Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-20-300-024 No. 4 Bearing Pressure Oil Tube - Nickel Plate The Outer Sealing Surface, Repair-024 (VRS3577)

General

Price and Availability - Refer to IAE.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Nickel plating eqiupment | LOCAL | Nickel plating equipment |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

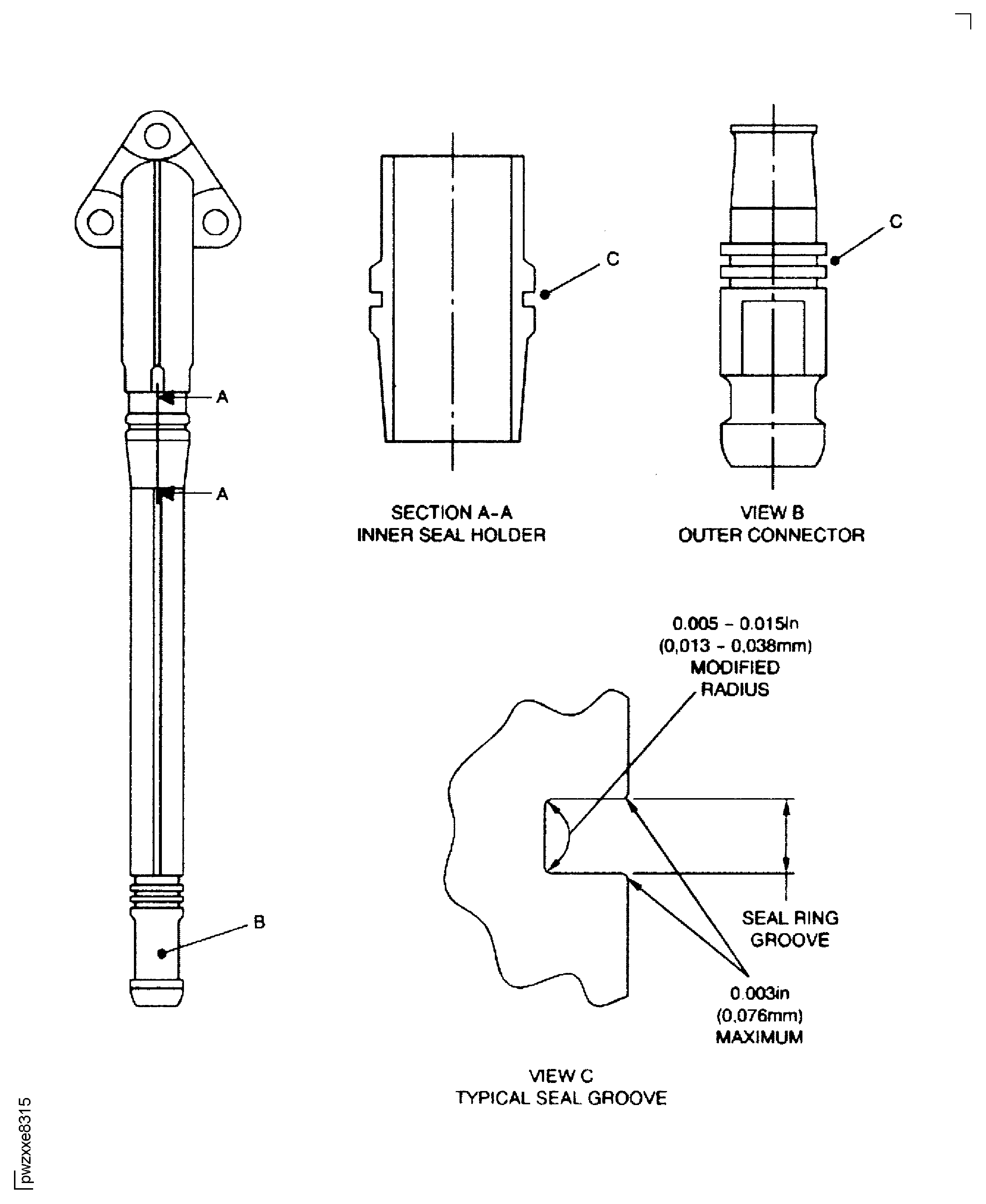

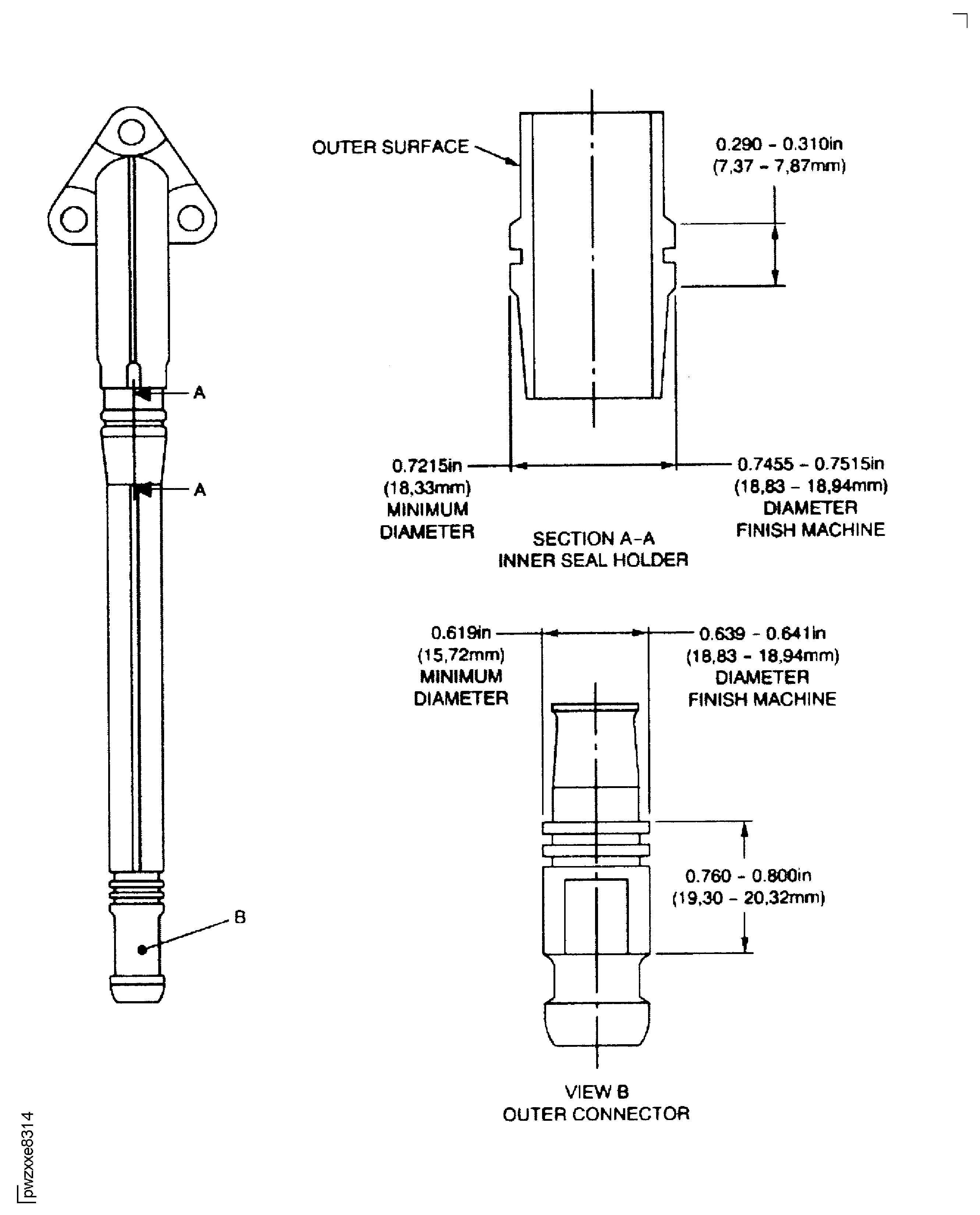

Refer to Figure (View A).

Remove the least amount of material. Do not go below 0.7215 in. (18.33 mm) diameter.

Machine the outer surfaces of the inner seal holder.

SUBTASK 72-42-20-320-088 Machine No. 4 Pressure Tube Outer Surfaces

Refer to SPM TASK 70-33-25-300-503.

NOTE

Plating is permitted outside machined area but must be removed. No plating permitted in seal grooves.

Nickel plate machined surface up to 0.7655 in. (19.44 mm) diameter.

SUBTASK 72-42-20-330-009 Nickel Plating of Machined Surface

Refer to Figure (View A).

Finish machine outer surface of inner seal holder surfaces to 0.7455 - 0.7515 in. (18.83 - 18.94 mm) diameter.

SUBTASK 72-42-20-320-089 Machining Outer Surfaces

Refer to Figure (View B).

Remove the least amount of material. Do not go below 0.619 in. (15.72 mm) diameter.

Machine the outer seal surface of outer connector.

SUBTASK 72-42-20-320-090 Machine Outer Seal Surfaces of Outer Connector

Refer to SPM TASK 70-33-25-300-503.

NOTE

Plating is permitted outside machined area but must be removed. No plating permitted in seal grooves.

Nickel plate machined surfaces up to 0.661 in. (16.79 mm) diameter.

SUBTASK 72-42-20-330-011 Nickel Plating of Machined Surfaces

Refer to Figure (View B).

Finish machine outer connector surfaces to 0.639 - 0.641 in. (18.83 - 18.94 mm) diameter.

SUBTASK 72-42-20-320-091 Machining Outer Connector Surfaces

Refer to Figure.

NOTE

Wear can be uneven on groove surfaces

Measure width of the seal ring groove of the inner seal holder at the wear locations.

Table 3. Oversize Seal Groove Dimensions For Inner Seal Holder (a)

0.069-0.071 in. (1.75 - 1.80 mm) for seal ring P/N 2A0333 P5

(b)

0.074-0.076 in. (1.88 - 1.93 mm) for seal ring P/N 2A0333 P10

(c)

0.079-0.081 in. (2.01 - 2.06 mm) for seal ring P/N 2A0333 P15

(d)

0.084 - 0.086 in. (2.13 - 2.18 mm) for seal ring P/N 2A0333 P20

If wear is greater than 0.003 in (0.076 mm) grind to subsequent oversize groove width

Refer to Figure.

Break edge 0.003 in. (0.076 mm) maximum.

Refer to Figure.

0.005 - 0.015 in. (0.013 - 0.038 mm) modified radius.

Refer to Figure.

NOTE

Wear can be uneven on groove surfaces.

Measure the width of the seal ring grooves of the outer tube connector at the wear locations.

Table 4. Oversize Seal Groove Dimensions For Outer Seal Holder (a)

0.0695 - 0.0715 in. (1.765 - 1.816 mm) for seal ring P/N 2A0364 P5

(b)

0.0745 - 0.0765 in. (1.89 - 1.943 mm) for seal ring P/N 2A0364 P10

(c)

0.0795 - 0.0815 in. (2.019 - 2.070 mm) for seal ring P/N 2A0364 P15

(d)

0.0845 - 0.0865 in. (2.146 - 2.197 mm) for seal ring P/N 2A0364 P20

If wear is greater than 0.003 in. (0.076 mm) grind to subsequent oversize groove width.

Break edge 0.003 inch (0.076 mm) maximum.

0.005 - 0.015 in. (0.013 - 0.038 mm) modified radius.

SUBTASK 72-42-20-320-092 Machine Seal Grooves to Accept Oversize Piston Rings

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions