DMC:V2500-A0-72-44-1001-01A-649A-CIssue No:003.00Issue Date:2015-05-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-10-300-022 HPT Stage 1 Support Assembly - Blend And Polish The Front Flange Holes, Repair-022 (VRS3650)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-010 | 2A1292 |

01-010 | 2A1358 |

01-010 | 2A1664 |

01-010 | 2A2703 |

01-010 | 2A3360 |

01-010 | 2A4027 |

01-010 | 2A3367 |

01-010 | 2A3896 |

General

Price and availability - Refer to IAE.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

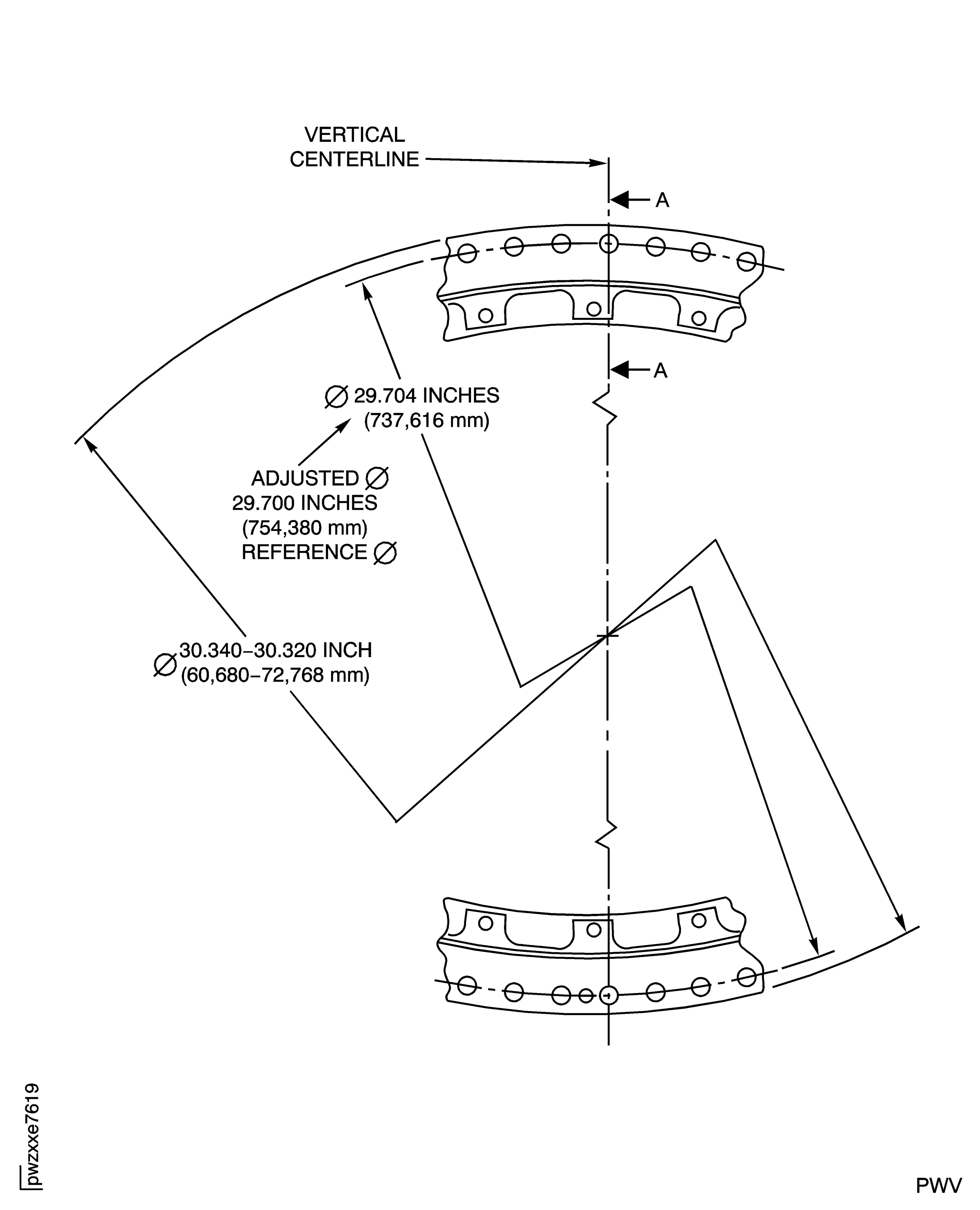

Refer to Figure.

SUBTASK 72-44-10-350-062 Blend and Polish Flange Bolt Holes That Have Cracks

No cracks are permitted.

Refer to the SPM TASK 70-23-05-230-501 (high sensitivity).

Fluorescent penetrant inspect each repaired bolt hole.

SUBTASK 72-44-10-230-071 Examine the Repair

Refer to Figure.

Refer to the SPM TASK 70-38-13-380-501.

Shot peen each blended hole at an intensity of 6A.

SUBTASK 72-44-10-380-053 Shot Peen the Repaired Area

Refer to TASK 72-44-10-200-000 (INSPECTION-000).

Examine the support after repair.

SUBTASK 72-44-10-220-185 Examine the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions