Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-34-300-040 HPC Centralizing Pad And Housing - Refit Or Replace Loose Or Damaged Pads (Stage 3 Through 5), Repair-040 (VRS6314)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

03-730 | 6A2925 |

03-730 | 6A3988 |

04-730 | 6A2927 |

04-730 | 6A4343 |

04-730 | 6A4810 |

05-730 | 6A2930 |

05-730 | 6A4335 |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor Stage 3 Housing | LAH | Aluminum Alloy |

HP Compressor Stage 4 and 5 Housings | EAF | Chrome Nickel Corrosion Resistant Steel |

HP Compressor Stage 3 to 5 Rubbing Pads | VEA | Polymide/Graphite Polytetrafluoroethylene |

General

This Repair must only be done when the instruction to do so is given in 72-41-34 INSPECTION

This Repair gives the instruction to refit or replace loose or damaged stage 3 to 5 HP Compressor rubbing pads

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM

Price and availability

Refer to International Aero Engines

Related repairs

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Oven | LOCAL | Oven | Hot Air | |

| Vertical Boring Machine | LOCAL | Vertical Boring Machine |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 08-005 HEAT CURING EPOXIDE RESINADHESIVE | LOCAL | CoMat 08-005 | ||

| CoMat 01-459 AQUEOUS WIPE CLEANER | 71410 | CoMat 01-459 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Rubbing Pad - Stage 3 | 6A2922 | As Required | ||

| Rubbing Pad - Stage 3 | 6A3953 | As Required | ||

| Rubbing Pad - Stage 4 | 6A2929 | As Required | ||

| Rubbing Pad - Stage 4 | 6A4811 | As Required | ||

| Rubbing Pad - Stage 5 | 6A2932 | As Required |

Safety Requirements

NONEProcedure

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Apply filled grade adhesive to each surface.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Heat the assembly to 347 to 365 deg F (175 to 185 deg C) for two hours.

Use hot air oven.

Cure adhesive.

SUBTASK 72-41-34-360-001 Replace the Rubbing Pads

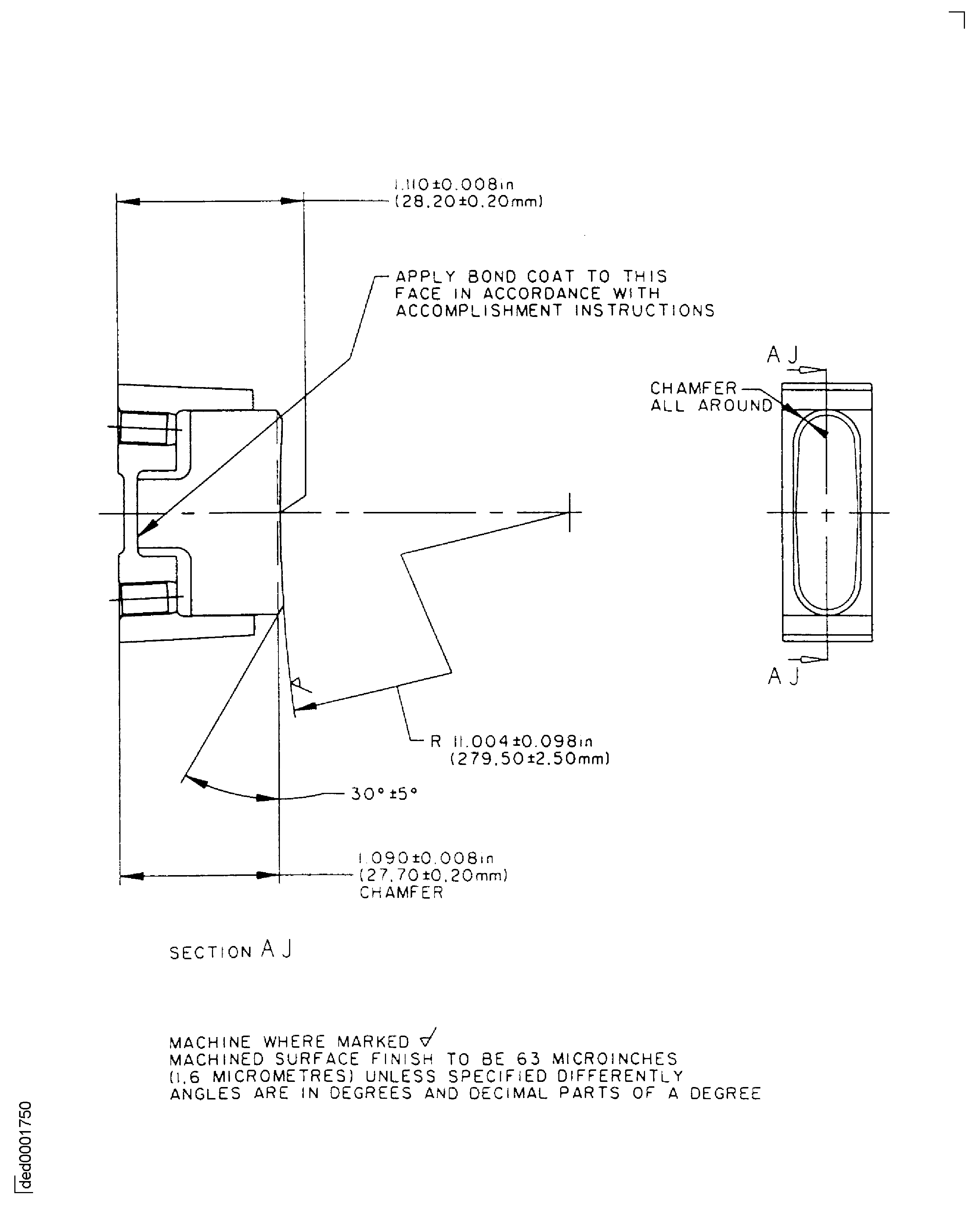

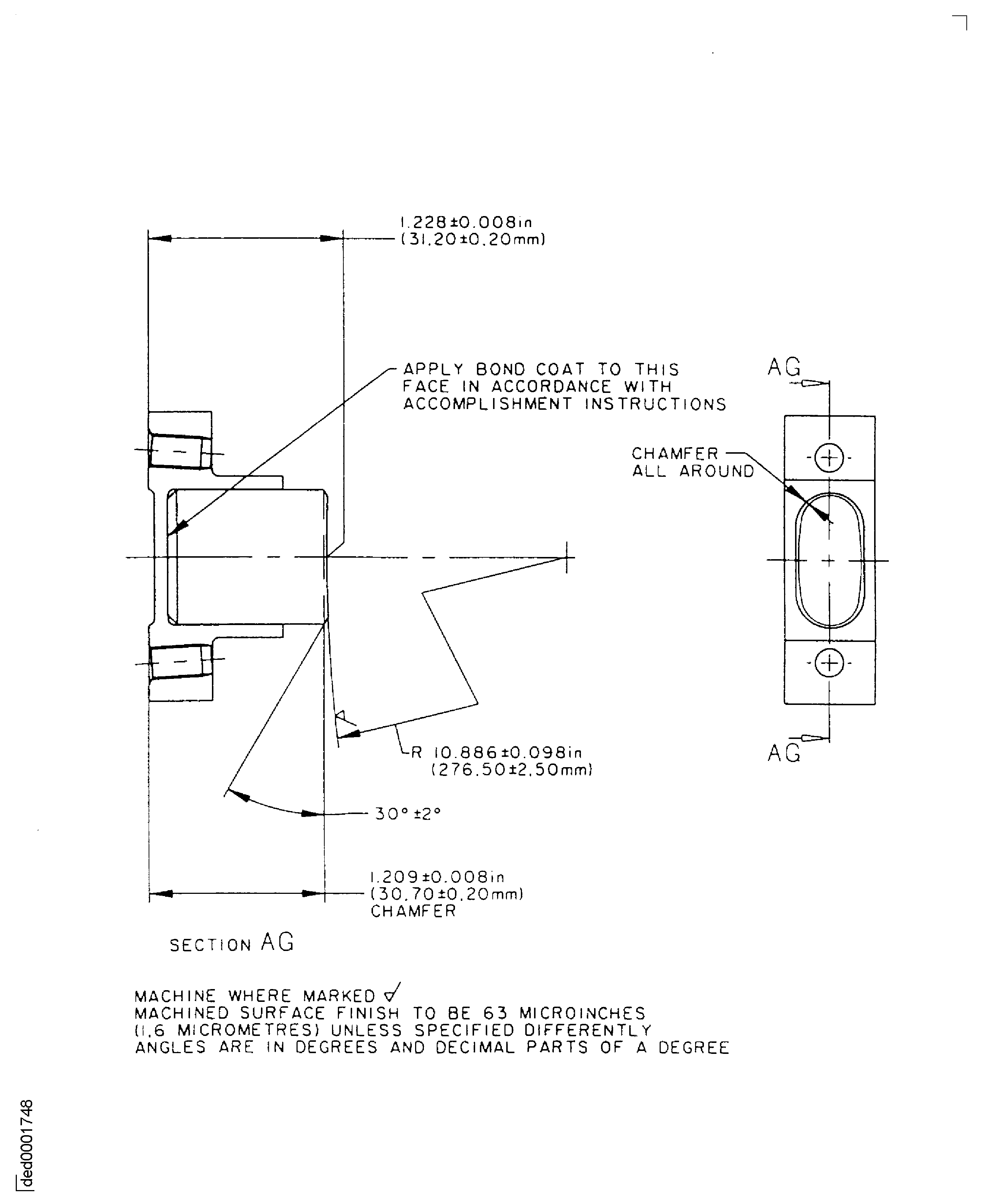

Figure: Repair details and dimensions Stage 3 - Housing 6A2925, Rubbing Pad 6A2922

Sheet 1

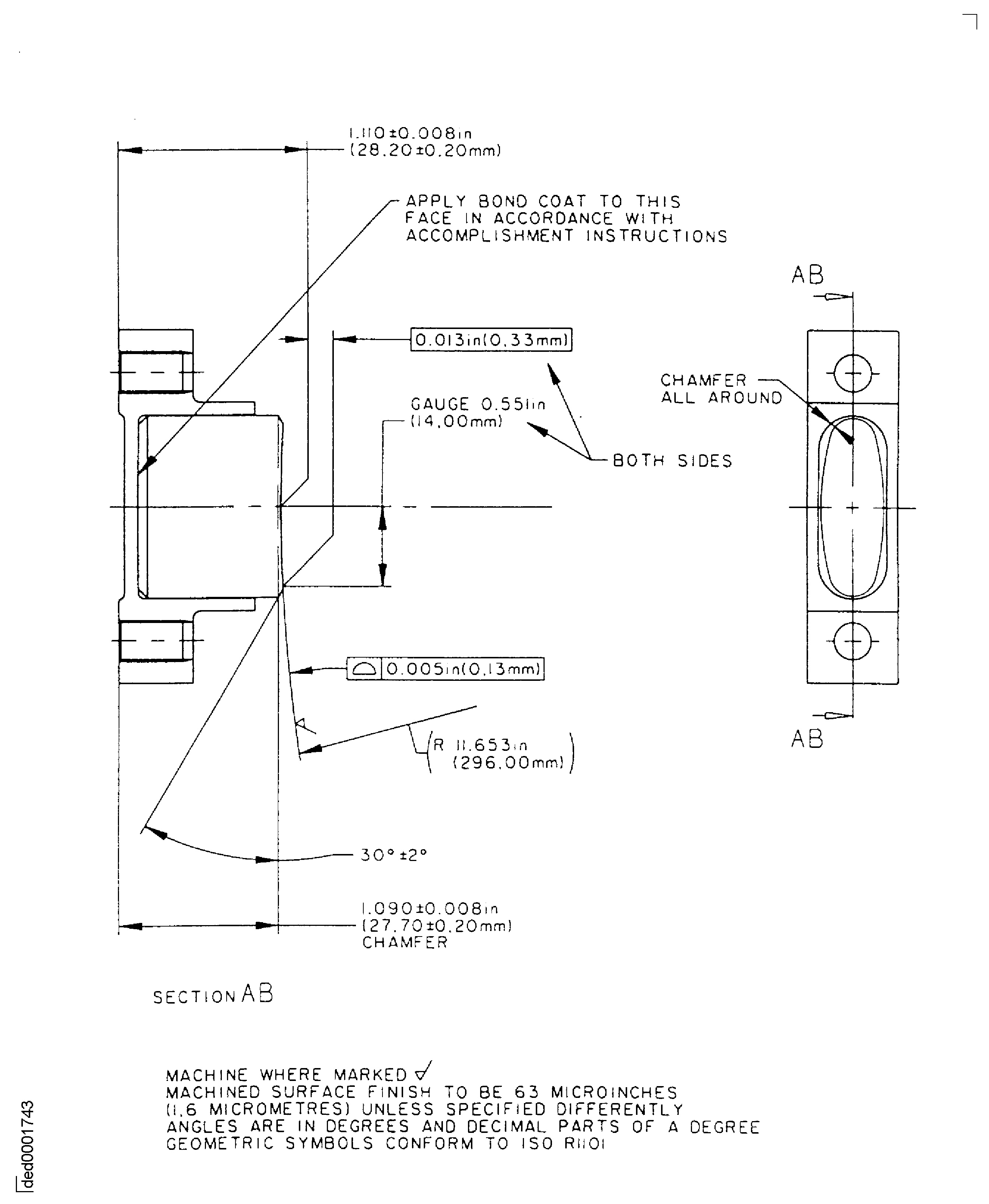

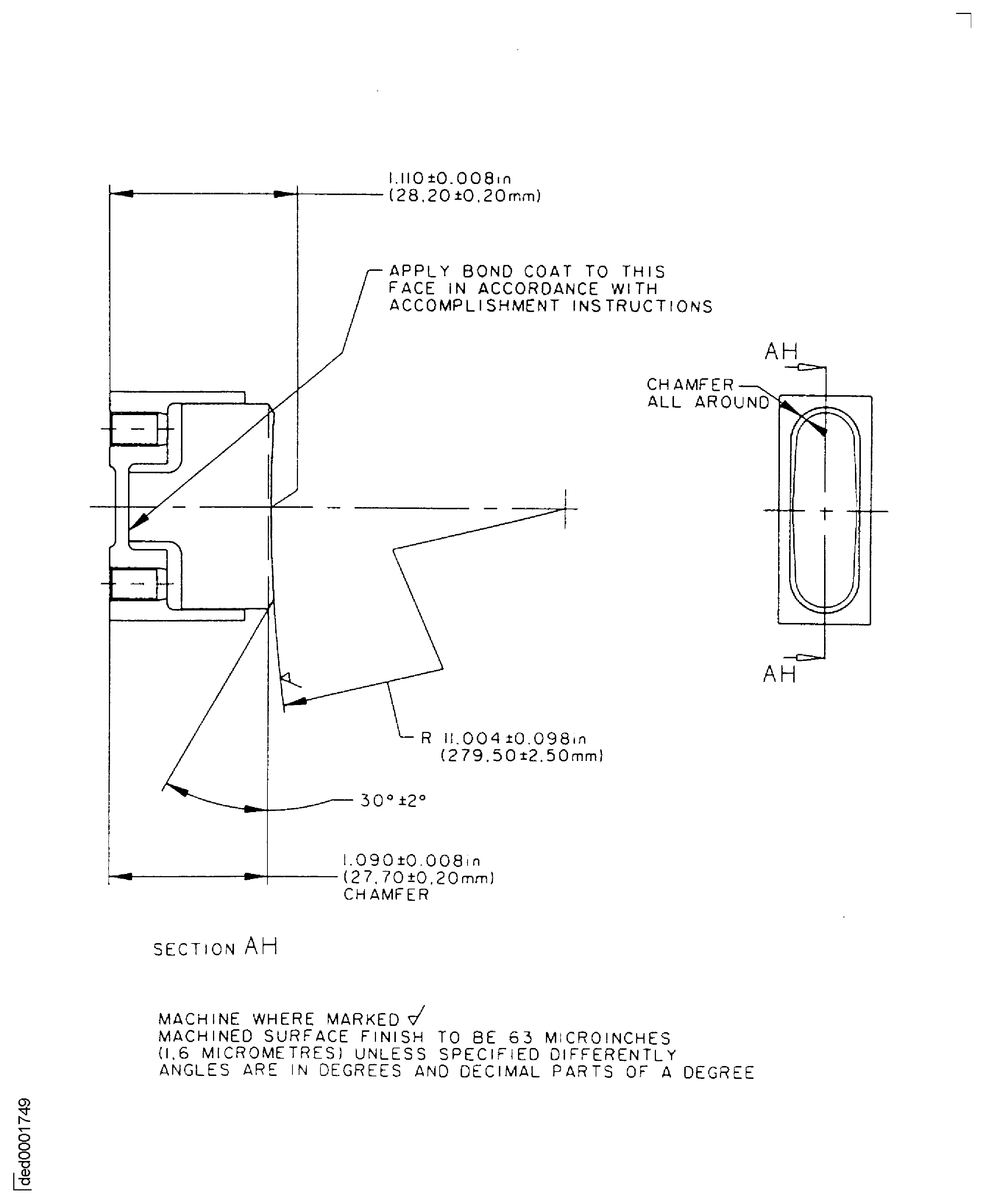

Figure: Repair details and dimensions Stage 3 - Housing 6A3988, Rubbing Pad 6A3953

Sheet 2

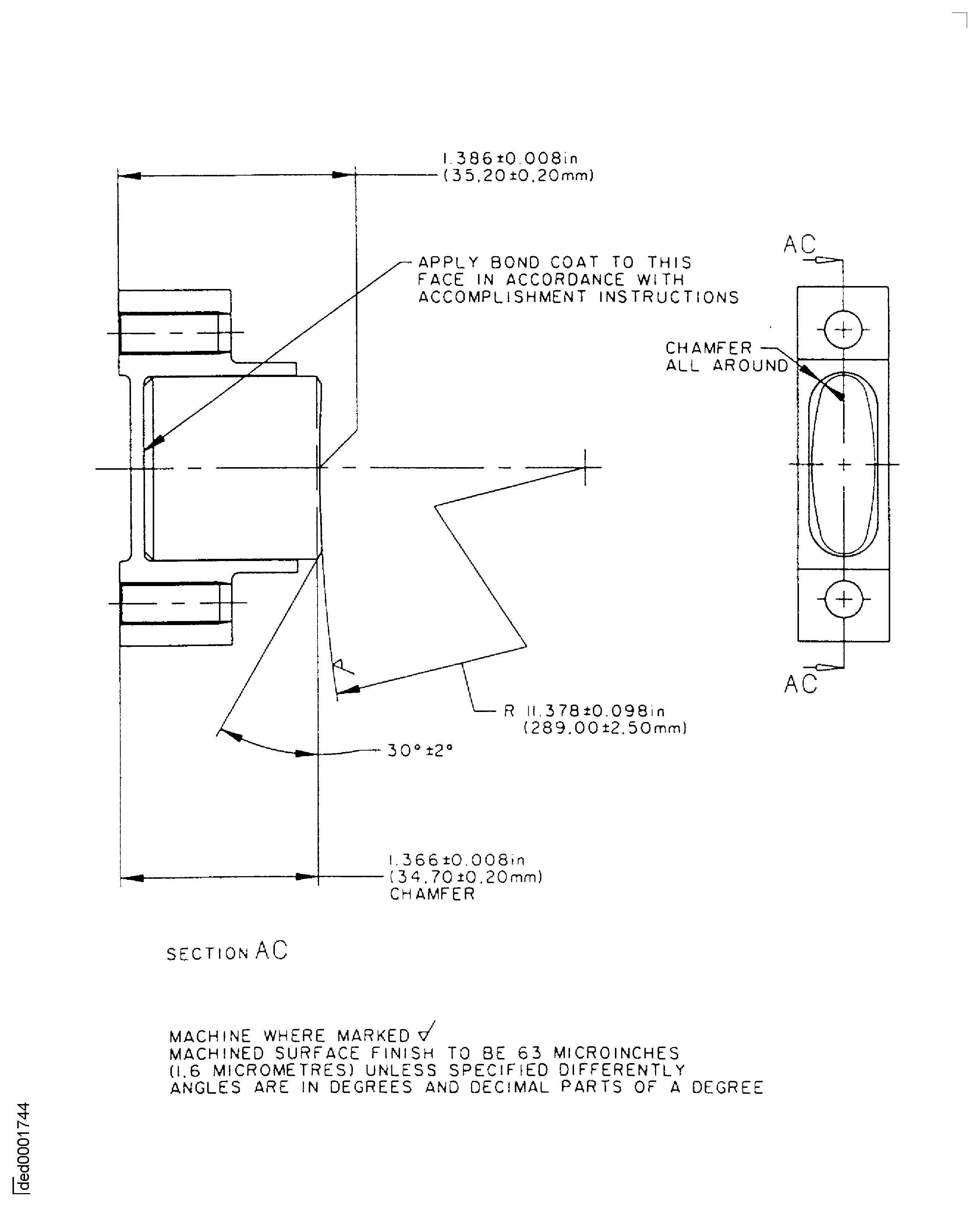

Figure: Repair details and dimensions Stage 4 - Housing 6A2927, Rubbing Pad 6A2929

Sheet 3

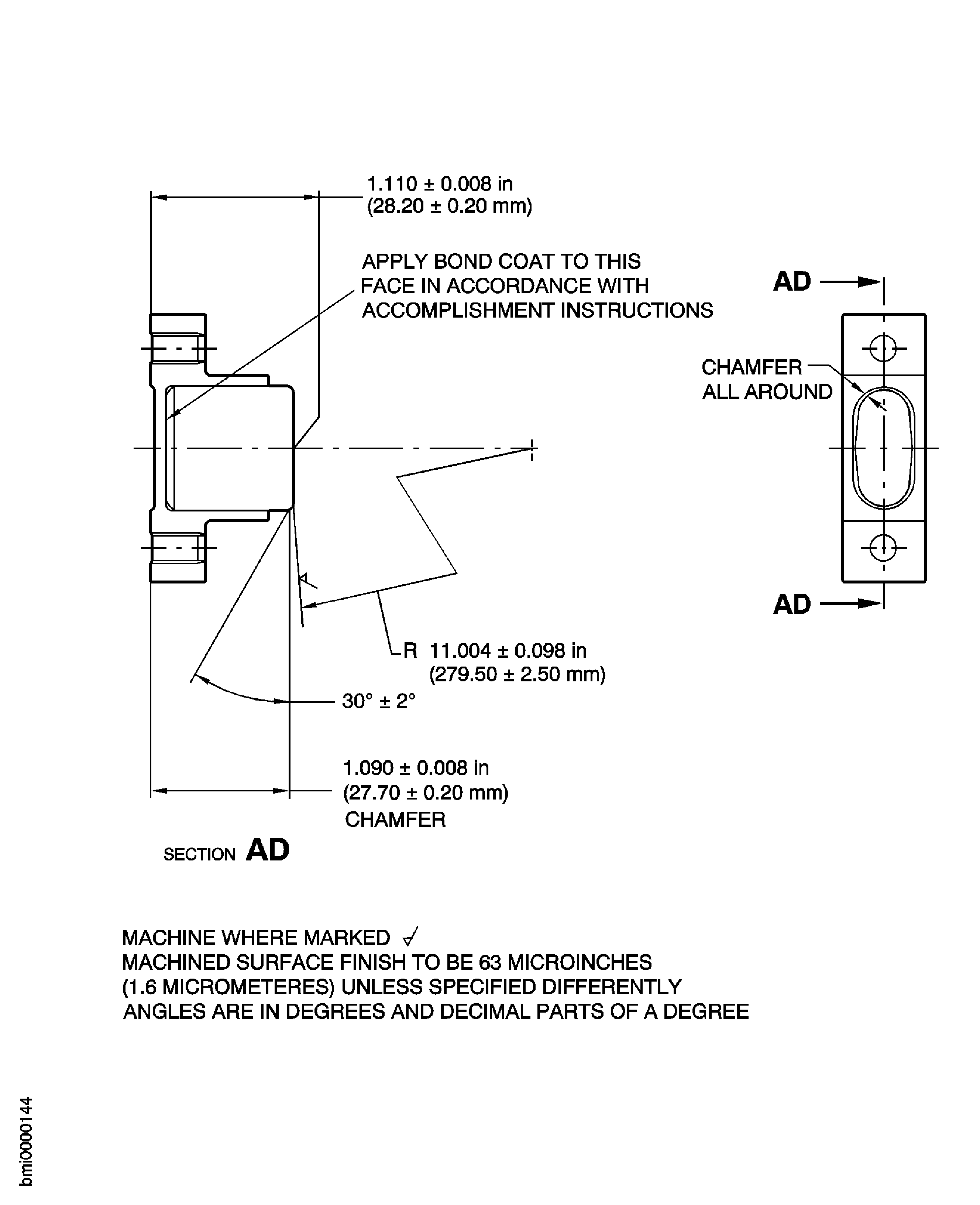

Figure: Repair details and dimensions Stage 4 - Housing 6A4343, Rubbing Pad 6A2929

Sheet 4

Figure: Repair details and dimensions Stage 4 - Housing 6A4810, Rubbing Pad 6A4811

Sheet 5

Figure: Repair details and dimensions Stage 5 - Housing 6A2930, Rubbing Pad 6A2932

Sheet 6

Figure: Repair details and dimensions Stage 5 - Housing 6A4335, Rubbing Pad 6A2932

Sheet 7