Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-34-300-059 HPC Inlet Guide Vane Ring Centralizing Pad And Housing - Refit Or Replace Loose Or Damaged Pads, Repair-059 (VRS6648)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

02-680 | 6A2917 | Assembly A |

02-680 | 6A3943 | Assembly B |

02-730 | 6A2920 | Assembly C |

02-730 | 6A3946 | Assembly D |

02-750 | 6A2923 | Assembly E |

02-750 | 6A3949 | Assembly F |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Housing Assembly RH and LH VIGV Connector - Assemblies A and C | EAF | Corrosion Resistant Steel |

Housing Assembly RH and LH VIGV Connector - Assemblies B and D | LAH | Aluminum Alloy |

Housing Assembly - Assembly E | EAK | Corrosion Resistant Steel |

Housing Assembly - Assembly F | LAH | Aluminum Alloy |

Rubbing Pads | VEA | Polymide/Graphite Polytetrafluoroethylene |

General

This Repair must only be done when the instruction to do so is given in TASK 72-41-34 (INSPECTION)

This Repair gives the instruction to refit or replace loose or damaged HP Compressor VIGV Centralizing Pad and Connector Housing Rubbing Pads.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM

Price and availability

Refer to International Aero Engines

Related repairs - none

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Oven | LOCAL | Oven | Hot air | |

| Vertical boring machine | LOCAL | Vertical boring machine |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 08-005 HEAT CURING EPOXIDE RESINADHESIVE | LOCAL | CoMat 08-005 | ||

| CoMat 01-459 AQUEOUS WIPE CLEANER | 71410 | CoMat 01-459 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Rubbing Pad - Assemblies A and B | 6A2919 | As required | ||

| Rubbing Pad - Assemblies C and D | 6A2922 | As required | ||

| Rubbing Pad - Assemblies E and F | 6A2922 | As required |

Safety Requirements

NONEProcedure

Refer to: Figure

Use serviceable rubbing pad removed from housing or fit new rubbing pad.

Use Rubbing Pad Part No: 02-692 6A2919 .

Visually and dimensionally inspect the fit of the rubbing pad in the housing.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Prepare surfaces to be bonded.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Apply filled grade adhesive to each surface.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Heat the assembly to 347 to 365 deg. F (175 to 185 deg C) for two hours.

Use hot air oven.

Cure adhesive.

SUBTASK 72-41-34-360-003-A00 Replace the Rubbing Pad, Assembly A

Refer to: Figure

Use serviceable rubbing pad removed from housing or fit new rubbing pad.

Use Rubbing Pad Part No: 02-692 6A2919 .

Visually and dimensionally inspect the fit of the rubbing pad in the housing.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Prepare surfaces to be bonded.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Apply filled grade adhesive to each surface.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

If refitting serviceable rubbing pad, ensure cut-out is aligned.

Use suitable clamps.

Assemble mating surfaces and clamp in place.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Heat the assembly to 347 to 365 deg. F (175 to 185 deg C) for two hours.

Use hot air oven.

Cure adhesive.

SUBTASK 72-41-34-360-003-B00 Replace the Rubbing Pad, Assembly B

Use serviceable rubbing pad removed from housing or fit new rubbing pad.

Use Rubbing Pad Part No: 02-744 6A2922 .

Visually and dimensionally inspect the fit of the rubbing pad in the housing.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Prepare surfaces to be bonded.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Apply filled grade adhesive to each surface.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

If refitting serviceable rubbing pad, ensure cut-out is aligned.

Use suitable clamps.

Assemble mating surfaces and clamp in place.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Heat the assembly to 347 to 365 deg. F (175 to 185 deg. C) for two hours.

Use hot air oven.

Cure adhesive.

SUBTASK 72-41-34-360-003-C00 Replace the Rubbing Pad, Assembly C

Use serviceable rubbing pad removed from housing or fit new rubbing pad.

