Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-00-300-004 HPT Stage 2 Air Seal - Blend Repair On The Knife Edges, Repair-004 (VRS3207)

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before this repair. |

Support Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Balancing equipment | LOCAL |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

CAUTION

Procedure

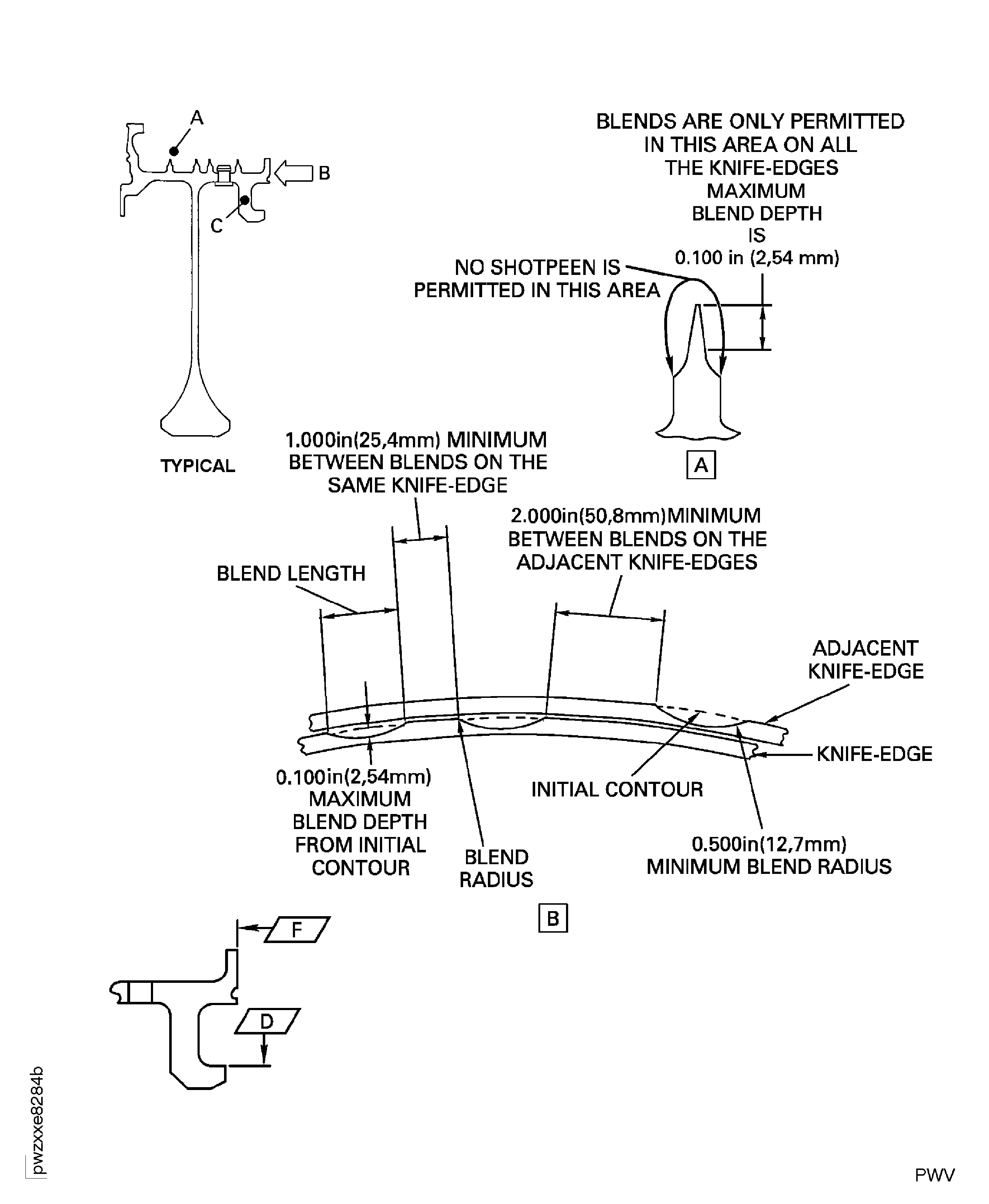

Use power blend method.

All blended areas must be smooth and continuous.

Blend smoothly into the initial knife-edge contour.

The maximum blend area for one knife-edge blend is 0.100 sq in. (65 sq mm).

The maximum cumulative blend area for all knife-edges is 0.200 sq in. (130 sq mm).

The minimum blend length to depth ratio is 15 to 1.

The minimum blend radius to depth ratio is 30 to 1.

Break the edges 0.003 in. to 0.015 in. (0.08 mm to 0.38 mm).

Chipped or missing coating at edges of blended areas is acceptable.

Blend 0.002 in. to 0.003 in. (0.05 mm to 0.08 mm) beyond damage.

Blend the knife-edge seals by SPM TASK 70-35-03-300-501.

SUBTASK 72-45-00-350-053-001 Blend the Stage 2 HPT Air Seal Knife-Edge Seals (Rotary Method)

All blended areas must be smooth and continuous.

Blend smoothly into the initial knife-edge contour.

The maximum blend area for one knife-edge blend is 0.100 sq in. (65 sq mm).

The maximum cumulative blend area for all knife-edges is 0.200 sq in. (130 sq mm).

The minimum blend length to depth ratio is 15 to 1.

The minimum blend radius to depth ratio is 30 to 1.

Break the edges 0.003 in. to 0.015 in. (0.08 mm to 0.38 mm).

Chipped or missing coating at edges of blended areas is acceptable.

Blend 0.002 in. to 0.003 in. (0.05 mm to 0.08 mm) beyond damage.

Blend the knife-edge seals by SPM TASK 70-35-03-300-501.

SUBTASK 72-45-00-350-053-002 Blend the Stage 2 HPT Air Seal Knife-Edges Seals (Manual Method)

Refer to SPM TASK 70-11-03-300-503.

Clean the air seal.

SUBTASK 72-45-00-110-001 Clean the Stage 2 HPT Air Seal

Do a fluorescent penetrant inspection of the repair area by the applicable part number task in TASK 72-45-00-200-000.

SUBTASK 72-45-00-230-055 Examine the Repair

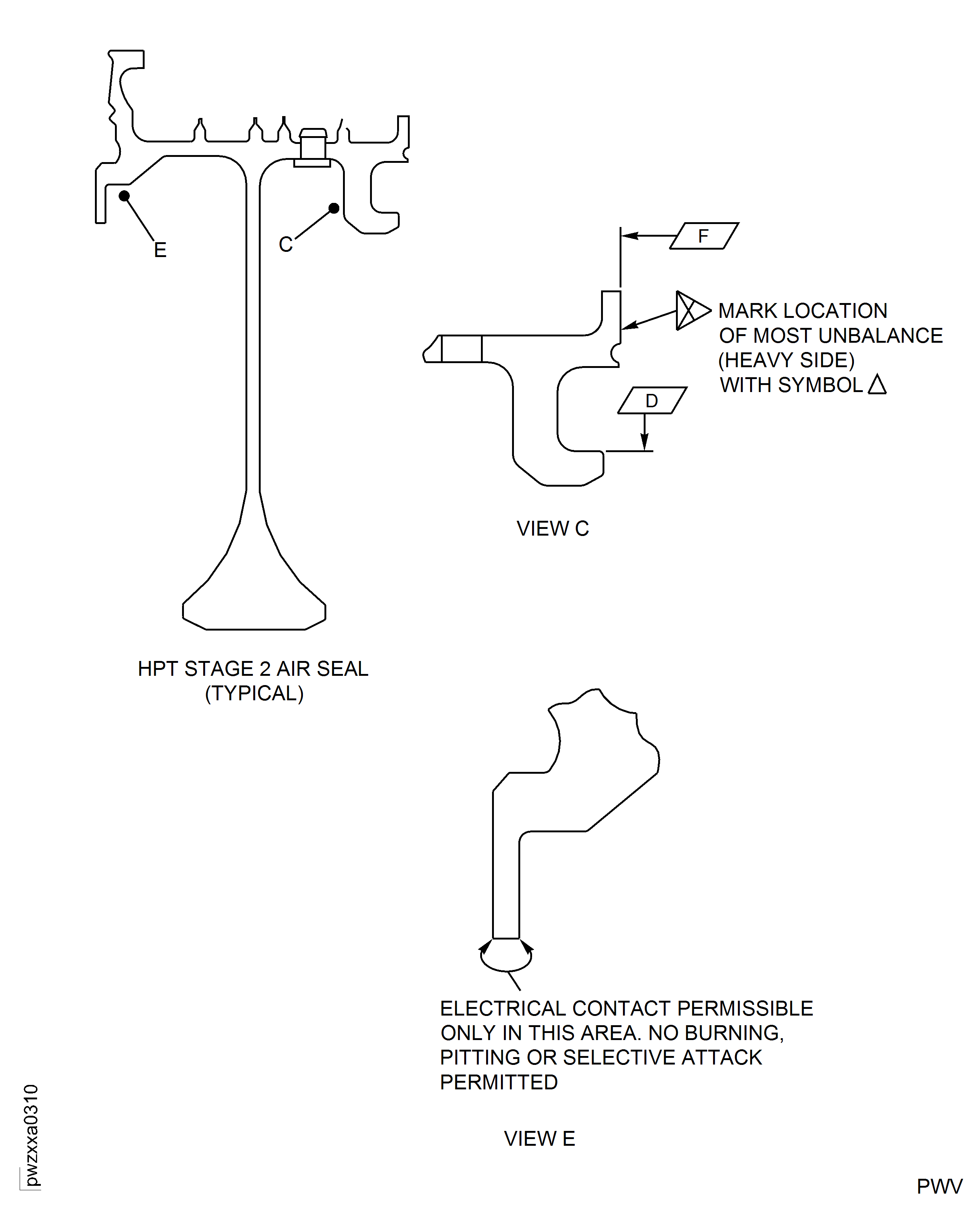

Install the HPT Stage 2 Air Seal into the fixture. Use appropriate fixture.

Constraint contact permitted only on Diameter D and Surface F. Use appropriate fixture.

Turn the HPT Stage 2 Air Seal at 900 RPM.

Record amount of unbalance in oz-in.

Static unbalance must not exceed 1.0 oz-in. (720.0 gmm). If static unbalance exceeds 1.0 oz-in. (720.0 gmm) then rebalance the HPT Stage 2 Air Seal by TASK 72-45-00-300-013 (REPAIR-013).

Remove prior unbalance marking and make a mark for amount and location of unbalance by TASK 70-09-00-400-501, Procedures to Make Permanent Identification And Location Marks. Use shallow electrolytic etch method only.

Do a balance check of the air seal after blend repair of the knife-edge seals.

SUBTASK 72-45-00-220-084 Examine the Air Seal for Balance After Blend Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Marking and Electrical Contact Location

Marking and Electrical Contact Location