Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-34-300-020 HPC Unison Ring Control Rod Connectors - Replace The Bushes (Stage 4 Through 6), Repair-020 (VRS6238)

Material of component

RR | ||

|---|---|---|

DESCRIPTION SYMBOL MATERIAL | ||

Variable stator vane | TAB | Titanium copper |

control rod connector | alloy | |

assembly, stage 4, 5 | ||

and 6 | ||

Bush | EAK | Modified 12 percent |

chromium steel | ||

General

This Repair must only be done when the instruction to do so is given in TASK 72-41-34 (INSPECTION).

This Repair instructs the replacement of standard or oversize bushes in the stage 4, 5 and 6 variable stator vane control rod connector assembly, as necessary.

The practices and processes referred to in the procedure by TASK/SUBTASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Boring machine | LOCAL | Boring machine | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Heat protection gloves | LOCAL | Heat protection gloves | ||

| Milling machine | LOCAL | Milling machine | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Bush - Standard - Assy A | 6A4361 | 2 | ||

| Bush - Oversize - Assy A | 6A4362 | 2 | (0.005in (0.127 mm)) | |

| Bush - Oversize - Assy A | 6A4363 | 2 | (0.010in (0.254 mm)) | |

| Bush - Standard - Assy B | 6A4361 | 2 | ||

| Bush - Oversize - Assy B | 6A4362 | 2 | (0.005in (0.127 mm)) | |

| Bush - Oversize - Assy B | 6A4363 | 2 | (0.010in (0.254 mm)) | |

| Bush - Standard - Assy C | 6A4361 | 2 | ||

| Bush - Oversize - Assy C | 6A4362 | 2 | (0.005in (0.127 mm)) | |

| Bush - Oversize - Assy C | 6A4363 | 2 | (0.010in (0.254 mm)) |

Safety Requirements

NONEProcedure

Refer to Step and machine oversize.

Cracked.

SUBTASK 72-41-34-220-233 Examine the Bush Location Bore(s)

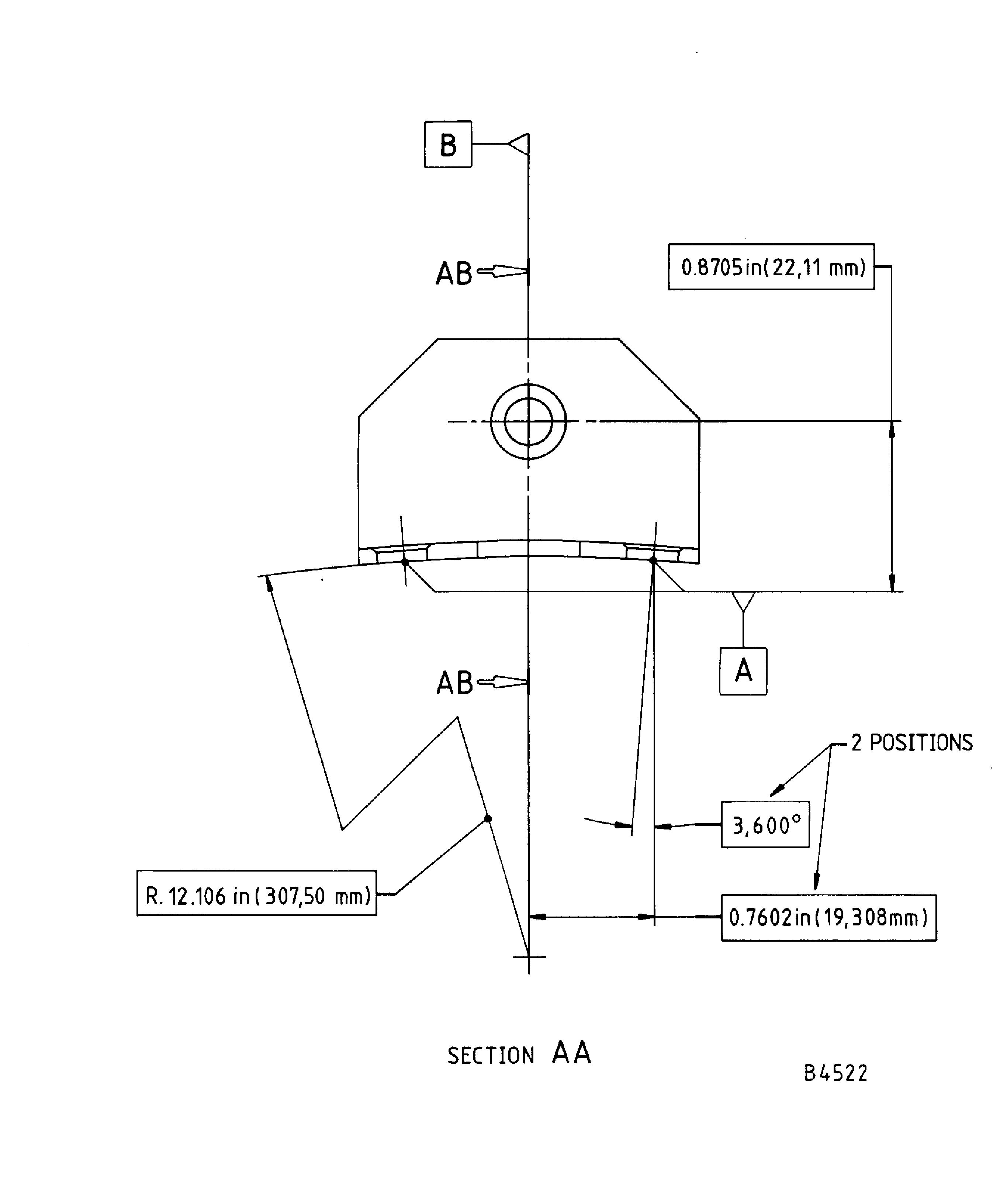

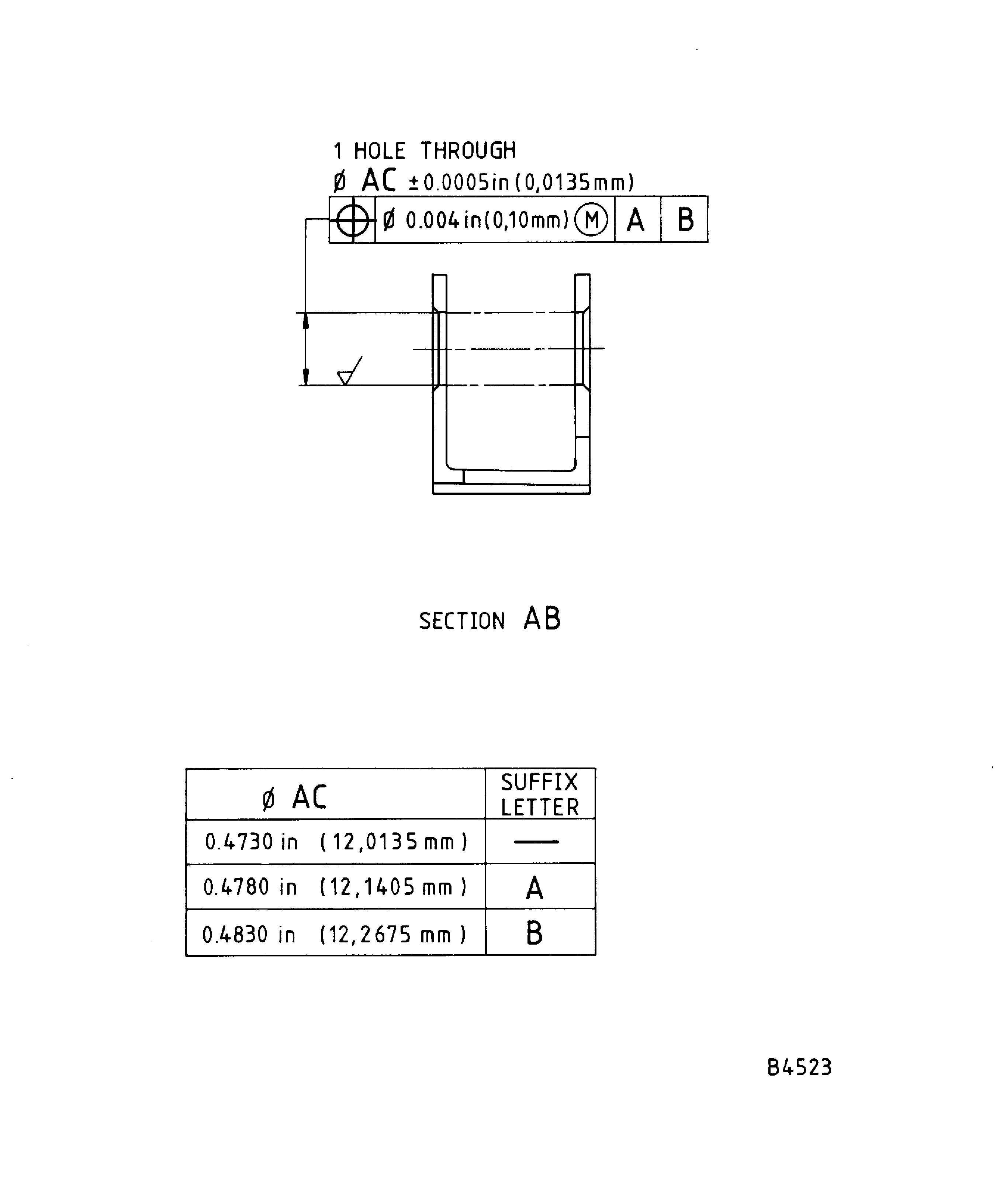

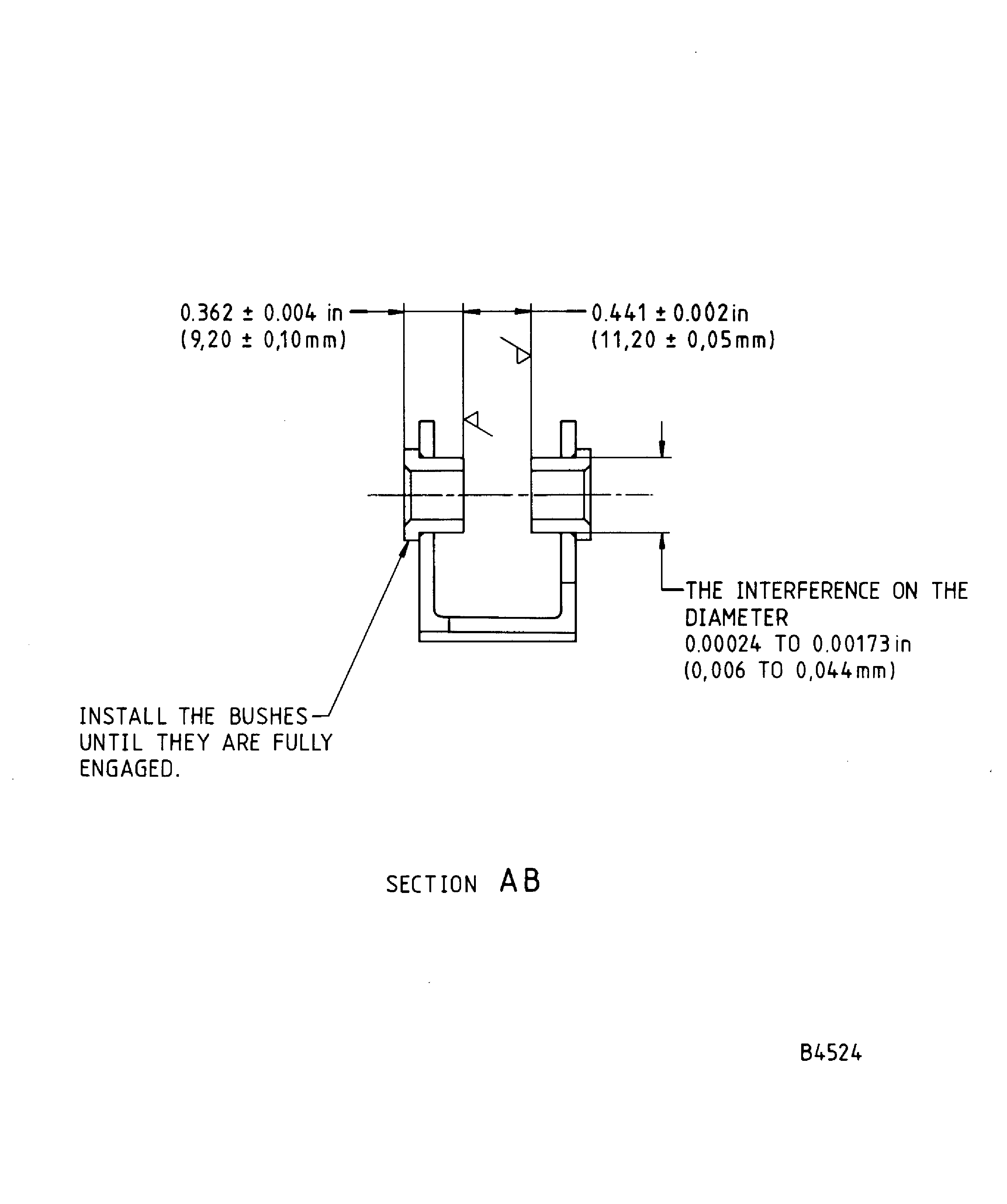

