Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5 AND Post SBE 72-0366

Common Information

TASK 72-41-34-040-001-B00 HPC Variable Stator Vane Actuation System - Disassemble The Front Bearing Housing Assembly From The Crankshaft, Disassembly-001 - SBE 72-0366

General

This TASK gives the procedure to remove the front bearing housing and spherical bearing assembly from the SBE 72-0366 VSV crankshaft assembly.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of threaded parts and parts with an interference fit. Let the parts soak before removal.

Refer to Figure for a view of the VSV crankshaft assembly.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1R19464 Extractor | 0AM53 | IAE 1R19464 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-058 PENETRATING OIL | 0AM53 | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

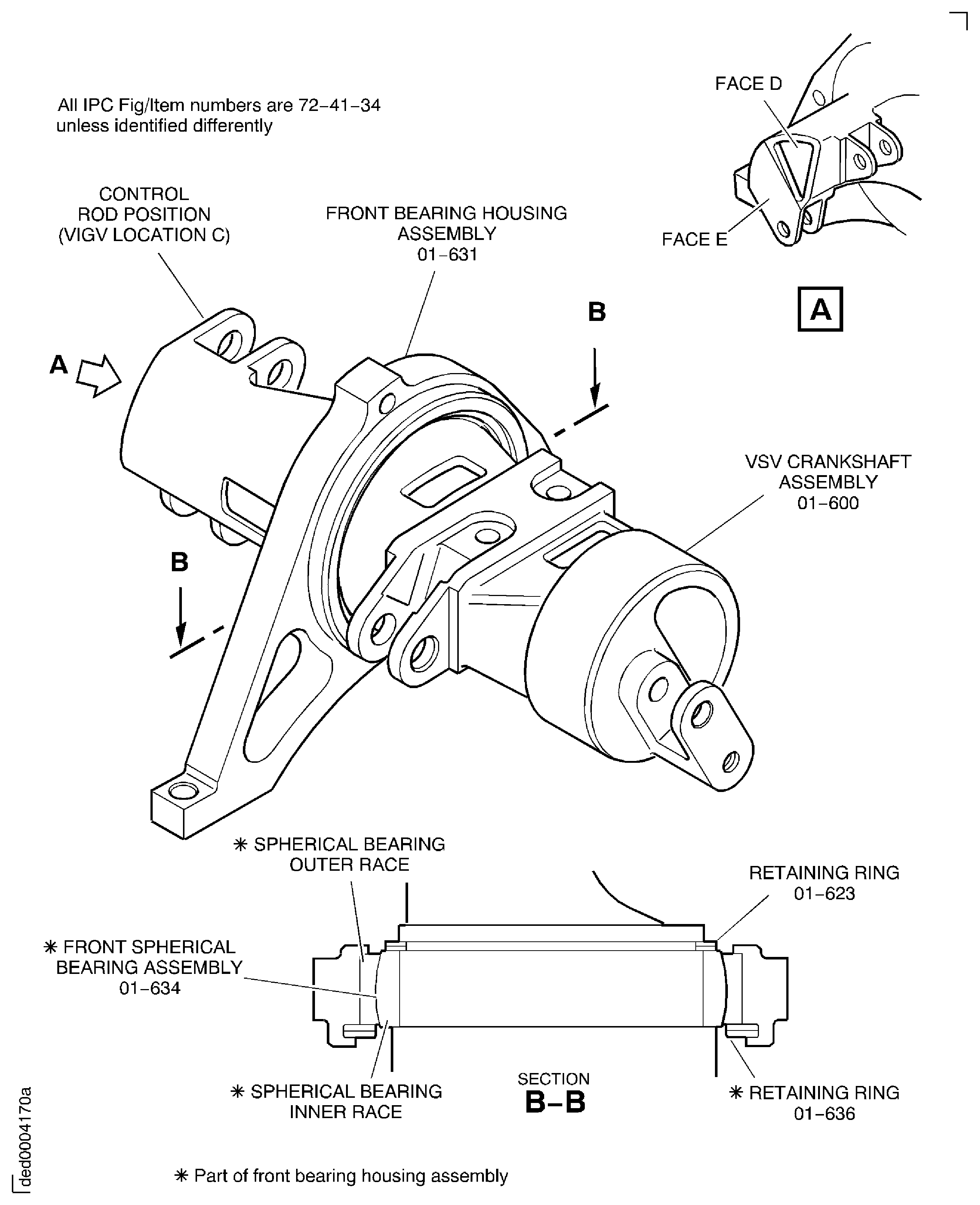

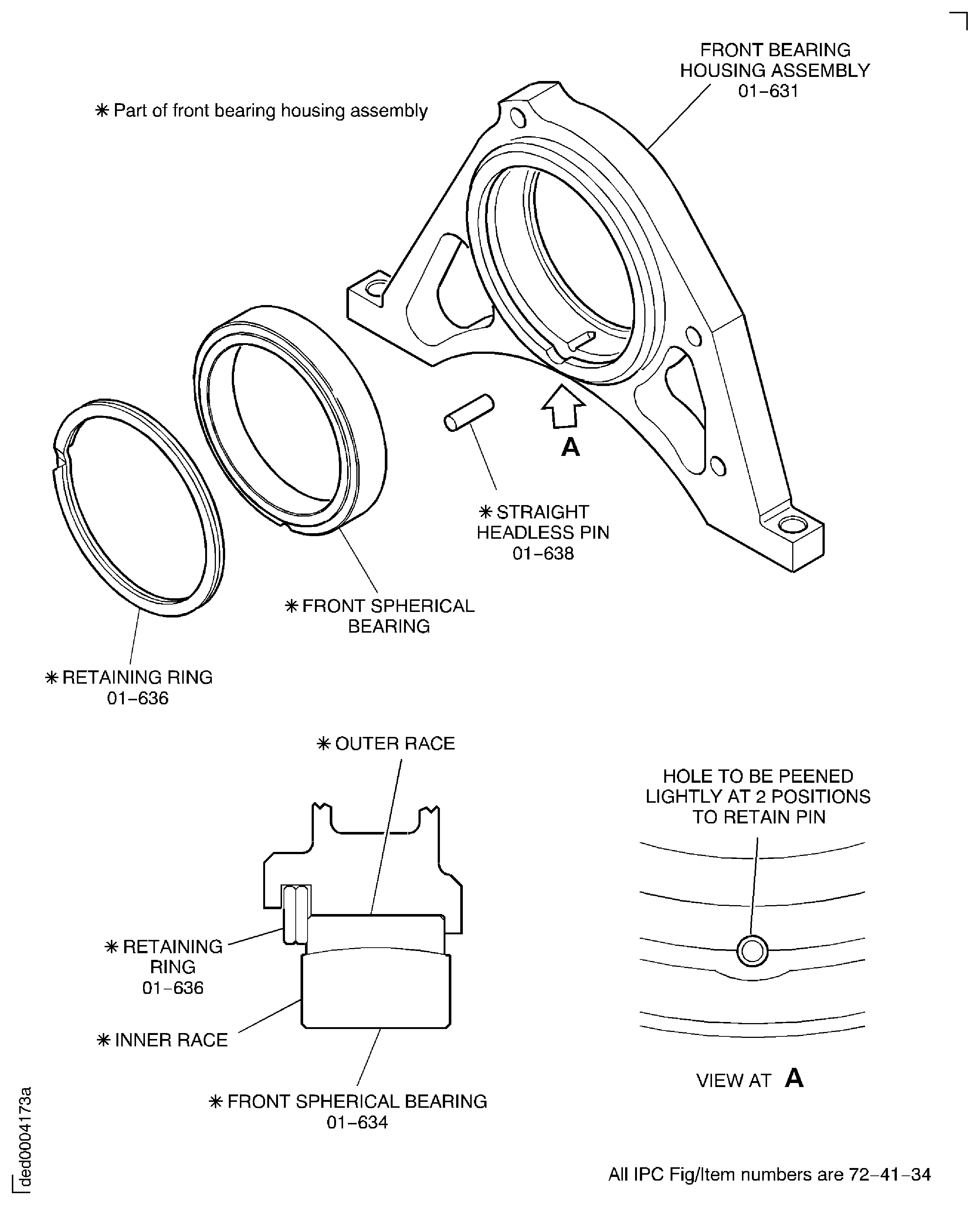

Unstake the hole which secures the location pin V2500-A5-72-41-34-01A-941A-D (72-41-34, 01-638), refer to the view at A, Figure. Refer to the SPM TASK 70-42-06-400-501.

SUBTASK 72-41-34-040-053 Remove the Front Bearing Housing Assembly from the VSV Crankshaft

Remove the retaining ring V2500-A5-72-41-34-01A-941A-D (72-41-34, 01-623) that secures the spherical bearing assembly to the crankshaft, refer to Figure.

