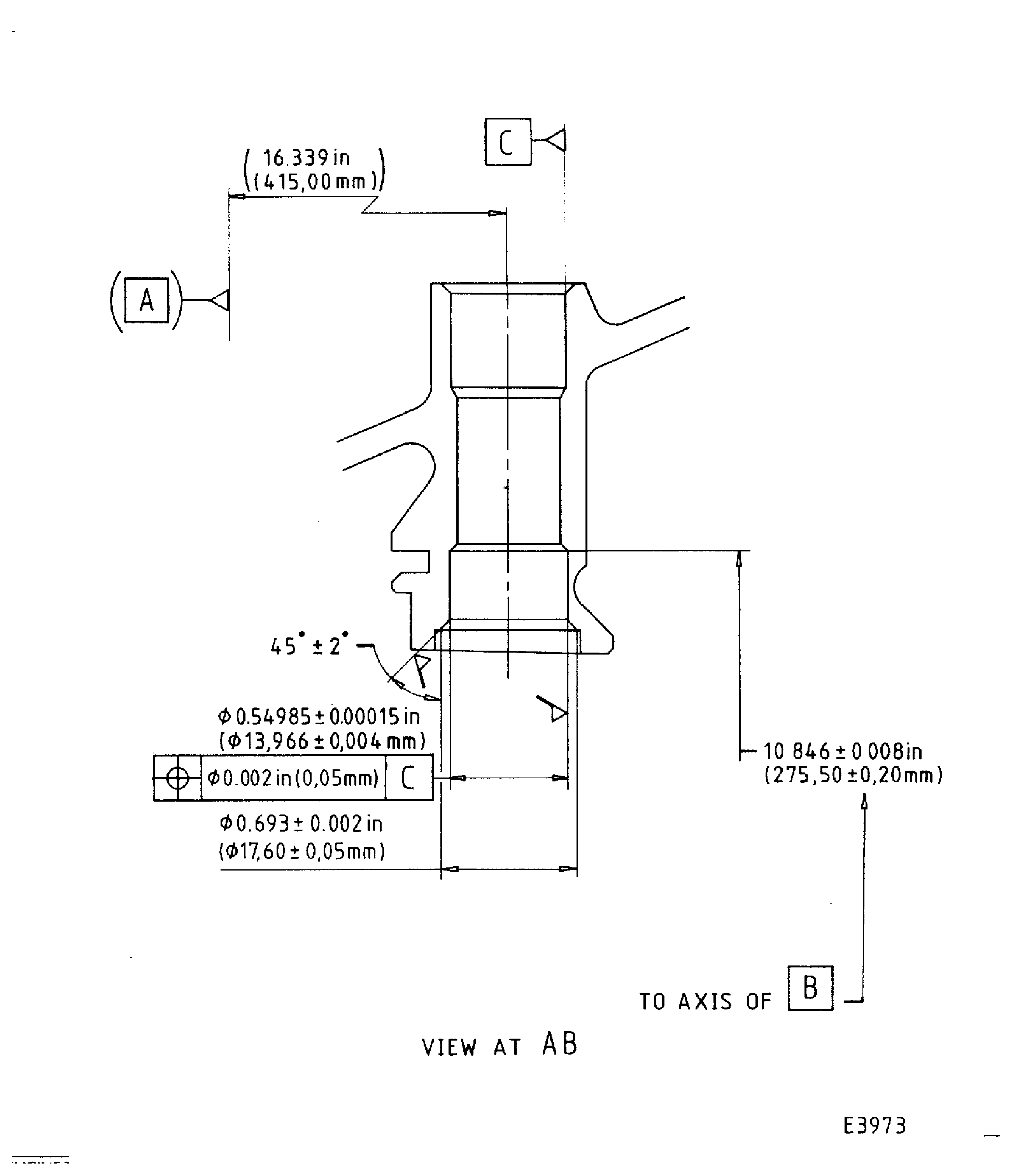

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions