Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-00-040-001 Diffuser And Combustion Group - Disassemble The Diffuser And Combustion Group, Disassembly-001

General

Fig./item number in parentheses in the procedure agree with those used in the IPC. Only the primary Fig./item numbers are used. For the Service Bulletin alpha variants refer to the IPC.

Remove and discard the lockwire before parts are disconnected or removed.

Discard all rubber seal rings, gaskets, cotter pins and seal washers removed in this procedure.

Refer to TASK 72-42-00-990-501 (DESCRIPTION AND OPERATION) for a sectional view of the diffuser case assembly.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1P16004 Handling bracket | 0AM53 | IAE 1P16004 | 2 | |

| IAE 1P16005 Build stand | 0AM53 | IAE 1P16005 | 1 | |

| IAE 1P16044 Lift fixture | 0AM53 | IAE 1P16044 | 1 | |

| IAE 1P16102 Lift sling | 0AM53 | IAE 1P16102 | 1 | |

| IAE 1P16103 Alignment fixture | 0AM53 | IAE 1P16103 | 1 | |

| IAE 1P16107 cover | 0AM53 | IAE 1P16107 | 1 | |

| IAE 1P16139 Wrench | 0AM53 | IAE 1P16139 | 1 | |

| IAE 1P16173 Lift sling | 0AM53 | IAE 1P16173 | 1 | |

| IAE 1P17000 Protective cover | 0AM53 | IAE 1P17000 | 1 | |

| IAE 1R18500 Extractor | 0AM53 | IAE 1R18500 | 1 | |

| IAE 1R18824 Extractor | 0AM53 | IAE 1R18824 | 1 | |

| IAE 1P16108 cover | 0AM53 | IAE 1P16108 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure

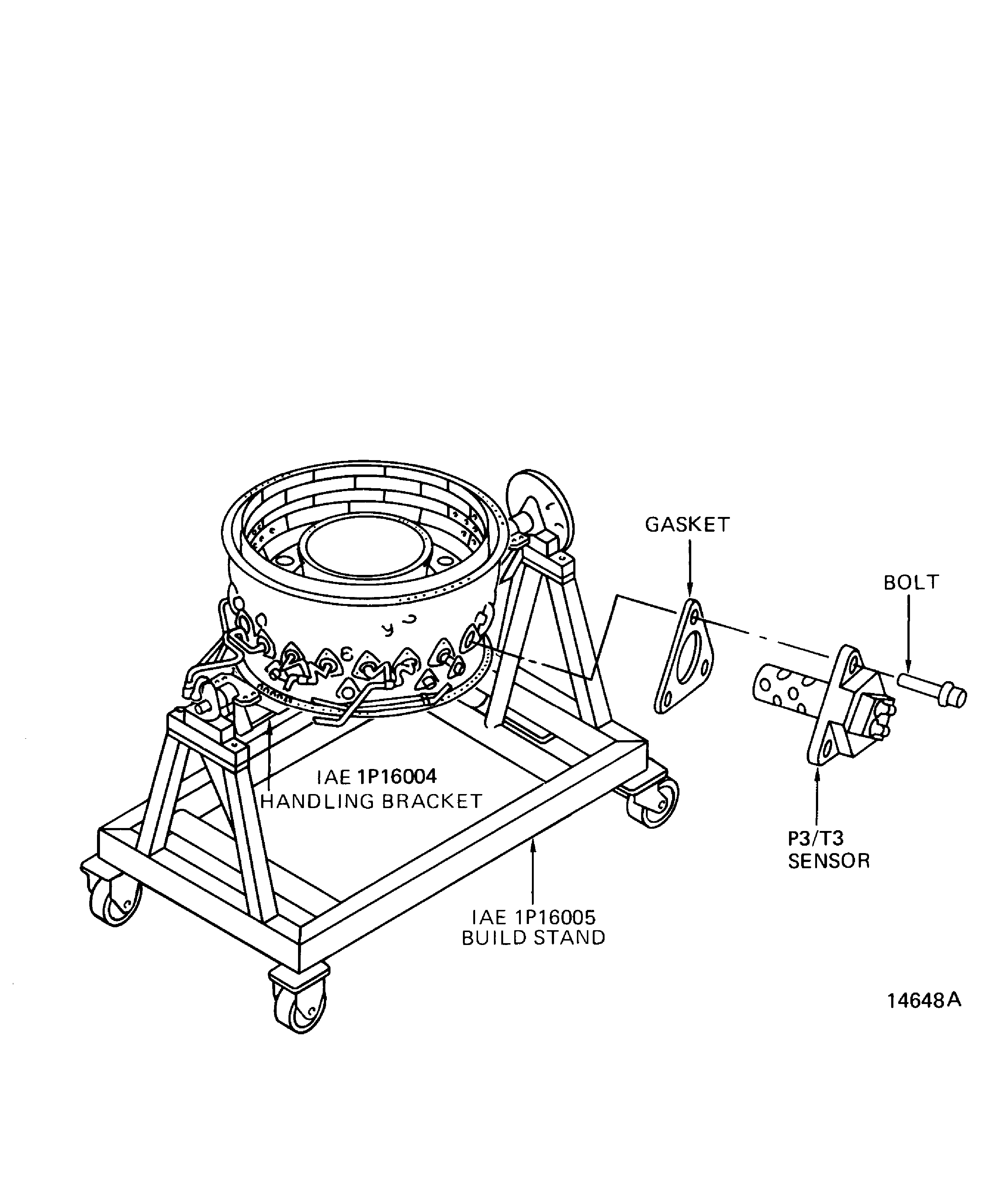

SUBTASK 72-42-00-040-058 Remove the P3/T3 Sensor from the Diffuser Case Boss

Refer to Figure

WARNING

DO NOT LET FUEL STAY ON YOUR SKIN. FUEL WHICH DRAINS FROM THE FUEL MANIFOLD CAN CAUSE PROBLEMS WITH YOUR SKIN.Disconnect the tube nuts from the fuel distribution valve. Use the IAE 1P16139 Wrench 1 off.

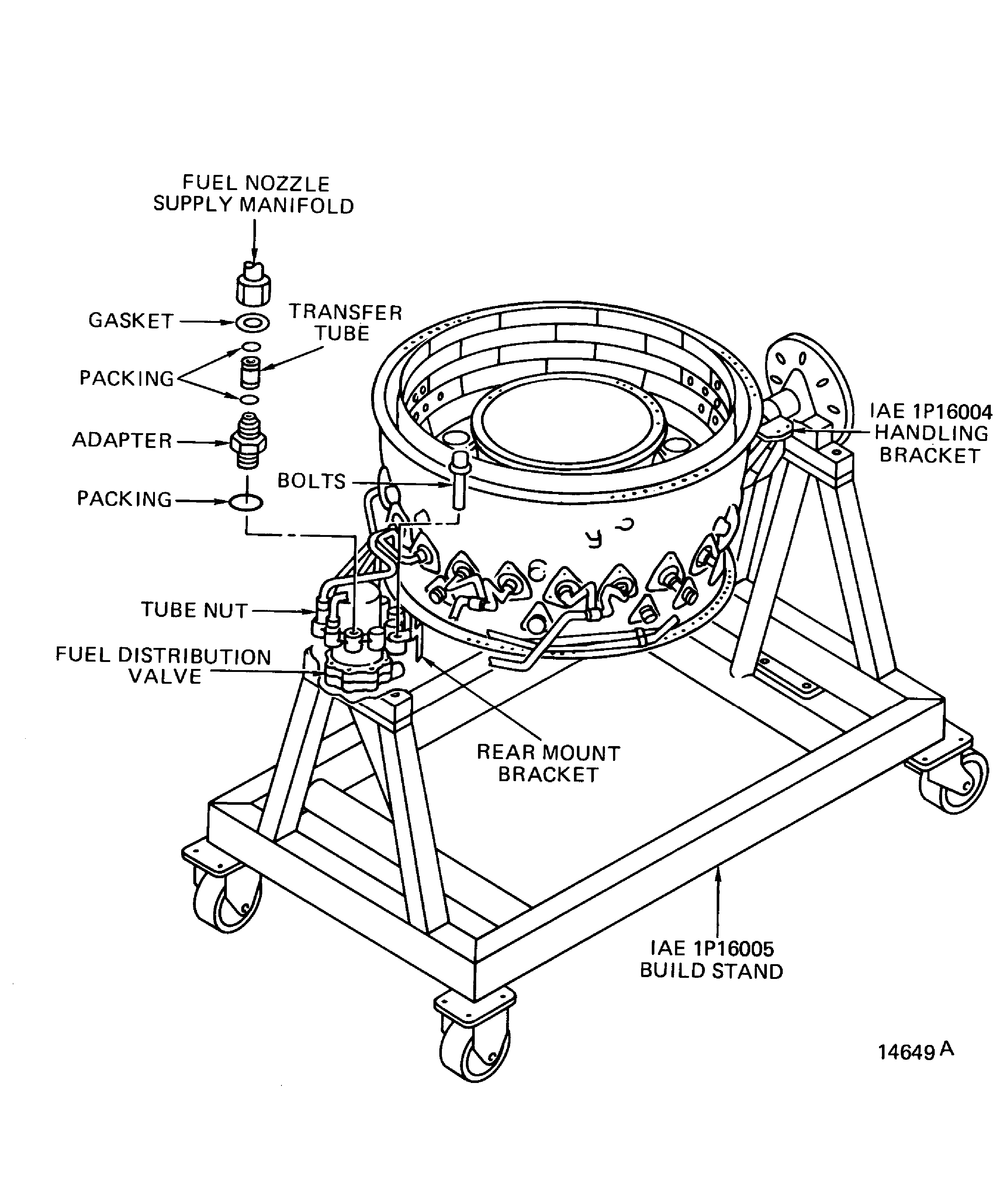

SUBTASK 72-42-00-040-059 Remove the Fuel Distribution Valve and Bracket

Refer to Figure

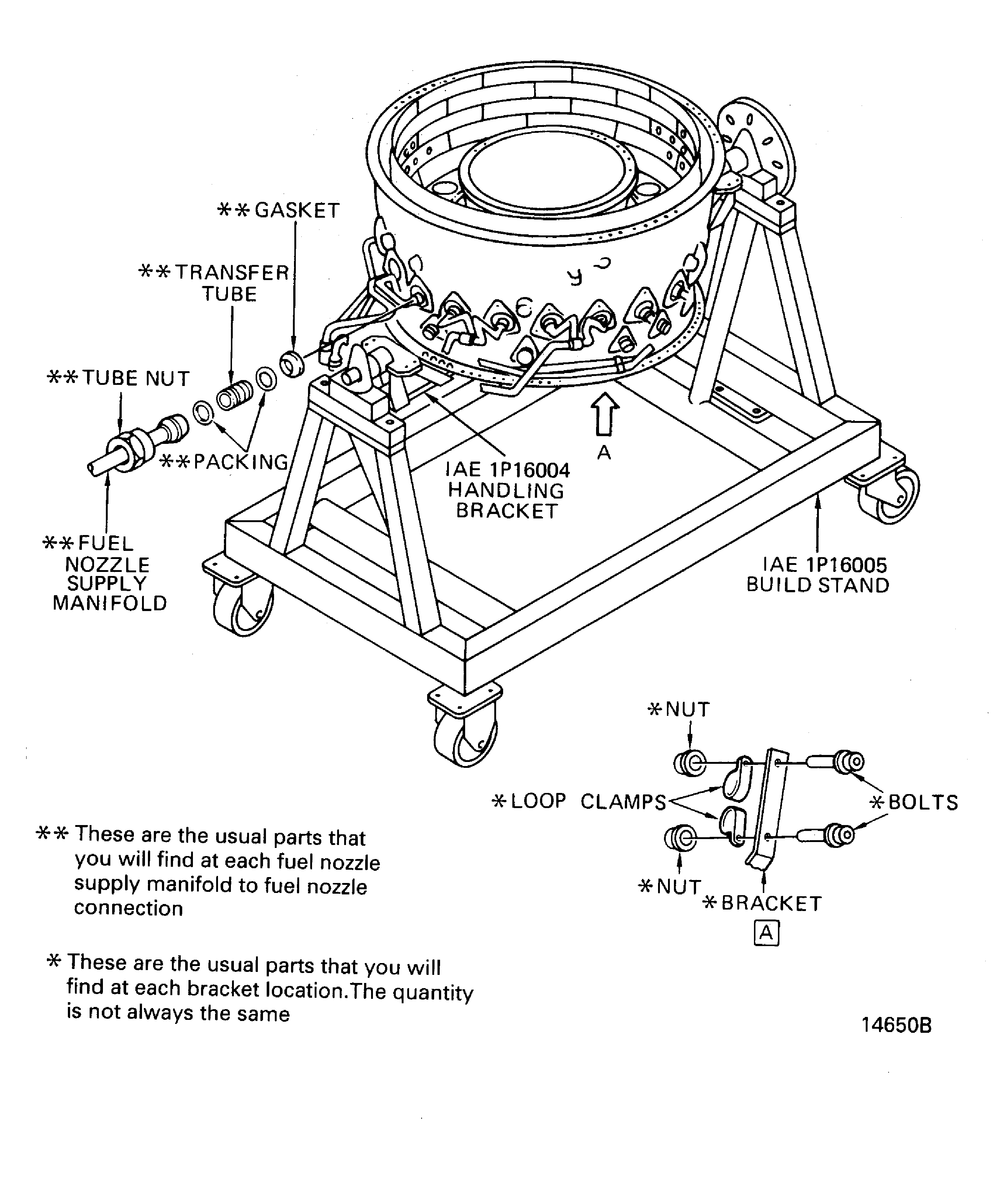

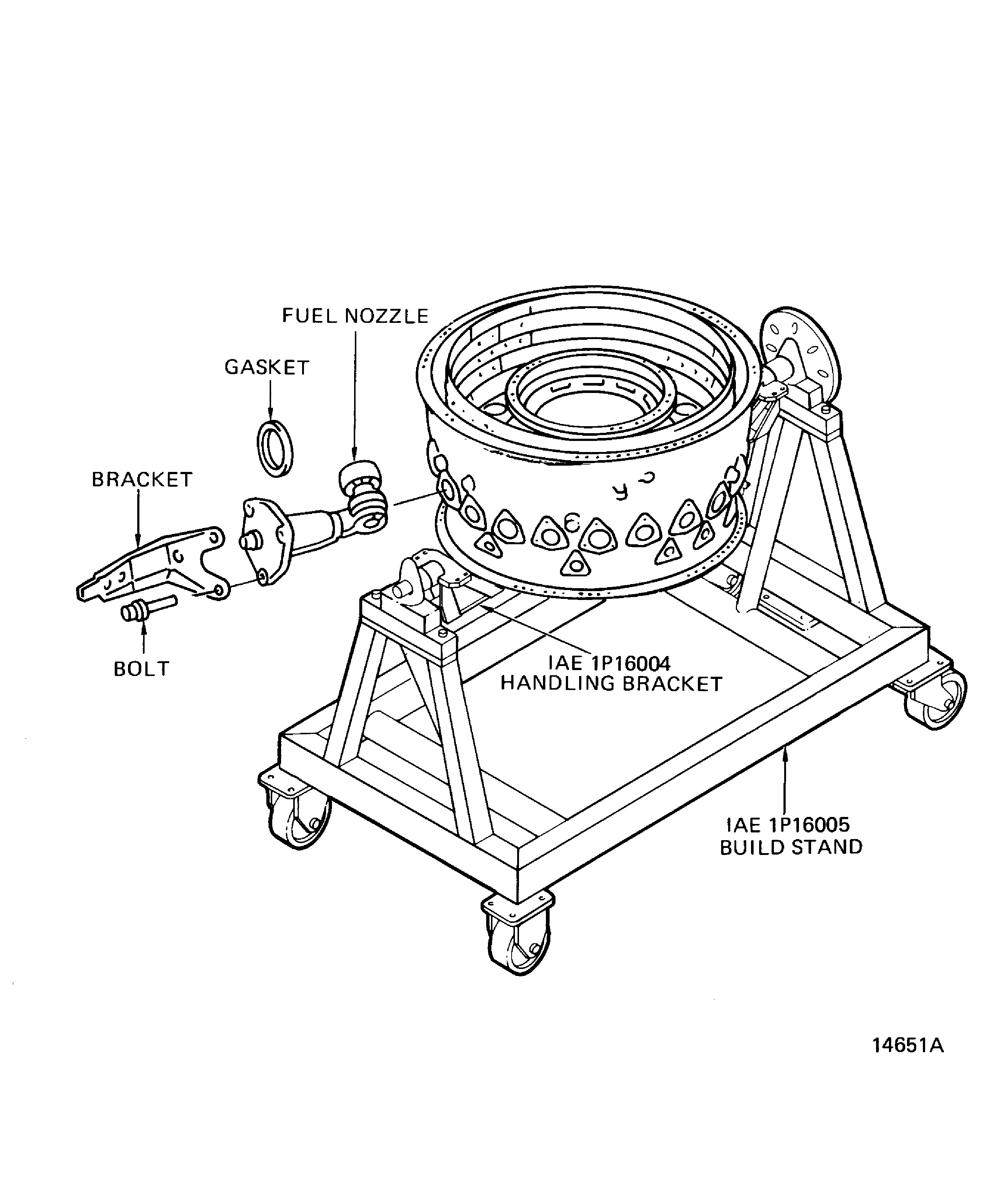

SUBTASK 72-42-00-040-061 Remove the Fuel Nozzles

Refer to Figure

NOTE

If you did not remove the lockwire from the adapter when you removed the adjacent fuel nozzle, remove it now.

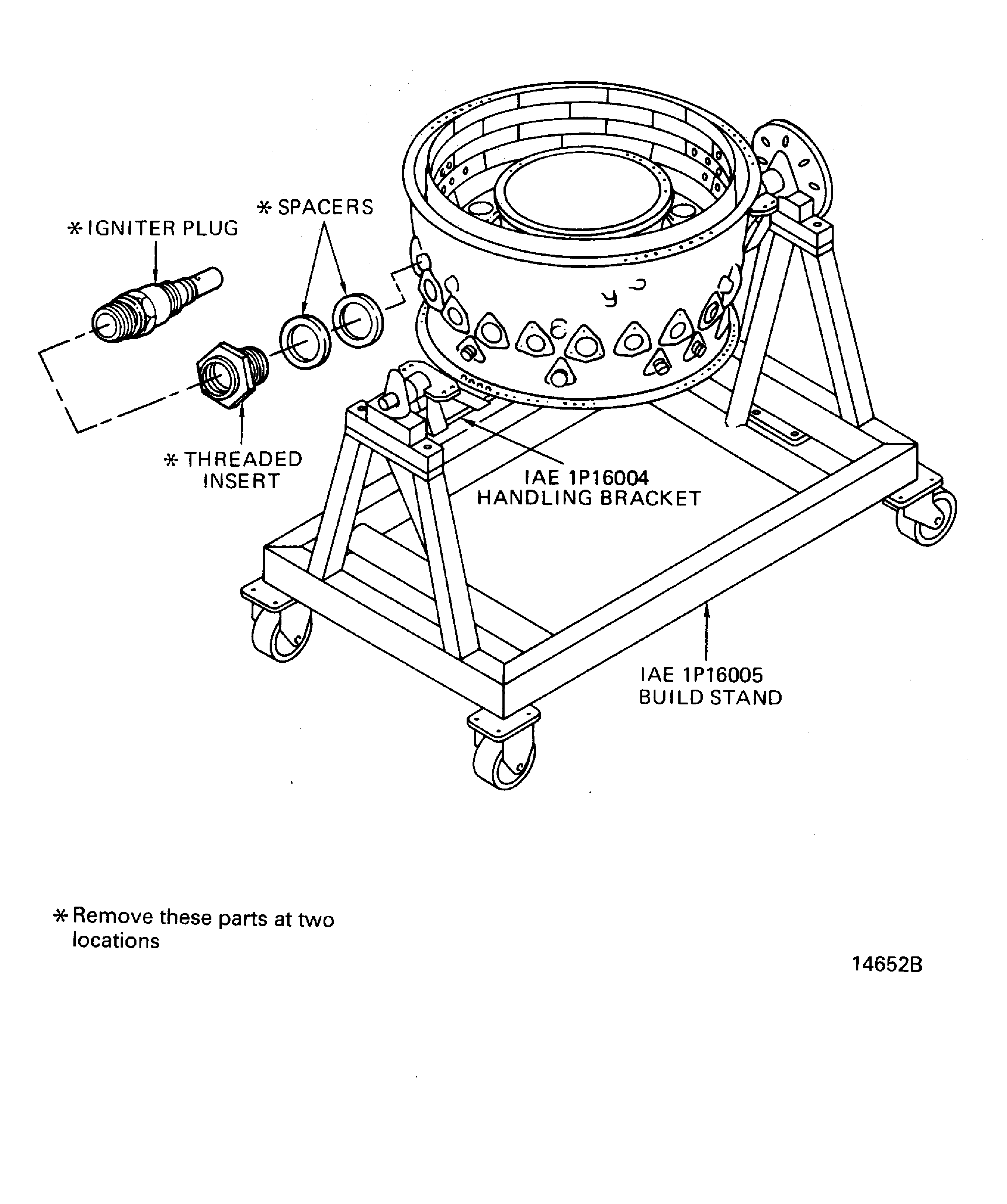

SUBTASK 72-42-00-040-062 Remove the Igniter Plugs

Refer to Figure

Put IAE 1R18500 Extractor 1 off in to position.

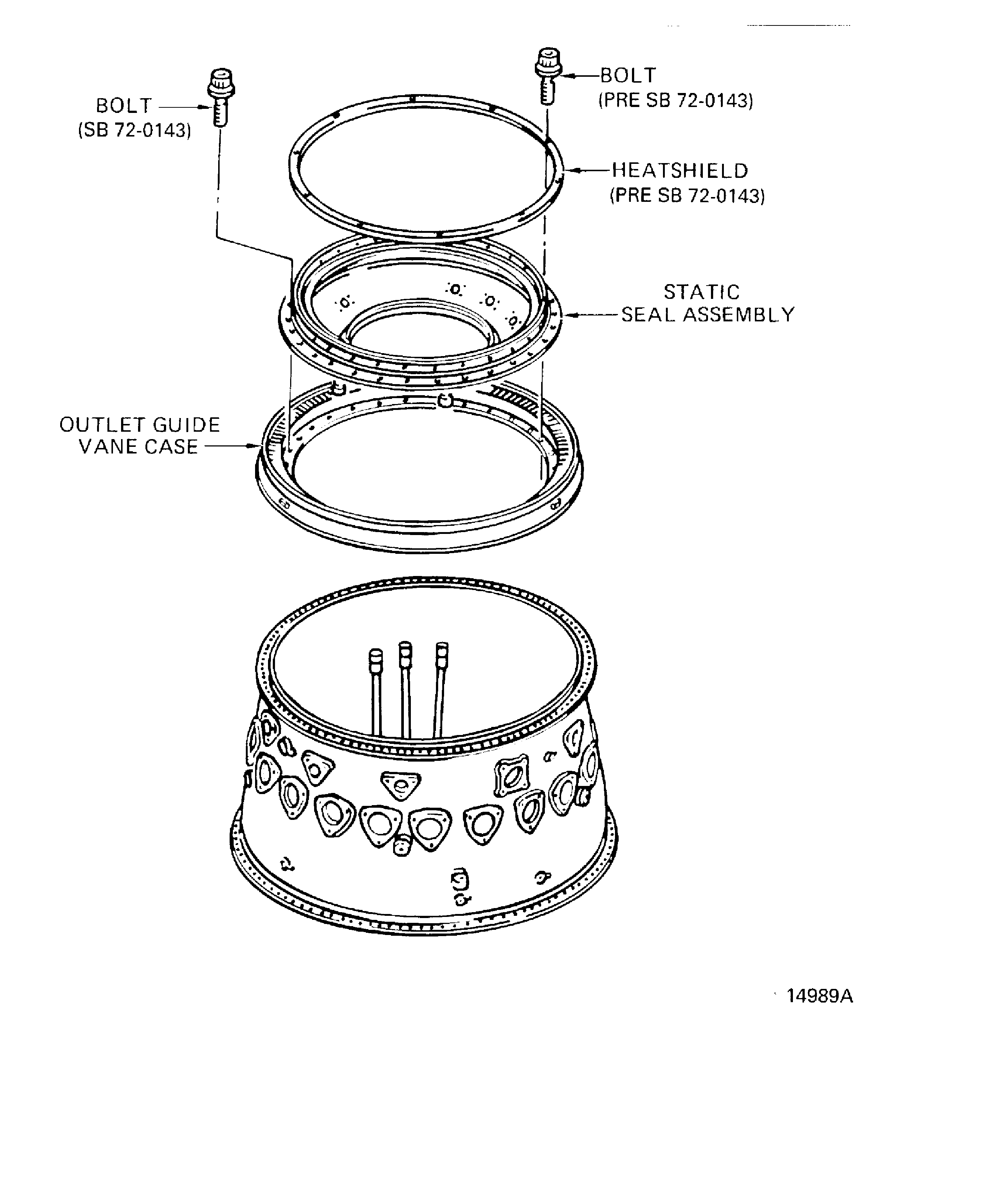

Remove the OGV case.

SUBTASK 72-42-00-040-053-A00 V2500-A1: Remove the Stage 12 Stator (Pre SBE 72-0143)

Refer to Figure

Put IAE 1R18500 Extractor 1 off in to position.

Remove the OGV case.

SUBTASK 72-42-00-040-053-B00 V2500-A1: Remove the Stage 12 Stator (SBE 72-0143 and Pre SBE 72-0221)

SBE 72-0143: Heatshield not required

Refer to Figure

Put IAE 1R18500 Extractor 1 off into position.

Remove the OGV case.

SUBTASK 72-42-00-040-053-C00 V2500-A1: Remove the Stage 12 Stator (SBE 72-0221)

SBE 72-0221: Introduce a new diffuser case

Refer to Figure.

Put IAE 1R18824 Extractor 1 off into position.

Remove the OGV case.

SUBTASK 72-42-00-040-053-D00 V2500-A5: Remove the Stage 12 Stator

Refer to Figure

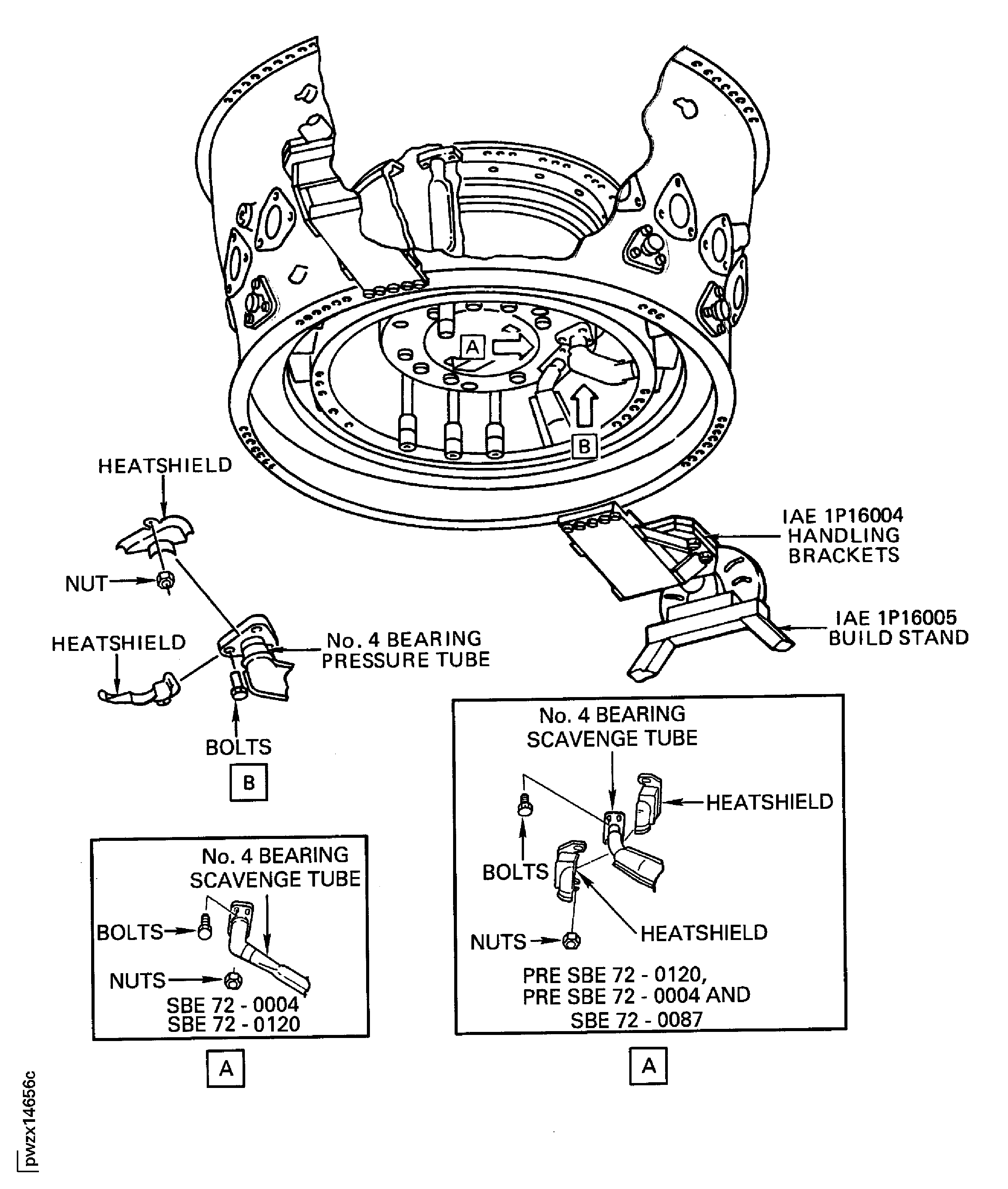

SUBTASK 72-42-00-040-055-A00 V2500-A1: Remove the Heatshields from the Tubes in the No. 4 Bearing Compartment (Pre SBE 72-0004, SBE 72-0087 and Pre SBE 72-0120)

SBE 72-0087: No. 4 bearing oil scavenge tube with heatshields.

Refer to Figure

SUBTASK 72-42-00-040-055-B00 V2500-A1: Remove the Heatshields from the Tubes in the No. 4 Bearing Compartment (SBE 72-0004 and SBE 72-0120)

SBE 72-0004: No. 4 bearing oil scavenge tube without heatshields.

SBE 72-0120: New No. 4 bearing oil scavenge tube and gasket.

Refer to Figure.

SUBTASK 72-42-00-040-055-C00 V2500-A5: Remove the Heatshields from the Tubes in the No. 4 Bearing Compartment

Refer to Figure

SUBTASK 72-42-00-040-056 Disconnect the Tubes from the No. 4 Bearing Front Compartment

Refer to Figure

Turn the positioning rods of the IAE 1P16103 Alignment fixture 1 off in to the fixture plate.

SUBTASK 72-42-00-040-063 Install the Alignment Fixture

Refer to Figure

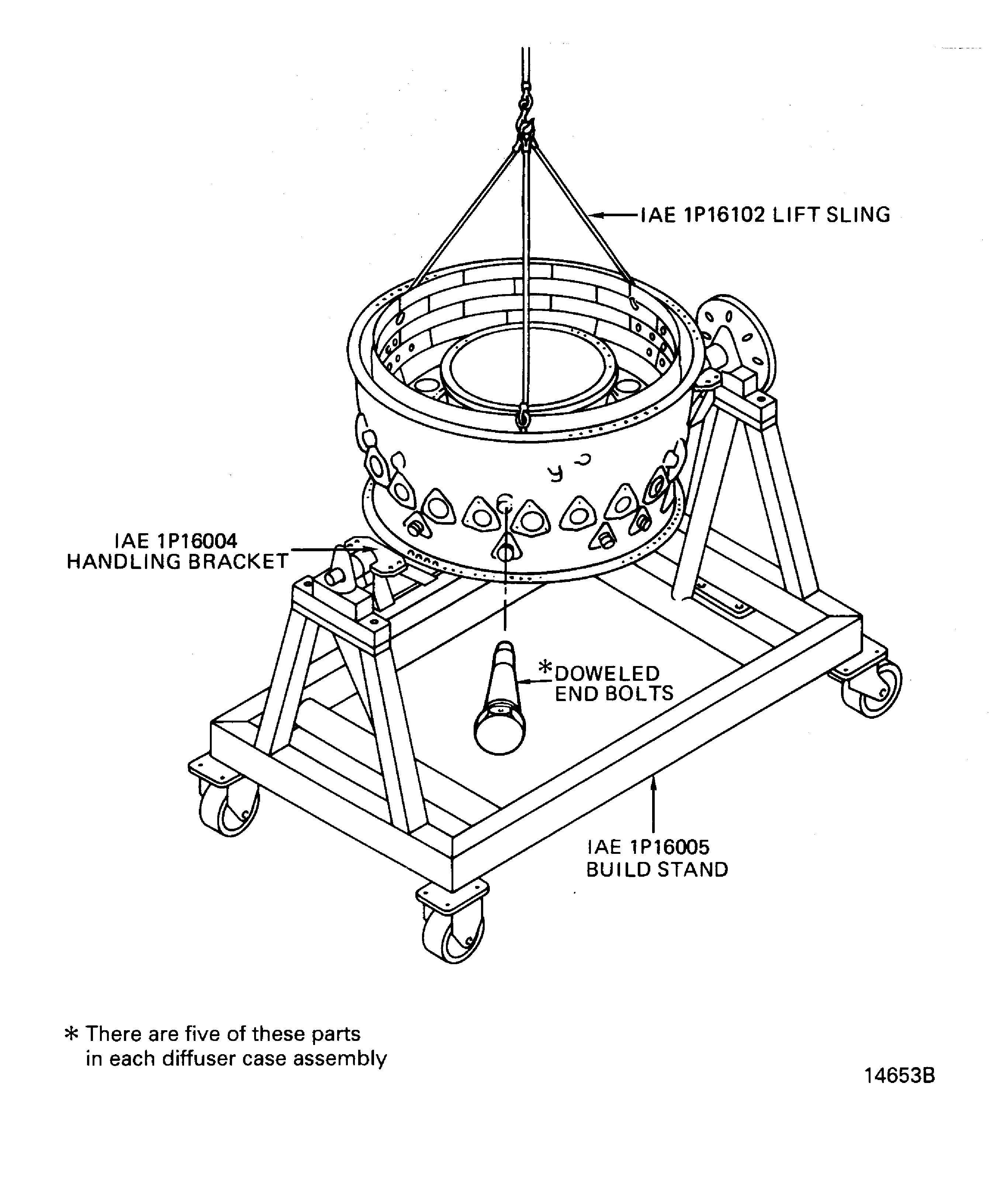

Install the IAE 1P16102 Lift sling 1 off on a hoist.

SUBTASK 72-42-00-040-064 Remove the Doweled End Bolts that Hold the Combustion Chamber in the Diffuser Case

Refer to Figure

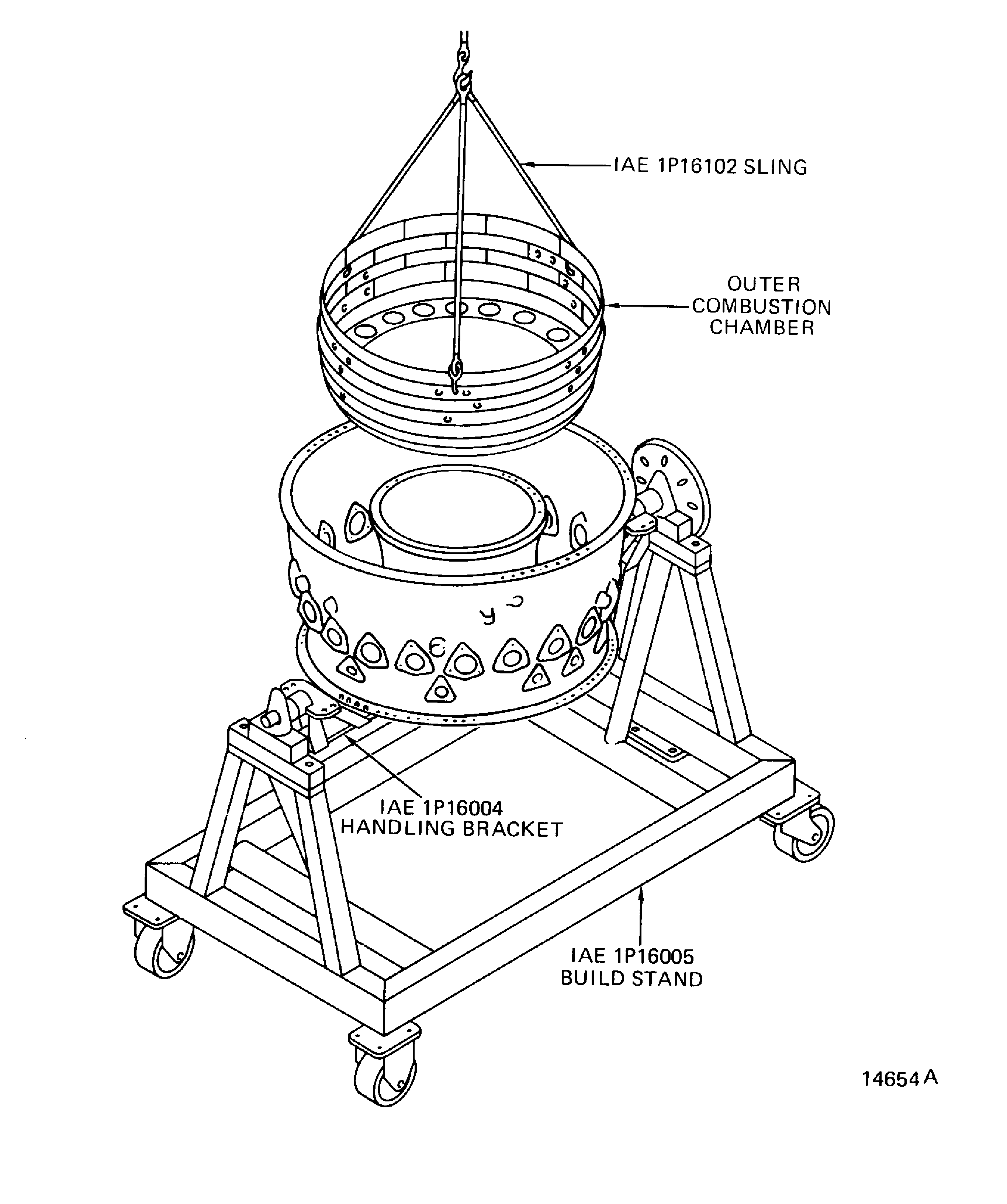

SUBTASK 72-42-00-040-052 Remove the Outer Combustion Chamber

Refer to Figure

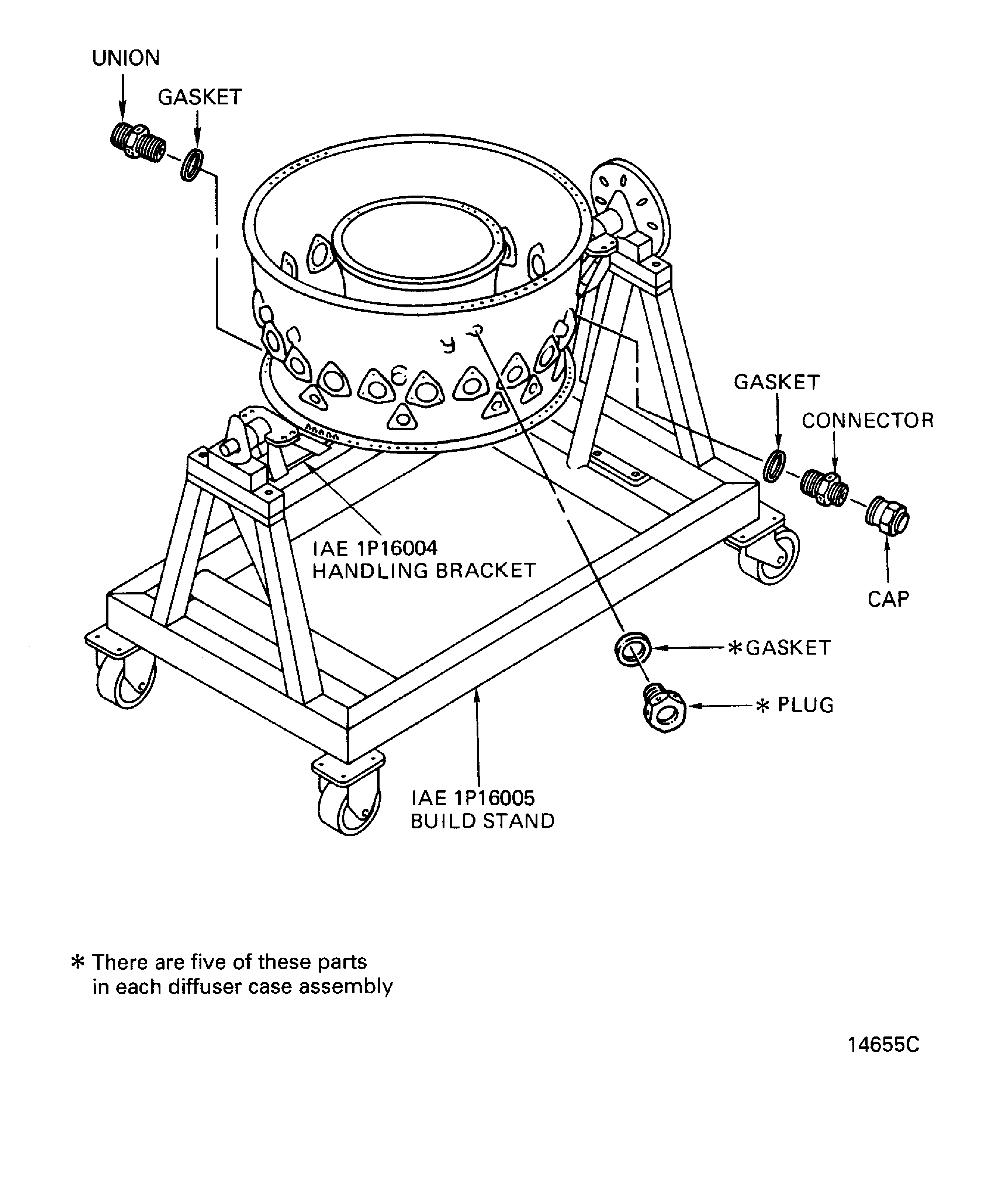

SUBTASK 72-42-00-040-065 Remove the Connector and Cap from the Diffuser Case

Refer to Figure.

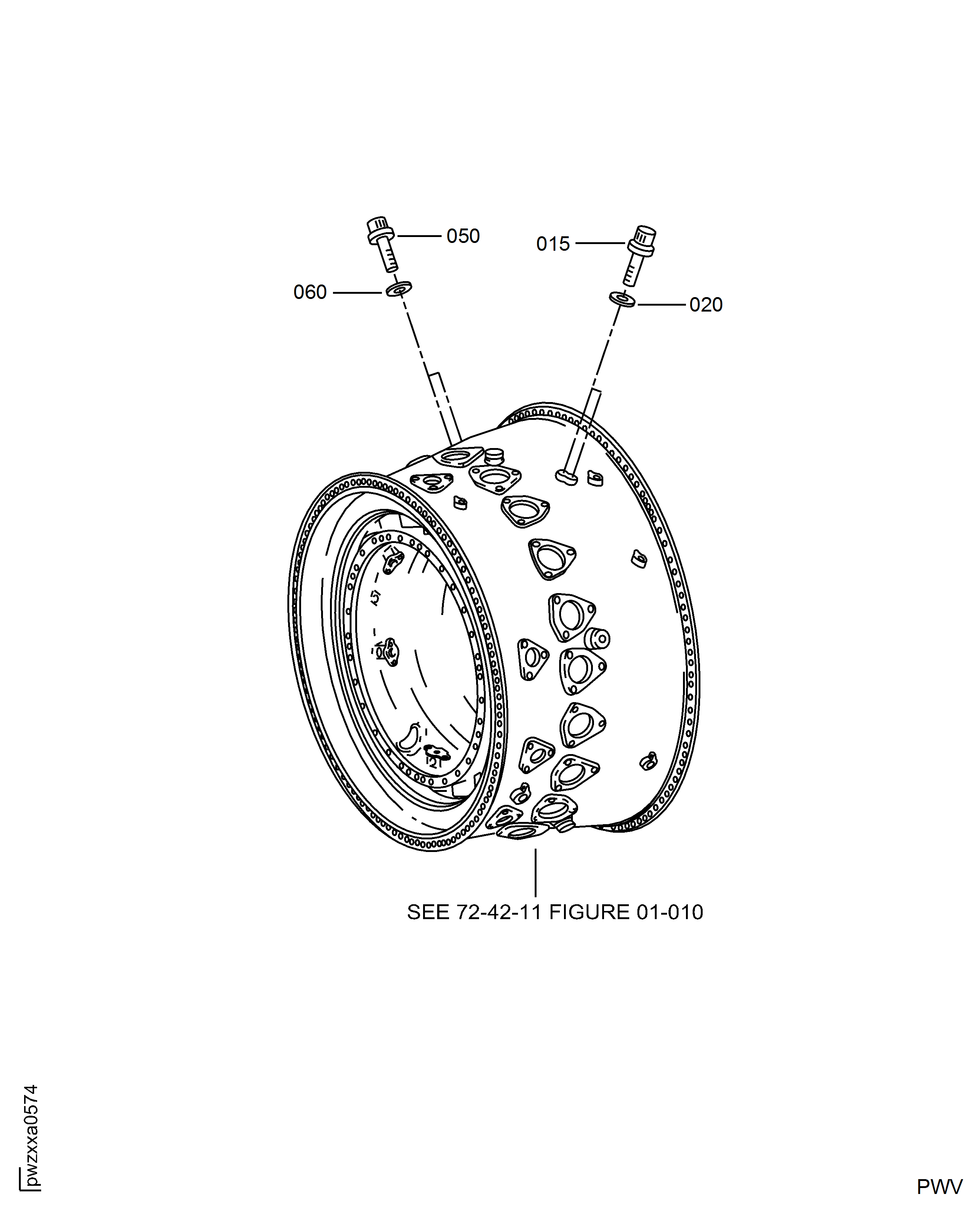

Remove the lockwire from the bolts.

Remove the bolts and the washers from the Diffuser Case.

SUBTASK 72-42-00-040-077 Remove the Four Bolts and Washers from the Diffuser Case

Refer to Figure

SUBTASK 72-42-00-040-066-A00 V2500-A1: Remove the Five Plugs and Gaskets from the Diffuser Case (Pre SBE 72-0221)

Refer to Figure

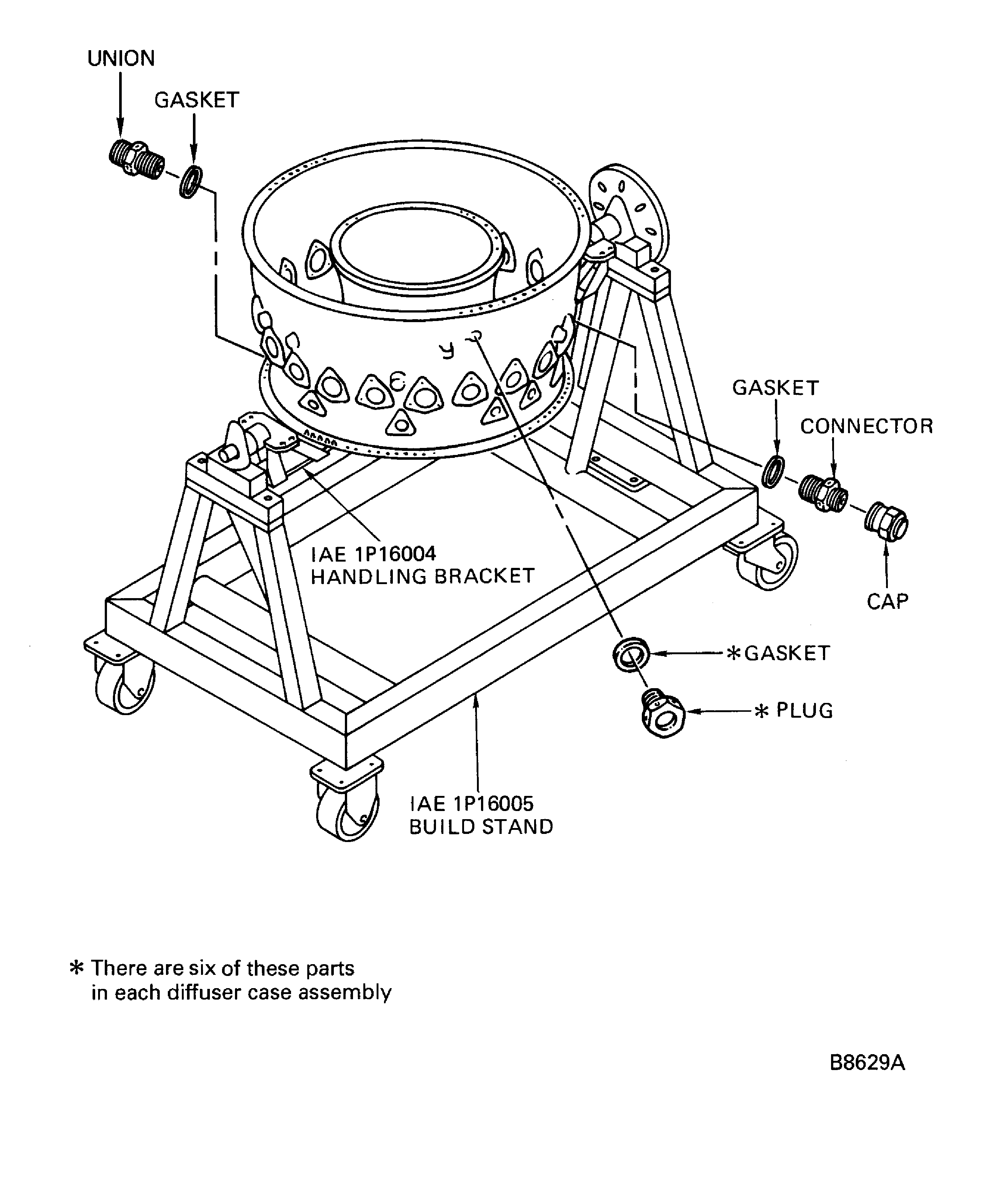

SUBTASK 72-42-00-040-066-B00 V2500-A1: Remove the Six Plugs and Gaskets from the Diffuser Case (SBE 72-0221)

SBE 72-0221: Introduce a new diffuser case

Refer to Figure

SUBTASK 72-42-00-040-066-C00 V2500-A5: Remove the Six Plugs and Gaskets from the Diffuser Case

Refer to Figure

Install the IAE 1P17000 Protective cover 1 off onto the No. 4 bearing face seal.

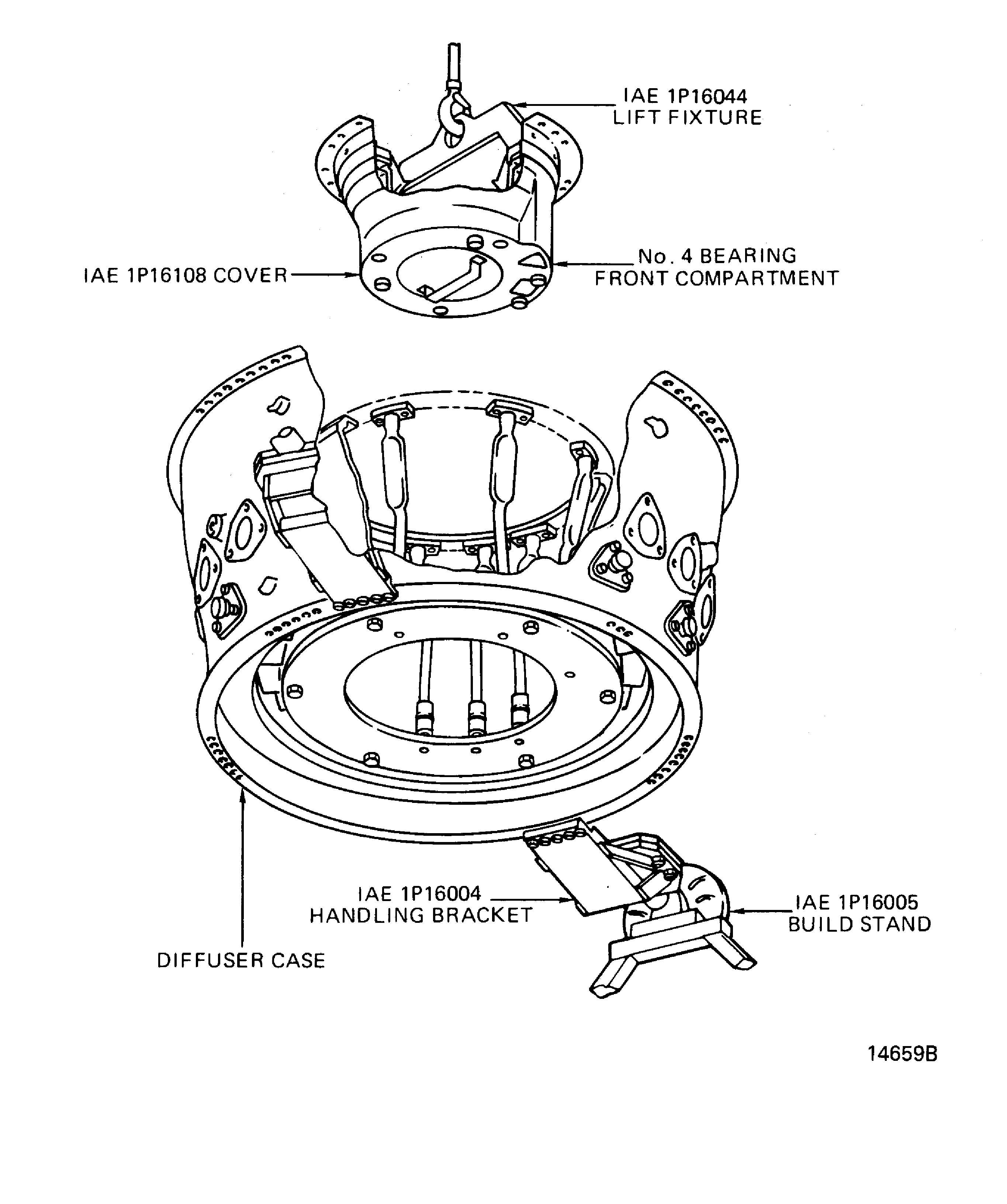

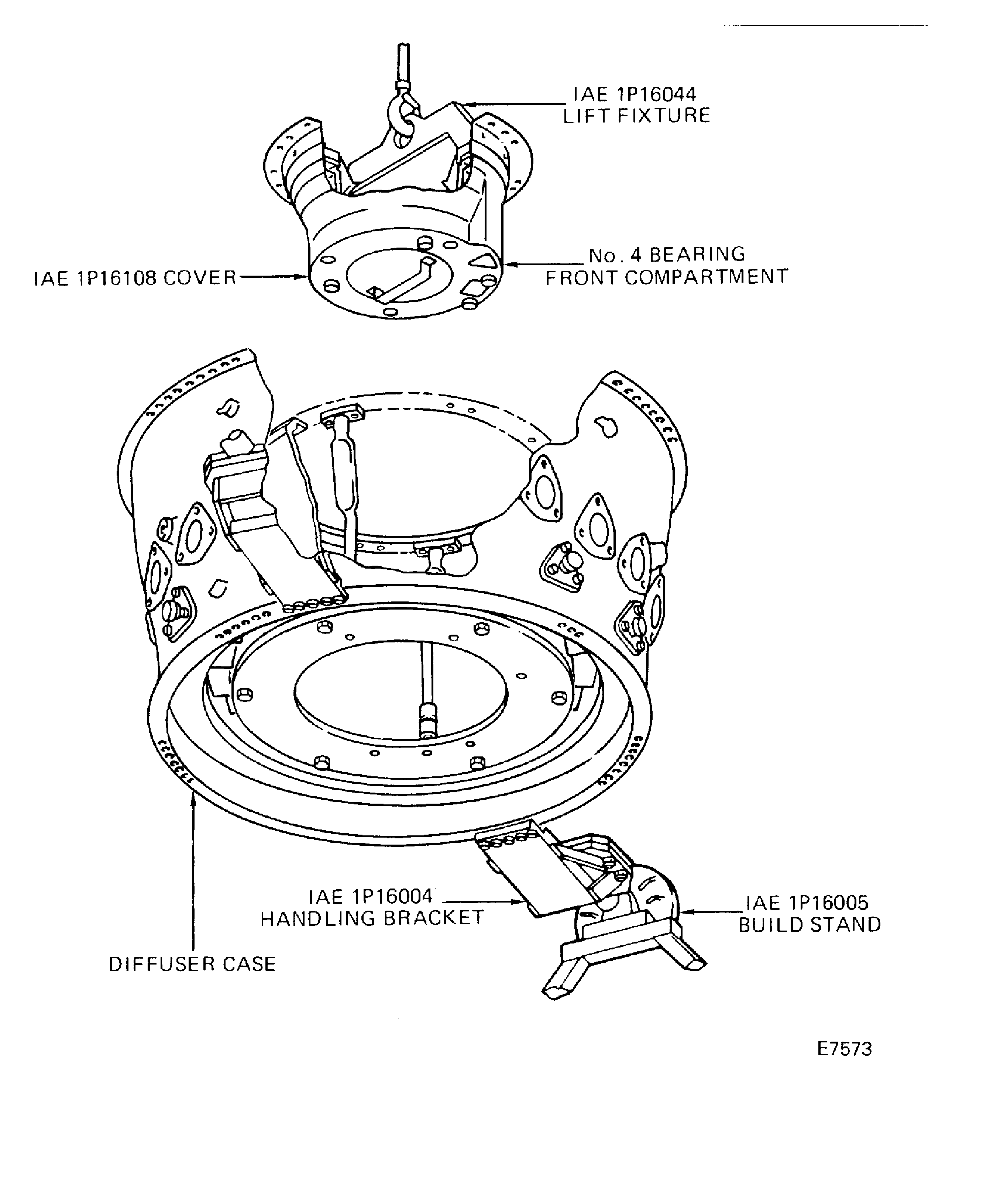

Install the IAE 1P16044 Lift fixture 1 off to the No. 4 bearing front compartment.

Remove the IAE 1P16108 cover 1 off from the No. 4 bearing front compartment.

SUBTASK 72-42-00-040-067 Remove the No. 4 Bearing Front Compartment from the Diffuser Case

Refer to Figure

SUBTASK 72-42-00-040-068 Remove the Thrust Balance Vent Tubes

Refer to Figure

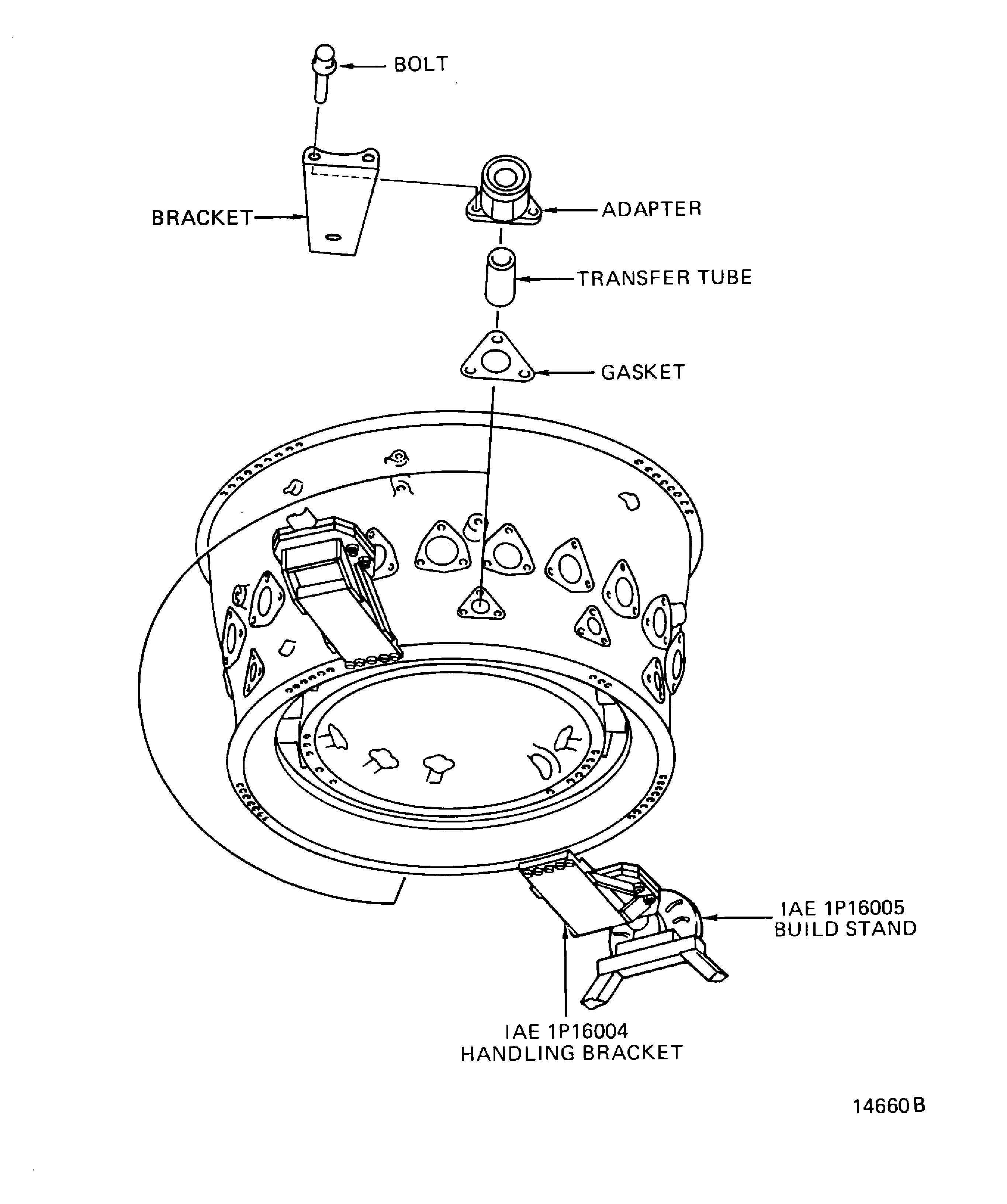

SUBTASK 72-42-00-040-069 Remove the Transfer Tubes and Adapters

Refer to Figure

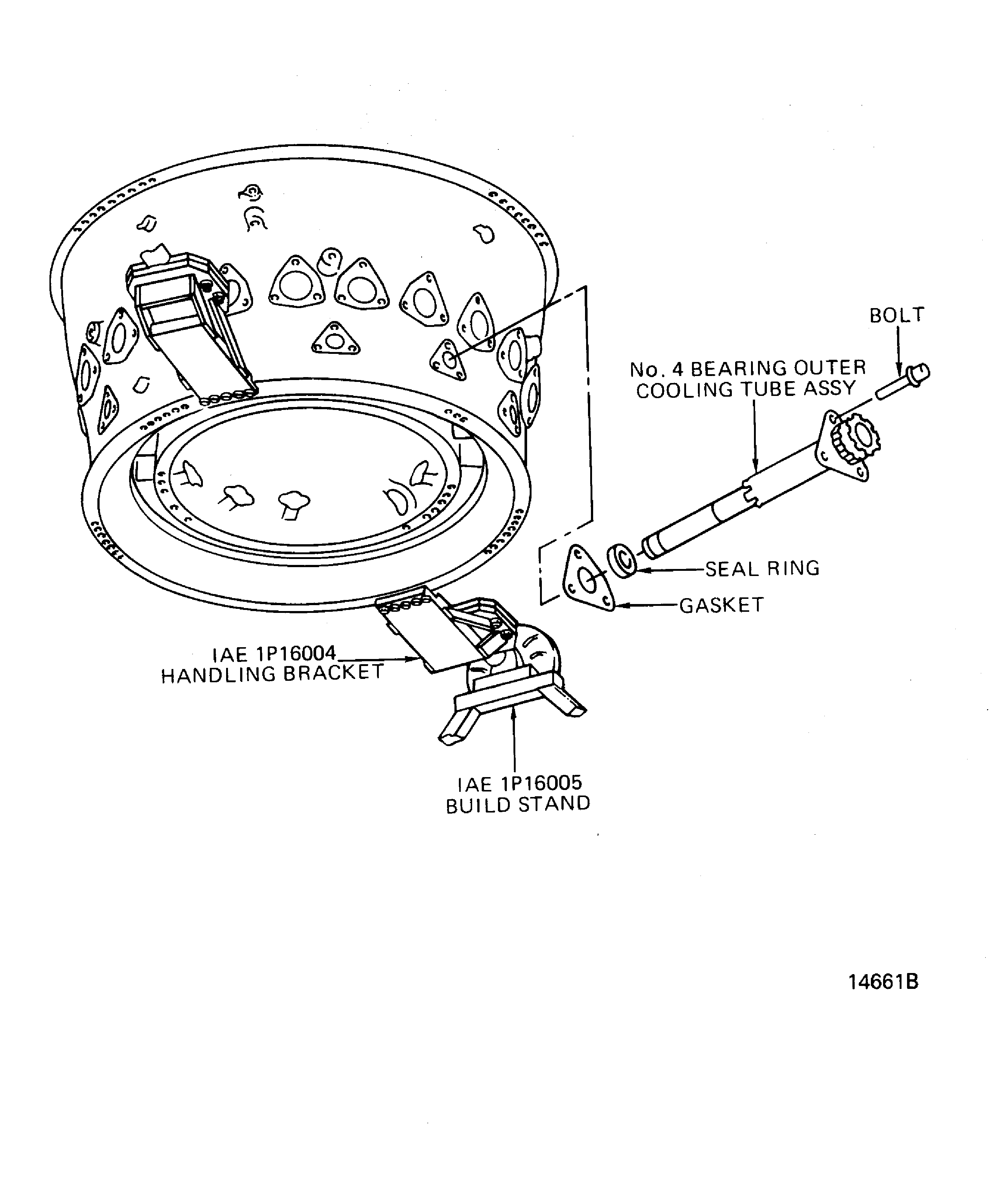

SUBTASK 72-42-00-040-070 Remove the No. 4 Bearing Outer Cooling Tubes

Refer to Figure

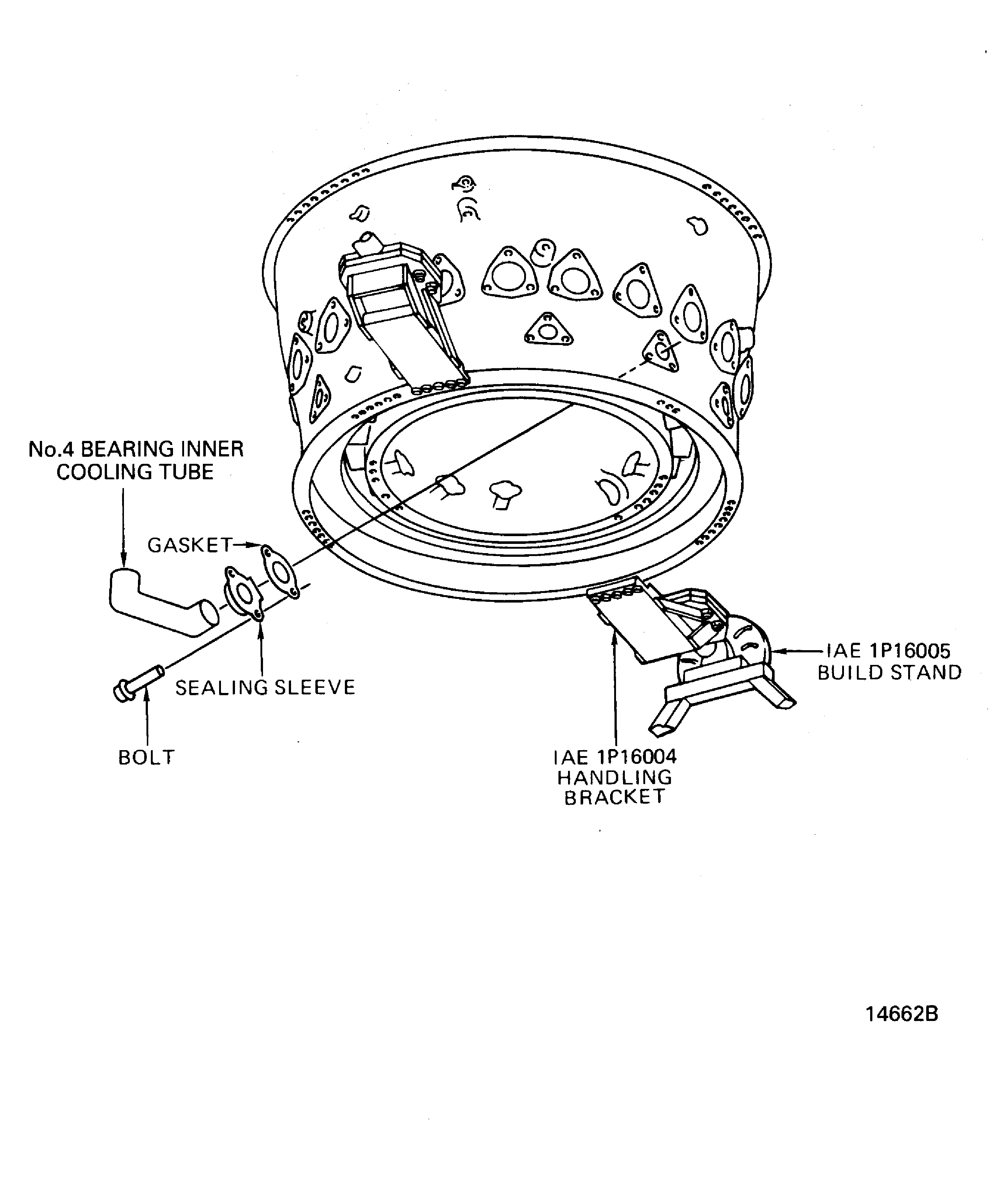

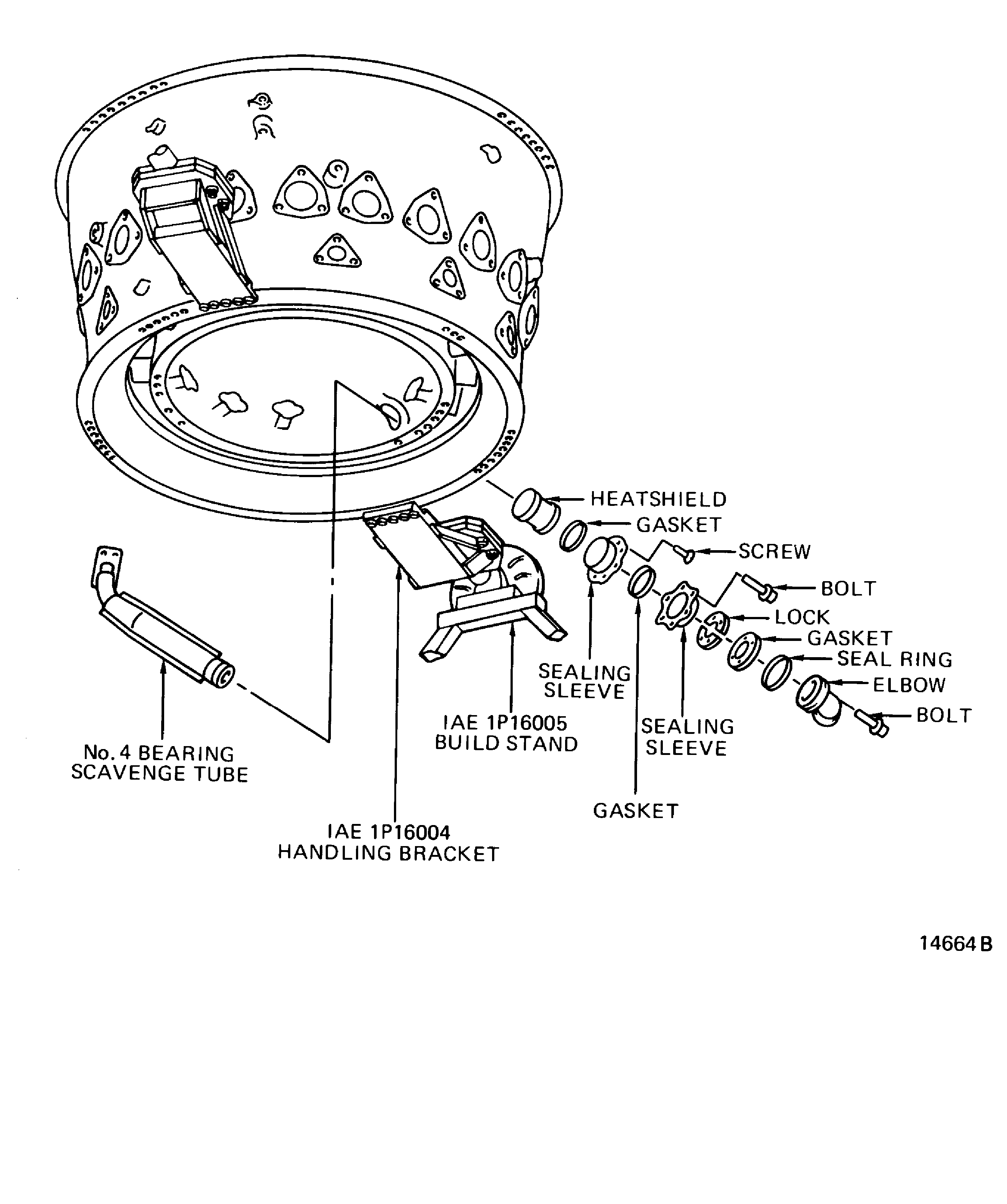

SUBTASK 72-42-00-040-071 Remove the No. 4 Bearing Inner Cooling Tube and Sealing Sleeves

Refer to Figure

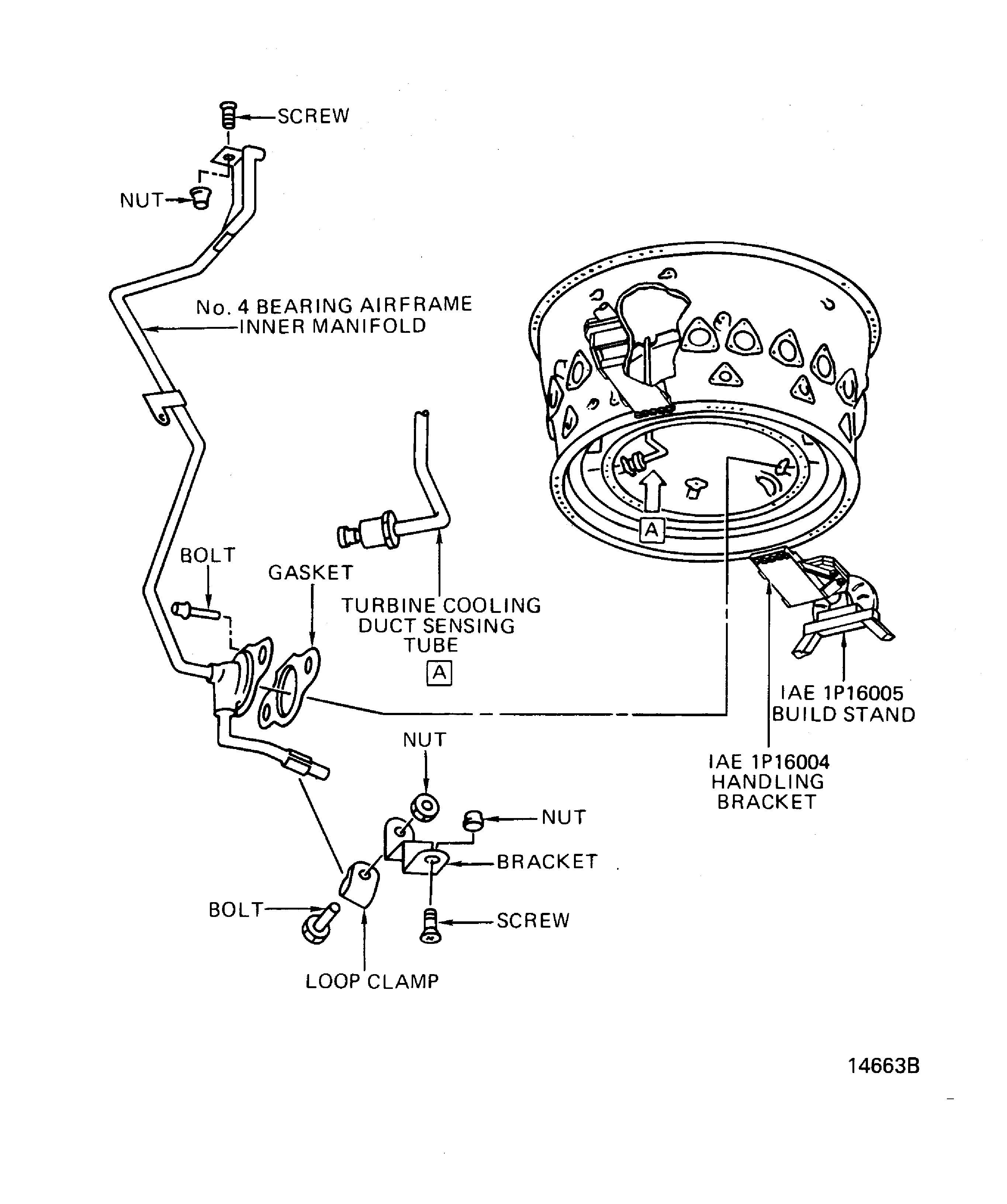

SUBTASK 72-42-00-040-072-A00 Remove the Turbine Cooling Air Duct Sensing Tube (Pre SBE 72-0016, Pre SBE 72-0166 and Pre SBE 72-0221)

Refer to Figure

SUBTASK 72-42-00-040-072-B00 Remove the Turbine Cooling Air Duct Sensing Tube (SBE 72-0016, Pre SBE 72-0166 and Pre SBE 72-0221)

SBE 72-0016: New No. 4 bearing and airframe manifold assembly

Refer to Figure

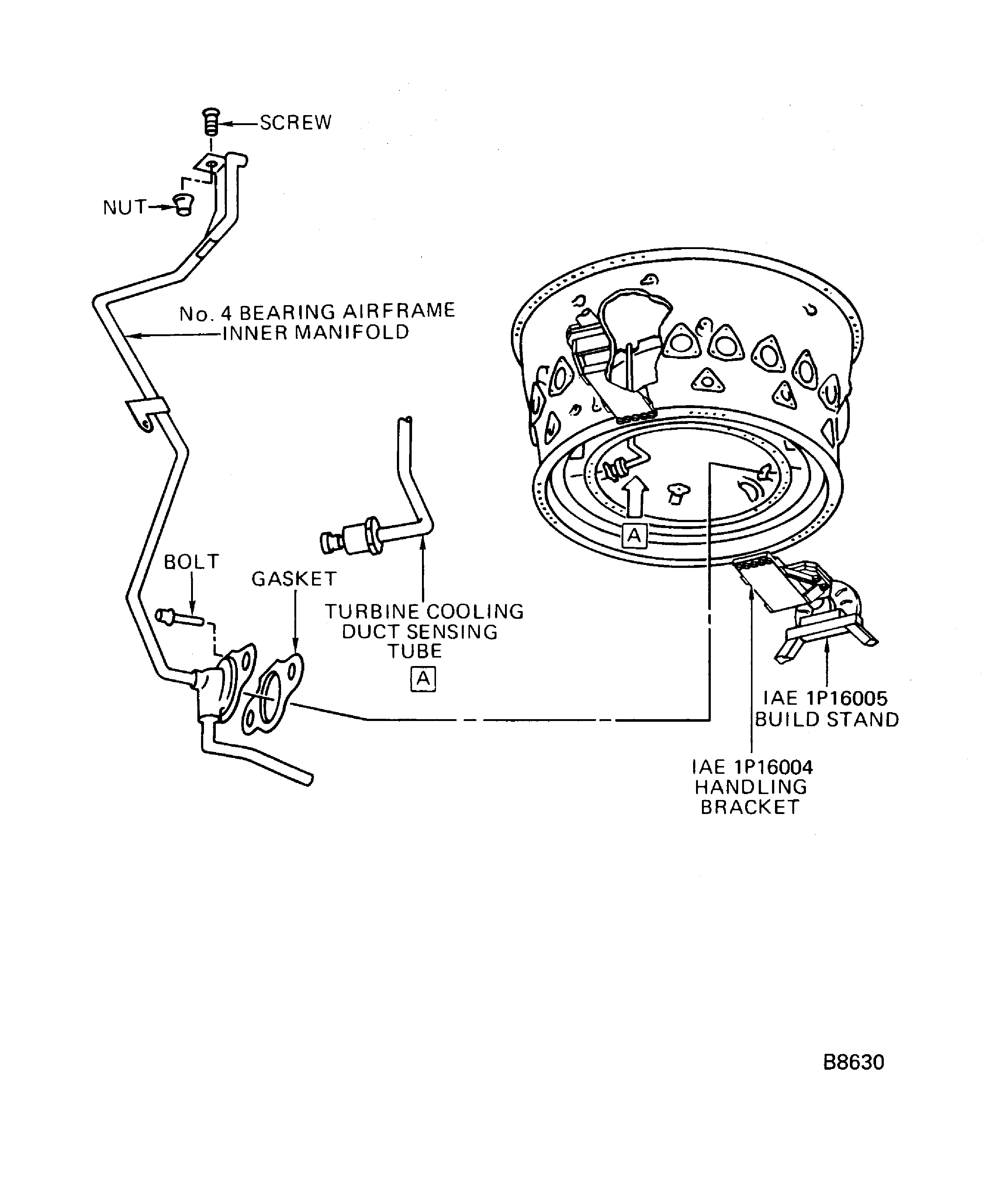

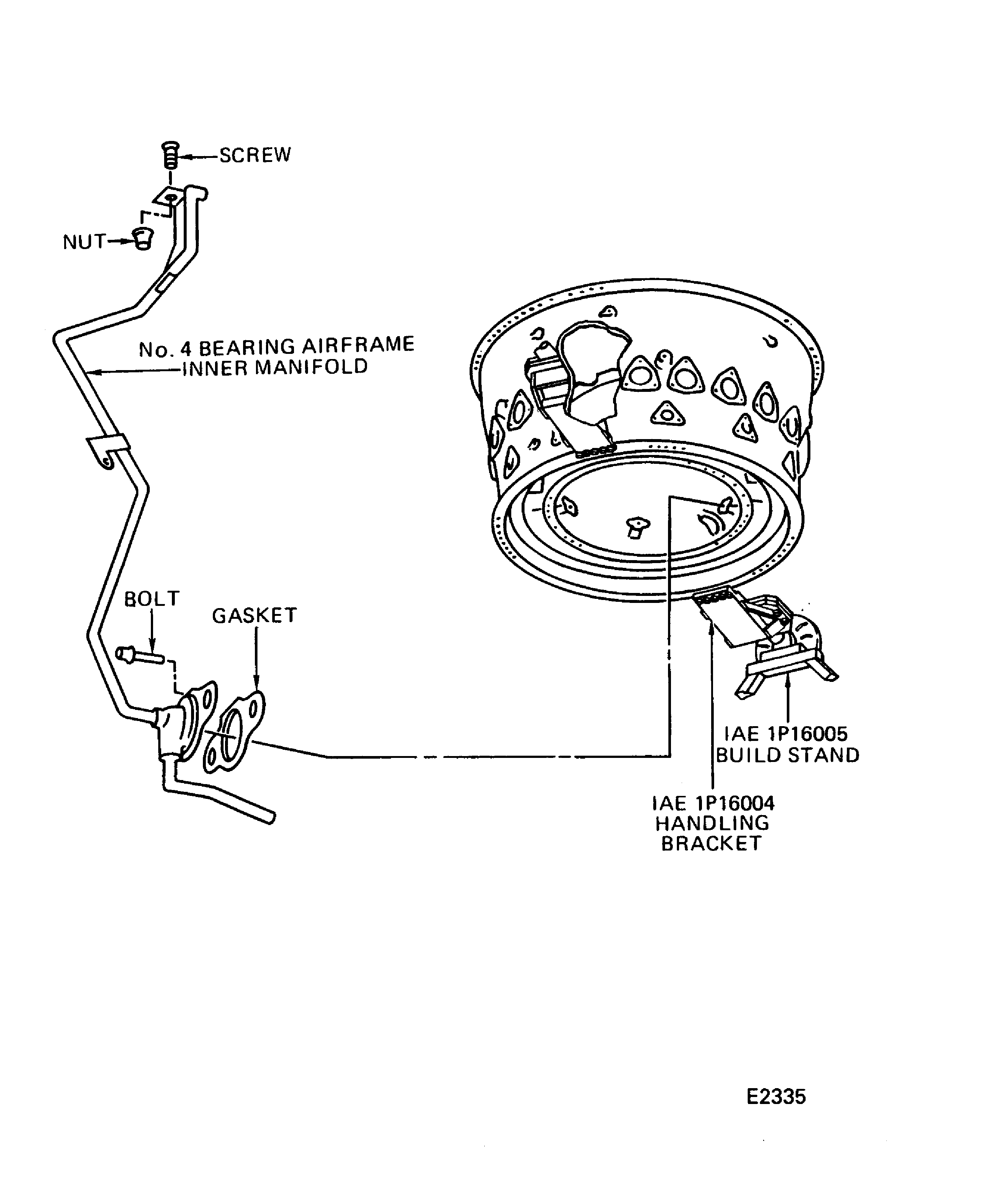

SUBTASK 72-42-00-040-073-A00 V2500-A1: Remove the No. 4 Bearing Airframe Manifold (Pre SBE 72-0016, Pre SBE 72-0166 and Pre SBE 72-0221)

Refer to Figure

SUBTASK 72-42-00-040-073-B00 V2500-A1: Remove the No. 4 Bearing Airframe Manifold (Pre SBE 72-0016, SBE 72-0166 and Pre SBE 72-0221)

SBE 72-0166: Remove the stage 1 HP turbine cooling air tubes

Refer to Figure

SUBTASK 72-42-00-040-073-C00 V2500-A1: Remove the No. 4 Bearing Airframe Manifold (SBE 72-0016, Pre SBE 72-0166 and Pre SBE 72-0221)

SBE 72-0016: New No. 4 bearing and airframe manifold assembly

Refer to Figure

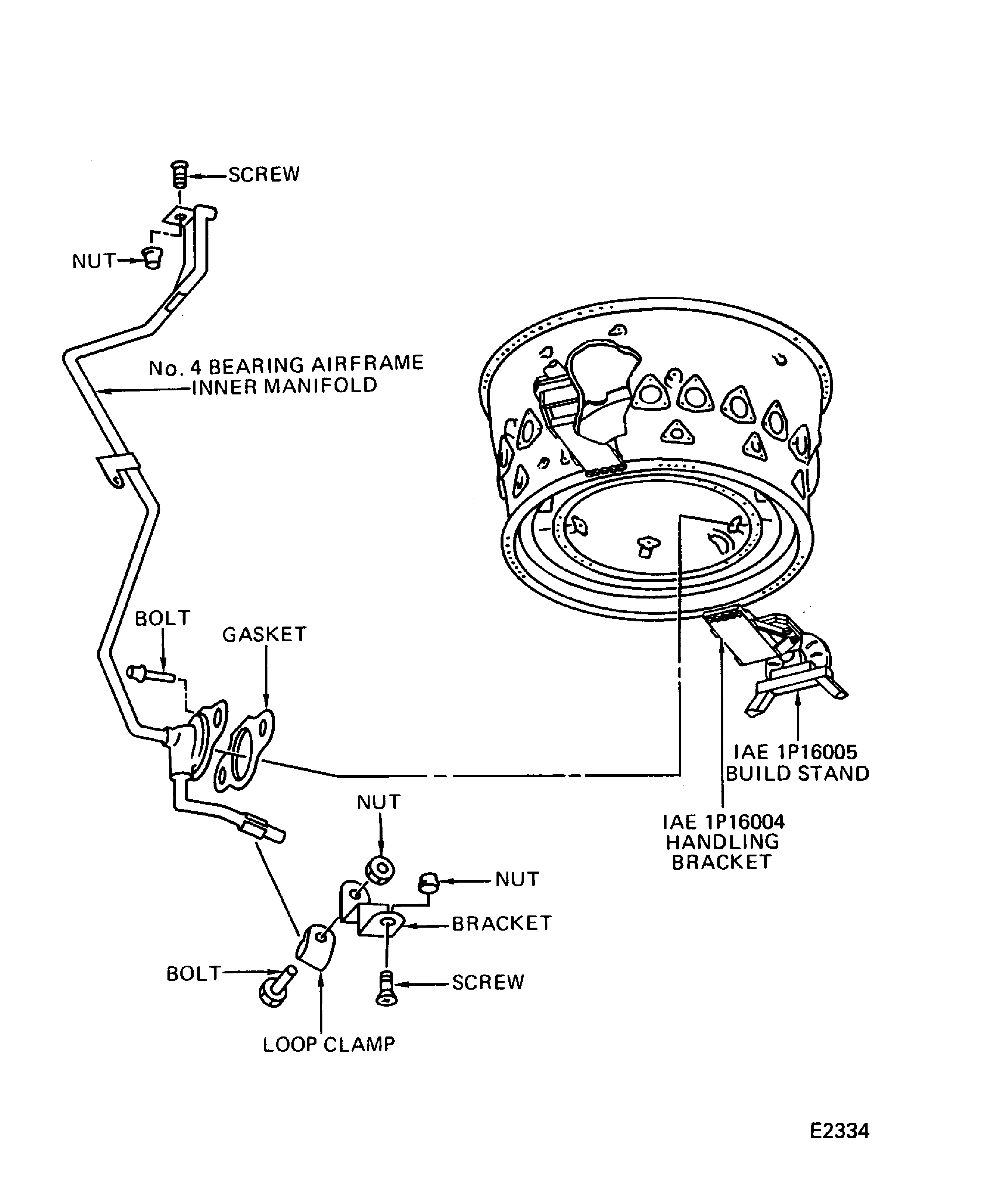

SUBTASK 72-42-00-040-073-D00 V2500-A1: Remove the No. 4 Bearing Airframe Manifold (SBE 72-0016, SBE 72-0166 and SBE 72-0221)

SBE 72-0016: New No. 4 bearing and airframe manifold assembly

SBE 72-0166: Remove the stage 1 HP turbine cooling air tubes

SBE 72-0221: Introduce a new diffuser case

Refer to Figure

SUBTASK 72-42-00-040-073-E00 V2500-A5: Remove the No. 4 Bearing Airframe Manifold (Pre SBE 72-0166)

Refer to Figure

SUBTASK 72-42-00-040-073-F00 V2500-A5: Remove the No. 4 Bearing Airframe Manifold (SBE 72-0166)

SBE 72-0166: Remove the stage 1 HP turbine cooling air tubes

Refer to Figure

SUBTASK 72-42-00-040-074 Remove the No. 4 Bearing Scavenge Tube

Refer to Figure

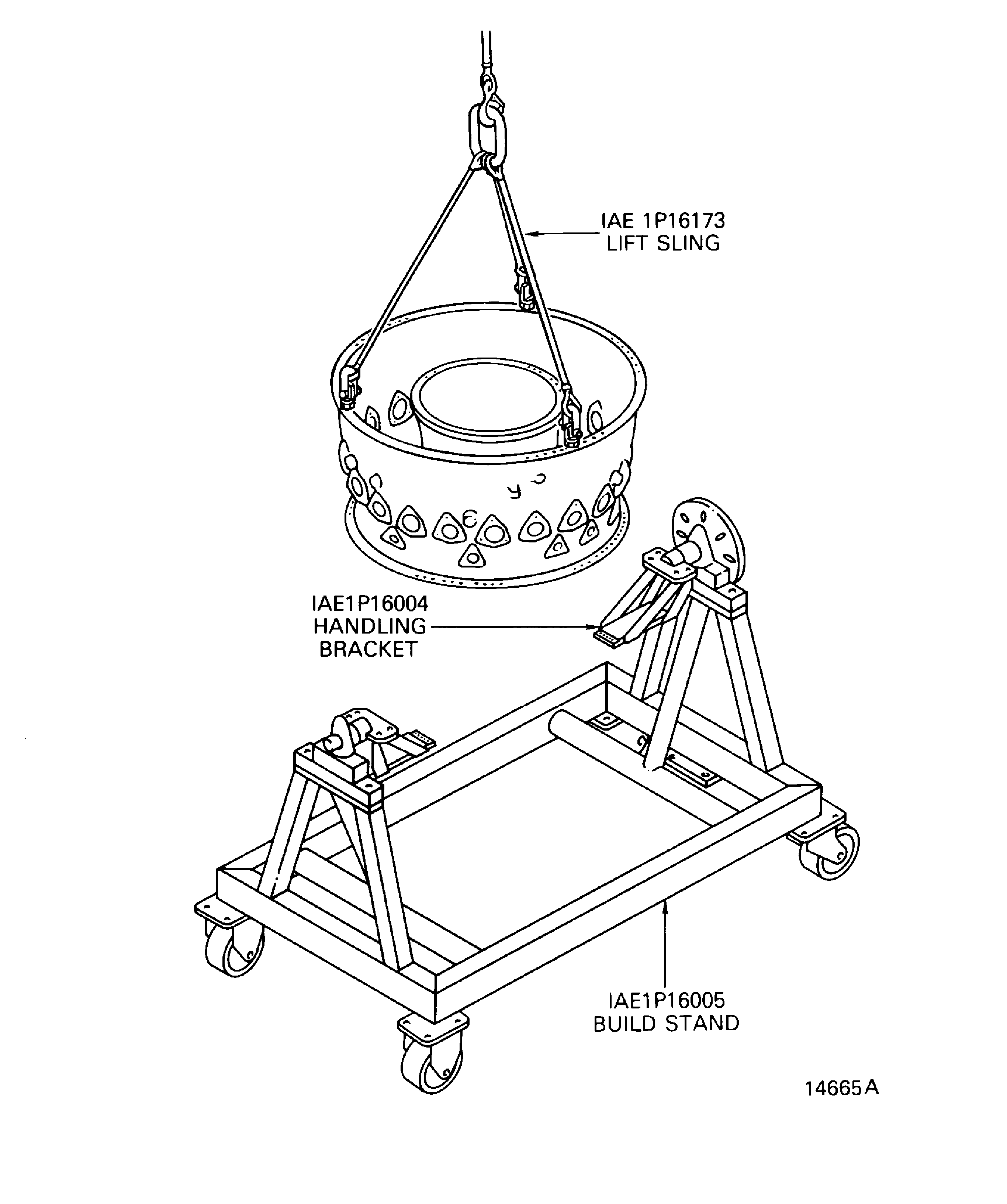

Attach the IAE 1P16173 Lift sling 1 off to the rear flange of the diffuser case.

SUBTASK 72-42-00-040-075 Remove the Diffuser Case from the Build Stand and Put it on a Pallet

Figure: Remove the P3/T3 Sensor

Remove the P3/T3 Sensor

Figure: Remove the Fuel Distribution Valve

Remove the Fuel Distribution Valve

Figure: Remove the Fuel Nozzle Supply Manifolds

Remove the Fuel Nozzle Supply Manifolds

Figure: Remove the Fuel Nozzles

Remove the Fuel Nozzles

Figure: Remove the Igniter Plugs

Remove the Igniter Plugs

Figure: Remove the Doweled End Bolts

Remove the Doweled End Bolts

Figure: Remove the Outer Combustion Chamber

Remove the Outer Combustion Chamber

Figure: Pre SBE 72-0221 V2500-A1: Remove the Nut Connector, Plug and Gaskets

Pre SBE 72-0221 V2500-A1: Remove the Nut Connector, Plug and Gaskets

Figure: Install the Four Bolts and Washers into Diffuser Case Assembly

Install the Four Bolts and Washers into Diffuser Case Assembly

Figure: SBE 72-0221 V2500-A1 and V2500-A5: Remove the Nut Connector, Plug and Gasket

SBE 72-0221 V2500-A1 and V2500-A5: Remove the Nut Connector, Plug and Gasket

Figure: Remove the Heatshields from the No. 4 Bearing Scavenge and Pressure Tubes

Remove the Heatshields from the No. 4 Bearing Scavenge and Pressure Tubes

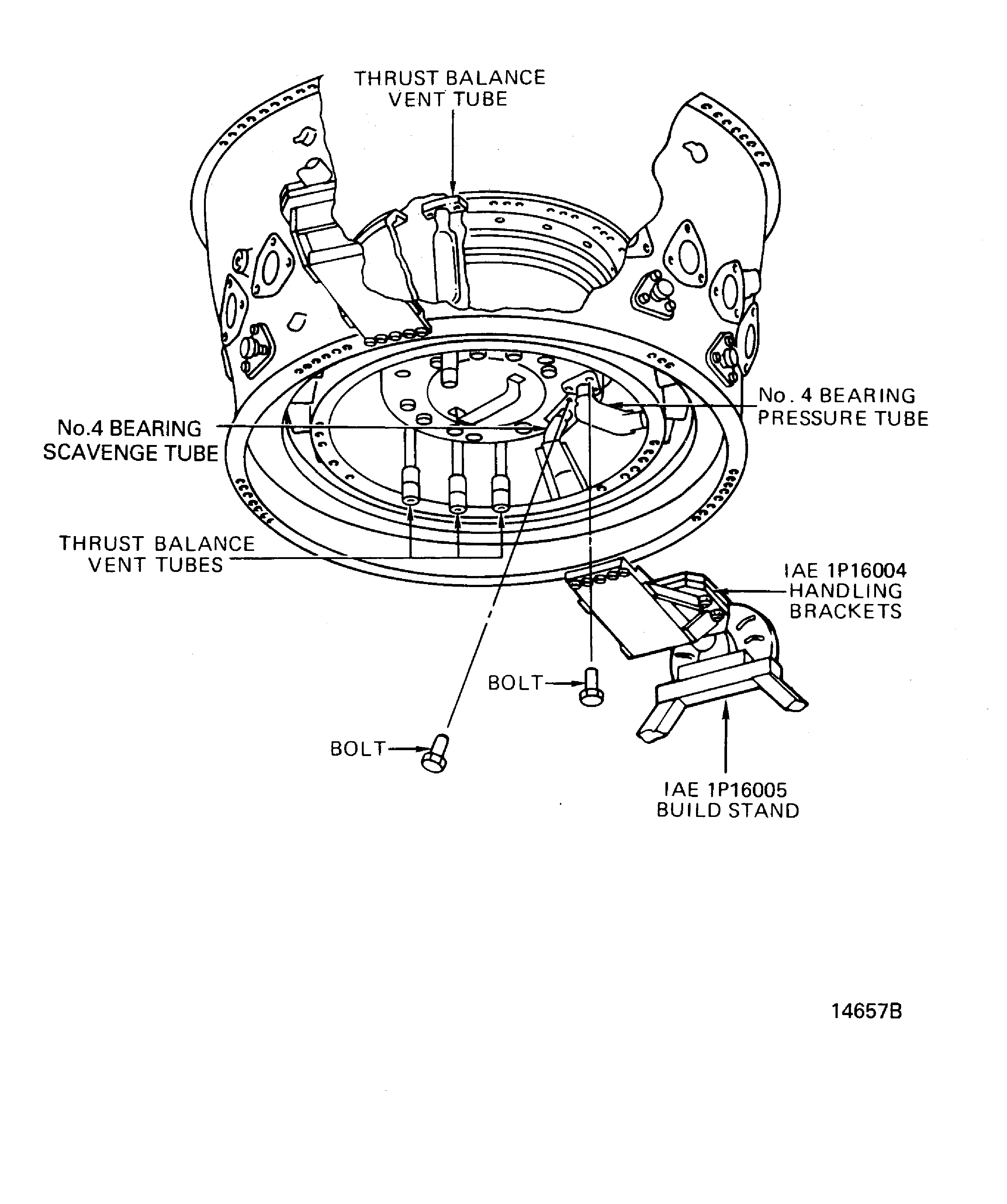

Figure: Pre SBE 72-0221 V2500-A1: Disconnect the No. 4 Bearing Pressure and Scavenge Tubes

Sheet 1

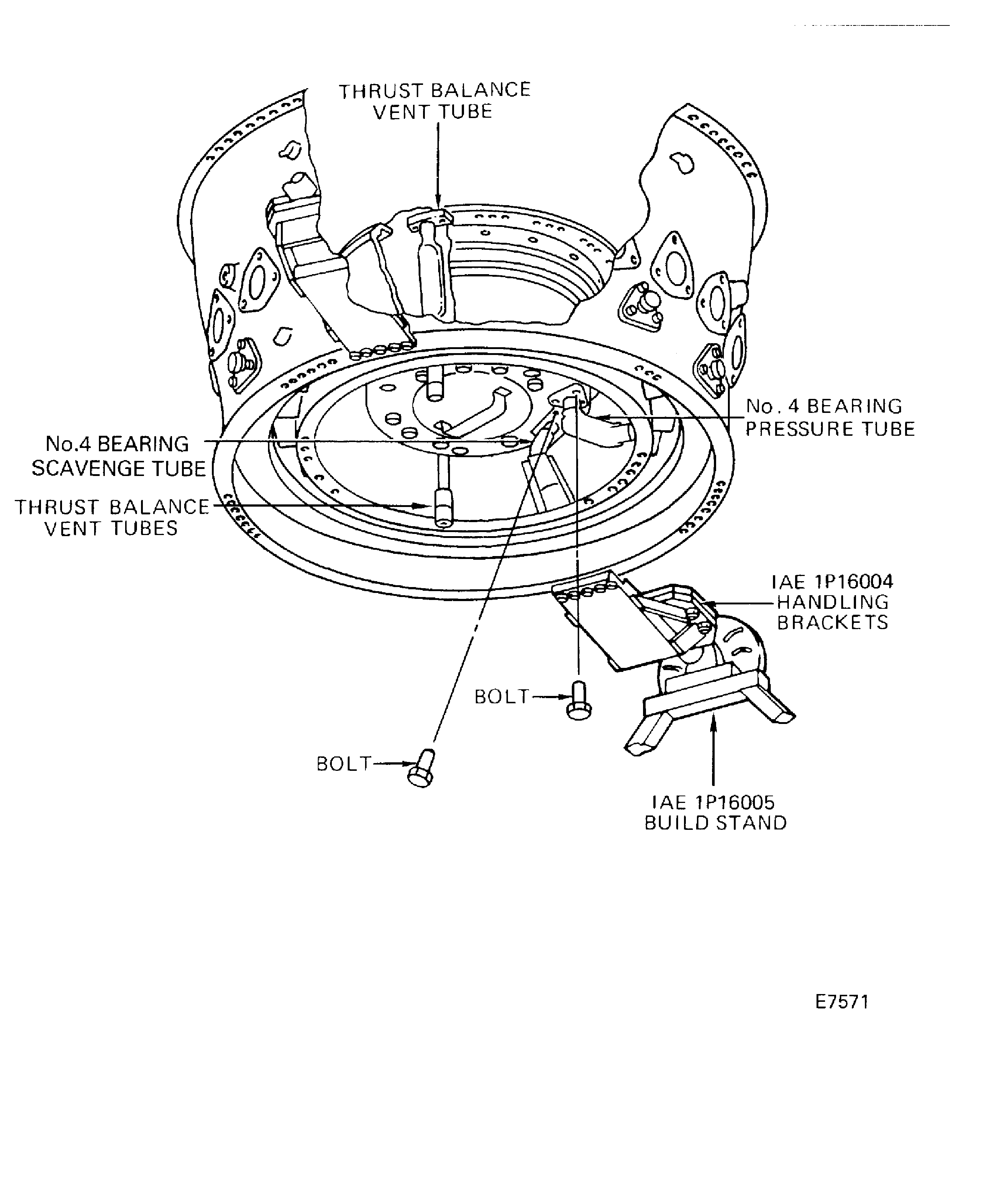

Figure: SBE 72-0221 V2500-A1 and V2500-A5: Disconnect the No. 4 Bearing Pressure and Scavenge Tubes

Sheet 2

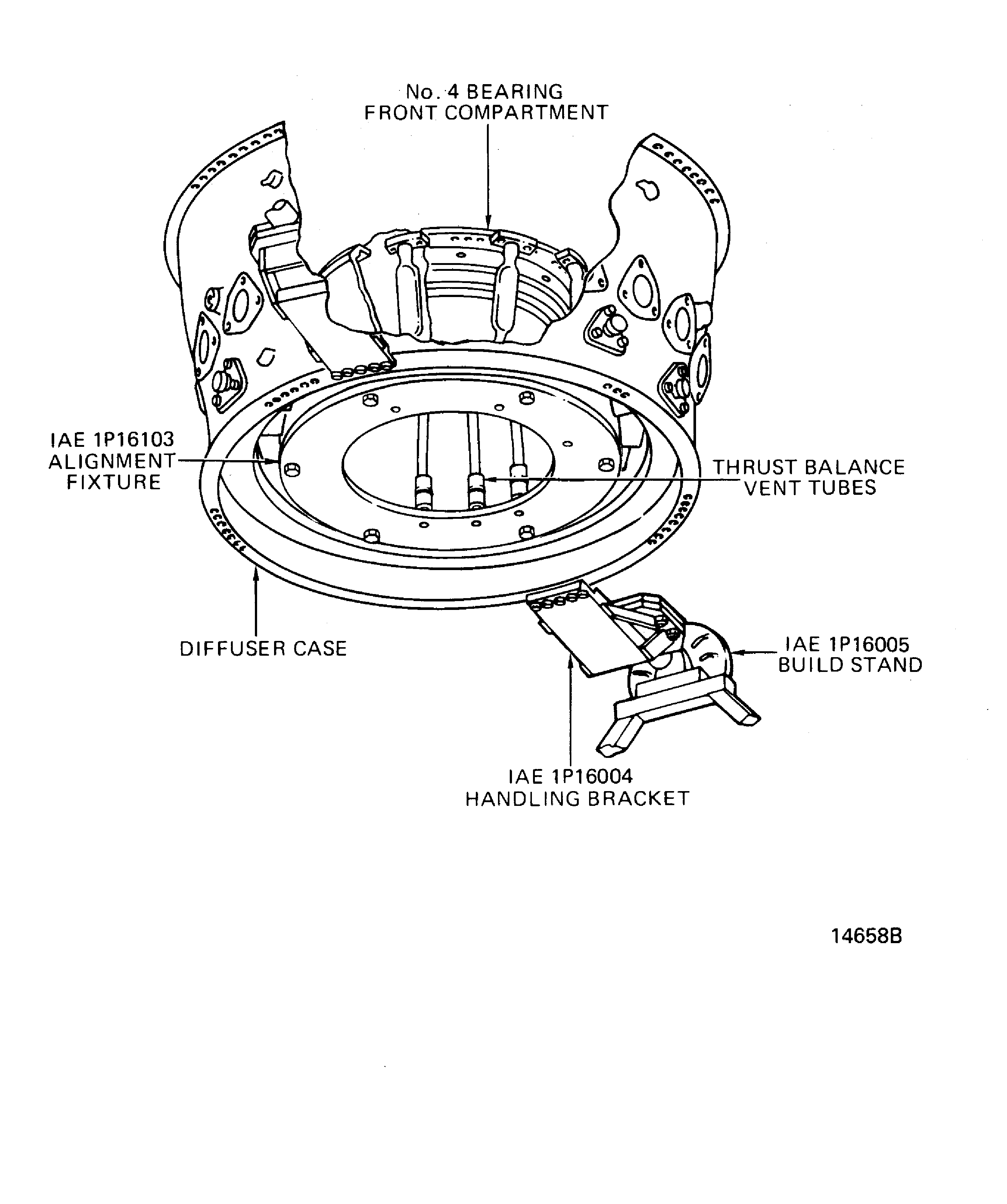

Figure: Pre SBE 72-0221 V2500-A1: Install the IAE 1P16103 alignment fixture

Sheet 1

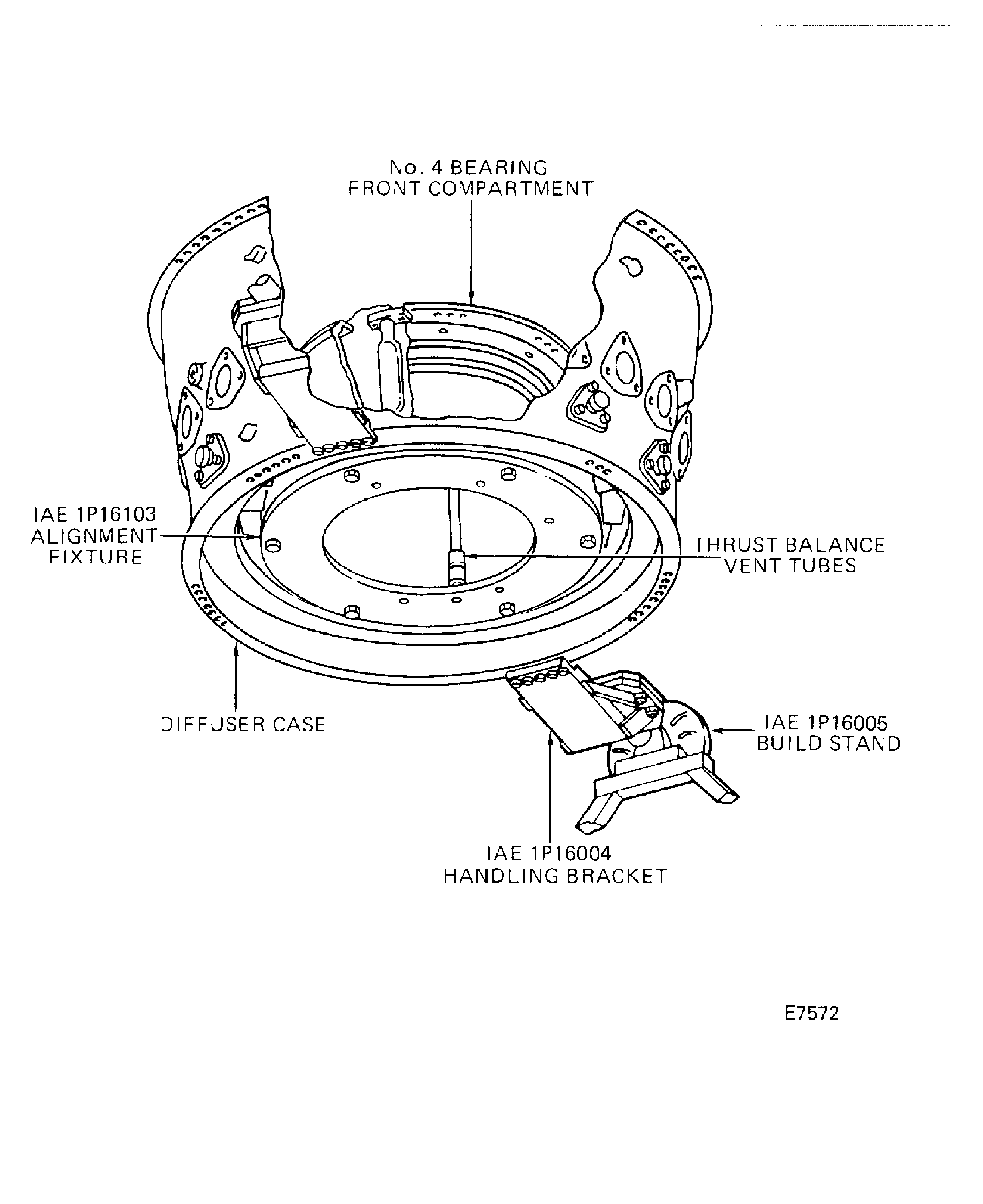

Figure: Pre SBE 72-0221 V2500-A1 and V2500-A5: Install the IAE 1P16103 Alignment Fixture

Sheet 2

Figure: Pre SBE 72-0221 V2500-A1: Remove the No. 4 Bearing Front Compartment

Sheet 1

Figure: SBE 72-0221 V2500-A1 and V2500-A5: Remove the No. 4 Bearing front Compartment

Sheet 2

Figure: Remove the Transfer Tubes and Adapters

Remove the Transfer Tubes and Adapters

Figure: Remove the No. 4 Bearing Outer Cooling Tube

Remove the No. 4 Bearing Outer Cooling Tube

Figure: Remove the No. 4 Bearing Inner Cooling Tube and Sealing Sleeves

Remove the No. 4 Bearing Inner Cooling Tube and Sealing Sleeves

Figure: Pre SBE 72-0016, Pre SBE 72-0166 and Pre SBE 72-0221 V2500-A1: Remove the Turbine Cooling Duct Air Sensing Tube and the No. 4 Bearing Airframe Manifold

Pre SBE 72-0016, Pre SBE 72-0166 and Pre SBE 72-0221 V2500-A1: Remove the Turbine Cooling Duct Air Sensing Tube and the No. 4 Bearing Airframe Manifold

Figure: SBE 72-0016, Pre SBE 72-0166 and Pre SBE 72-0221 V2500-A1 and Pre SBE 72-0166 V2500-A5: Remove the Turbine Cooling Duct Air Sensing Tube and the No. 4 Bearing Airframe Manifold

SBE 72-0016, Pre SBE 72-0166 and Pre SBE 72-0221 V2500-A1 and Pre SBE 72-0166 V2500-A5: Remove the Turbine Cooling Duct Air Sensing Tube and the No. 4 Bearing Airframe Manifold

Figure: Pre SBE 72-0016 and Pre SBE 72-0221 V2500-A1 and SBE 72-0166: Remove the No. 4 Bearing Airframe Manifold

Pre SBE 72-0016 and Pre SBE 72-0221 V2500-A1 and SBE 72-0166: Remove the No. 4 Bearing Airframe Manifold

Figure: SBE 72-0016 72-0166, and 72-0221 V2500-A1 and SBE 72-0166 V2500-A5: Remove the Turbine Cooling Duct Air Sensing Tube and the No. 4 Bearing Airframe Manifold

SBE 72-0016 72-0166, and 72-0221 V2500-A1 and SBE 72-0166 V2500-A5: Remove the Turbine Cooling Duct Air Sensing Tube and the No. 4 Bearing Airframe Manifold

Figure: Remove the No. 4 Bearing Scavenge Tube

Remove the No. 4 Bearing Scavenge Tube

Figure: Remove the Diffuser Case From the Build Stand

Remove the Diffuser Case From the Build Stand

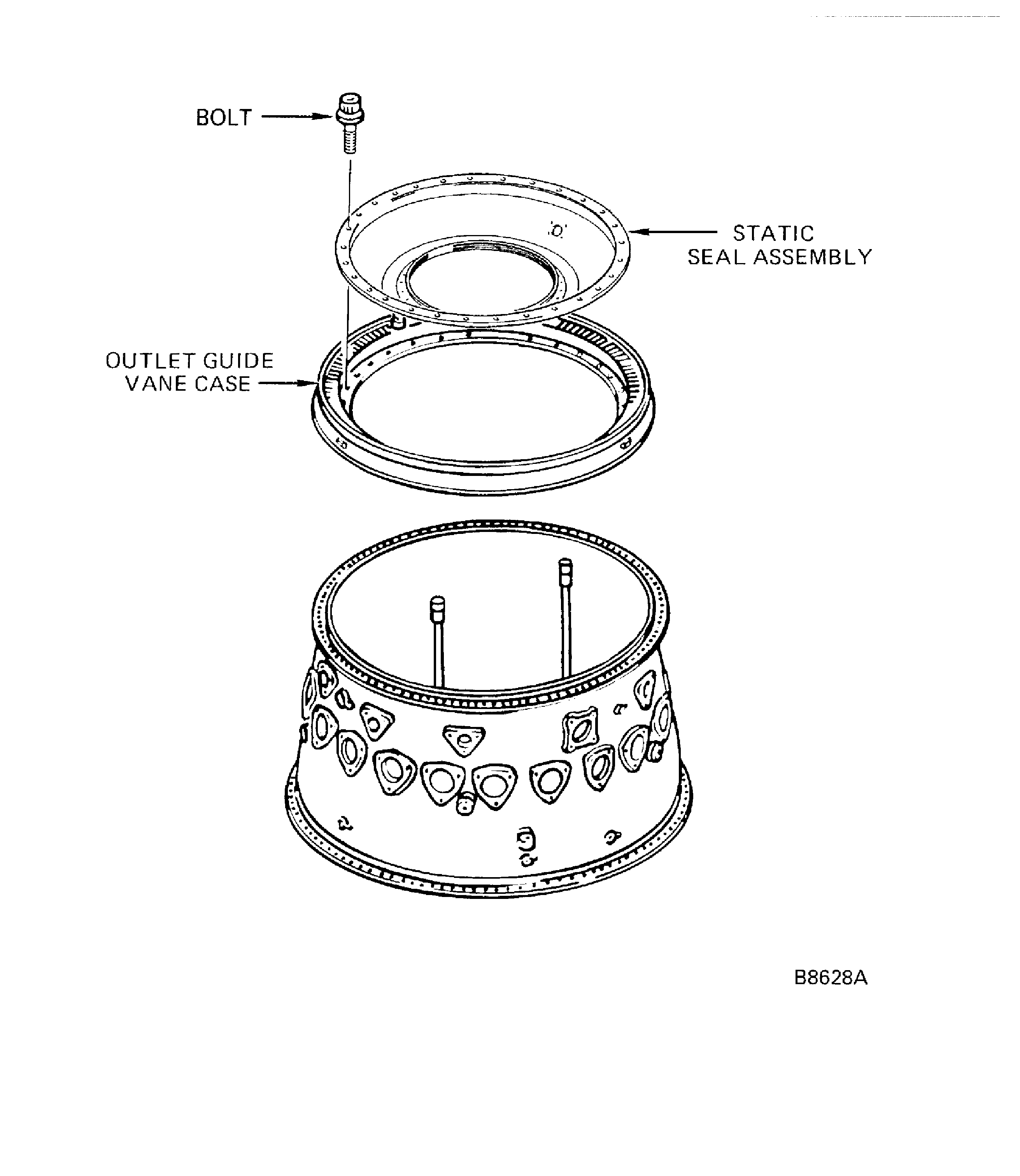

Figure: Pre SBE 72-0221 V2500-A1: Remove the Outlet Guide Vane (OGV), the Static Seal Assembly and the Heatshield

Pre SBE 72-0221 V2500-A1: Remove the Outlet Guide Vane (OGV), the Static Seal Assembly and the Heatshield

Figure: SBE 72-0221 V2500-A1 and V2500-A5: Remove the Outlet Guide Vane (OGV) and the Static Seal Assembly

SBE 72-0221 V2500-A1 and V2500-A5: Remove the Outlet Guide Vane (OGV) and the Static Seal Assembly