Use Rubbing Pad No: 02-744 6A2922 .

Visually and dimensionally inspect the fit of the rubbing pad in the housing.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Prepare surfaces to be bonded.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Apply filled grade adhesive to each surface.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

If refitting serviceable rubbing pad, ensure cut-out is aligned.

Use suitable clamps.

Assemble mating surfaces and clamp in place.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Heat the assembly to 347 to 365 deg. F (175 to 185 deg. C) for two hours.

Use hot air oven.

Cure adhesive.

SUBTASK 72-41-34-360-003-D00 Replace the Rubbing Pad, Assembly D

Use serviceable rubbing pad removed from housing or fit new rubbing pad.

Use Rubbing Pad No: 02-764 6A2922 .

Visually and dimensionally inspect the fit of the rubbing pad in the housing.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Prepare surfaces to be bonded.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Apply filled grade adhesive to each surface.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

If refitting serviceable rubbing pad, ensure cut-out is aligned.

Assemble mating surfaces and clamp in place.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Heat the assembly to 347 to 365 deg. F (175 to 185 deg. C) for two hours.

Use hot air oven.

Cure adhesive.

SUBTASK 72-41-34-360-003-E00 Replace the Rubbing Pad, Assembly E

Use serviceable rubbing pad removed from housing or fit new rubbing pad.

Use Rubbing Pad No: 02-764 6A2922 .

Visually and dimensionally inspect the fit of the rubbing pad in the housing.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Prepare surfaces to be bonded.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Apply filled grade adhesive to each surface.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

If refitting serviceable rubbing pad, ensure cut-out is aligned.

Use suitable clamps.

Assemble mating surfaces and clamp in place.

Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-016.

Heat the assembly to 347 to 365 deg. F (175 to 185 deg. C) for two hours.

Use hot air oven.

Cure adhesive.

SUBTASK 72-41-34-360-003-F00 Replace the Rubbing Pad, Assembly F

Refer to: Figure

SUBTASK 72-41-34-320-055-A00 Machine Rubbing Pad in the HP Compressor Housing Assembly, Assembly A

Refer to: Figure

SUBTASK 72-41-34-320-055-B00 Machine Rubbing Pad in the HP Compressor Housing Assembly, Assembly B

Refer to: Figure and Fig. 72-41-34-990-257

Refer to the SPM TASK 70-38-02-300-503, SUBTASK 70-38-02-300-002.

Touch-up surface protection (if required).

SUBTASK 72-41-34-320-055-D00 Machine Rubbing Pad in the HP Compressor Housing Assembly, Assembly D

Refer to the SPM TASK 70-38-02-300-503, SUBTASK 70-38-02-300-002.

Touch-up surface protection (if required).

SUBTASK 72-41-34-320-055-F00 Machine Rubbing Pad in the HP Compressor Housing Assembly, Assembly F

Refer to: Figure

SUBTASK 72-41-34-220-466-A00 Dimensionally and Visually Examine the Housing Assembly, Assembly A

Refer to: Figure

SUBTASK 72-41-34-220-466-B00 Dimensionally and Visually Examine the Housing Assembly, Assembly B

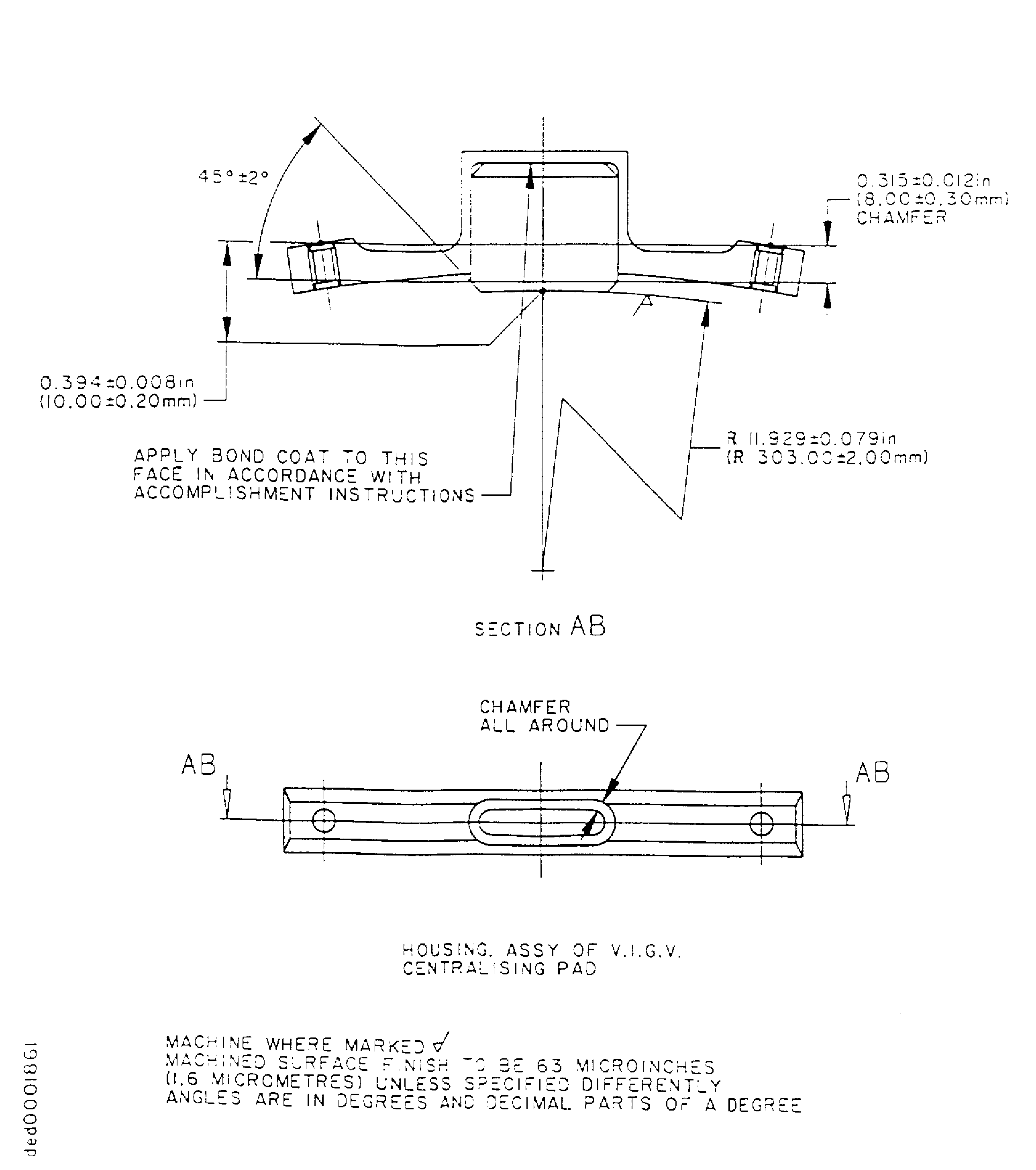

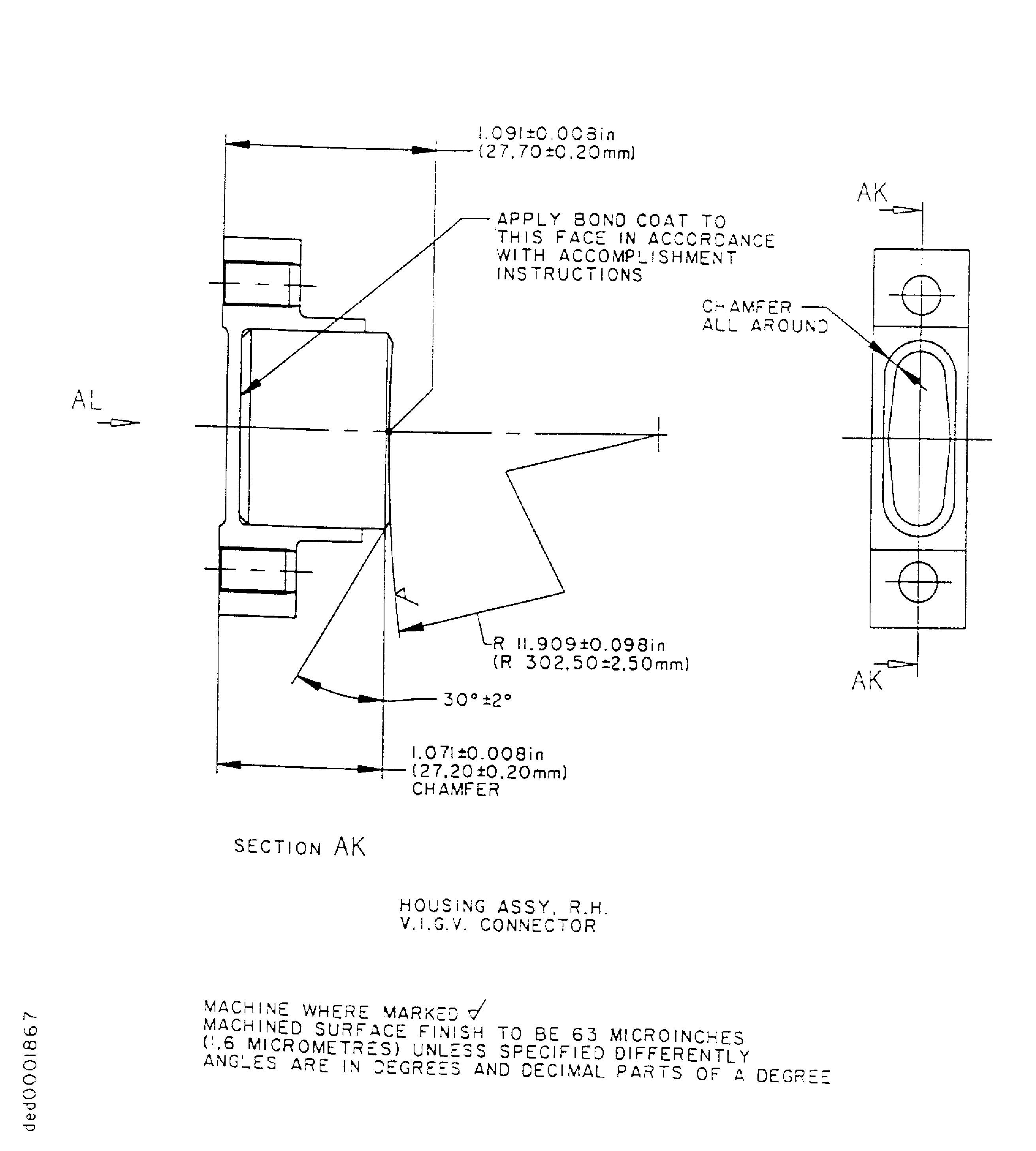

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

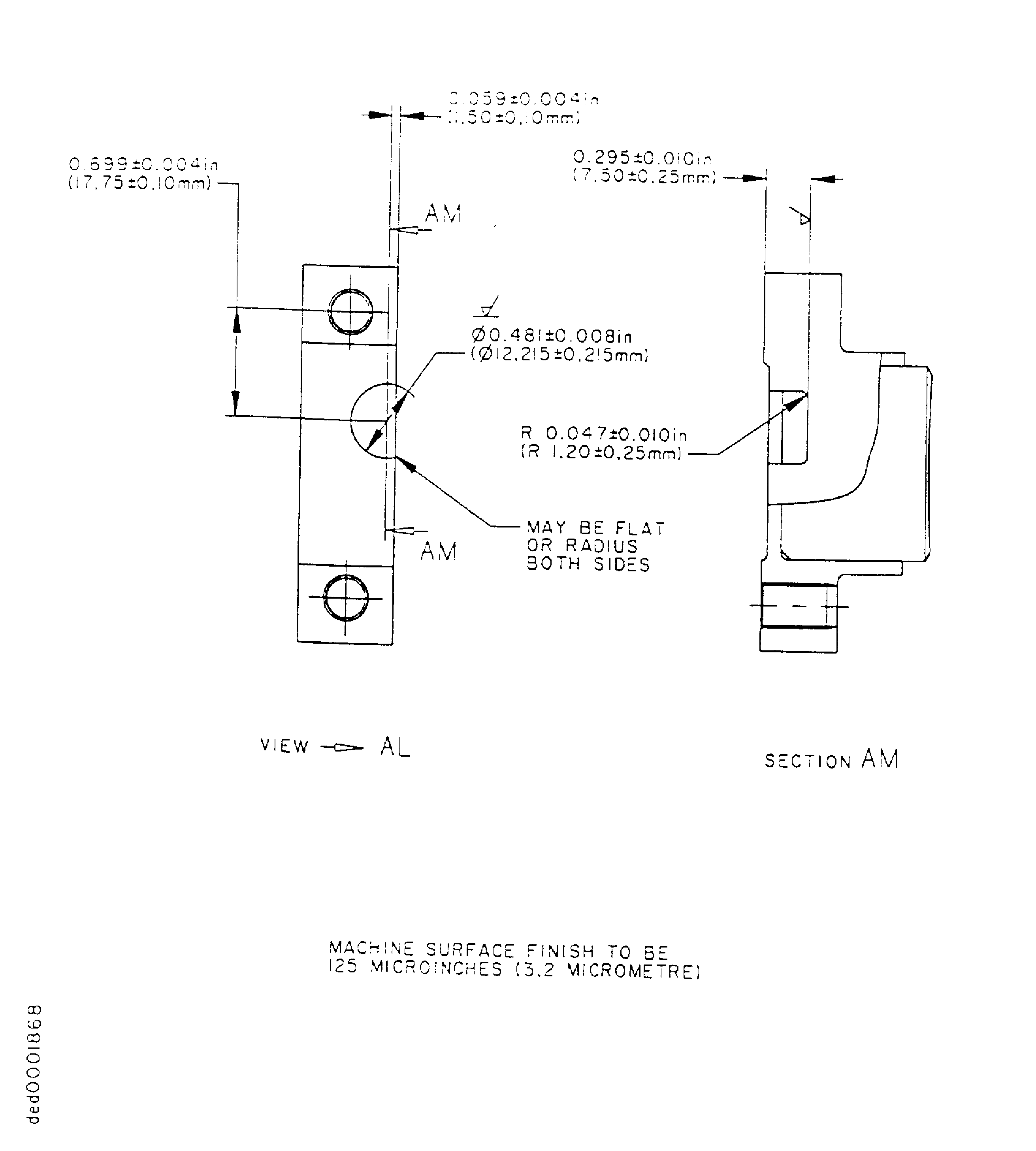

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

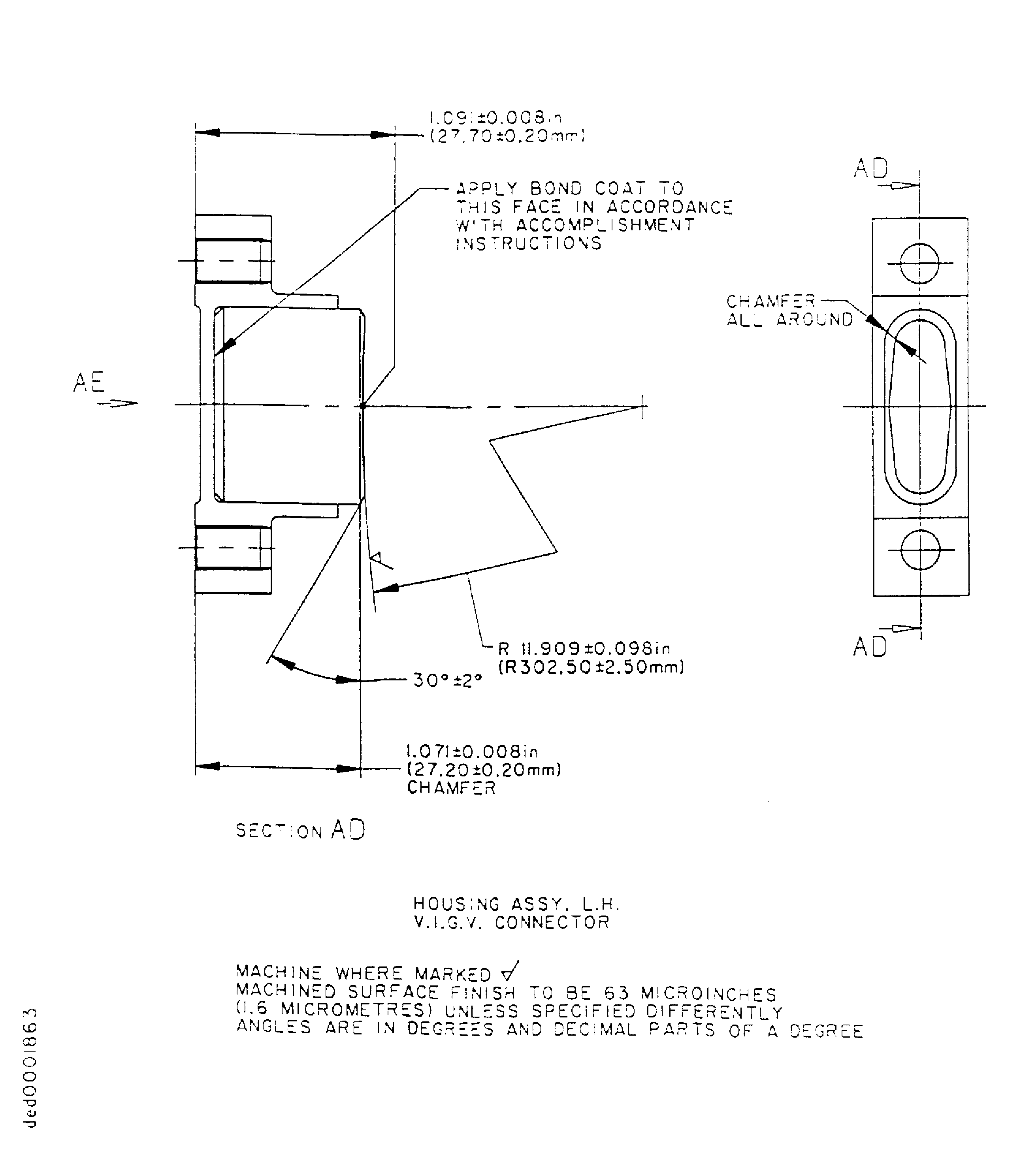

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

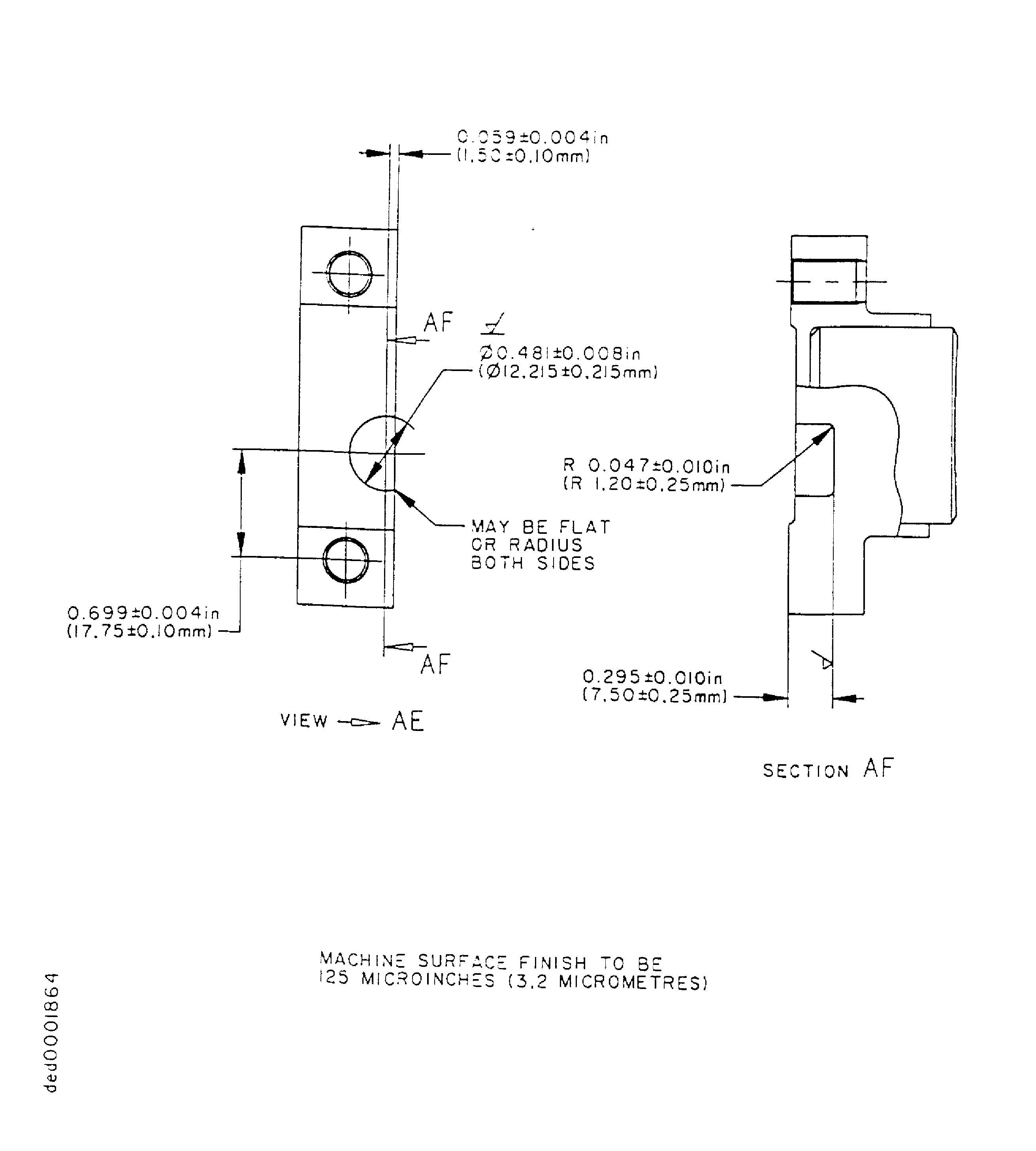

Figure: Repair details and dimensions - Assembly D

Repair details and dimensions - Assembly D

Figure: Repair details and dimensions - Assembly D

Repair details and dimensions - Assembly D

Figure: Repair details and dimensions - Assembly E

Repair details and dimensions - Assembly E

Figure: Repair details and dimensions - Assembly E

Repair details and dimensions - Assembly E

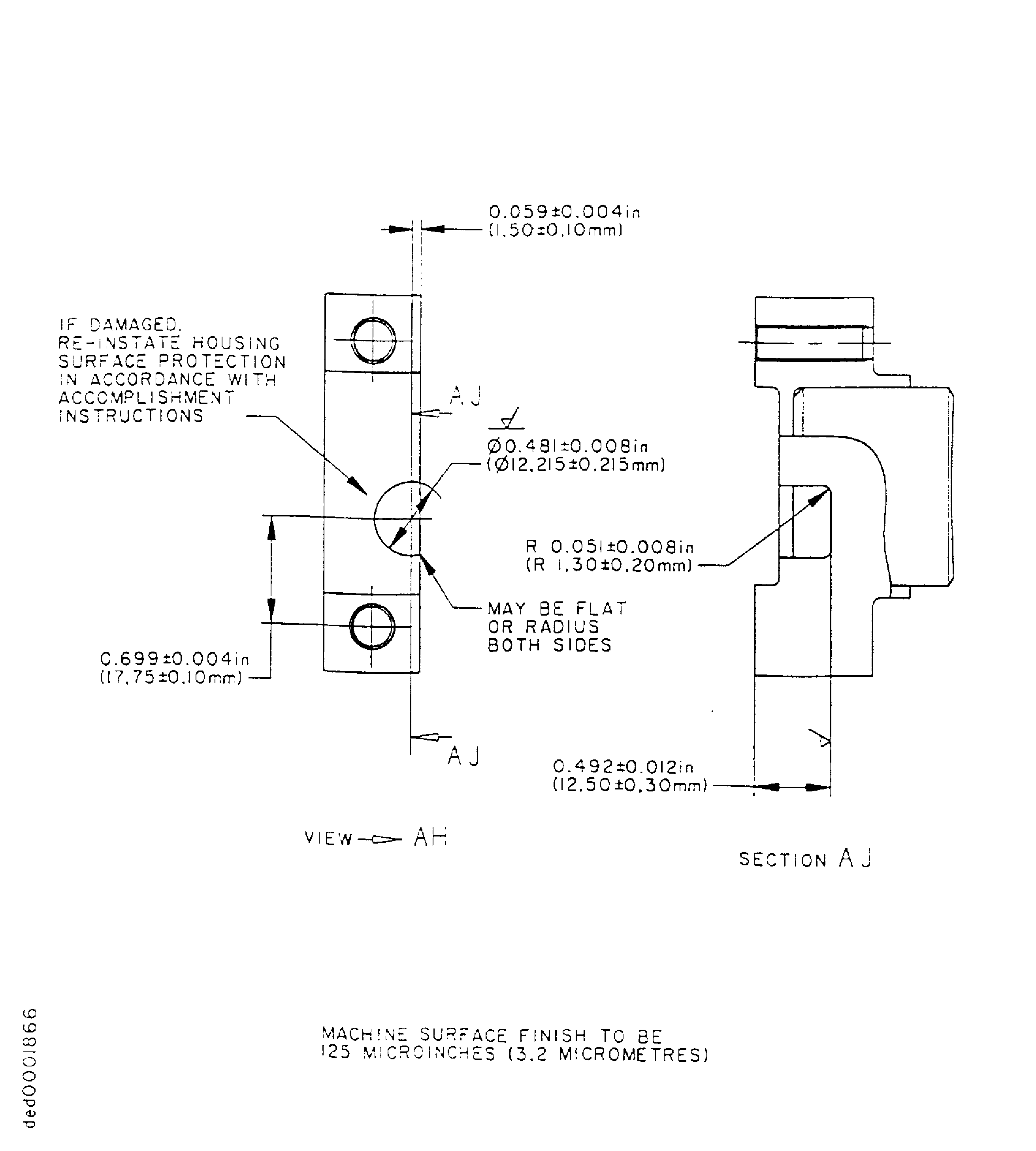

Figure: Repair details and dimensions - Assembly F

Repair details and dimensions - Assembly F

Figure: Repair details and dimensions - Assembly F

Repair details and dimensions - Assembly F