DMC:V2500-A0-72-42-3301-00A-720A-BIssue No:002.00Issue Date:2021-02-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-33-300-022 No. 4 Bearing Front Seal Support - Repair Damaged Threads, Repair-022 (VRS3669)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

No. 4 bearing seal support assembly | - | Wrought and cast Titanium base alloy |

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers in the SPM.

NOTE

Equivalent material or equipment can be used.

NOTE

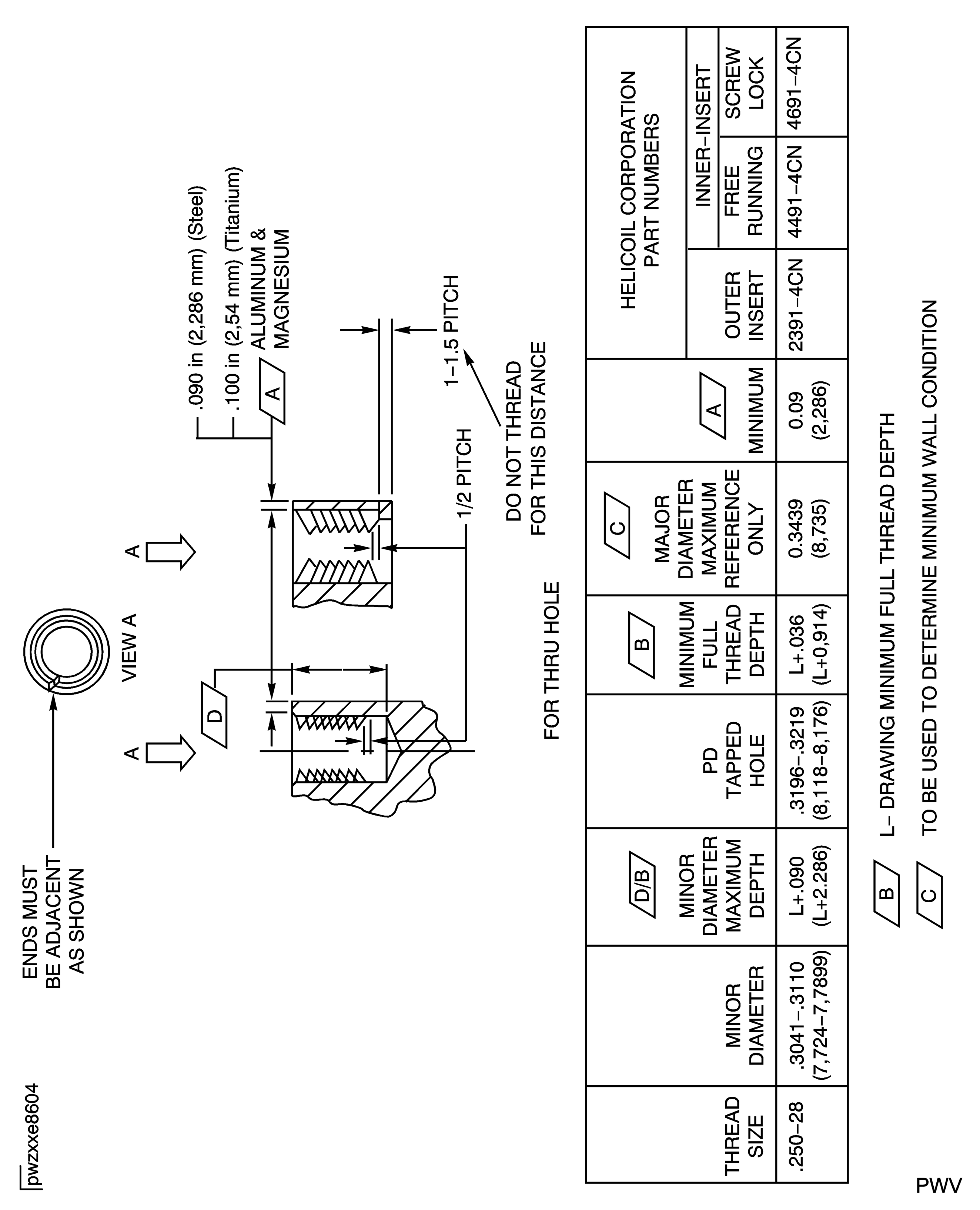

The tools for the removal and the installation of the inserts can be purchased from Helicoil Products Division/Mite Corporation, Supplier Code 01556, Danbury CT 06810. Helicoil part numbers are provided in this repair.

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before this repair. |

Support Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Removal tool | LOCAL | 1227-6 | (Helicoil Products) | |

| Outer helical wire thread insert tang removal tool | LOCAL | 4032-4 | (Helicoil Products) | |

| Tang removal tool | LOCAL | 3695-4 | (Helicoil Products) | |

| Thread insert installation tool | LOCAL | 2705-4 | (Helicoil Products) | |

| Installation tool | LOCAL | 7552-4 | (Helicoil Products) |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Outer insert (free running) | 0AM53 | 2391-4CN375 | 1 - 4 | |

| Inner insert (screw locking) | 0AM53 | 4691-4CN339 | 1 - 4 |

Safety Requirements

NONEProcedure

Refer to the SPM TASK 70-35-08-300-501.

Use tool P/N 1227-6.

NOTE

If the hole is already tapped for a double helical wire thread insert, it is permitted to install a double helical wire thread insert by Steps 7, 8 and 10.

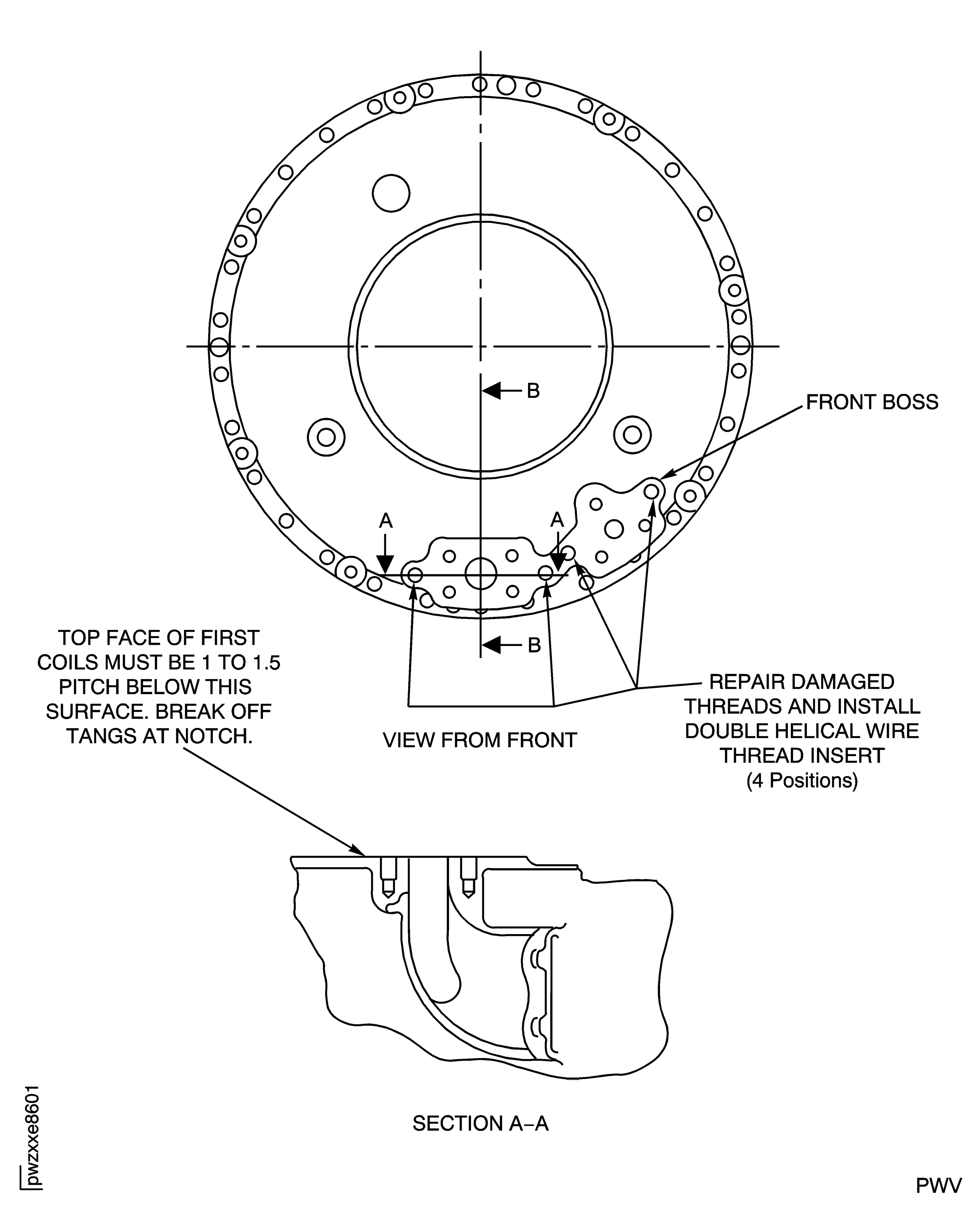

Remove the damaged or loose inserts from the boss.

SUBTASK 72-42-33-350-079 Remove the Damaged or Loose Inserts from the Boss

Refer to the SPM TASK 70-35-08-300-501.

Install the outer inserts and break off the tangs.

SUBTASK 72-42-33-350-080 Install the Outer Inserts

Figure: No. 4 Bearing Seal Support Assembly Thread Repair

Sheet 1

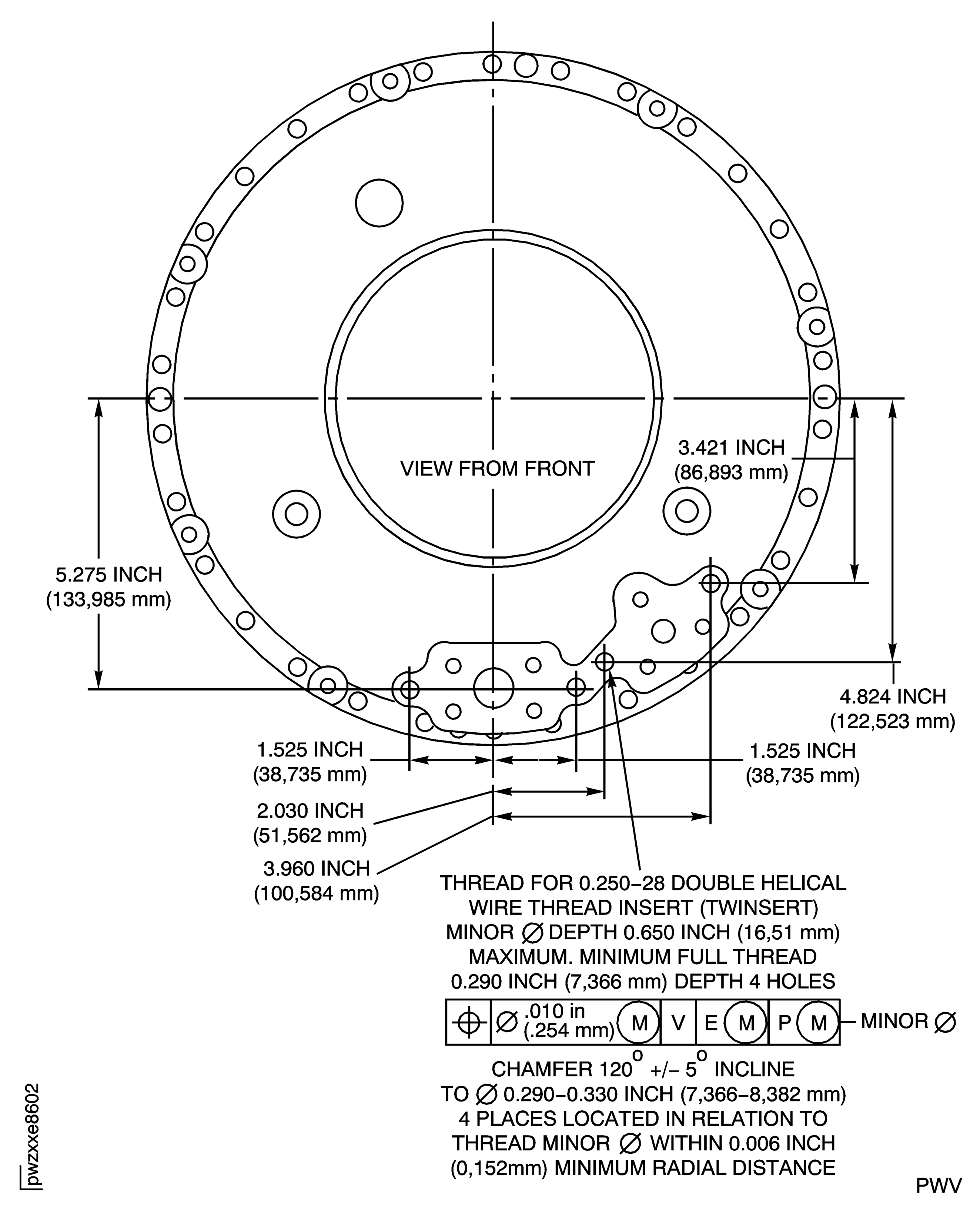

Figure: No. 4 Bearing Seal Support Assembly Thread Repair

Sheet 2

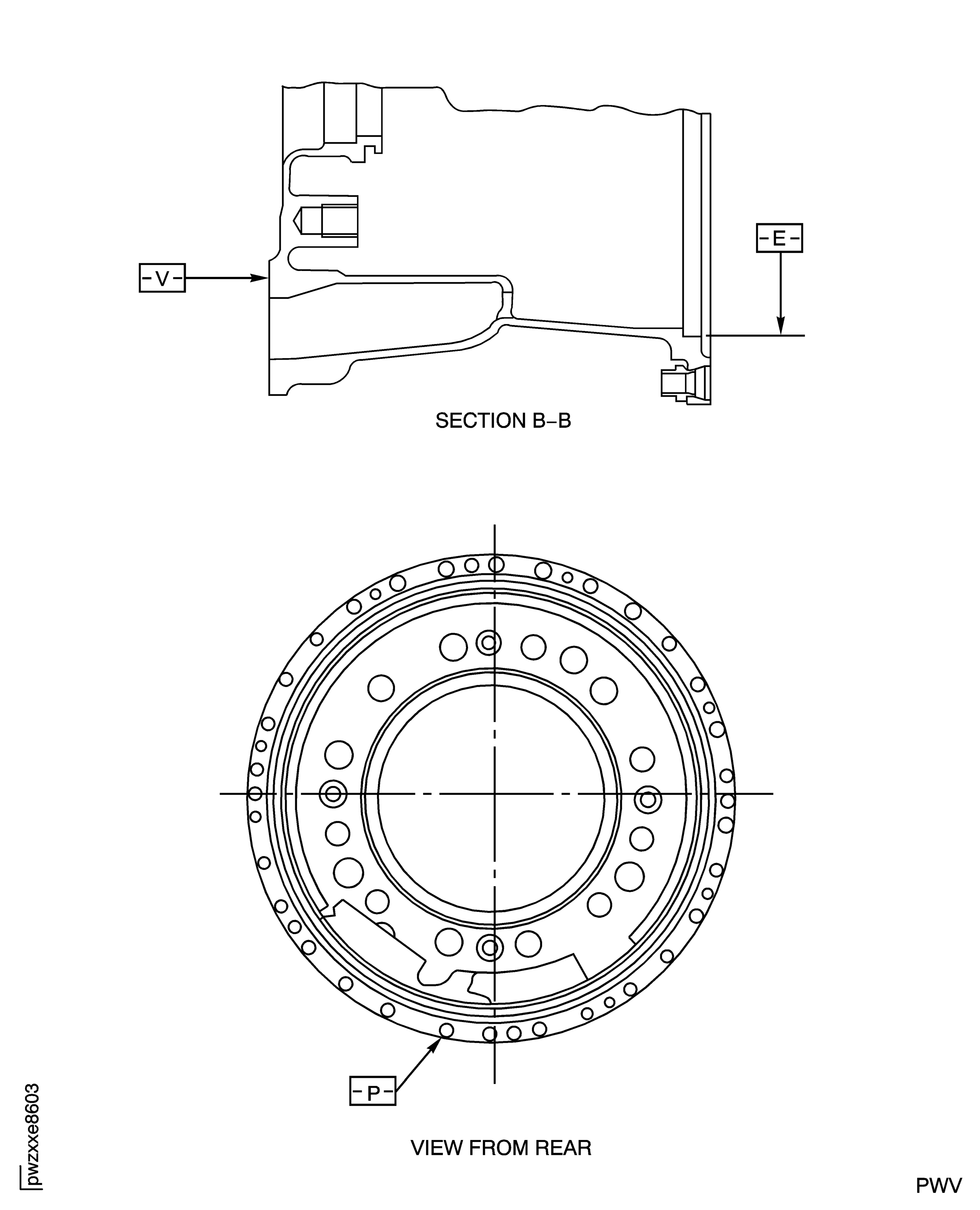

Figure: No. 4 Bearing Seal Support Assembly Thread Repair

Sheet 3

Figure: No. 4 Bearing Seal Support Assembly Thread Repair

Sheet 4