Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-20-300-033 HPT Stage 1 Vane - Airfoil Touch-Up Coating Repair, Repair-033 (VRS3613)

General

Price and availability - Refer to IAE

The practices and processes referred to in the procedure by TASK number are in the SPM.

Refer to Figure.or the area that is to be repaired.

Repair Facilities

The proprietary nature of this repair requires that any facility not authorized to accomplish this repair either utilize the Authorized Repair Vendors listed below or contact IAE Repair Development Group to determine if a qualification program can be initiated at their facility.

ATTN: Manager Maintenance Operations

IAE International Aero Engines AG

400 Main Street M/S 121-10

East Hartford, CT 06108

USA

Authorized repair vendors for repair VRS3613 are listed below:

Pratt and Whitney Engine Services

North Haven Airfoil Repair Operation

415 Washington Avenue

North Haven, CT 06473

USA

Pratt and Whitney Global Service Partners,

Dallas Airfoil Repair Operations (GSP-DARO)

1177 Great Southwest Parkway - Mail Stop 970-00

Grand Prairie, TX 75050

USA

Tel: (972) 343-1300

Fax: (972) 343-1301

The designation of an authorized vendor indicates that the repair vendor has demonstrated the necessary capability to enable it to carry out the listed repair work. However, IAE makes no warranties or representations concerning the qualifications or quality standards of the repair vendors to carry out the repair work and accepts no responsibility whatsoever for any work that may be carried out by a repair vendor, other than when IAE is listed as the repair vendor. Authorized repair vendors do not act as agents or representatives of IAE.

NOTE

The application of IAE 265 is intended to provide an expedient and economical method of local airfoil coating touch-up repair.

It may be used only when there is no visual evidence of oxidation or corrosion degradation of the base metal.

In no case shall the application of IAE 265 be used as a substitute for the primary coating systems during complete coating refurbishment.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to TASK 72-44-20-200-000 (INSPECTION-000).

Examine the vane after the repair.

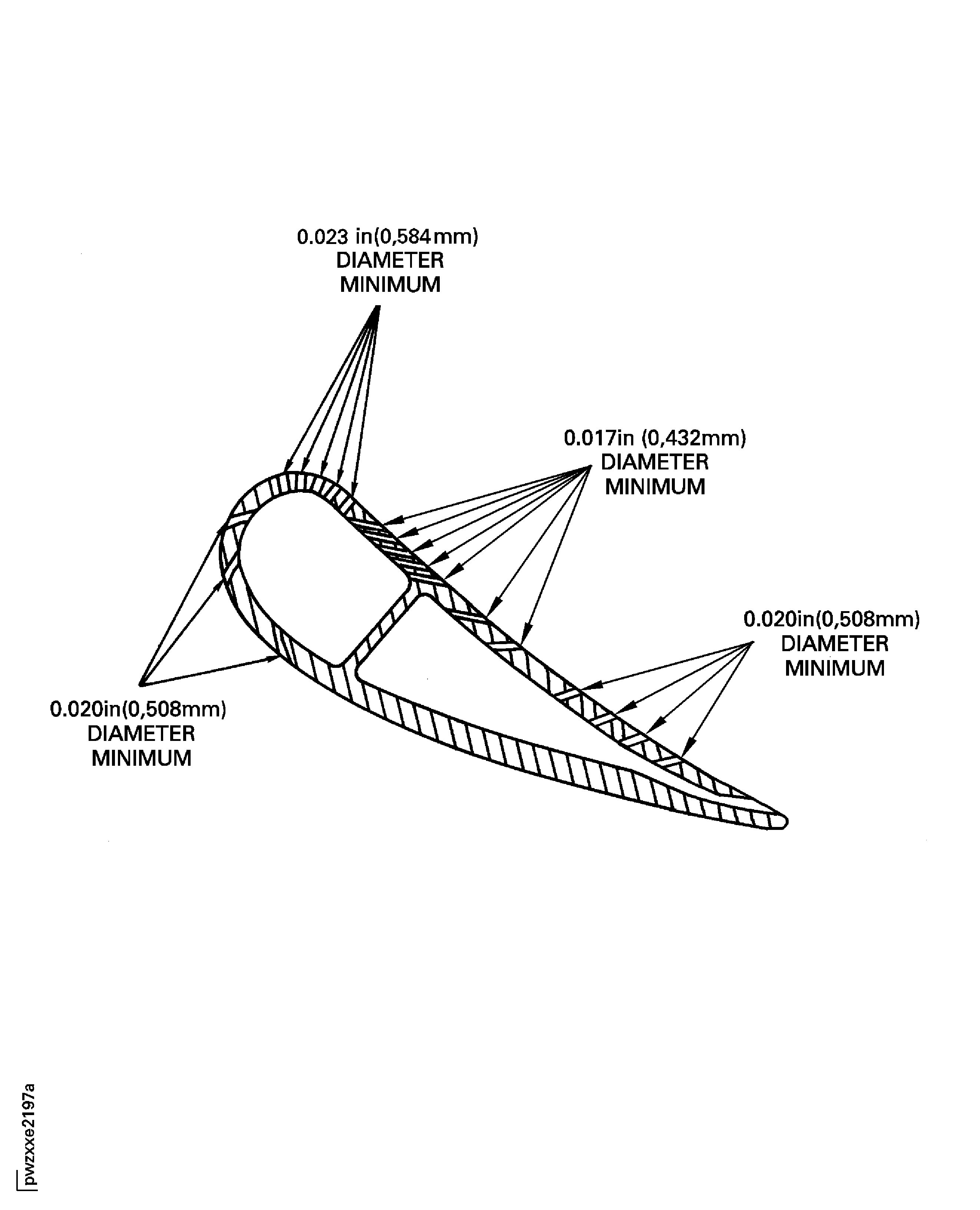

All cooling holes must be at the minimum diameter. If applicable, open all holes to the minimum diameter. Refer to TASK 72-44-20-300-032 (REPAIR-032).

Refer to Figure.

Examine the platform cooling holes.

SUBTASK 72-44-20-300-001 Examine the Repair

Figure: (V2500-A1) Stage 1 HPT Vane (PN 2A5591) Cooling Hole repair Area

(V2500-A1) Stage 1 HPT Vane (PN 2A5591) Cooling Hole repair Area