Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-32-300-001 HPC Inlet Variable Stator Vane - Blend Repair, Repair-001 (VRS6033)

Effectivity

FIG/ITEM | PART NO | ASSEMBLY |

|---|---|---|

01-500 | 6A3690 | A |

01-500 | 6A4201 | B |

01-500 | 6A5653 | B |

01-500 | 6A7472 | B |

01-500 | 6A7723 | B |

01-500 | 6A8058 | A |

01-500 | 6A8405 | B |

01-500 | 6B1269 | C |

01-600 | 6A3692 | A |

01-600 | 6A4203 | B |

01-600 | 6A5655 | B |

01-600 | 6A7474 | B |

01-600 | 6A7725 | B |

01-600 | 6A8060 | A |

01-600 | 6A8407 | B |

01-600 | 6B1270 | C |

Material of component

The HP compressor inlet guide vane is manufactured from titanium alloy.

General

This repair must only be done when the instruction to do so is given in 72-41-32 Inspection/Check.

This repair gives the instruction to remove damage on the HP compressor variable inlet guide vane by material removal.

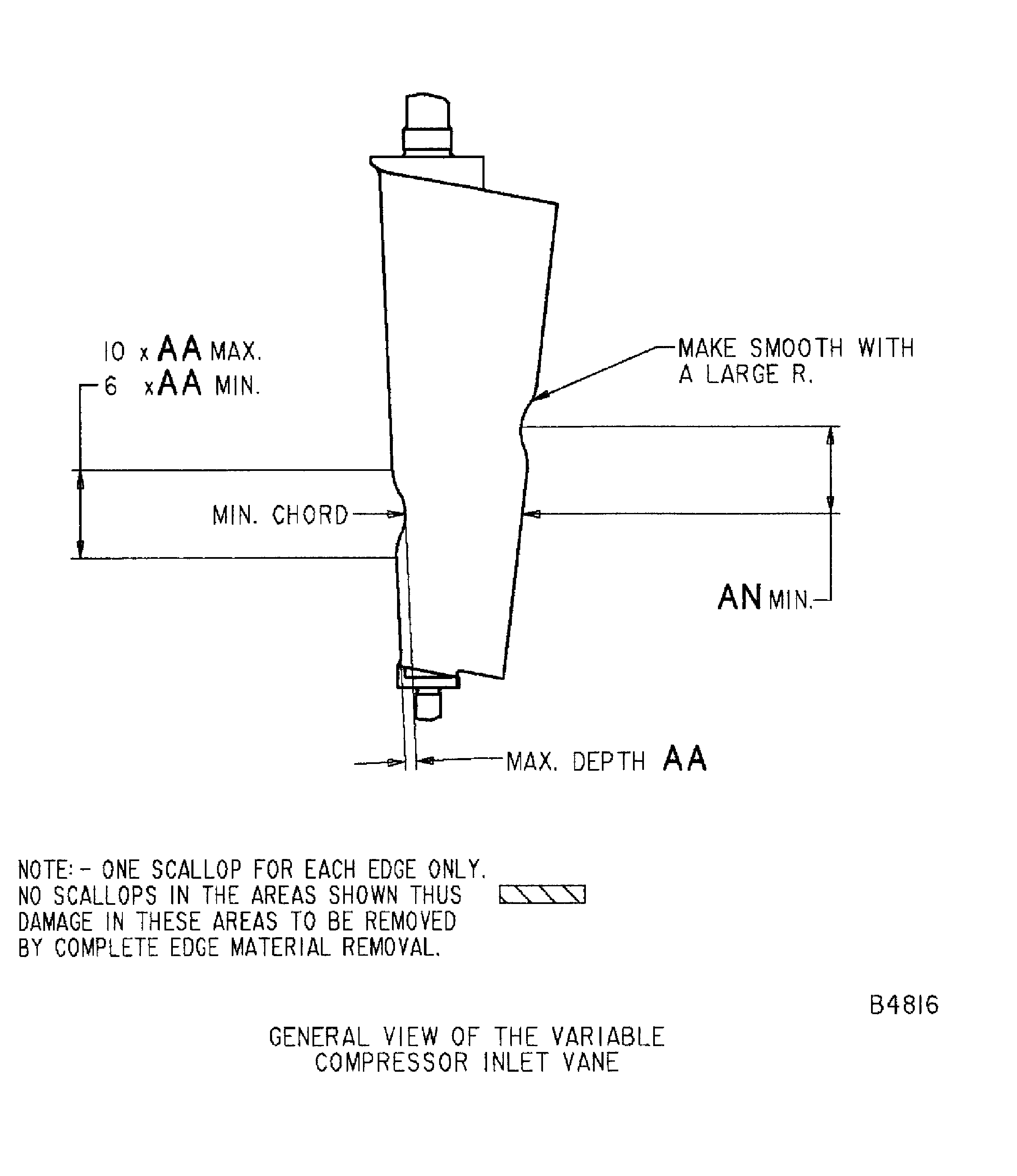

If the minimum chord width is reached, then the vanes must be marked with the applicable code symbol.

Not more than ten percent of variable inlet guide vanes dressed to the maximum limit of this repair, marked with the applicable code symbol, should be included in any one vane stage.

Variable inlet guide vanes must be repaired as soon as damage or wear is monitored, to get back HP compressor efficiency and extend the vane life.

Material removal from the HP compressor variable inlet guide vane airfoil fillet radius is not permitted.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines

Related repairs - none

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Dimensional inspection equipment | LOCAL | Dimensional inspection equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-075 WATERPROOF SILICON CARBIDE | IE241 | CoMat 05-075 | ||

| CoMat 05-076 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-076 | ||

| CoMat 05-077 WATERPROOF SILICON CARBIDE | K6835 | CoMat 05-077 | ||

| CoMat 05-079 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-079 | ||

| CoMat 05-082 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-082 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

NONESafety Requirements

NONEProcedure

Use portable grinding equipment.

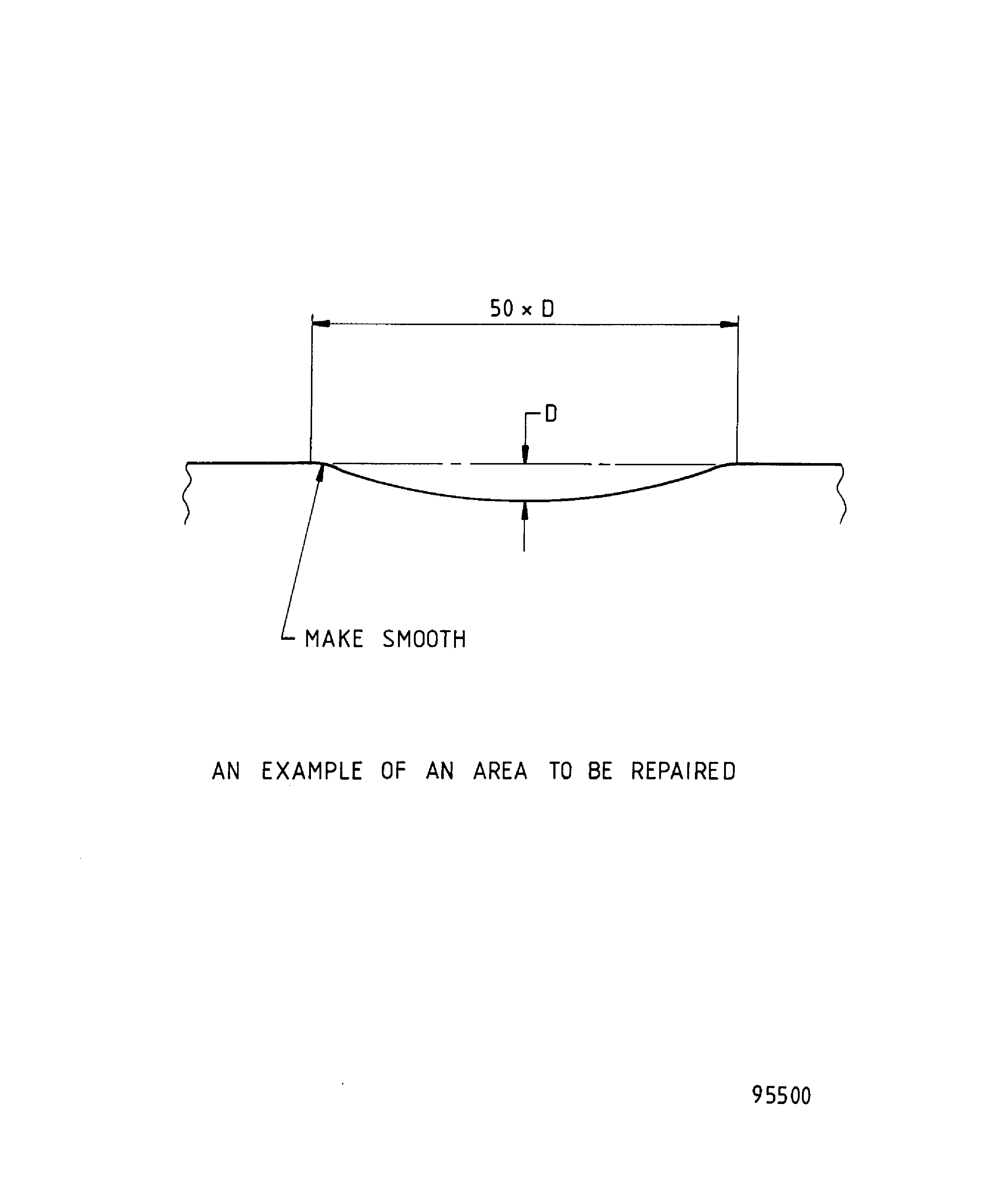

Continue to remove material until all the damage is removed.

The maximum depth to remove the damage must not be more than 0.005 in. (0.13 mm).

The diameter of the repaired area is to be 50 times the depth.

Refer to the material removal limits shown below.

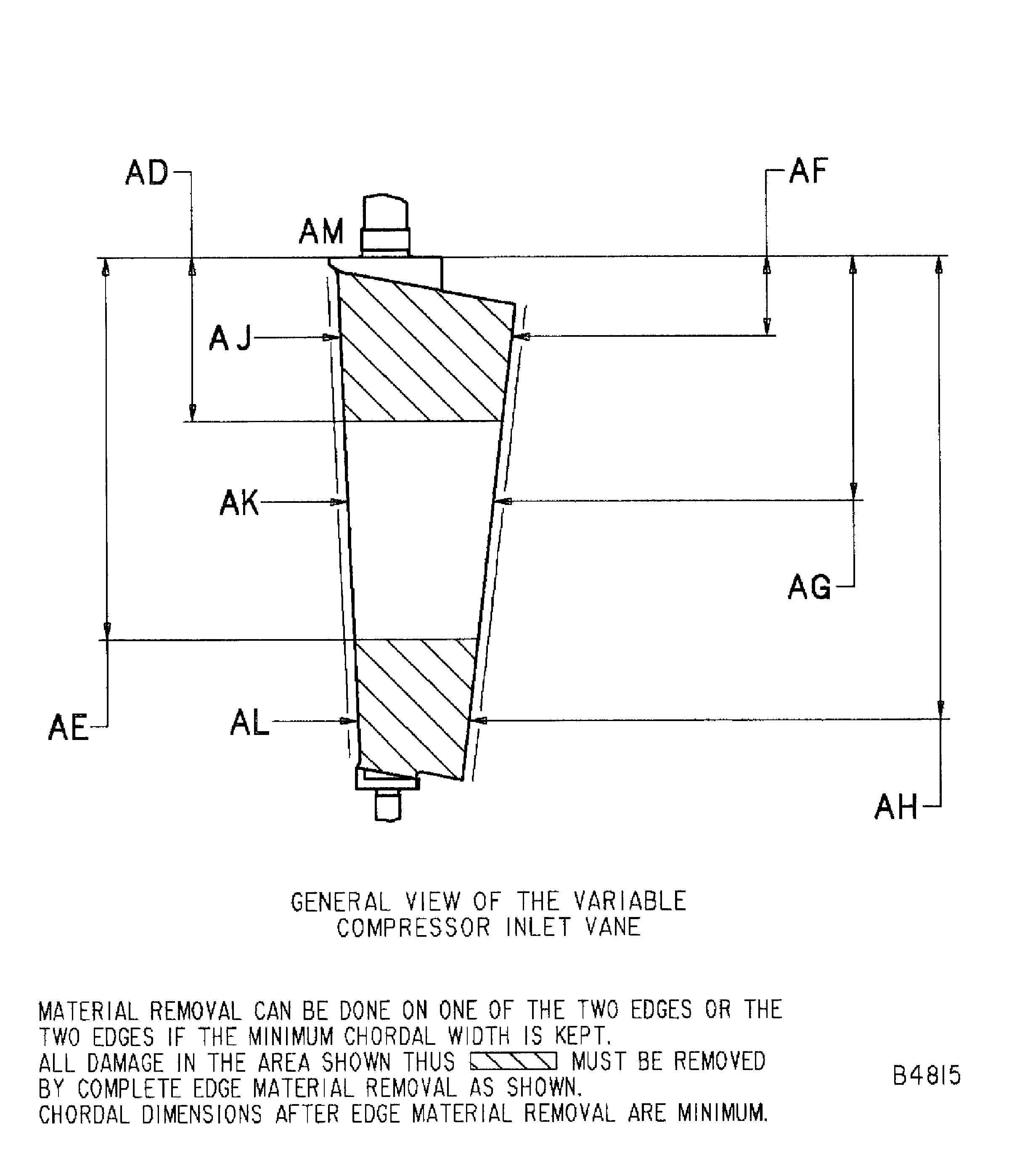

AD 1.970 in. (50.04 mm).

AE 4.330 in. (109.98 mm).

AF 0.890 in. (22.61 mm).

AG 2.800 in. (71.12 mm).

AH 5.380 in. (136.65 mm).

AJ 1.882 in. (47.80 mm).

AK 1.583 in. (40.21 mm).

AL 1.187 in. (30.15 mm).

AN 1.000 in. (25.40 mm).

Remove damage on the airfoil surfaces by material removal.

Use CoMat 05-082 WATERPROOF SILICON CARBIDE and/or CoMat 05-079 WATERPROOF SILICON CARBIDE, as necessary.

Make sure all the damage marks are completely removed and the area is made smooth into the adjacent material.

Make smooth the repaired area.

Use CoMat 05-077 WATERPROOF SILICON CARBIDE or CoMat 05-076 WATERPROOF SILICON CARBIDE and/or CoMat 05-075 WATERPROOF SILICON CARBIDE.

Polish the repaired area to remove scratches and to give a surface finish the same as the adjacent material.

Polish the repaired area.

SUBTASK 72-41-32-350-051-A00 Remove Damage from the HP Compressor Variable Inlet Guide Vane, Assembly A

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE TOOL SPEED AS LOW AS POSSIBLE.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU DRESS MATERIAL, BLEND AND POLISH, TO MAKE SMOOTH, NO SPARKS ARE PRODUCED.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Use portable grinding equipment.

Continue to remove material until all the damage is removed.

The maximum depth to remove the damage must not be more than 0.005 in. (0.13 mm).

The diameter of the repaired area is to be 50 times the depth.

Refer to the material removal limits shown below.

AD 1.970 in. (50.04 mm).

AE 4.330 in. (109.98 mm).

AF 0.910 in. (23.11 mm).

AG 2.790 in. (70.87 mm).

AH 5.290 in. (134.37 mm).

AJ 1.891 in. (48.03 mm).

AK 1.612 in. (40.94 mm).

AL 1.245 in. (31.62 mm).

AN 1.000 in. (25.40 mm).

Remove damage on the airfoil surfaces by material removal.

Use CoMat 05-082 WATERPROOF SILICON CARBIDE and/or CoMat 05-079 WATERPROOF SILICON CARBIDE, as necessary.

Make sure all the damage marks are completely removed and the area is made smooth into the adjacent material.

Make smooth the repaired area.

Use CoMat 05-077 WATERPROOF SILICON CARBIDE or CoMat 05-076 WATERPROOF SILICON CARBIDE and/or CoMat 05-075 WATERPROOF SILICON CARBIDE.

Polish the repaired area to remove scratches and to give a surface finish the same as the adjacent material.

Polish the repaired area.

SUBTASK 72-41-32-350-051-B00 Remove Damage from the HP Compressor Variable Inlet Guide Vane, Assembly B and Assembly C

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE TOOL SPEED AS LOW AS POSSIBLE.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU DRESS MATERIAL, BLEND AND POLISH, TO MAKE SMOOTH, NO SPARKS ARE PRODUCED.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Refer to Figure.

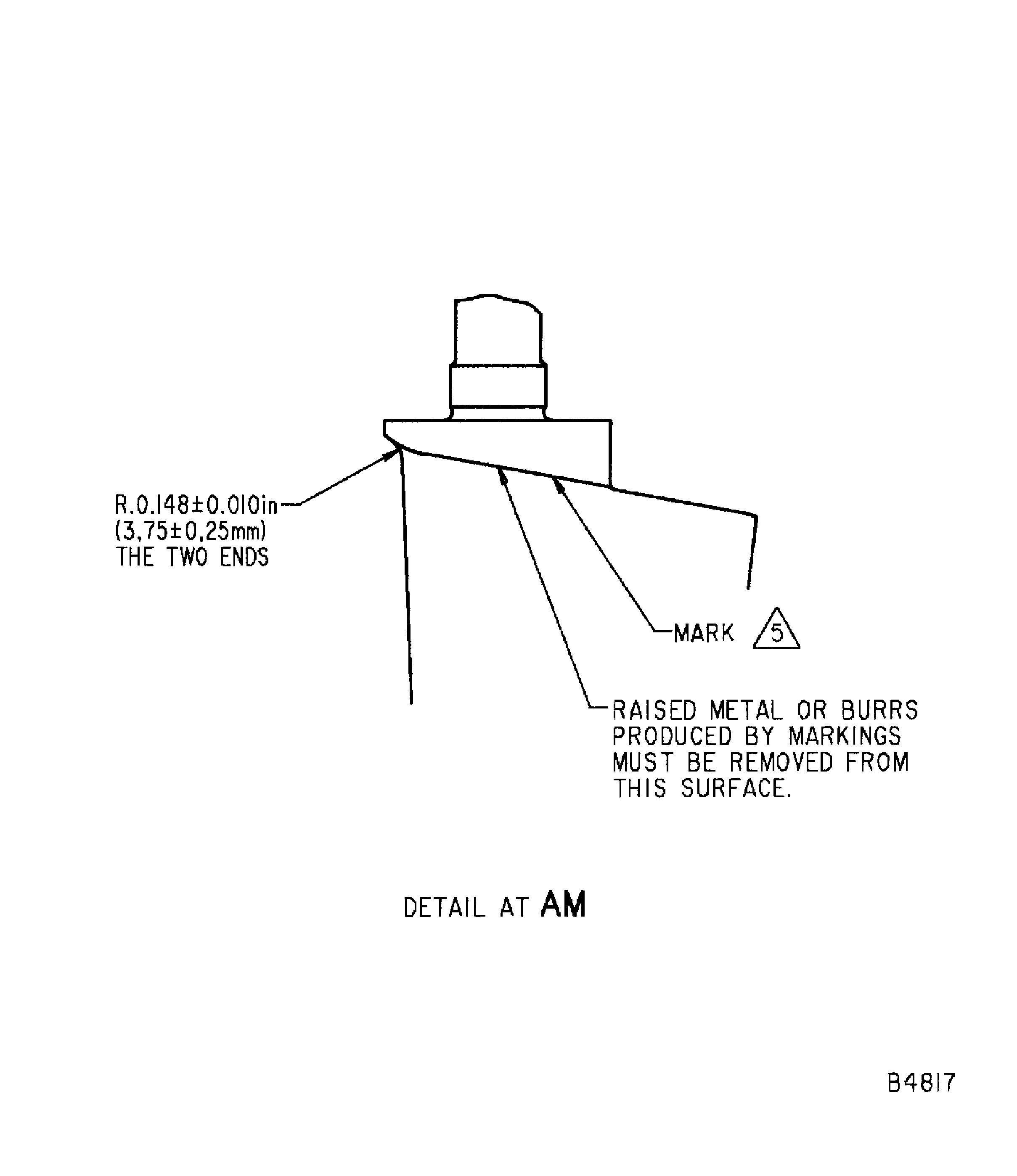

SUBTASK 72-41-32-350-081 Identify the Repair

Figure: Repair Details and Dimensions - Assembly A, Assembly B and Assembly C

Repair Details and Dimensions - Assembly A, Assembly B and Assembly C

Figure: Repair Details and Dimensions - Assembly A, Assembly B and Assembly C

Repair Details and Dimensions - Assembly A, Assembly B and Assembly C

Figure: Repair Details and Dimensions - Assembly A, Assembly B and Assembly C

Repair Details and Dimensions - Assembly A, Assembly B and Assembly C

Figure: Repair Details and Dimensions - Assembly A, Assembly B and Assembly C

Repair Details and Dimensions - Assembly A, Assembly B and Assembly C