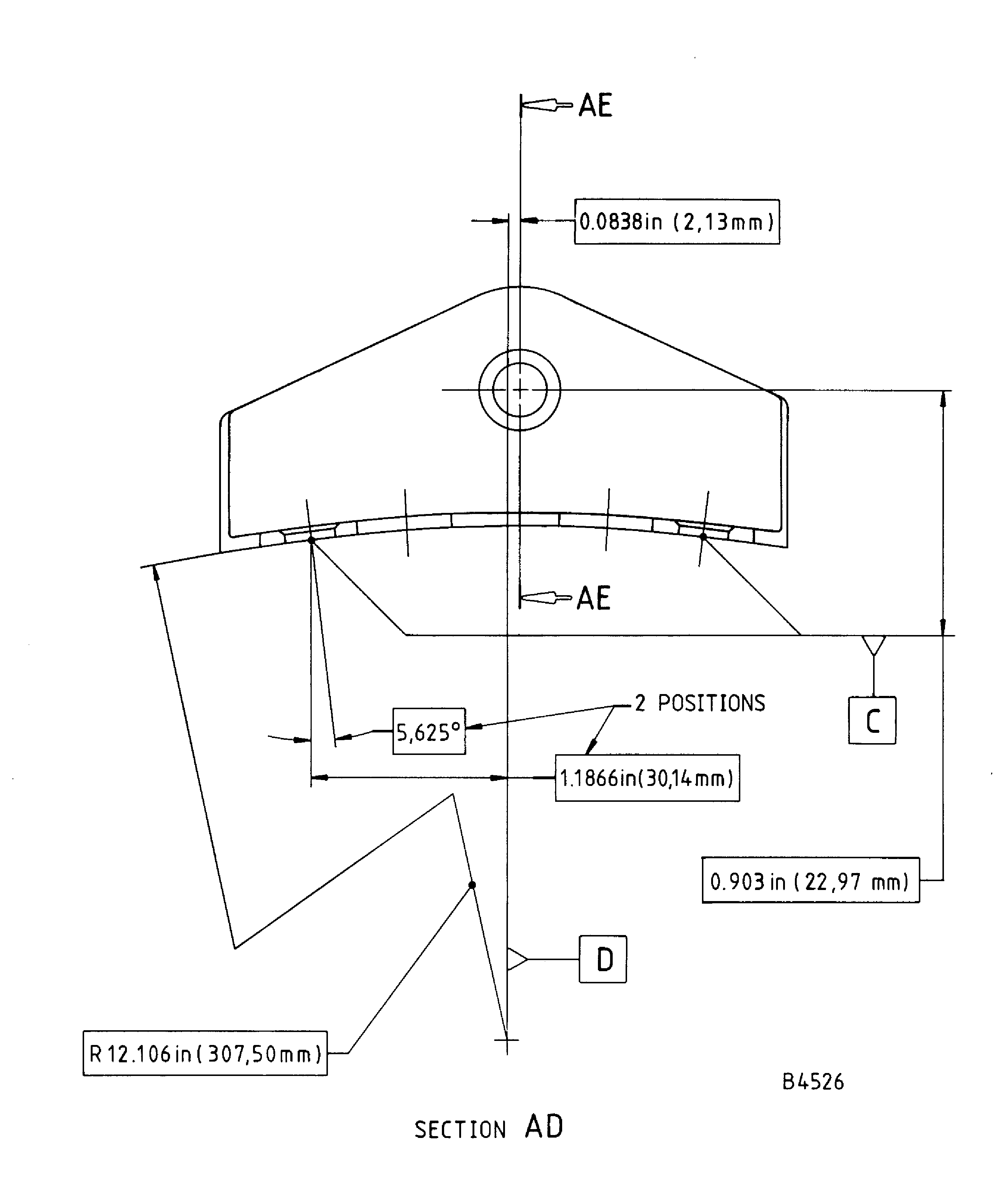

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

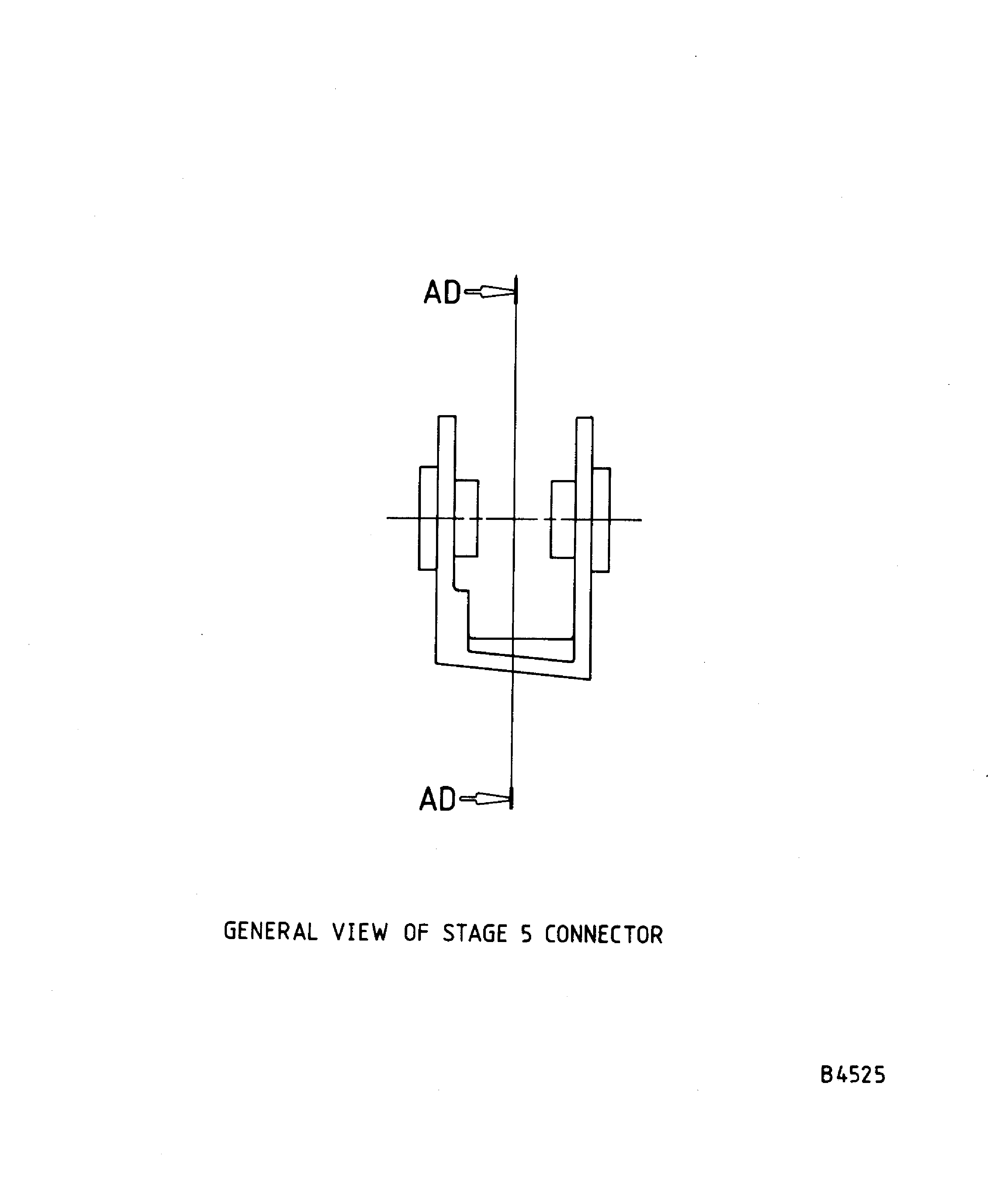

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

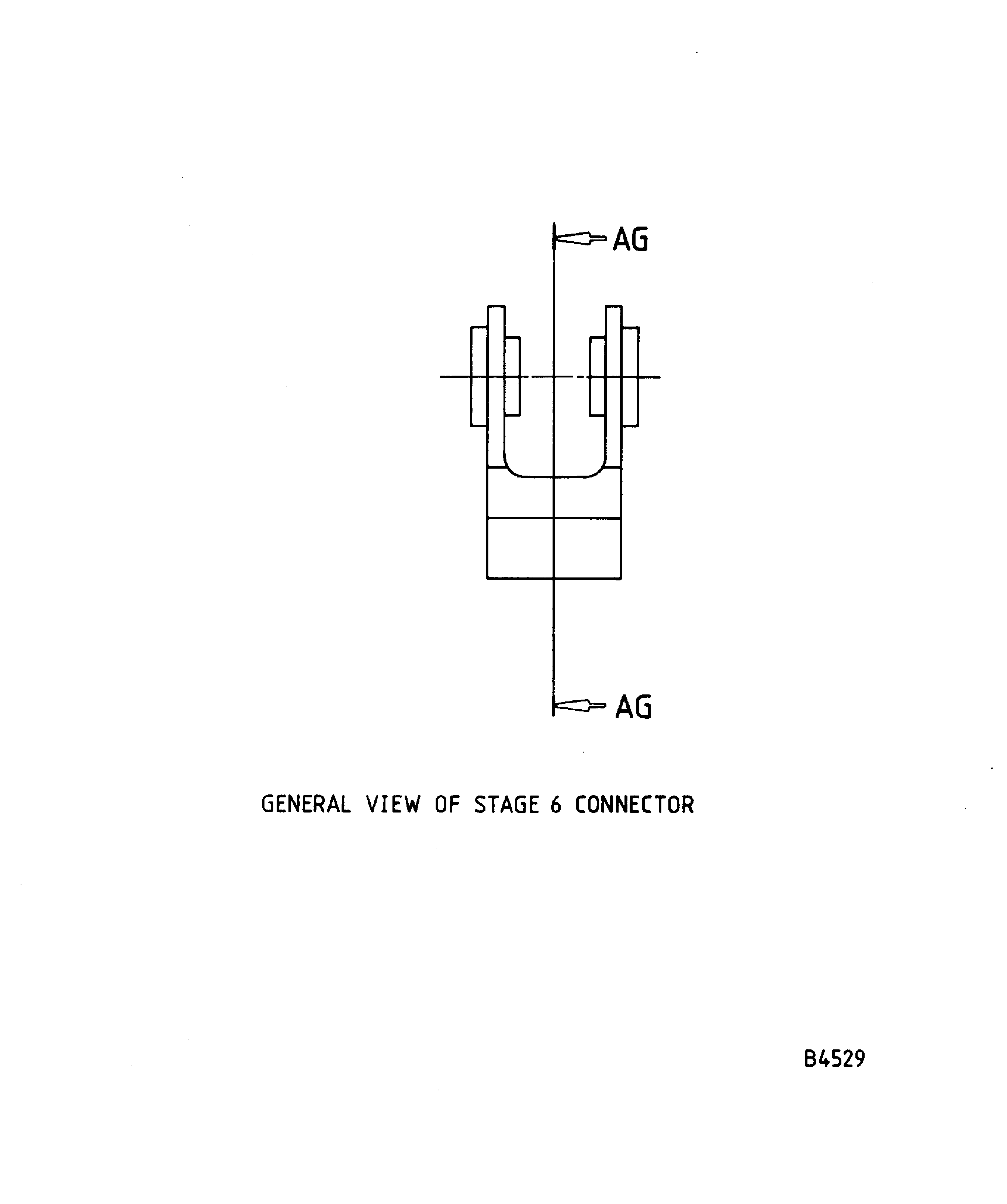

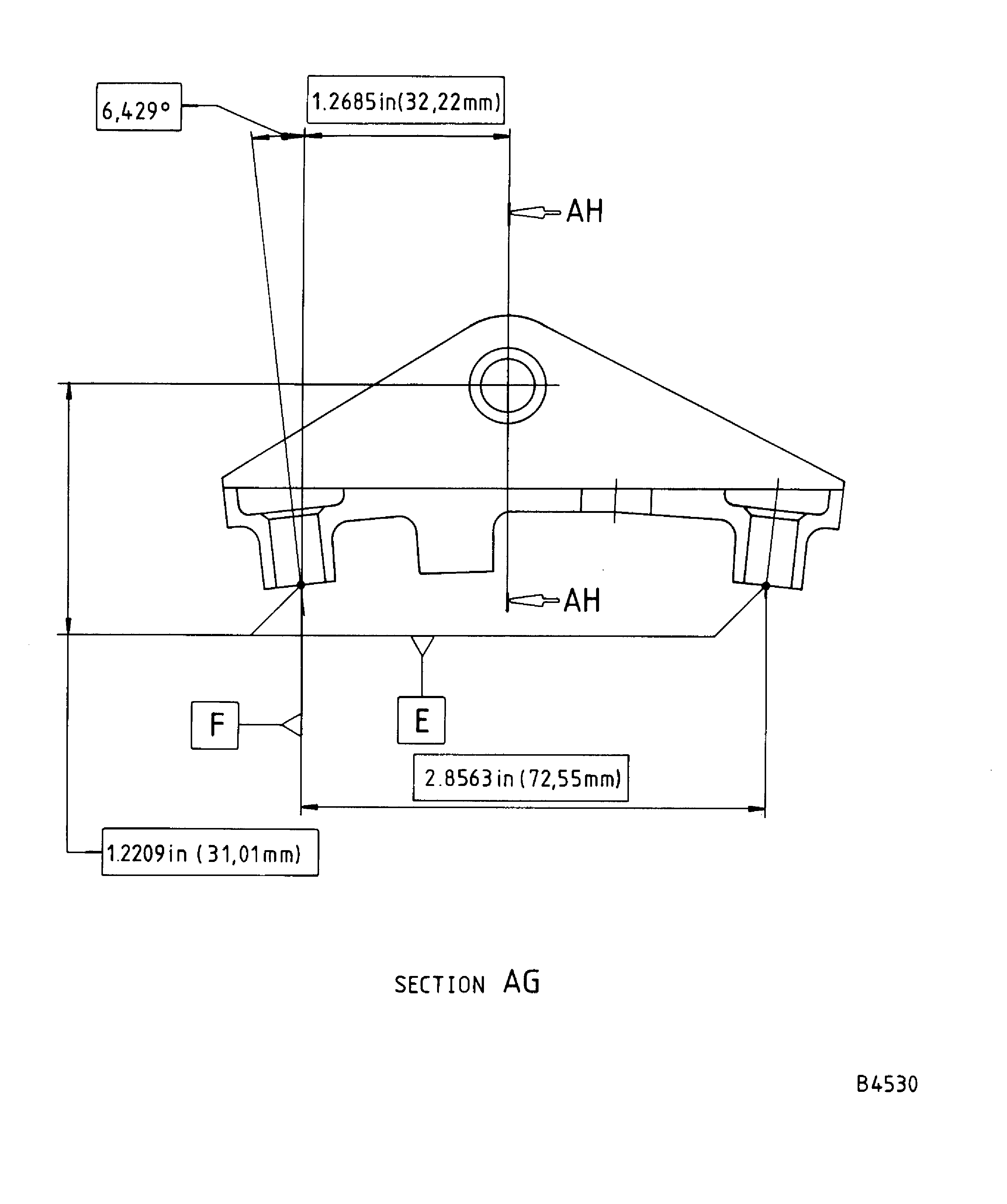

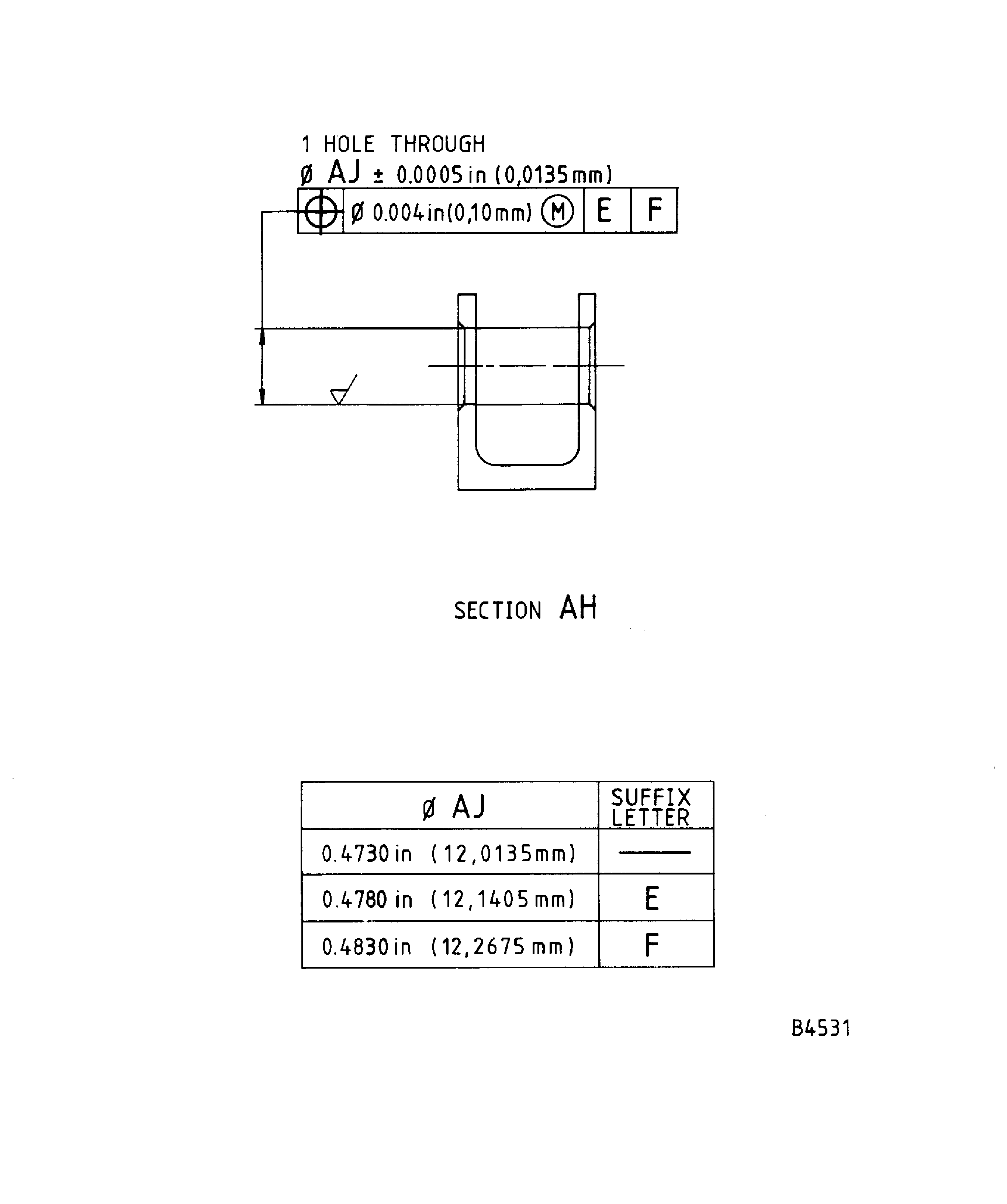

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C