Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-34-300-007 HPC Variable Stator Vane Levers - Replace The Lever Pins, Repair-007 (VRS6196)

Material of component

RR | ||

|---|---|---|

DESCRIPTION SYMBOL MATERIAL | ||

Lever assy | TAW and TCA | Titanium alloy |

Shoulder pin | TAB | Titanium alloy |

General

This repair must only be done when the instruction to do so is given in 72-41-34 Inspection.

This repair has been raised for the replacement of the shoulder pins on the actuating mechanism levers by hot squeeze riveting.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Drilling machine | LOCAL | Drilling machine | ||

| Standard workshop tools | LOCAL | Standard workshop tools | ||

| Hand grinder | LOCAL | Hand grinder | ||

| Resistance welding machine | LOCAL | Resistance welding machine | ||

| Drift | LOCAL | Drift | ||

| Drill | LOCAL | Drill | 4.5 mm | |

| Crack test equipment | LOCAL | Crack test equipment | ||

| IAE 3R18654 Top electrode | 0AM53 | IAE 3R18654 | ||

| IAE 3R18655 Bottom electrode | 0AM53 | IAE 3R18655 |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Shoulder pin | 6A2444 | 1 | ||

| Shoulder pin | 6A2444 | 1 | ||

| Shoulder pin | 6A2444 | 1 | ||

| Shoulder pin | 6A2444 | 1 | ||

| Shoulder pin | 6A2444 | 1 |

Safety Requirements

NONEProcedure

Refer to the SPM TASK 70-11-01-300-503, SUBTASK 70-11-01-300-002.

Remove grease from the lever and the new shoulder pin.

SUBTASK 72-41-34-110-055 Chemically Clean

Fit IAE 3R18654 Top electrode 1 off and IAE 3R18655 Bottom electrode 1 off to the resistant welding machine.

Hot squeeze rivet.

Refer to the SPM TASK 70-39-02-390-501.

Hot squeeze rivet.

SUBTASK 72-41-34-390-051 Hot Squeeze Rivet

CAUTION

DO NOT OVERHEAT THE MATERIAL.NOTE

Weld test pieces must be used to set machine positions. Use a low voltage position and the minimum quantity of heat necessary to make the rivet forge over. If too much heat is used the material will crack and oxidise.

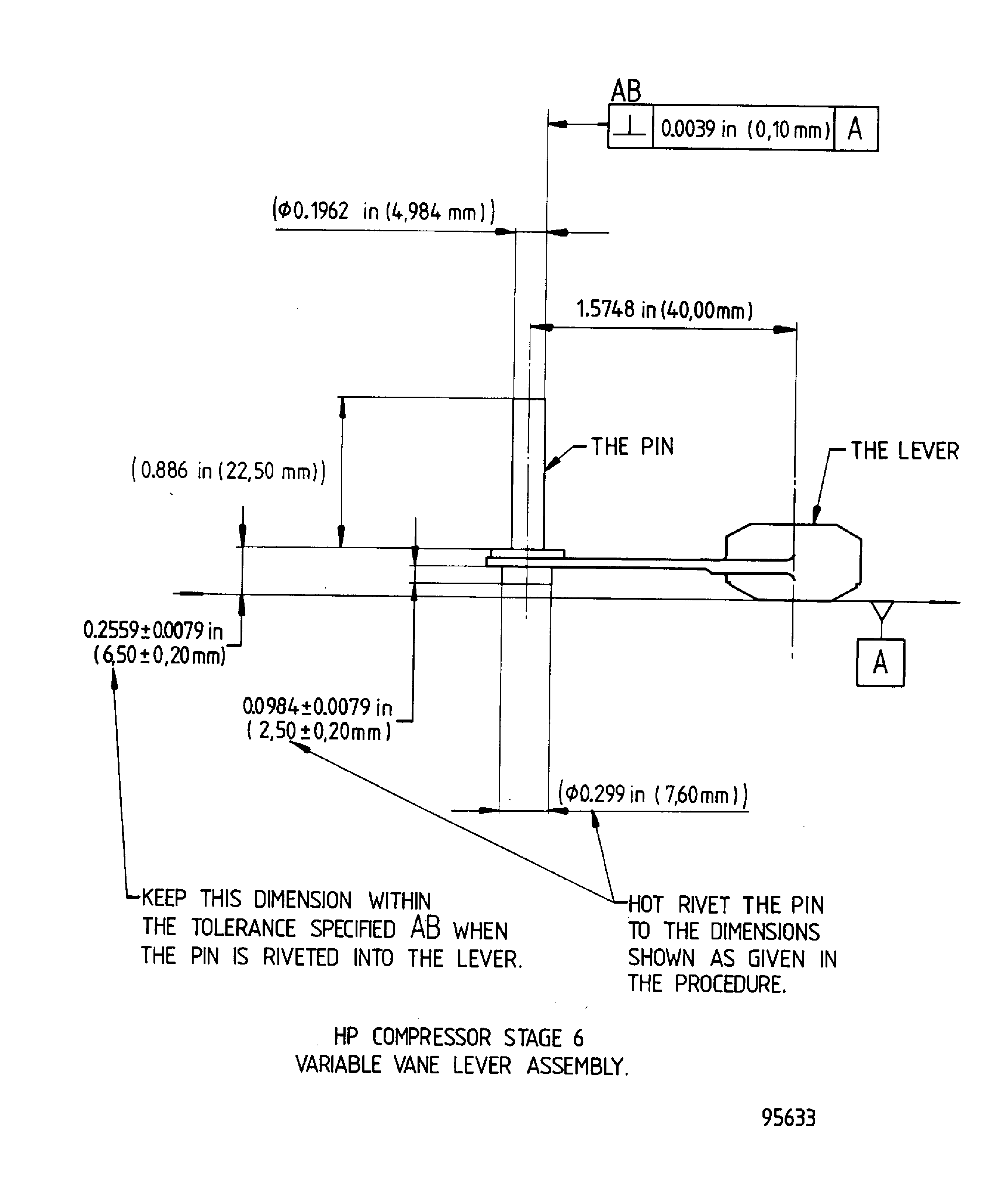

Figure: HP compressor stage 4 variable vane lever assembly

HP compressor stage 4 variable vane lever assembly

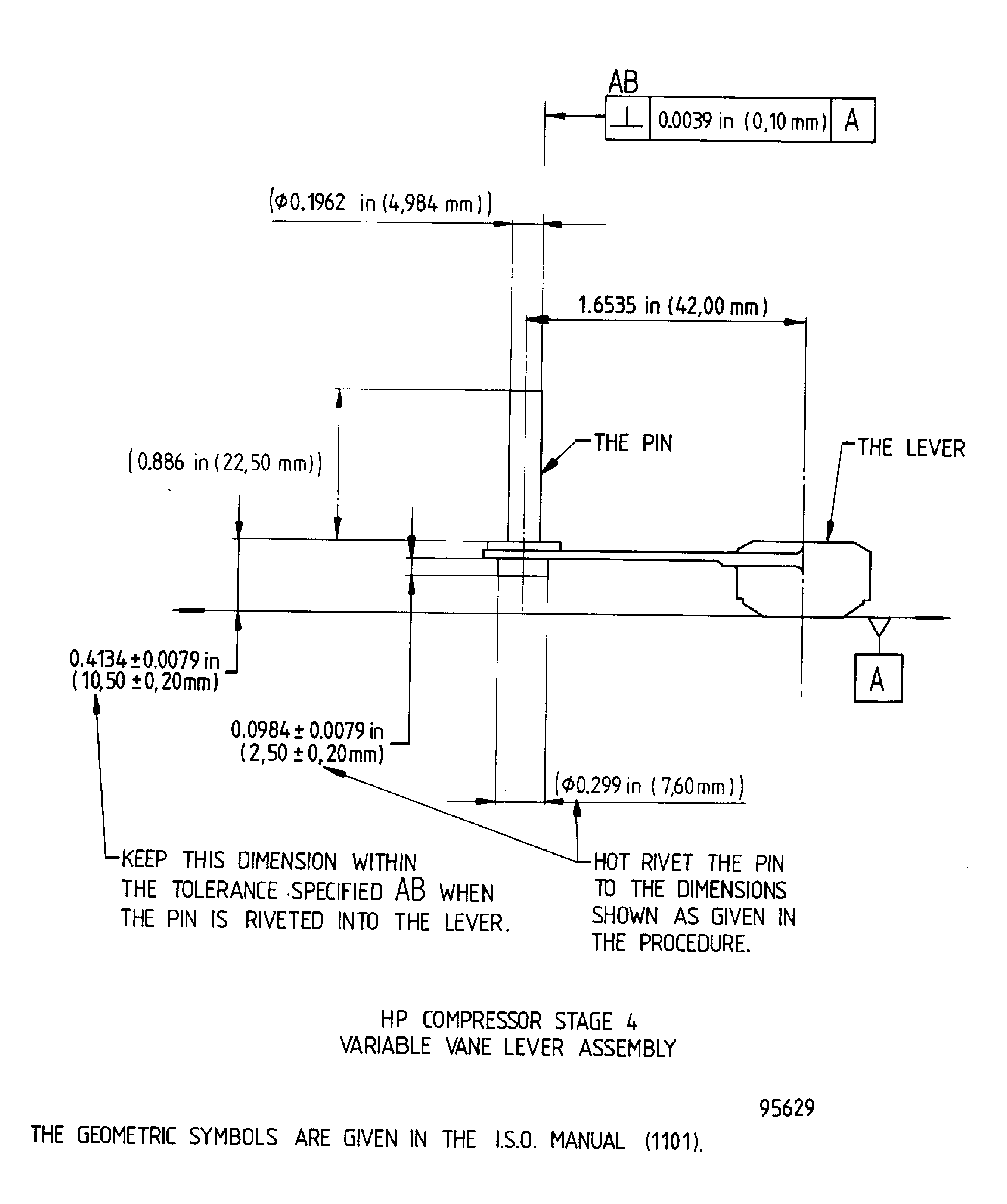

Figure: HP compressor stage 5 variable vane lever assembly

HP compressor stage 5 variable vane lever assembly

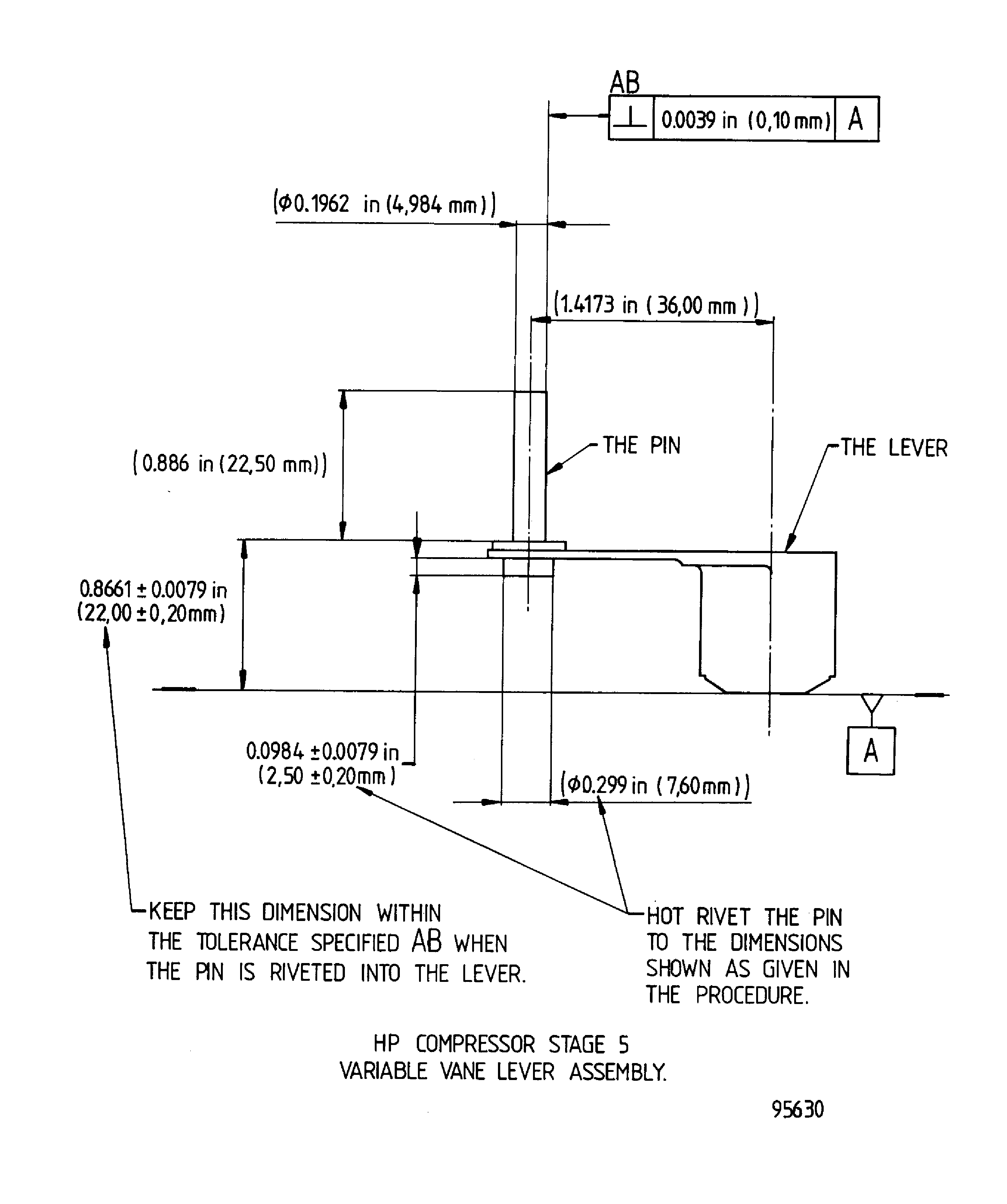

Figure: HP compressor stage 5 variable vane lever assembly

HP compressor stage 5 variable vane lever assembly

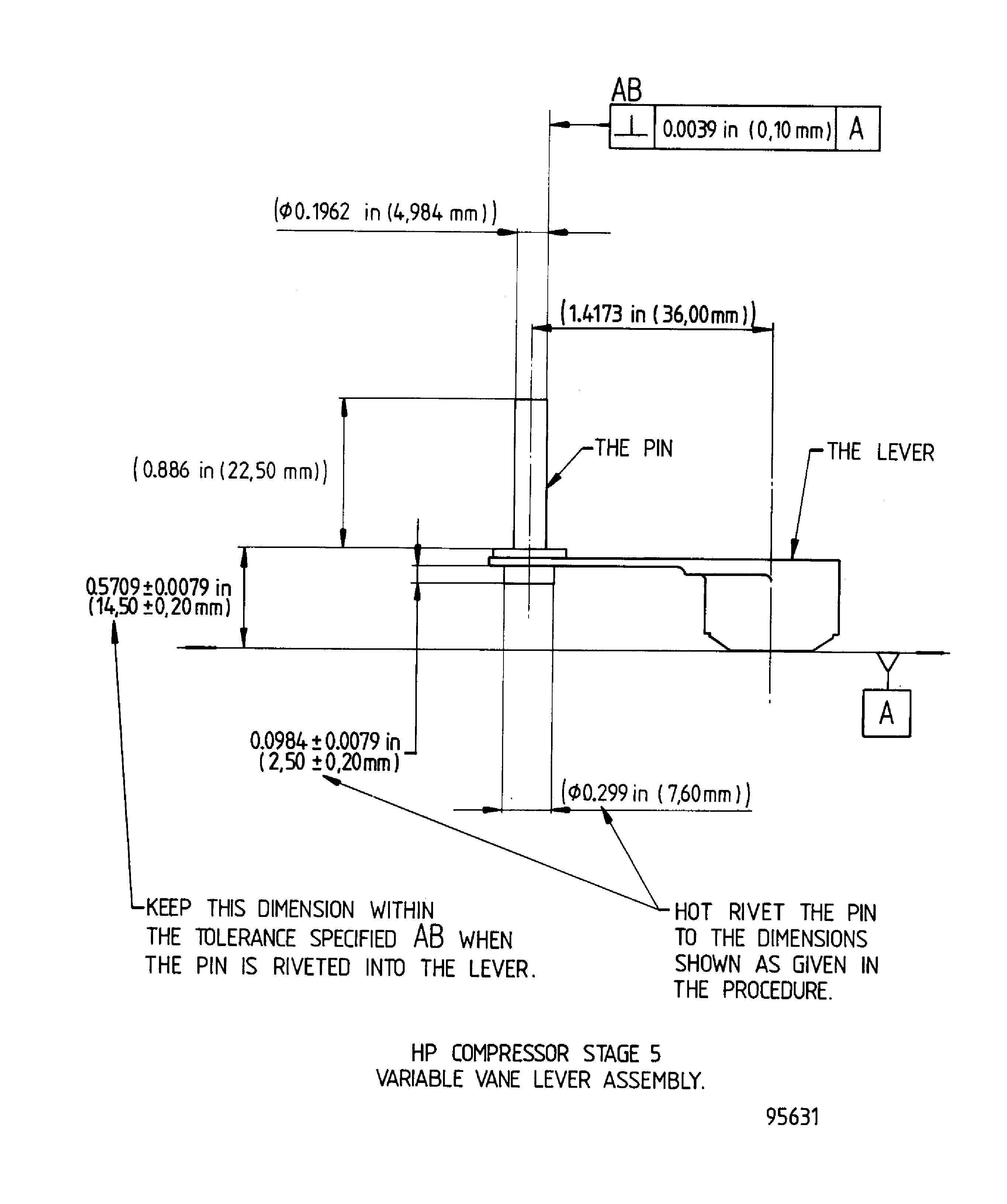

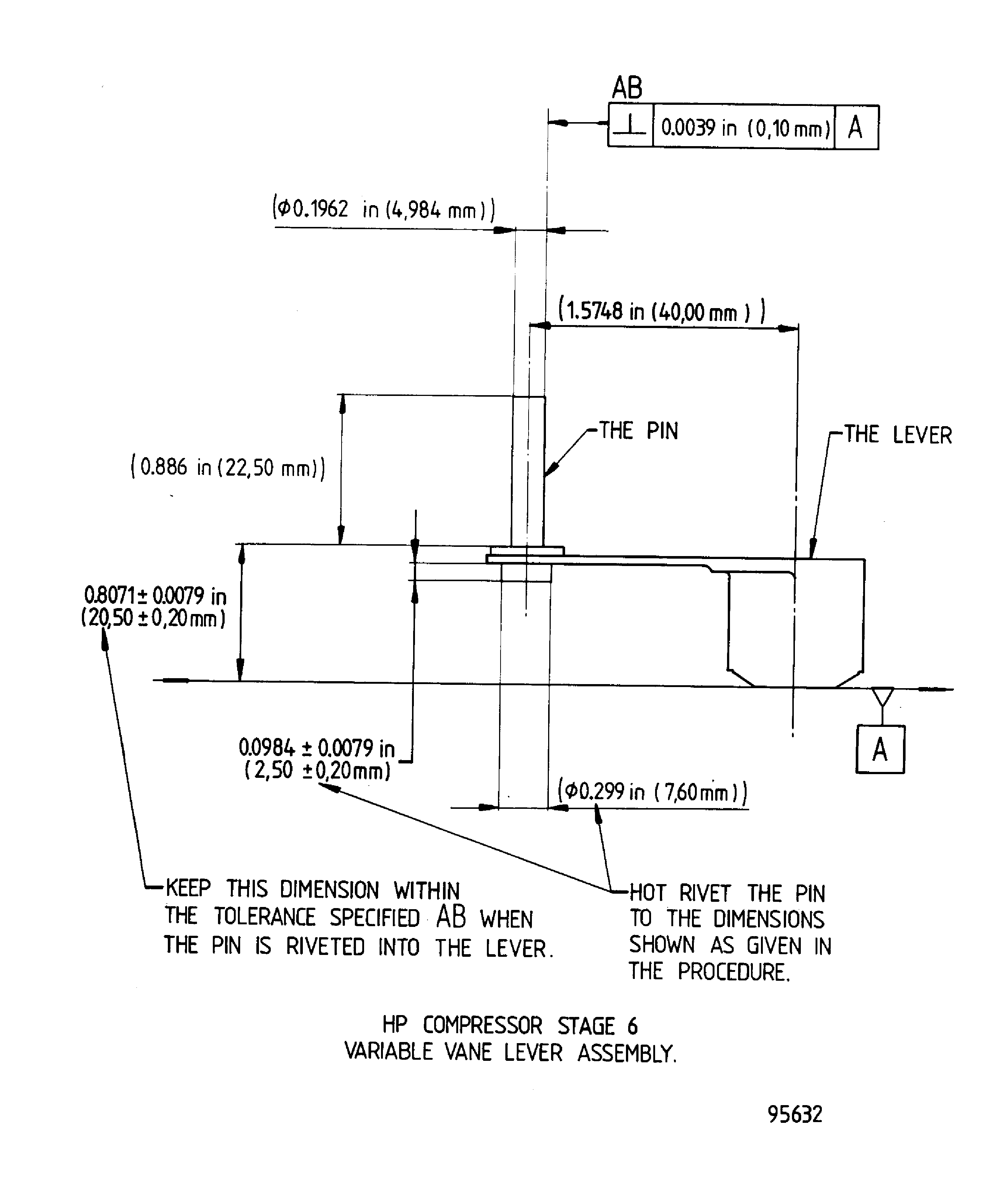

Figure: HP compressor stage 6 variable vane lever assembly

HP compressor stage 6 variable vane lever assembly

Figure: HP compressor stage 6 variable vane lever assembly

HP compressor stage 6 variable vane lever assembly