Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-24-300-010 HPT Stage 2 Ring Segment And Vane Cluster - Unplug The Trailing Edge Slots And Cooling Holes, Repair-010 (VRS3317)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

02-070 | 2A0172CL21 |

02-071 | 2A0172CL22 |

02-072 | 2A0172CL23 |

02-073 | 2A0172CL24 |

02-074 | 2A0172CL25 |

02-075 | 2A0172CL26 |

02-076 | 2A0172CL27 |

02-077 | 2A0172CL28 |

02-078 | 2A0172CL29 |

02-079 | 2A0172CL30 |

02-080 | 2A0172CL31 |

02-081 | 2A0172CL32 |

02-082 | 2A0172DL33 |

02-083 | 2A0172CL34 |

02-084 | 2A0172CL35 |

02-087 | 2A0172CL38 |

02-088 | 2A0172CL39 |

02-089 | 2A0172CL40 |

02-090 | 2A0172CL41 |

02-093 | 2A0172CL36 |

02-094 | 2A0172CL36-5 |

02-095 | 2A0172CL37 |

02-096 | 2A0172CL37-5 |

02-270 | 2A1072CL21 |

02-271 | 2A1072CL22 |

02-272 | 2A1072CL23 |

02-273 | 2A1072CL24 |

02-274 | 2A1072CL25 |

02-275 | 2A1072CL26 |

02-276 | 2A1072CL27 |

02-277 | 2A1072CL28 |

02-278 | 2A1072CL29 |

02-279 | 2A1072CL30 |

02-280 | 2A1072CL31 |

02-281 | 2A1072CL32 |

02-282 | 2A1072CL33 |

02-283 | 2A1072CL34 |

02-284 | 2A1072CL35 |

02-287 | 2A1072CL38 |

02-288 | 2A1072CL39 |

02-289 | 2A1072CL40 |

02-290 | 2A1072CL41 |

02-293 | 2A1072CL36 |

02-294 | 2A1072CL36-5 |

02-295 | 2A1072CL37 |

02-296 | 2A1072CL37-5 |

02-070 | 2A2072CL21 |

02-071 | 2A2072CL22 |

02-072 | 2A2072CL23 |

02-073 | 2A2072CL24 |

02-074 | 2A2072CL25 |

02-075 | 2A2072CL26 |

02-076 | 2A2072CL27 |

02-077 | 2A2072CL28 |

02-078 | 2A2072CL29 |

02-079 | 2A2072CL30 |

02-080 | 2A2072CL31 |

02-081 | 2A2072CL32 |

02-082 | 2A2072CL33 |

02-083 | 2A2072CL34 |

02-084 | 2A2072CL35 |

02-087 | 2A2072CL38 |

02-088 | 2A2072CL39 |

02-089 | 2A2072CL40 |

02-090 | 2A2072CL41 |

02-093 | 2A2072CL36 |

02-094 | 2A2072CL36-5 |

02-095 | 2A2072CL37 |

02-096 | 2A2072CL37-5 |

02-270 | 2A2172CL21 |

02-271 | 2A2172CL22 |

02-272 | 2A2172CL23 |

02-277 | 2A2172CL28 |

02-278 | 2A2172CL29 |

02-279 | 2A2172CL30 |

02-280 | 2A2172CL31 |

02-281 | 2A2172CL32 |

02-282 | 2A2172CL33 |

02-283 | 2A2172CL34 |

02-284 | 2A2172CL35 |

02-287 | 2A2172CL38 |

02-288 | 2A2172CL39 |

02-289 | 2A2172CL40 |

02-290 | 2A2172CL41 |

02-293 | 2A2172CL36 |

02-296 | 2A2172CL37-5 |

02-070 | 2A2772CL21 |

02-071 | 2A2772CL22 |

02-072 | 2A2772CL23 |

02-073 | 2A2772CL24 |

02-074 | 2A2772CL25 |

02-075 | 2A2772CL26 |

02-076 | 2A2772CL27 |

02-077 | 2A2772CL28 |

02-078 | 2A2772CL29 |

02-079 | 2A2772CL30 |

02-080 | 2A2772CL31 |

02-081 | 2A2772CL32 |

02-082 | 2A2772CL33 |

02-083 | 2A2772CL34 |

02-084 | 2A2772CL35 |

02-085 | 2A2772CL36 |

02-086 | 2A2772CL37 |

02-087 | 2A2772CL38 |

02-088 | 2A2772CL39 |

02-089 | 2A2772CL40 |

02-090 | 2A2772CL41 |

02-270 | 2A2872CL21 |

02-271 | 2A2872CL22 |

02-272 | 2A2872CL23 |

02-273 | 2A2872CL24 |

02-274 | 2A2872CL25 |

02-275 | 2A2872CL26 |

02-276 | 2A2872CL27 |

02-277 | 2A2872CL28 |

02-278 | 2A2872CL29 |

02-279 | 2A2872CL30 |

02-280 | 2A2872CL31 |

02-281 | 2A2872CL32 |

02-282 | 2A2872CL33 |

02-283 | 2A2872CL34 |

02-284 | 2A2872CL35 |

02-285 | 2A2872CL36 |

02-286 | 2A2872CL37 |

02-287 | 2A2872CL38 |

02-288 | 2A2872CL39 |

02-289 | 2A2872CL40 |

02-290 | 2A2872CL41 |

02-050 | 2A3372 |

02-050 | 2A3812 |

02-250 | 2A2272 |

02-260 | 2A2372 |

02-260 | 2A3472 |

02-260 | 2A3822 |

02-260 | 2A317 |

02-070 | 2A3272CL21 |

02-071 | 2A3272CL22 |

02-072 | 2A3272CL23 |

02-073 | 2A3272CL24 |

02-074 | 2A3272CL25 |

02-075 | 2A3272CL26 |

02-076 | 2A3272CL27 |

02-077 | 2A3272CL28 |

02-078 | 2A3272CL29 |

02-079 | 2A3272CL30 |

02-080 | 2A3272CL31 |

02-081 | 2A3272CL32 |

02-082 | 2A3272CL33 |

02-083 | 2A3272CL34 |

02-084 | 2A3272CL35 |

02-085 | 2A3272CL36 |

02-086 | 2A3272CL37 |

02-087 | 2A3272CL38 |

02-088 | 2A3272CL39 |

02-089 | 2A3272CL40 |

02-090 | 2A3272CL41 |

02-050 | 2A5102 |

02-260 | 2A5202 |

02-050 | 2A5502 |

02-050 | 2A5602 |

General

Price and availability - refer to IAE

The practices and processes referred to in this procedure by TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Reamers | LOCAL | Reamers | ||

| Spring wire | LOCAL | Spring wire | ||

| Ultrasonic cleaning equipment | LOCAL | Ultrasonic cleaning equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-339 ALKALI CLEANER (GENERAL PURPOSE) | LOCAL | CoMat 01-339 | ||

| CoMat 10-058 PENETRATING OIL | 0AM53 | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

Apply CoMat 10-058 PENETRATING OIL to the holes.

Let the oil soak into unwanted material in the holes.

Use a rotary motion while you probe.

Intermittently move the reamer farther into the hole and then remove it while you hold the vane so the holes point down to let unwanted material fall out.

Unplug the trailing edge slots and the cooling holes with a reamer. Use spring wire with a pin vise if you cannot reach an area with a reamer.

SUBTASK 72-45-24-350-078 Unplug the Trailing Edge Slots and the Cooling Holes

CAUTION

REAMERS ARE RECOMMENDED AS AN ALTERNATIVE TO SPRING WIRE OR DRILL BITS FOR THE INITIAL PROBING. WIRE CAN BREAK OFF LARGER PIECES OF UNWANTED MATERIAL AND FORCE THEM INTO THE INTERNAL CAVITY. DRILLS BREAK EASIER AND CAN GET CAUGHT IN THE HOLE.Refer to the SPM TASK 70-13-02-300-501.

Use CoMat 01-339 ALKALI CLEANER (GENERAL PURPOSE) at a temperature of 150 deg F (66 deg C) maximum.

Position the vane at different angles to remove unwanted material from the inner areas of the vane.

NOTE

Ultrasonics will increase the temperature of the solution.

Do an ultrasonic cleaning to remove unwanted material from internal areas.

SUBTASK 72-45-24-130-054 Clean the Vane Assembly

Refer to the SPM TASK 70-72-01-720-501.

If the airflow is not sufficient, hand probe the holes again.

Increase the hole size in small increments. Hand probe only a few holes at a time so you do not cause too much airflow.

If there is too much airflow, examine the vanes again to find out if the condition is caused by the vane or by air leaks in the test setup.

If there is too much airflow, reject the vanes.

Do an airflow check of the airfoil holes in the vane cluster assembly. It is not necessary to do an airflow check of the platform cooling holes.

SUBTASK 72-45-24-720-051 Do an Airflow Check of the Vane Cluster Assembly

Refer to the SPM TASK 70-13-02-300-501.

Use CoMat 01-339 ALKALI CLEANER (GENERAL PURPOSE) at a temperature of 150 deg F (66 deg C) maximum.

NOTE

Ultrasonics will increase the temperature of the solution.

Do an ultrasonic cleaning to remove unwanted material from internal areas.

SUBTASK 72-45-24-130-055 Clean the Vane Assembly

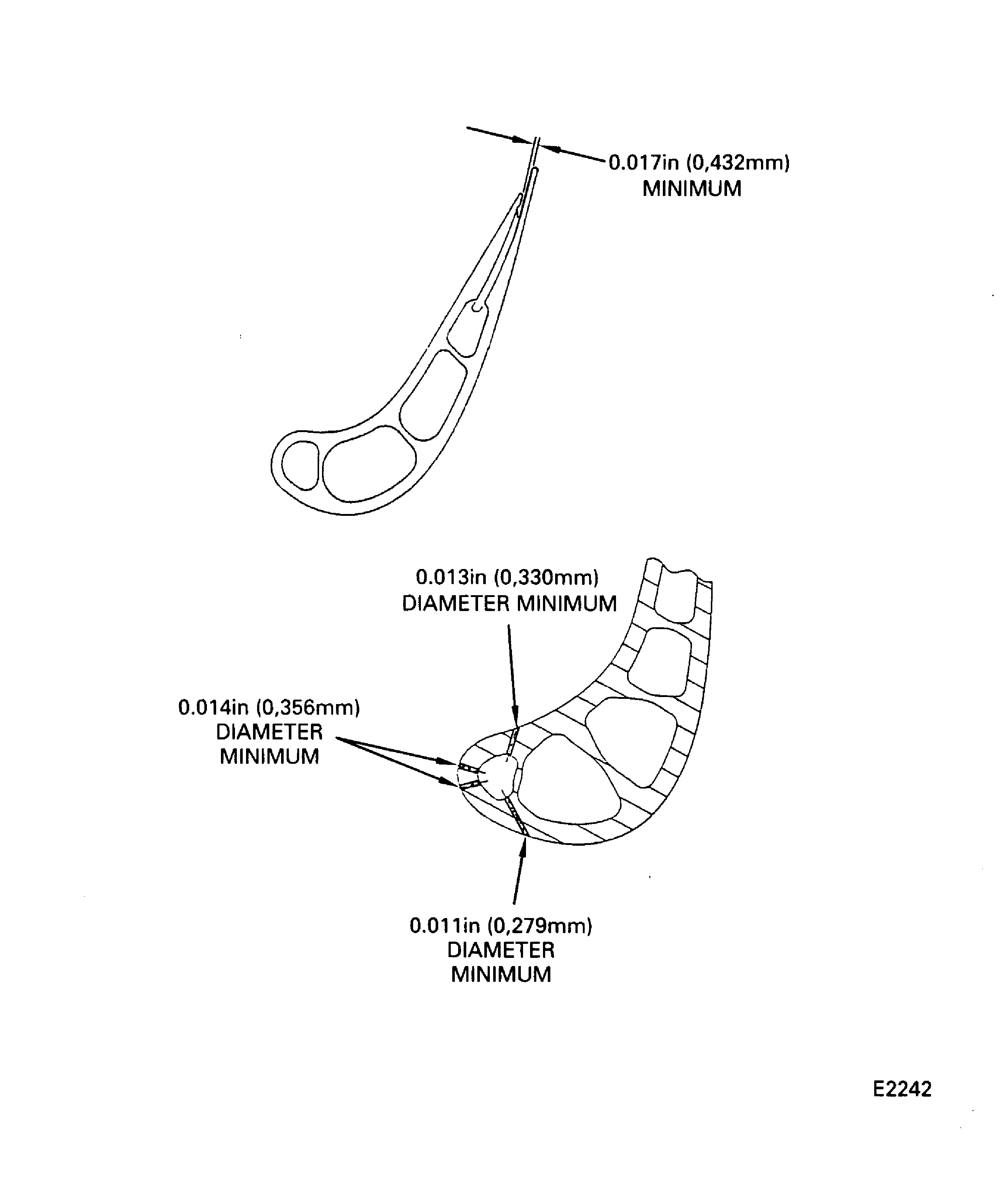

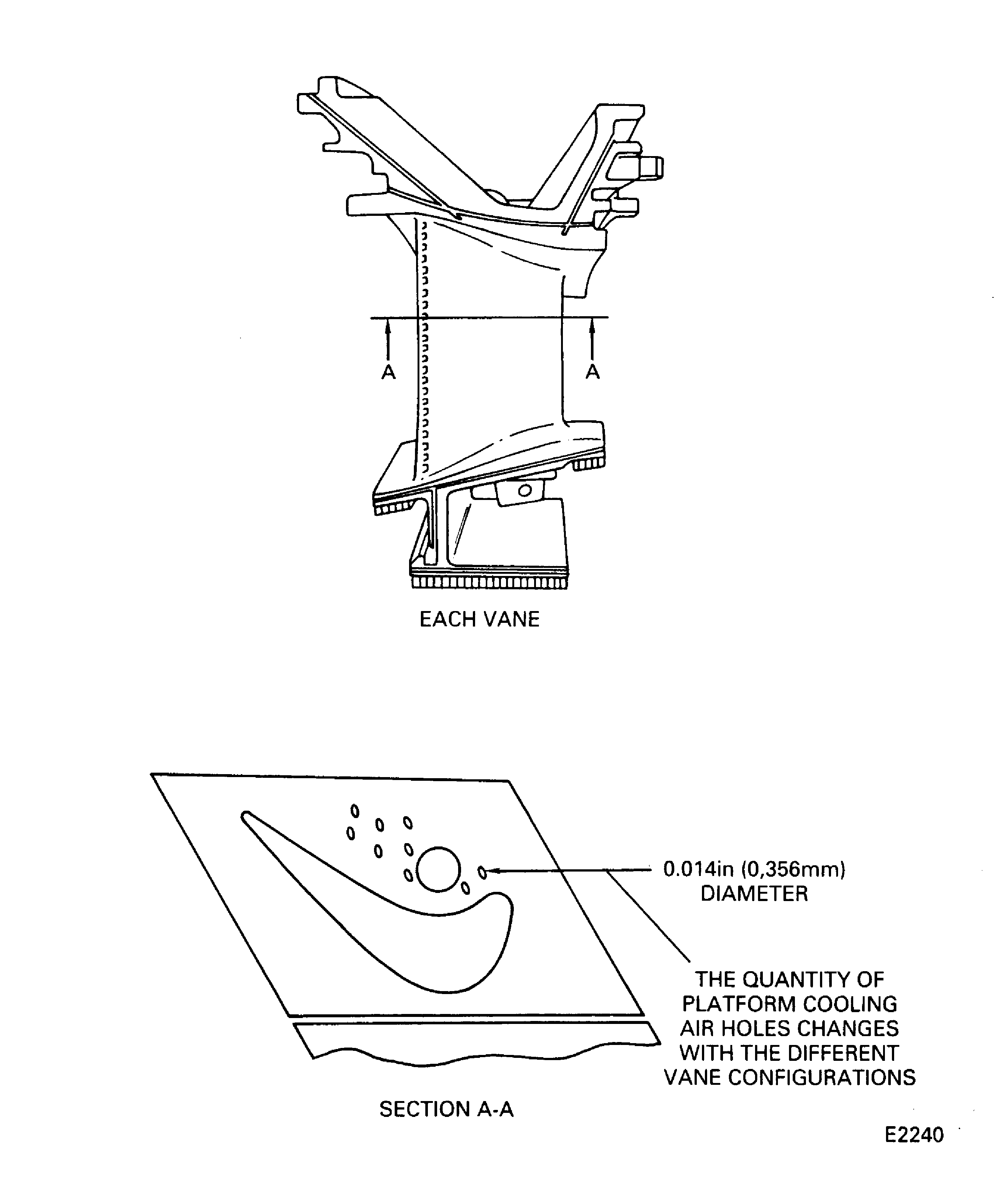

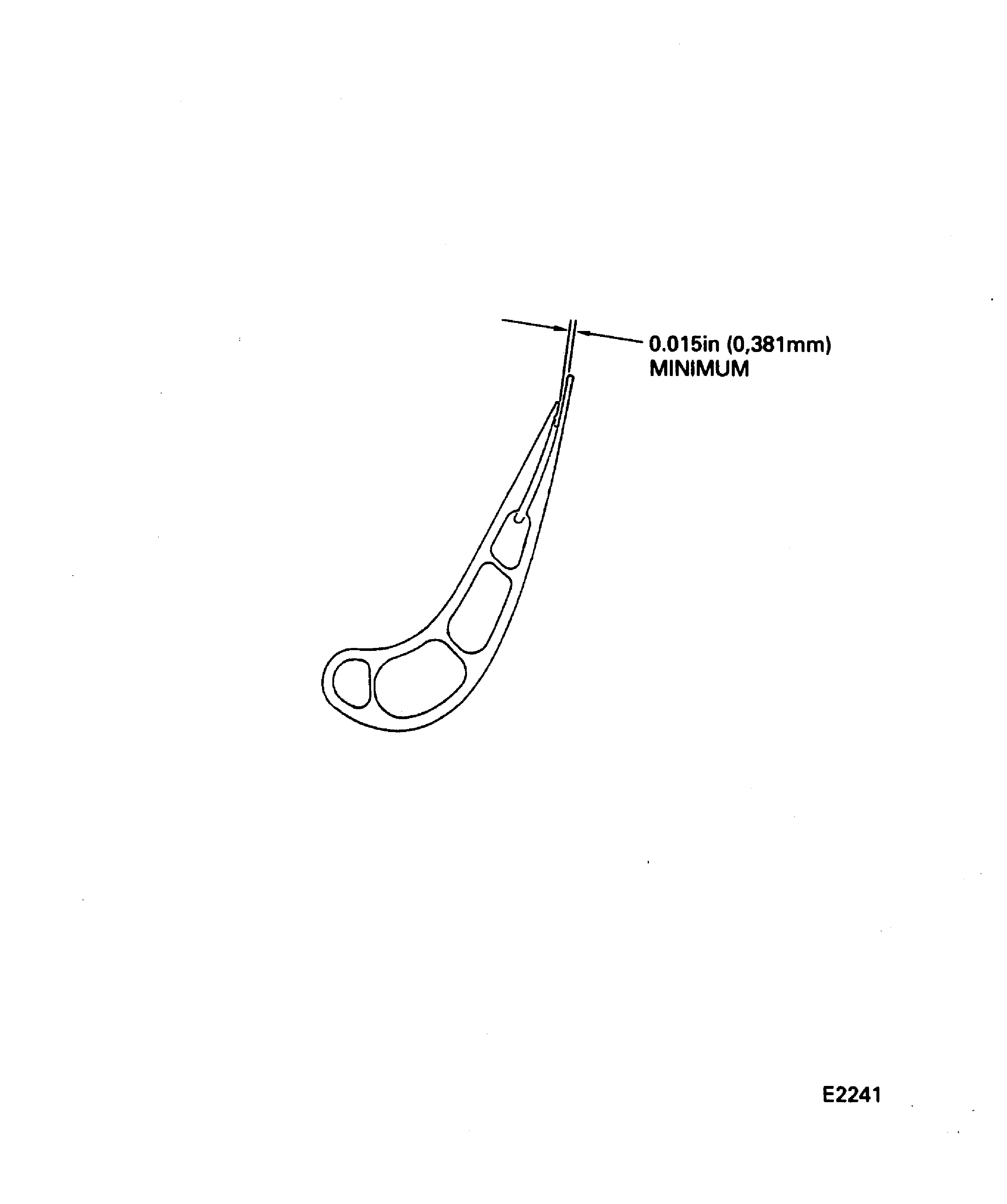

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions