Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-23-300-061 Weld Repair the Rear Faces of the Stage 3 Shroud Seal Segment, Repair 061 (VRS4558)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Hand held grinder | LOCAL | Hand held grinder | ||

| IAE 3M14212 Grinding/turning fixture | 0AM53 | IAE 3M14212 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-287 WELDING FILLER WIRE | LOCAL | CoMat 03-287 |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-11-03-300-503.

Aqueous cleaning.

SUBTASK 72-50-23-110-166 Clean the Stage 3 Shroud Seal Segment

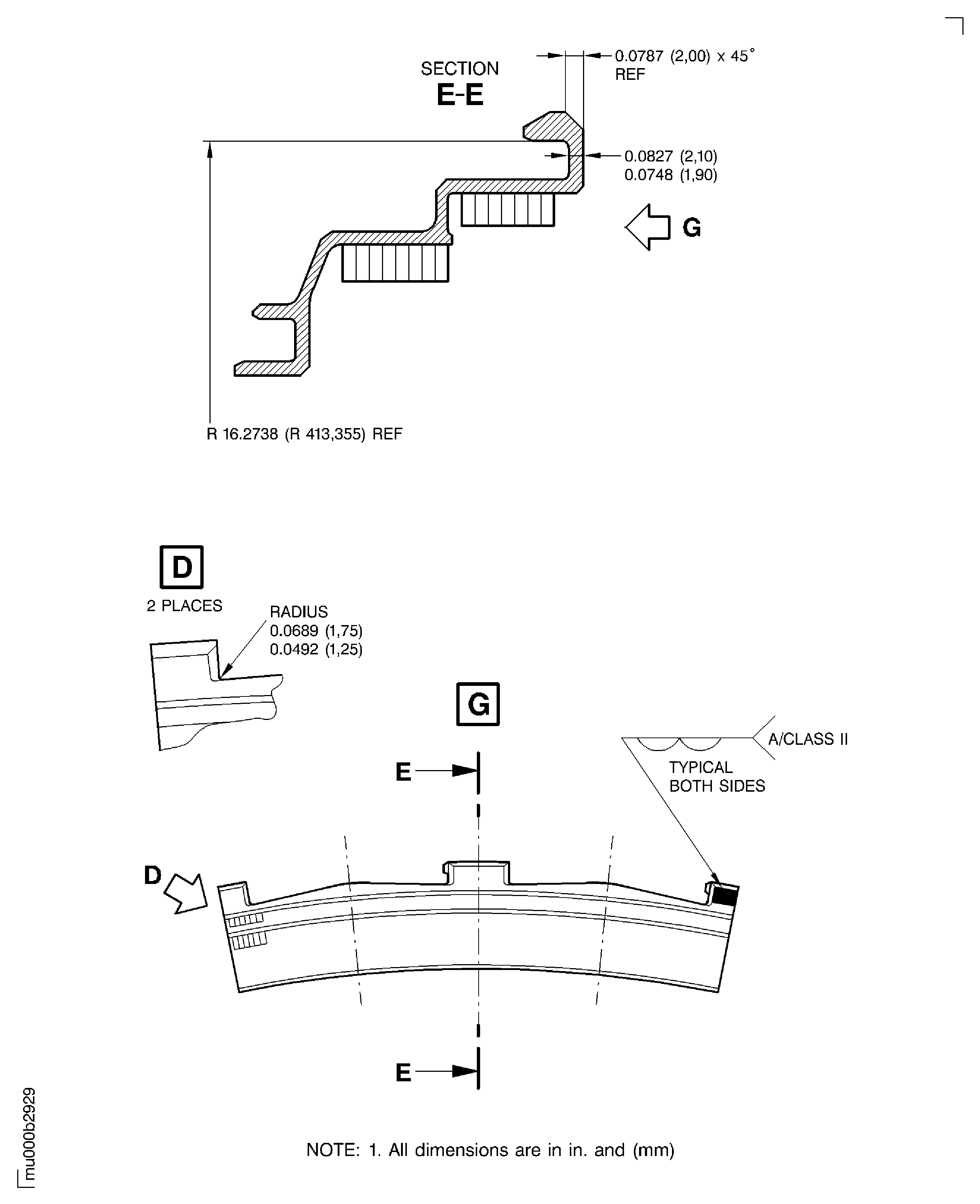

Refer to Figure.

Refer to the SPM TASK 70-31-13-310-501. Make sure that there is sufficient material to do last machining.

Use CoMat 03-287 WELDING FILLER WIRE. To prevent honeycomb braze damage, several weld passes should be made. Prevent too much temperature build-up.

Gas tungsten arc weld the worn surfaces.

SUBTASK 72-50-23-310-098 Weld Repair the Worn Surfaces

Refer to Figure.

Use cold work.

Make sure that the shroud seal segment aligns with the IAE 3M14212 Grinding/turning fixture 1 off.

Bend the shroud seal segment back to shape if required.

SUBTASK 72-50-23-320-092 Dress the Welded Areas

CAUTION

DO NOT OVERHEAT THE AREAS WHICH ARE DRESSED.Refer to Figure.

Examine dimensionally.

SUBTASK 72-50-23-220-178 Examine the Machined Areas

Refer to the SPM TASK 70-11-03-300-503.

Aqueous cleaning.

SUBTASK 72-50-23-110-167 Clean the Stage 3 Shroud Seal Segment

Figure: Repair Details and Dimensions

Repair Details and Dimensions