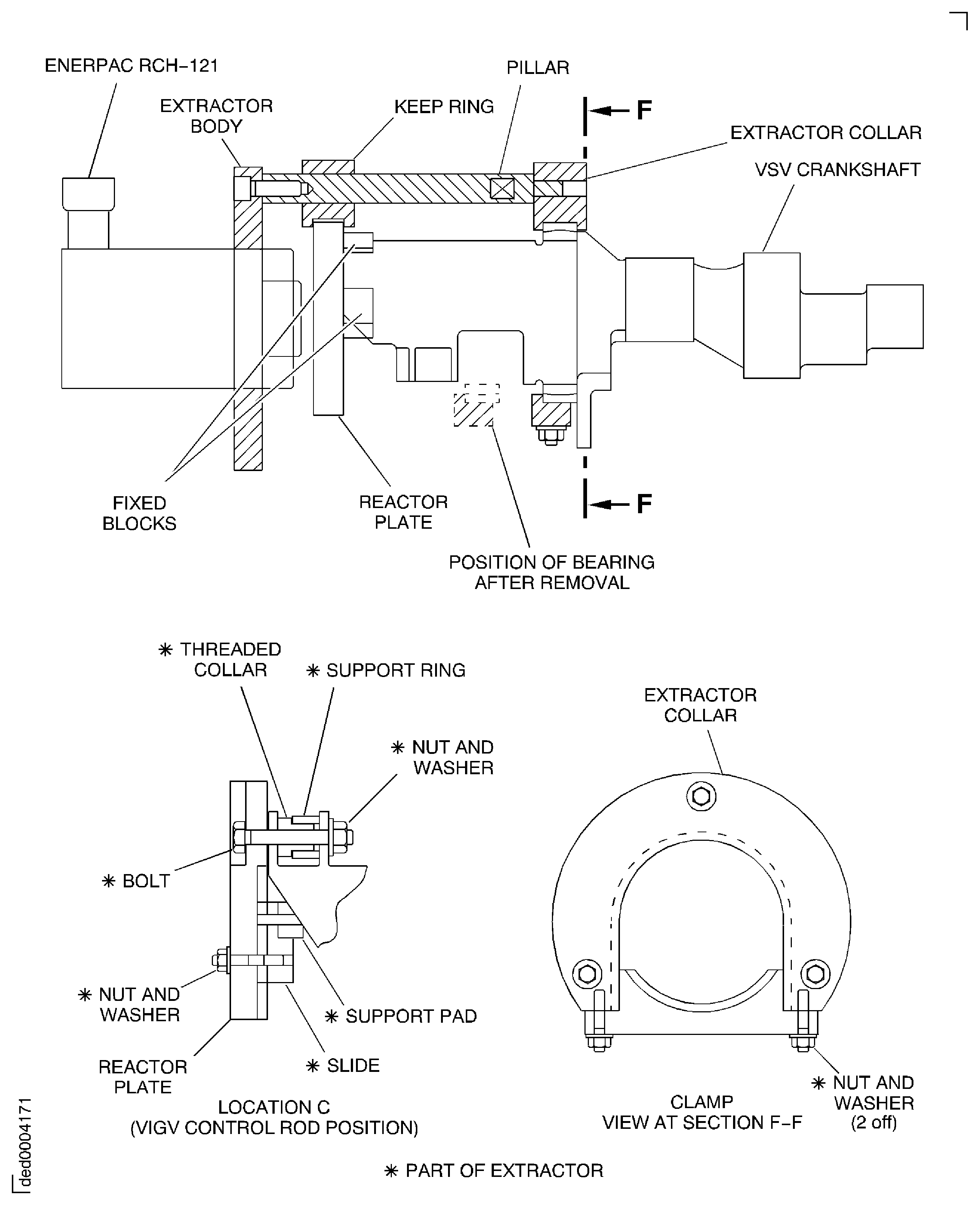

Locate the fixed blocks on the reactor plate on each side of the VIGV crankshaft lugs at location C and reactor plate on face D of the VSV crankshaft. Refer to Figure.

Install the IAE 1R19464 Extractor to the crankshaft, refer to Figure.

CAUTION

YOU MUST NOT EXCEED THE RECOMMENDED HYDRAULIC OPERATING SUPPLY PRESSURE TO THE HYDRAULIC CYLINDER OR DAMAGE TO THE TOOLING AND COMPONENT COULD OCCUR.Operate the hydraulic pump to supply the cylinder with an operating supply pressure of 2,800 PSI (193 BAR) and slowly remove the spherical bearing from the crankshaft.

Remove the spherical bearing.

SUBTASK 72-41-34-040-054 Remove the Spherical Bearing Assembly from the VSV Crankshaft

Figure: View showing the front bearing housing assembly

View showing the front bearing housing assembly

Figure: Remove the front bearing housing assembly

Remove the front bearing housing assembly

Figure: Remove spherical bearing from VSV crankshaft assembly

Remove spherical bearing from VSV crankshaft assembly