Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-41-34-300-021 HPC Stage 6 Unison Rings - Replace The Bushes And Bracket Assemblies, Repair-021 (VRS6232)

Material of component

RR | ||

|---|---|---|

DESCRIPTION SYMBOL MATERIAL | ||

Ring | TAB | Titanium alloy |

Bush | VEB | Graphite filled polymide resin |

General

This Repair must only be done when the instruction to do so is given in TASK 72-41-34 (INSPECTION).

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines AG

Related repairs

HP Compressor Actuating Ring and Associated Housings - Replacement of the Inserts. Refer to TASK 72-41-34-300-013 (VRS6155)

NOTE

Equivalent materials or equipment can be used.

More equipment and materials necessary to do this Repair are in the SPM TASK given below:

TASK 70-23-01-230-501

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Drilling machine | LOCAL | Drilling machine | ||

| Drill | LOCAL | Drill | 0.307 in. (7.8 mm) dia | |

| Standard Workshop Equipment | LOCAL | Standard Workshop Equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Bush - assy A | UP10815 | A/R | ||

| Bush - assy B | UP10815 | A/R | ||

| Bracket assy - assy A | 6A2899 | A/R | ||

| Bracket assy - assy B | 6A2899 | A/R | ||

| Bracket assy - assy A | 6A2903 | A/R | ||

| Bracket assy - assy B | 6A3683 | A/R |

Safety Requirements

NONEProcedure

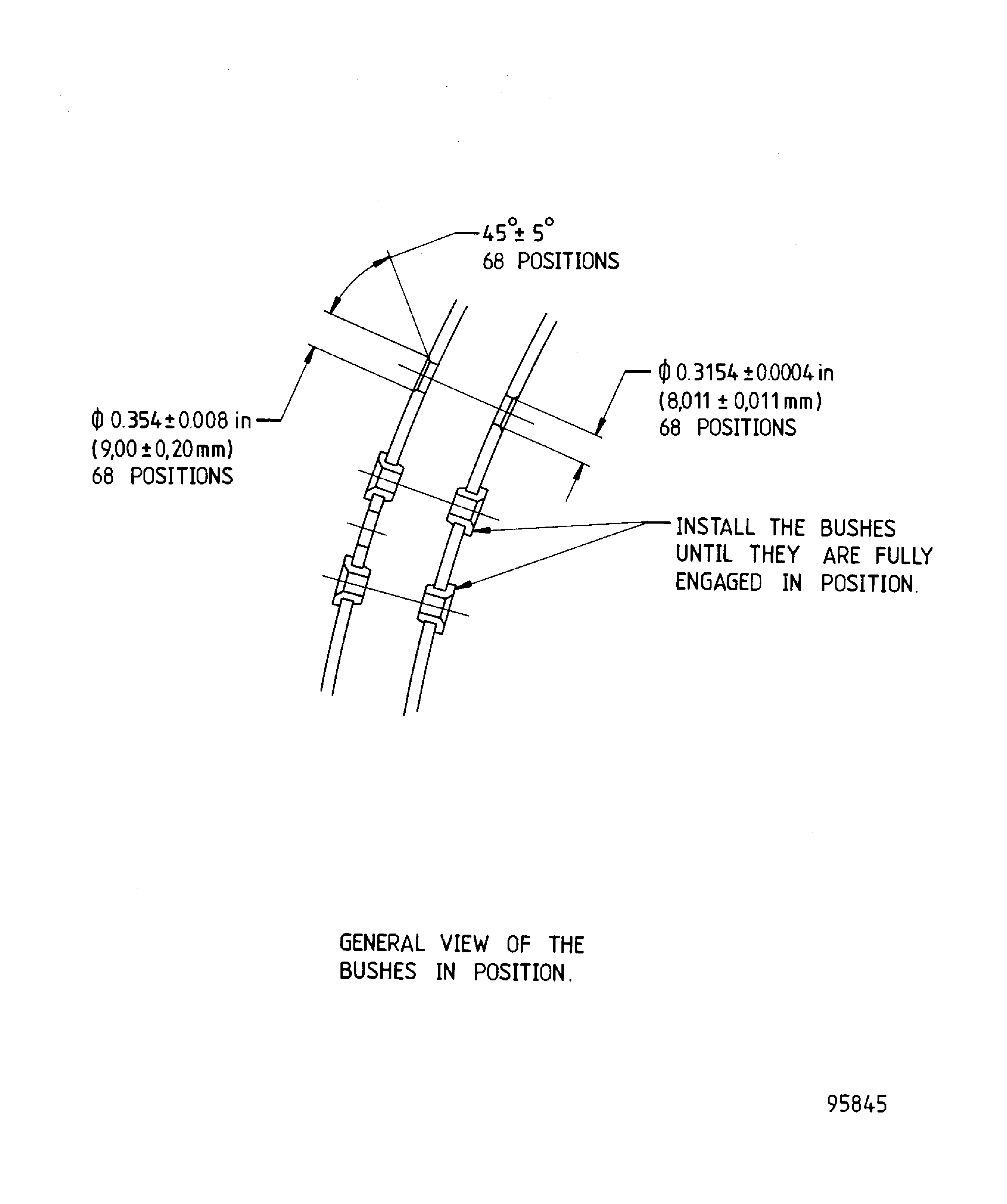

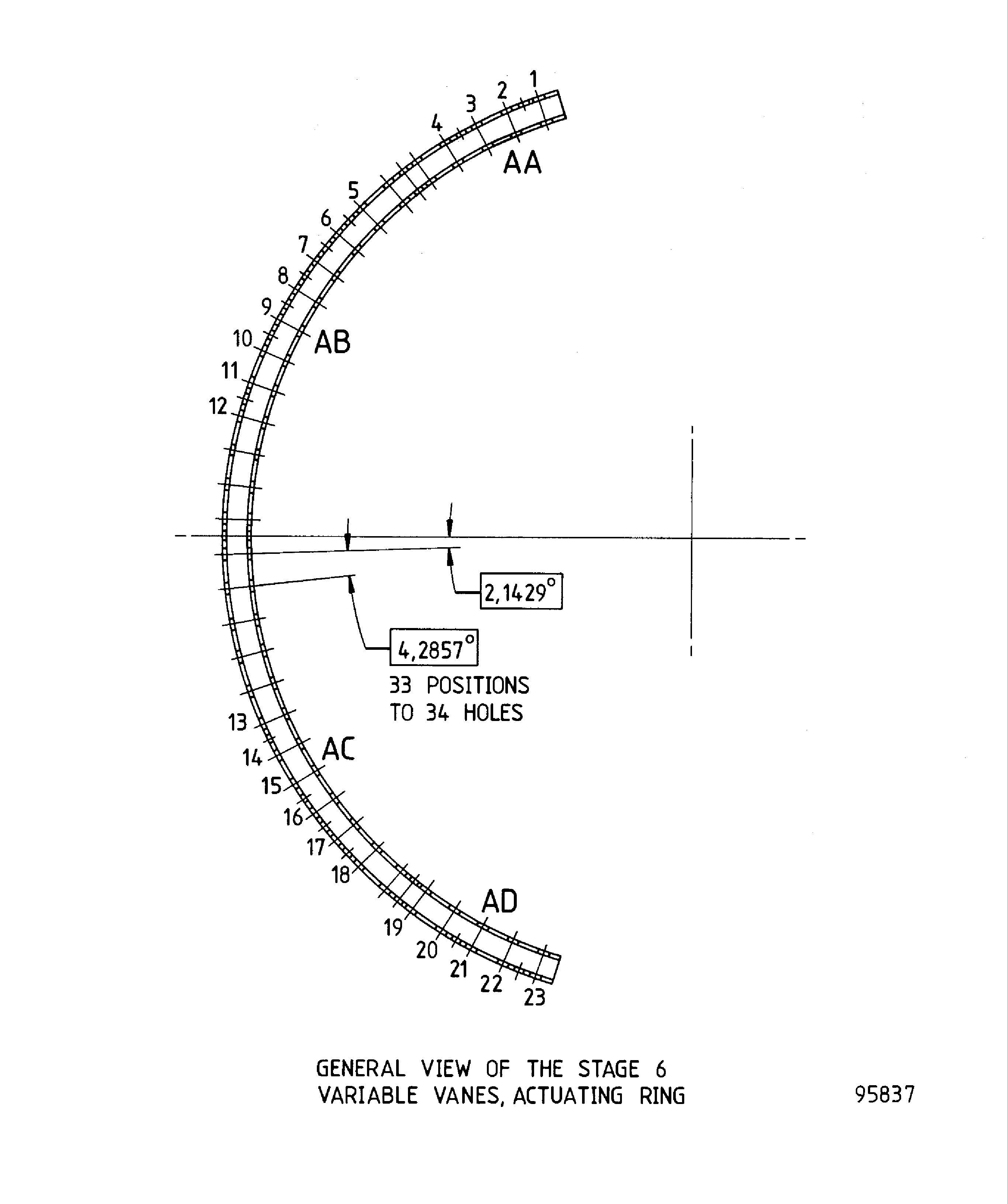

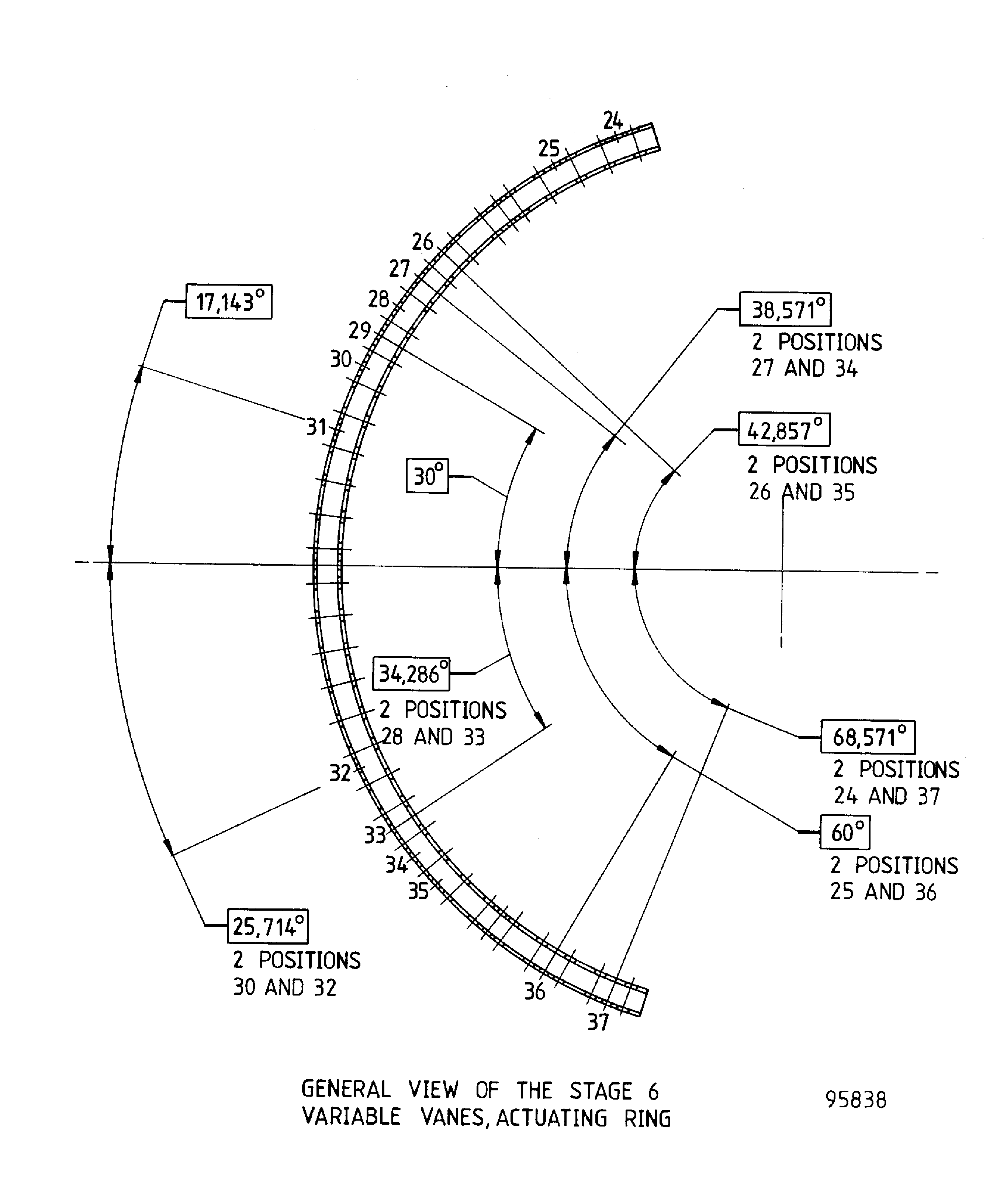

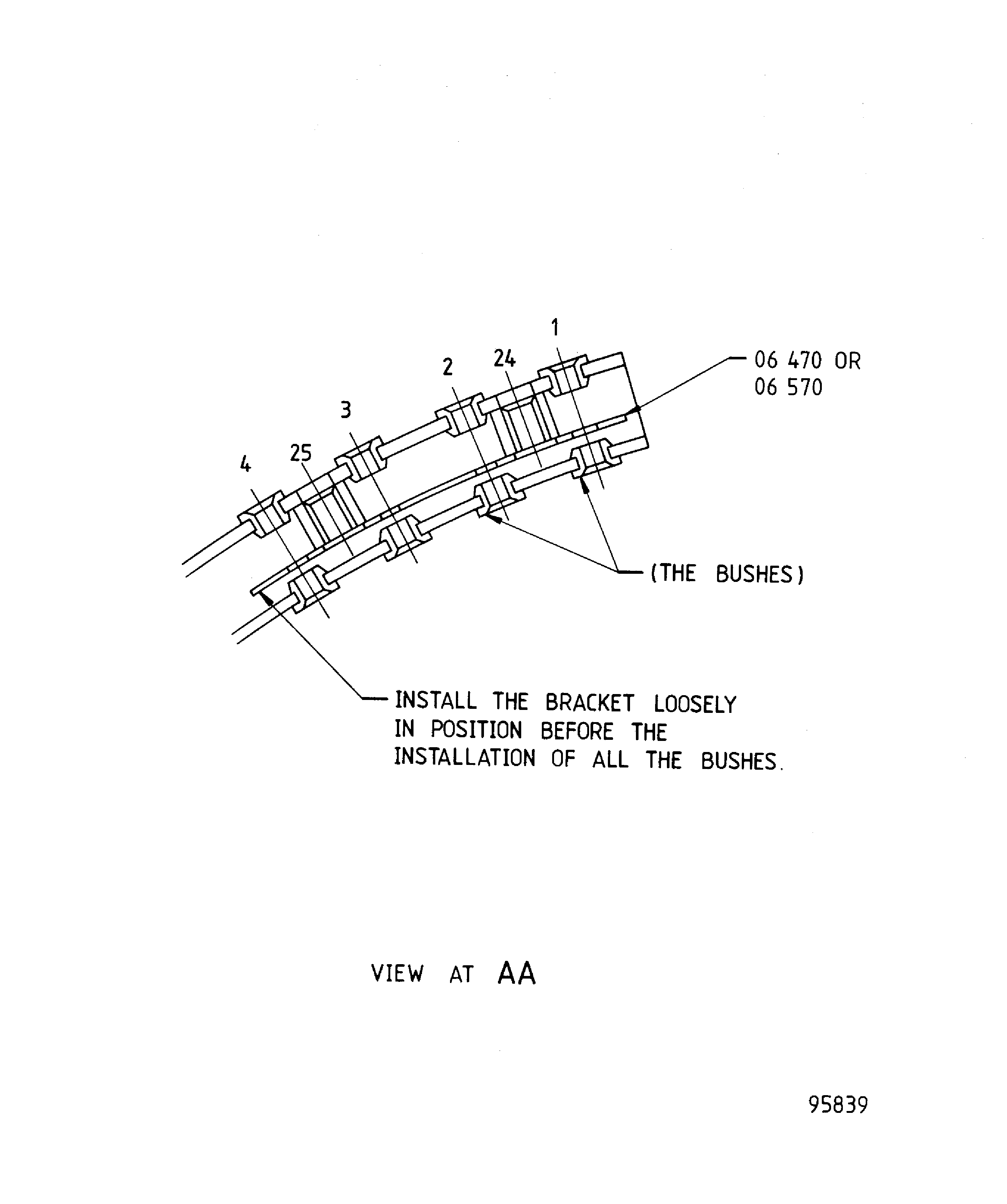

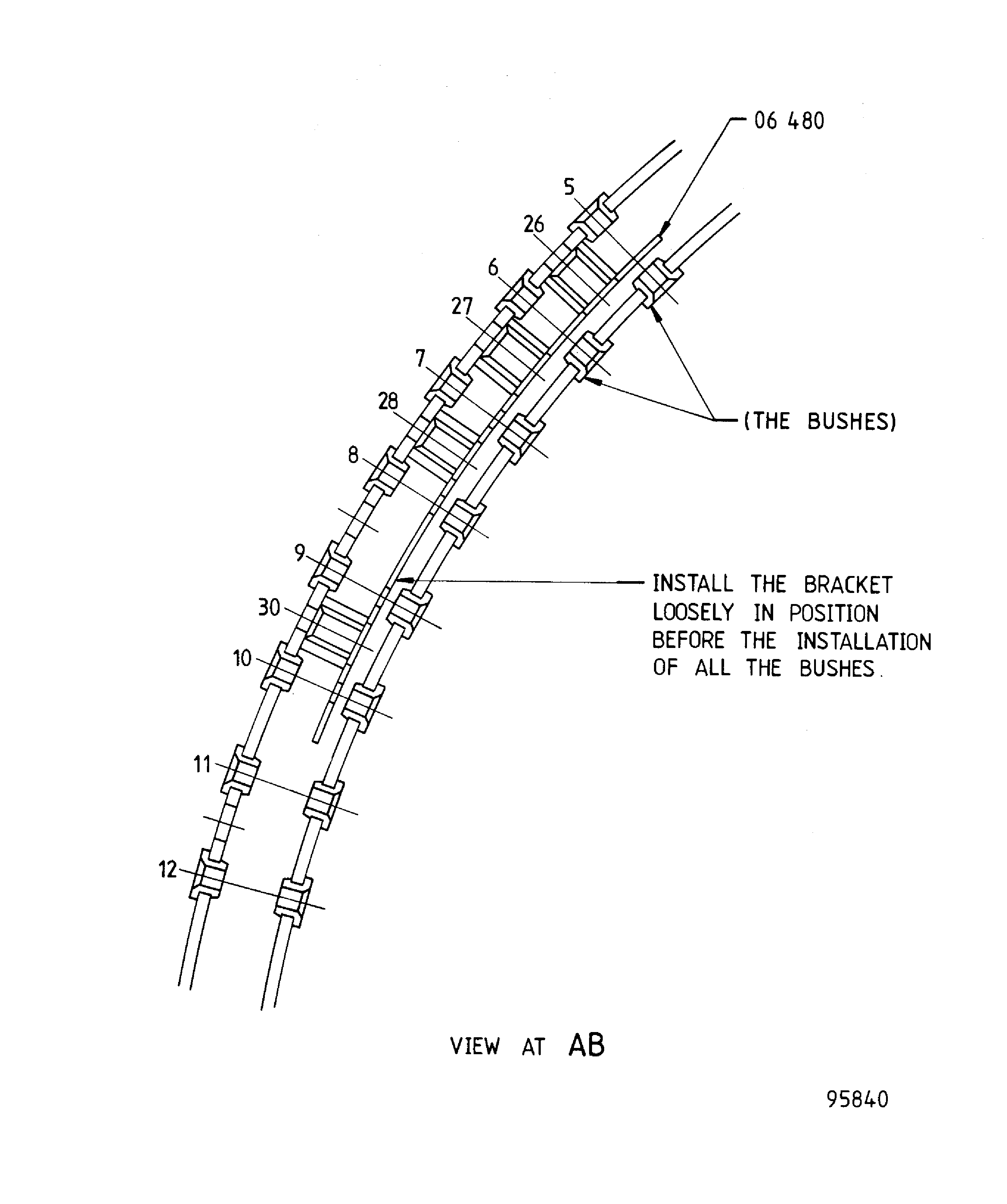

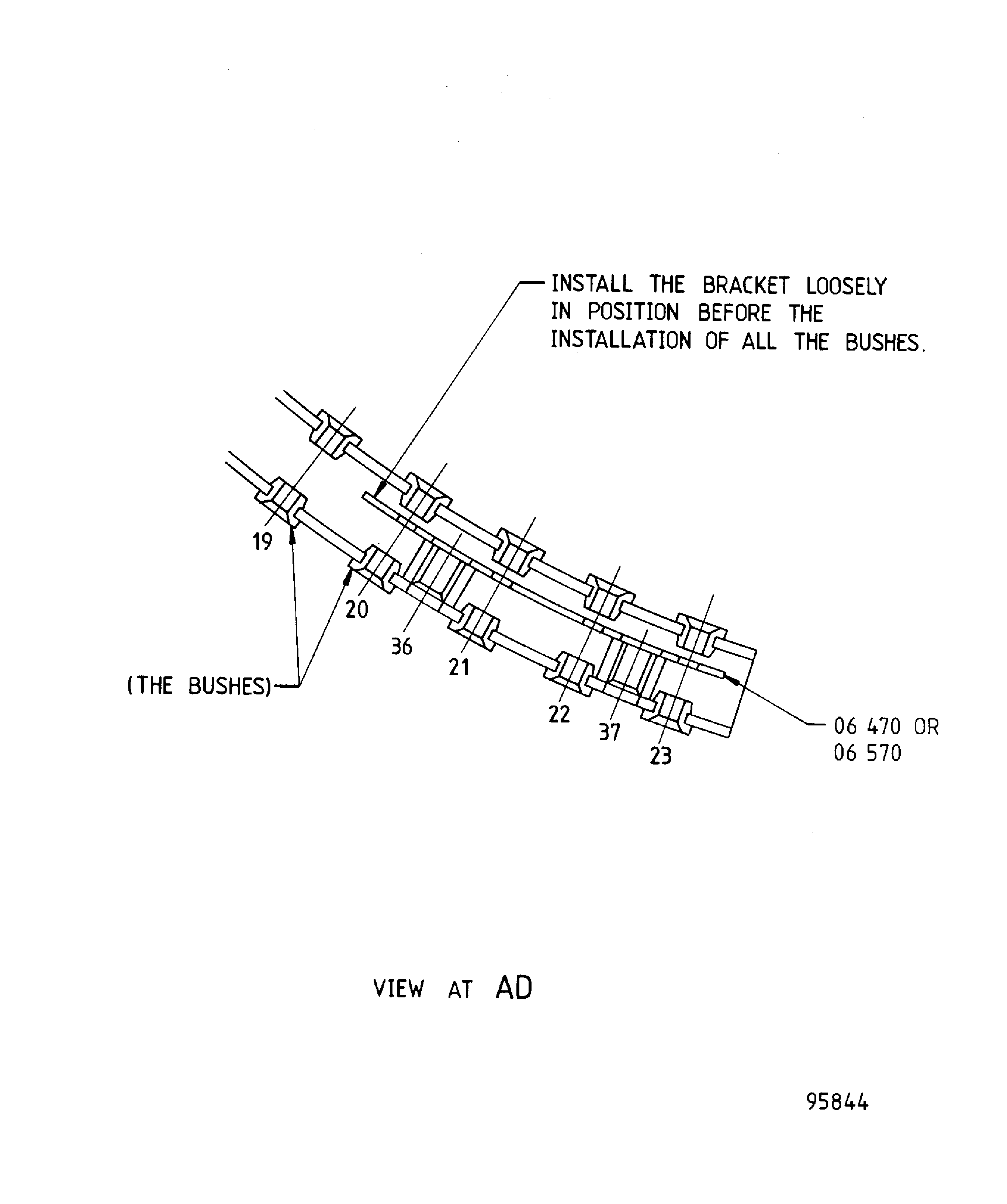

Figure: Repair details and dimensions

Repair details and dimensions

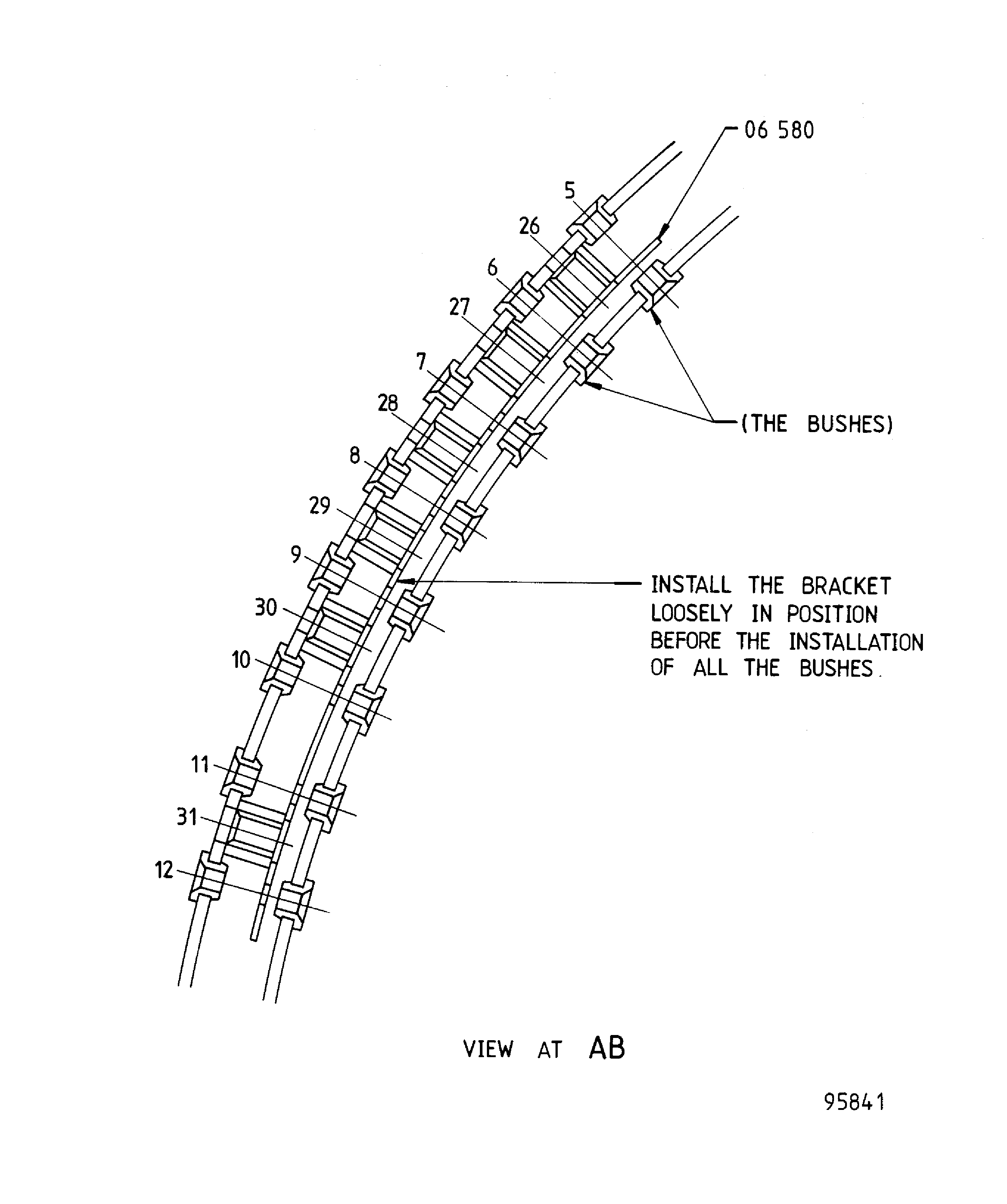

Figure: Repair details and dimensions

Repair details and dimensions

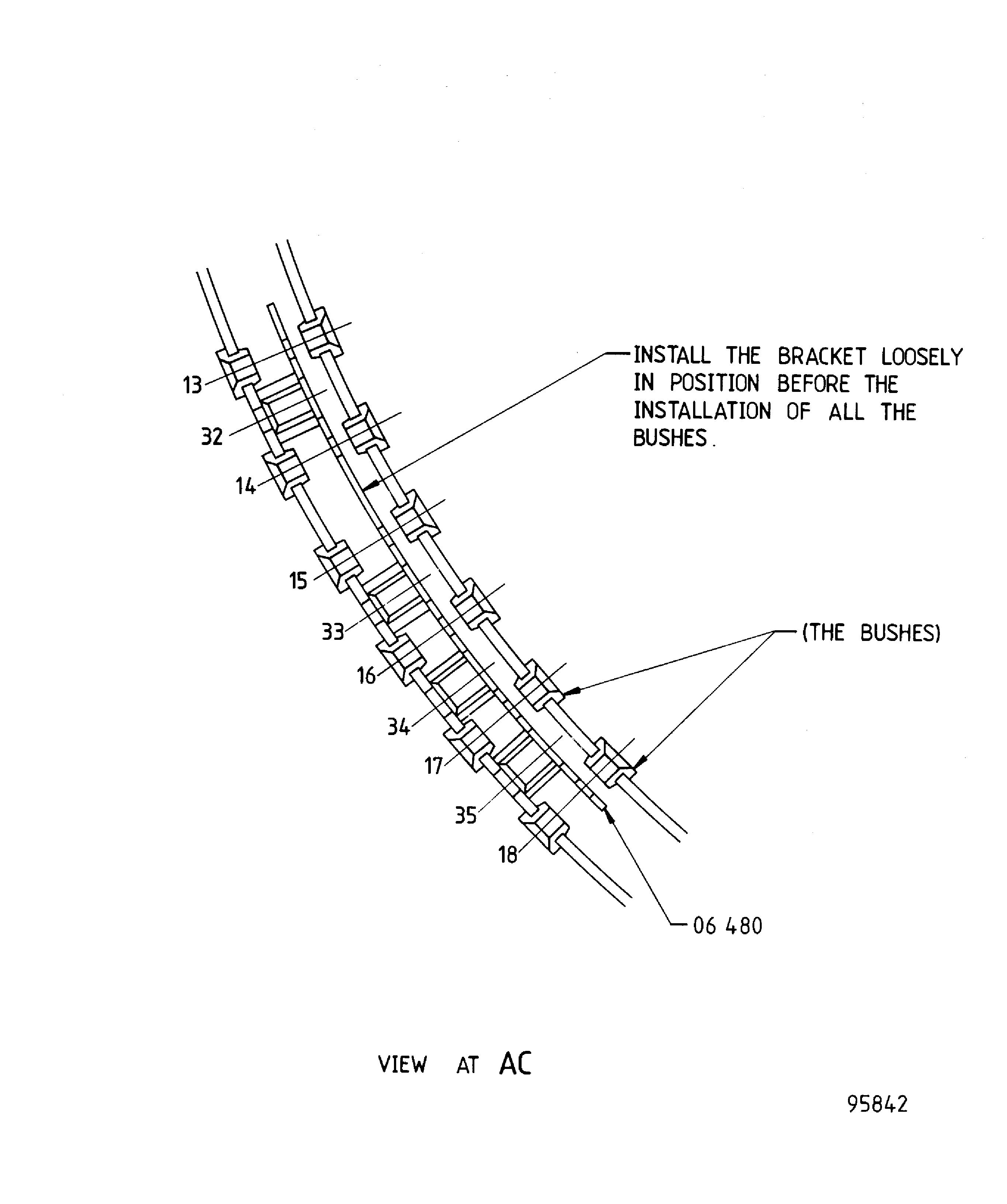

Figure: Repair details and dimensions

Repair details and dimensions

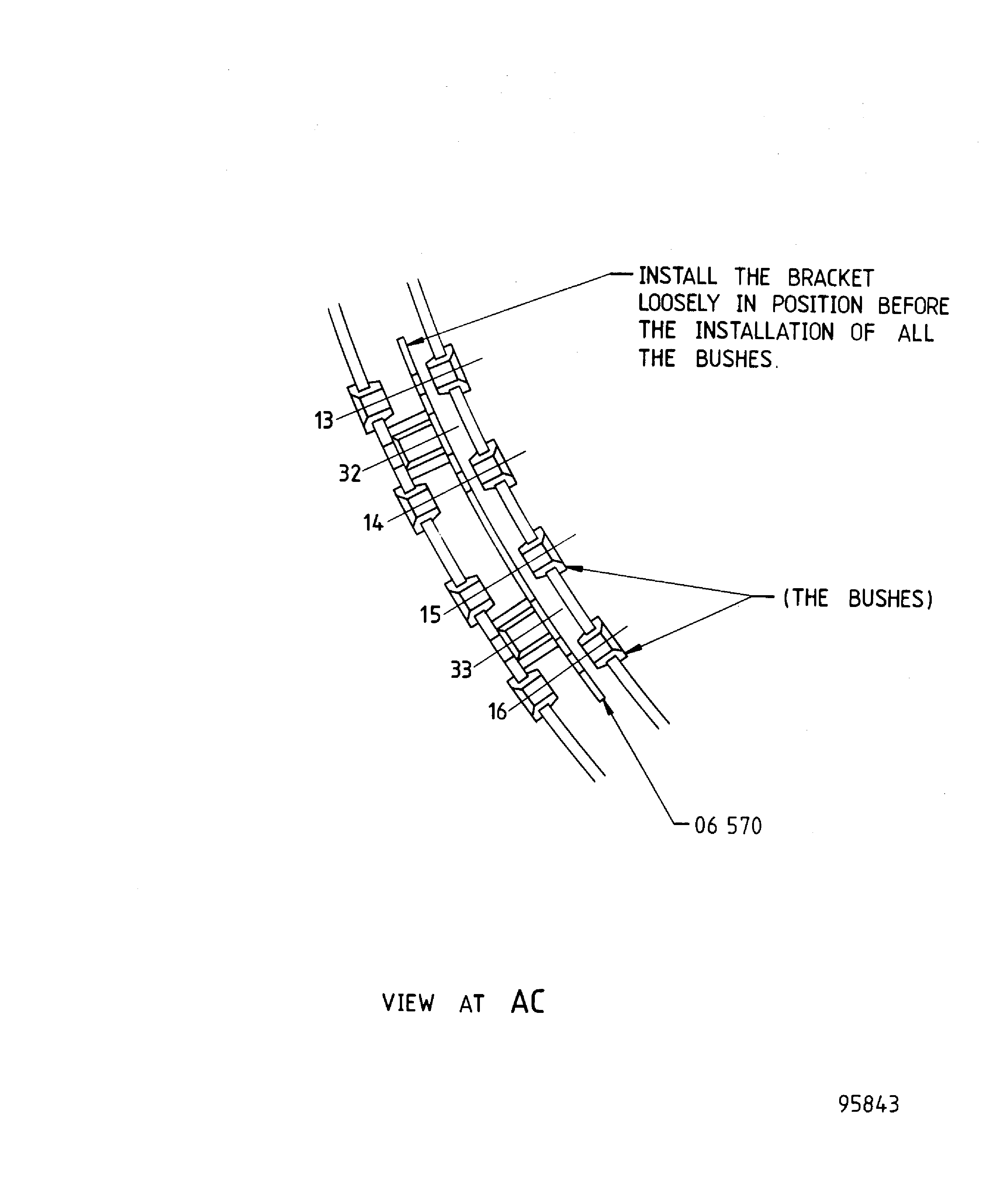

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions