Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-38-13-380-501 Shotpeening With Cast Steel Shot (Conforming To The Current Revision Of AMS 2430 And AMS 2431) Or Conditioned Cut Wire Shot (Conforming To The current revision Of AMS 2430 And AMS 2431)

General

This task gives the procedure to peen with cast steel shot or conditioned cut wire shot (steel or stainless steel) that agrees with the current revision of AMS 2430 and AMS 2431.

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Do all specified FPI, FMPI, and other NDT inspections before you peen the part. |

Support Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Stacked sieve set | LOCAL | Stacked sieve set | ||

| Rotating and tapping, testing apparatus | LOCAL | Rotating and tapping, testing apparatus | ||

| 10X magnifying glass | LOCAL | 10X magnifying glass | ||

| Test block | LOCAL | Test block | ||

| Almen "A" test strips | LOCAL | Almen "A" test strips | Supplied by these manufacturers: 92830, 1LUR8 3W485 | |

| Almen gage No.2 | LOCAL | Almen gage No.2 | Supplied by these manufacturers: OCJ83, 3W485 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-050 HIGH TEMPERATURE GLASS CLOTH TAPE | 76381 | CoMat 02-050 | ||

| CoMat 02-062 MASKING TAPE | 0AM53 | CoMat 02-062 | ||

| CoMat 02-228 MASKING TAPE (HEAVY DUTY) | 52152 | CoMat 02-228 | ||

| CoMat 02-232 MASKING TAPE | 52152 | CoMat 02-232 | ||

| CoMat 02-250 ELECTROLYTE | IE345 | CoMat 02-250 | ||

| CoMat 02-266 TAPE, DOUBLE LAYER | 07512 | CoMat 02-266 | ||

| CoMat 02-267 HEAT RESISTANT TAPE | LOCAL | CoMat 02-267 | ||

| CoMat 02-368 TAPE - SILICONE COATED, GLASS FABRIC | LOCAL | CoMat 02-368 | ||

| CoMat 02-369 MASKING TAPE (HEAVY) | 0AM53 | CoMat 02-369 | ||

| CoMat 02-372 TAPE - HIGH TEMPERATURE, GLASS CLOTH, COATED | LOCAL | CoMat 02-372 | ||

| CoMat 02-373 FABRIC, SILICONE-COATED FIBERGLASS | LOCAL | CoMat 02-373 | ||

| CoMat 02-376 TAPE-GLASS CLOTH, DOUBLE ADHESIVE, 0.105" THICK | 07512 | CoMat 02-376 | ||

| CoMat 02-392 TAPE - SILICONE COATED, GLASS FABRIC | 60890 | CoMat 02-392 | ||

| CoMat 02-394 TAPE, HIGH-TEMPERATURE, GLASS CLOTH, COATED, HVOF | 07512 | CoMat 02-394 | ||

| CoMat 02-397 TAPE, SILICONE RUBBER/GLASS CLOTH | LOCAL | CoMat 02-397 | ||

| CoMat 05-028 METALLIC SHOT (CAST STEEL), S230 | IE249 | CoMat 05-028 | ||

| CoMat 05-029 CAST STEEL SHOT, S110 | LOCAL | CoMat 05-029 | ||

| CoMat 05-032 CAST STEEL SHOT, S170 | 42736 | CoMat 05-032 | ||

| CoMat 05-138 SHOT, CAST STEEL, S110 | 81349 | CoMat 05-138 | ||

| CoMat 05-176 CAST STEEL SHOT, S170 | 42736 | CoMat 05-176 | ||

| CoMat 05-177 CUT WIRE SHOT,CW-14 | LOCAL | CoMat 05-177 | ||

| CoMat 05-178 CUT WIRE SHOT, CW-20 | LOCAL | CoMat 05-178 | ||

| CoMat 05-187 STAINLESS STEEL CUT WIRE SHOT, SCW-20 | LOCAL | CoMat 05-187 | ||

| CoMat 05-188 STAINLESS STEEL CUT WIRE SHOT, SPECIAL CONDITIONED, SCW-20 | LOCAL | CoMat 05-188 | ||

| CoMat 05-233 WROUGHT CARBON STEEL SHOT, CW-28 | LOCAL | CoMat 05-233 | ||

| CoMat 05-234 CAST STEEL SHOT, HIGH HARDNESS, S110 | LOCAL | CoMat 05-234 | ||

| CoMat 05-235 STAINLESS STEEL CUT WIRE SHOT, SPECIAL CONDITIONED, SCW-14 | LOCAL | CoMat 05-235 | ||

| CoMat 05-236 CAST STEEL SHOT, HIGH HARDNESS, S170 | LOCAL | CoMat 05-236 | ||

| CoMat 05-247 METALLIC SHOT (CAST STEEL), HIGH HARDNESS, S230 | LOCAL | CoMat 05-247 | ||

| CoMat 05-248 CONDITIONED CUT-WIRE STEEL SHOT, SIZE SAE J441 CW-14 | 0FUN2 | CoMat 05-248 | ||

| CoMat 05-251 CAST STEEL SHOT, S230 | 55807 | CoMat 05-251 | ||

| CoMat 05-260 SHOT, CUT WIRE, CARBON STEEL, CONDITIONED, AWCH 14 | LOCAL | CoMat 05-260 | ||

| DELETED | LOCAL | DELETED |

Spares

NONESafety Requirements

WARNING

Procedure

It is necessary to do all specified FPI, FMPI, and other NDT inspections before you do this task.

S-xxx series shot sizes (such as S-110) are SAE J444 sizes for cast shot.

CW-xx series shot sizes (such as CW-14) are SAE J441 sizes for carbon steel conditioned cut wire shot.

SCW-xx series shot sizes (such as SCW-14) are SAE J441 sizes for stainless steel conditioned cut wire shot.

ASR xxx series shot sizes (such as ASR 110) are AMS 2431/1 sizes for regular-hardness cast steel shot.

ASH xxx series shot sizes (such as ASH 110) are AMS 2431/2 sizes for high-hardness cast steel shot.

AWCR xx series shot sizes (such as AWCR 14) are AMS 2431/3 sizes for regular-hardness carbon steel conditioned cut wire shot.

AWS xx series shot sizes (such as AWS 14) are AMS 2431/4 sizes for stainless steel conditioned cut wire shot.

AWCH xx series shot sizes (such as AWCH 14) are AMS 2431/8 sizes for high-hardness carbon steel conditioned cut wire shot.

The specified cast steel shot and conditioned cut wire shot in this task agree with the requirements in the current revisions of AMS 2430 and AMS 2431.

NOTE

Engine life-limited parts are those specified in Chapter 5 of Engine Manuals and Overhaul Manuals (for A0 engine model refer to TASK 05-10-01-200-001-A00 thru TASK 05-10-01-200-001-D00 and for D5 engine model refer to V2500-D5-05-10-0100-01A-288A-D), and those other high energy rotating parts such as, disks, spacers, hubs and shafts that have life limits in sections other than Chapter 5 in older overhaul manuals.For certain applications, hand-held peening is permitted. However, it is necessary to automated equipment to peen blades and life-limited rotating hardware in those areas with specified intensity.

Intensity and authorization requirements will be listed in the applicable technical data.

Each robot axis which controls the nozzle positions shall be numerically controlled and monitored with a process tolerance of plus or minus 0.062 inch (plus or minus 1.575 mm) or plus or minus 2 degrees.

Nozzle translation speed shall be computer numerically controlled and monitored with a process tolerance of plus or minus 10 percent.

Turntable shall be computer numerically controlled and monitored, with a process tolerance of plus or minus 10 percent or plus or minus 2 rpm, whichever is greater. When table indexing is required, turntable shall index plus or minus 1 degree. Table position shall be numerically controlled and monitored for position with a process tolerance of plus or minus 0.062 inch (plus or minus 1.575 mm).

Air pressure, through each nozzle, must be computer numerically controlled or computer controlled and monitored, with a process tolerance of plus or minus 2 psi (plus or minus 13.8 kPa).

Peening cycle time must be computer numerically controlled or computer controlled and monitored with a process tolerance of plus or minus 5 seconds for each individual dwell position.

Machines equipped with shot flow controllers shall have a process tolerance of plus or minus 20 percent. Machines utilizing a fixed orifice to meter shot flow, shall be equipped with shot flow monitors. Shot flow monitors shall be calibrated for each nozzle/orifice plate combination at minimum and maximum usable pressures. Orifice plate size shall be documented.

Machine preventative maintenance and verification of the above parameters must be performed annually, at a time interval that is not more than 14 months. It is necessary to keep a record of the maintenance and results of verification.

The computer controller must interrupt the peening cycle within 5 seconds after nozzle speed, turntable speed, air pressure, or shot flow outside of the specified tolerance is sensed. The computer controller must provide a message of the fault. After the out-of-tolerance condition is corrected, continue the peening cycle from the position of interruption to complete the balance of the operation.

Shotpeening of areas on parts designated as "peening critical" (where the words "peening critical" are specified in the repair) is subject also to the requirements of AMS 2432 (Shotpeen, Computer Monitored), except as follows to be in compliance with the more stringent controls of PWA 36930 Computer Controlled Peening:

Moveable nozzle(s) that direct the spray streams of cast steel shot or conditioned cut steel wire in a controlled and repeatable manner.

A machine function that lets the stream flow of cast steel shot or conditioned cut steel wire stabilize before the nozzles are aimed at the part.

A rotating or traversing table that moves the part at a specified rate through the spray stream of cast steel shot or conditioned cut steel wire.

A mechanism that automatically moves the cast steel shot or conditioned cut steel wire and feeds it through the machine to the nozzles.

A timing device that controls the peening time.

A meter to record machine operation hours.

A separator that automatically removes broken and deformed shot during machine operation.

A device that contains and controls the dust and other unwanted material that is a result of the shotpeening process.

The shotpeen machine must have the features in the subsequent list:

Keeps a constant table rotation or movement of the traversing table to prevent shot spray on one location for too much time.

Shuts off the peening cast steel shot or conditioned cut steel wire stream air pressure supply to stop the spray of cast steel shot or conditioned cut steel wire when the rotation or movement of the table stops.

The automated shotpeen machine must have a start-and-stop safety interlock switch that:

The Almen gage must have 0.0001 inch (0.0025 mm) maximum graduations. Refer to SAE J442 Surface Vehicle Standard for Test Strip, Holder, and Gage for Shot Peening.

Almen test strips and Almen gages are available from the sources in the list that follows and are also available from other sources. Refer to the V2500-00-00-00-00-00A-00KA-D for Vendor List for the source names/addresses identified by these numbers.

Almen Test Strips:

Almen Gage:

1LUR8

0CJ83

3W485

3W485

92830

Almen test strips, Test blocks, and gauges must agree with the requirements of AMS 2430.

Equipment:

Do all necessary FPI, FMPI, or other NDT inspections before peening. Do all necessary FPI, FMPI, or other NDT inspections before peening.

For all rotating parts with blade slots, for which re-peening is necessary, shotpeen blade slots to an intensity of 6A, unless specified differently.

When no specific areas to be peened are indicated, parts must be peened on all areas other than small holes and cavities to which the beads have no access.

Unless specified differently, surfaces of holes (other than lightening holes that open into areas where shotpeening is specified) and all keyways must show no indications of peening.

When shotpeening of gear teeth and splines is specified, the total area of flank surfaces, top lands, and roots of teeth must be peened to the specified intensity; ends of teeth must be peened but the minimum peening intensity requirement will be waived.

For all life-limited rotating parts that are to be plasma coated, shotpeen the area to be coated to an intensity of 6A, unless specified differently. This procedure is included in TASK 70-34-18-380-501.

"Peening optional" means that peening on the areas shown is optional and can have full, partial, or no coverage.

If it is necessary to specify a different tolerance on peening intensity, then specify a range of intensity or specify a basic intensity with a tolerance. For example, an intensity of either 12 - 15A or 12A +3/-0 shows an arc height of 0.012 - 0.015 inch (0.305 - 0.381 mm) on the Almen "A" test strip.

Unless specified differently, the variation in boundaries of areas to be peened, when limited, must be minus 0.000 to plus 0.125 inch (3.175 mm) into the area where peening is not specified.

A +30 percent/-0 arc height difference from the specified intensity is permitted, but with no less than 3 Almen units or 0.003 inch (0.076 mm) arc height, unless specified differently for a specific part.

EXAMPLE: If the intensity specified for a part is 10A, an arc height of 0.010 - 0.013 inch (0.254 - 0.330 mm, or +30 percent/-0) is satisfactory; if the specified intensity for another part is 6A, an arc height of 0.006 - 0.009 inch (0.153 - 0.228 mm, or +50 percent/-0) is satisfactory. In each example, it is best to have the mean arc height to make sure that a small decrease or increase in shop air pressure will not put the peening intensity out of the specified limits.

To make arc height measurements on the Almen gage, put the test strip on the gage so that the indicator pointer pushes against the test strip surface that is not peened. The arc height is read over a chordal length of 1.25 inches (31.750 mm).

Almen test strips must be flat within 0.000 inch plus or minus 0.001 inch (0.000 mm plus or minus 0.025 mm) when measured on an Almen gage. When you measure the flatness of the specimen, you must make an adjustment for the effect of the gage magnet; measure the flatness from both faces of the specimen and then get an average of the results.

Record the Almen test strip readings and be sure to keep these records for each part to show that the part agrees with the intensity requirements. You must keep these records for a time that agrees with regulatory and customer requirements for quality records.

It is necessary to plot saturation curves to find the parameter values that are necessary for the peening procedure to give the specified intensity on a repair surface. If you change to an alternative peening media of different type (cast vs. cut wire), size, or hardness, it is necessary to plot saturation curves to find the correct parameter values for the alternative media.

When necessary, you can get taper peening on a surface if you put this surface in the fringe area of the peening stream. In the taper peen area, the intensity and coverage must gradually approach zero.

Process Requirements.

SUBTASK 70-38-13-300-001 General Requirements

SHOTPEENING: The use of a high-speed stream of cast steel shot or conditioned cut steel wire, propelled by air pressure, that hits the part surface to cause compressive stress. The compressive stress gives increased fatigue strength and resistance to stress corrosion.

PEENING INTENSITY: A measure of the energy of the cast steel shot or conditioned cut steel wire stream indicated by the arc height of a peened Almen test strip at the saturation point on a saturation curve.

COVERAGE: The percentage of the specified part surface that has been peened so that visual inspection at 10X minimum magnification shows a continuous pattern of dimples that overlap and that is the same in all areas and obliterates, or removes, the initial surface finish.

FULL COVERAGE: One hundred percent of the specified part surface shows a continuous pattern of dimples that overlap and that is the same in all areas and obliterates, or removes, the initial surface finish as seen by visual inspection at a minimum of 10X magnification.

MULTIPLE COVERAGE: The minimum peening time to get full coverage is multiplied to get coverage greater than full coverage. For example, the time to get 125 percent coverage is 1.25 times the minimum time for full coverage, and the time to get 200 percent coverage is 2.0 times the minimum time for full coverage.

SATURATION CURVE: A plot of the Almen test strip arc height in relation to the test strip peening time.

SATURATION POINT: The point on the saturation curve at the minimum peening time for which the Almen test strip arc height will increase by not more than 10 percent at 2.0 times the peening time.

SUBTASK 70-38-13-300-002 Definitions

Cast steel shot (for example, AMS 2431/1 or AMS 2431/2): After each 40 hours maximum of operation.

Steel (non-stainless) cut wire shot (for example, AMS 2431/3 or AMS 2431/8): After each 80 hours maximum of operation.

Stainless steel cut wire shot (for example, AMS 2431/4): After each 120 hours maximum of operation.

Do a sieve analysis test at the applicable interval. Use the procedures in the latest revision to AMS 2430 and AMS 2431 in accordance with ASTM E11 and ASTM B214.

SUBTASK 70-38-13-380-001 Examine the Cast Steel Shot and the Conditioned Cut Wire Shot and the Equipment

Use the shot that the repair specifies, but if the repair specifies only cast steel shot, then it is permitted to use one of the conditioned cut wire shot peening media in the same shot size group below as an alternative peening media.

Where S-110/ASR 110/CW-14/AWCR 14/SCW-14/AWS 14 shot size is specified, use one of the peening media in the subsequent list.

Where S-170/ASR 170/CW-20/AWCR 20/SCW-20/AWS 20 shot size is specified, use one of the peening media in the subsequent list.

NOTE

It is not permitted to use S-230 shot unless specified in a repair.Where S-230/ASR 230/CW-28/AWCR 28 shot size is specified, use one of the peening media in the subsequent list:

Use one of the peening media from the shot size group below that agrees with the specified shot size in the repair.

NOTE

S-170/ASR 170/CW-20/AWCR 20/SCW-20/AWS 20 cast steel shot or conditioned cut wire shot can be an alternative for the S-110/ASR 110/CW-14/AWCR 14/SCW-14/AWS 14 shot only when the smallest nominal radius of any fillet in the area to be peened is 0.034 inch (0.864 mm) or larger.NOTE

If the repair does not specify the size of the high-hardness shot, then it is necessary to use S-110/ASH 110/CW-14/AWCH 14/SCW-14/AWS 14 size high-hardness shot.Where S-110/ASH 110/CW-14/AWCH 14/SCW-14/AWS 14 shot size is specified, use one of the peening media in the subsequent list:

Where S-170/ASH 170/CW-20/AWCH 20/SCW-20/AWS 20 shot size is specified, use CoMat 05-236 CAST STEEL SHOT, HIGH HARDNESS, S170.

Where S-230/ASH 230/CW-28/AWCH 28 shot size is specified, use CoMat 05-247 METALLIC SHOT (CAST STEEL), HIGH HARDNESS, S230.

If the repair procedure specifies that it is permitted to use peening media that is harder than 55 HRC, or if the repair procedure does not specify the hardness of the peening media, then it is permitted to use the high-hardness peening media from the applicable shot size group:

Fill the machine with the necessary amount of applicable peening media that follow:

SUBTASK 70-38-13-380-006 Fill the Shotpeening Machine

Put the necessary number of Almen "A" test strips in a Test block.

Put the Test block on the rotating table in the machine cabinet. The Almen A test strip surface to be shotpeened must be in the correct position. The position must be exactly the same as that of the surface of the part to be shotpeened.

NOTE

Refer to the latest revision of the AMS 2430 specification for test strip and block data.Set the position of the fixed nozzle or nozzles so that the peening streams have an angle of impingement as close to 90 degrees as possible to the areas to be peened.

NOTE

The arc height must be determined for each test strip on the fixture at the start and at the end of each lot (same set-up, parameters, and test piece fixture) and at the start of each work shift for a minimum of every eight hours of machine operation.If area to be peened is wider than the blast spray pattern of a single nozzle, set up additional fixed nozzles, with overlapping spray, to be sure the area is fully shot peened.

Remove the test strips from the cabinet and measure them with the Almen gage No.2.

To find the air pressure that is necessary to get the arc height for the specified intensity, do the subsequent procedure:

NOTE

If more than one nozzle is to be used for coverage, all the nozzles must be turned on for this test.A separate test strip must be used for each part dimension that requires intensity.In no case must a peened specimen, after removal from the holding device, be installed again for additional peening.Put a new test strip in the Test block.

If the arc height is not of the average specified for the part, do as follows:

Remove the Test block.

SUBTASK 70-38-13-380-002 Calibrate the Shotpeening Machine

NOTE

One test strip is necessary for each nozzle to be used.Measure the arc height of each strip on an Almen gage.

Make a plot of the arc height in relation to the peening time to get a saturation curve. Refer to SAE J443 Procedures for Using Standard Shot Peening Test Strip. Peen more Almen test strips for different lengths of time if more data points are necessary.

NOTE

Test strips peened for the saturation time or longer must show full coverage.The saturation point is at the minimum peening time for which two times the peening time will increase the arc height by not more than 10 percent or 0.001 inch (0.025 mm), whichever is greater. The arc height at the saturation point is the peening intensity.

If the peening intensity is not in the tolerance limits specified for the part, adjust the air pressure or table speed, or use a different size shot, and then do this saturation curve procedure again.

The arc height must be determined for each test strip on the fixture at the start and at the end of each lot (same set-up, parameters, test piece fixture), the start of each work shift, and a minimum of every eight hours of machine operation.

Peen a minimum of four Almen test strips for different lengths of time at the same pressure and table speed.

Remove the Test block.

Remove the masking tape, if used, from the part and clean away remaining masking by the solvent wipe method, if necessary. Refer to SPM TASK 70-11-26-300-503.

Clean the part, if necessary. Refer to SPM TASK 70-11-03-300-503.

Visually examine the shotpeening of the part; use 10X magnifying glass to examine the part.

CAUTION

ANY POST-PEEN PROCESSING MUST AGREE WITH THE LATEST MATERIAL REMOVAL REQUIREMENTS OF AMS 2430. FAILURE TO COMPLY WITH THESE REQUIREMENTS COULD CAUSE A LOSS OF THE COMPRESSIVE STRESS THAT WAS A RESULT OF THE PEENING PROCESS.Preserve the parts in a corrosion preventive, as necessary. Refer to TASK 70-38-05-300-503.

SUBTASK 70-38-13-380-004 Inspect the parts

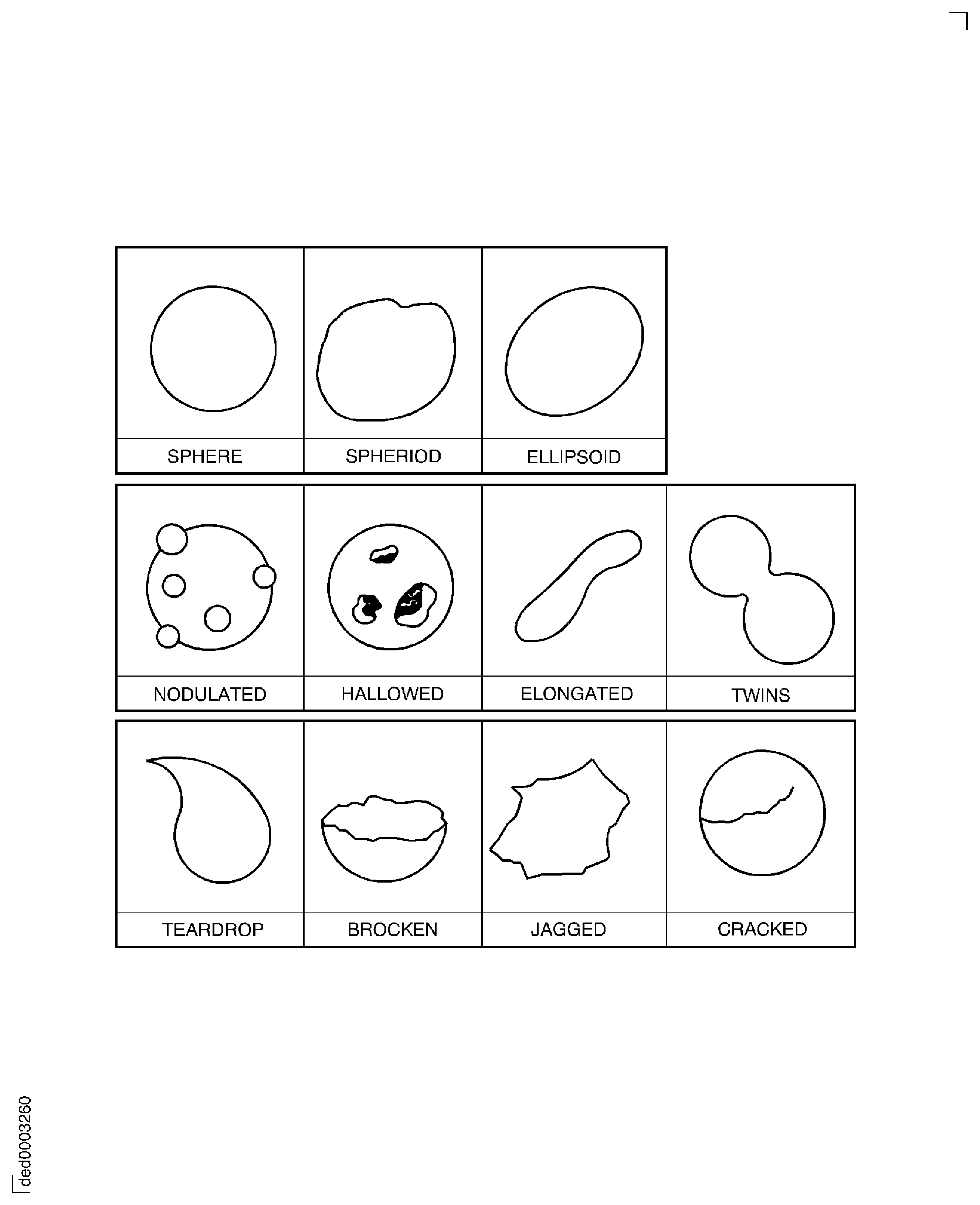

Figure: Metallic media shape allowance

Metallic media shape allowance