Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-32-840-001 LPT Stage 3 Blade - Weld Build Up For Shingling Stop, Rework-001 - SBE72-0134

General

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Refer to the indicated Service Bulletin for specific application requirements

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 3M14382 Welding fixture | 0AM53 | IAE 3M14382 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-283 COATING ALLOY | 0CZB2 | CoMat 03-283 |

Spares

NONESafety Requirements

NONEProcedure

Refer to TASK 72-50-32-200-000 (INSPECTION/CHECK-000).

Inspect turbine blade.

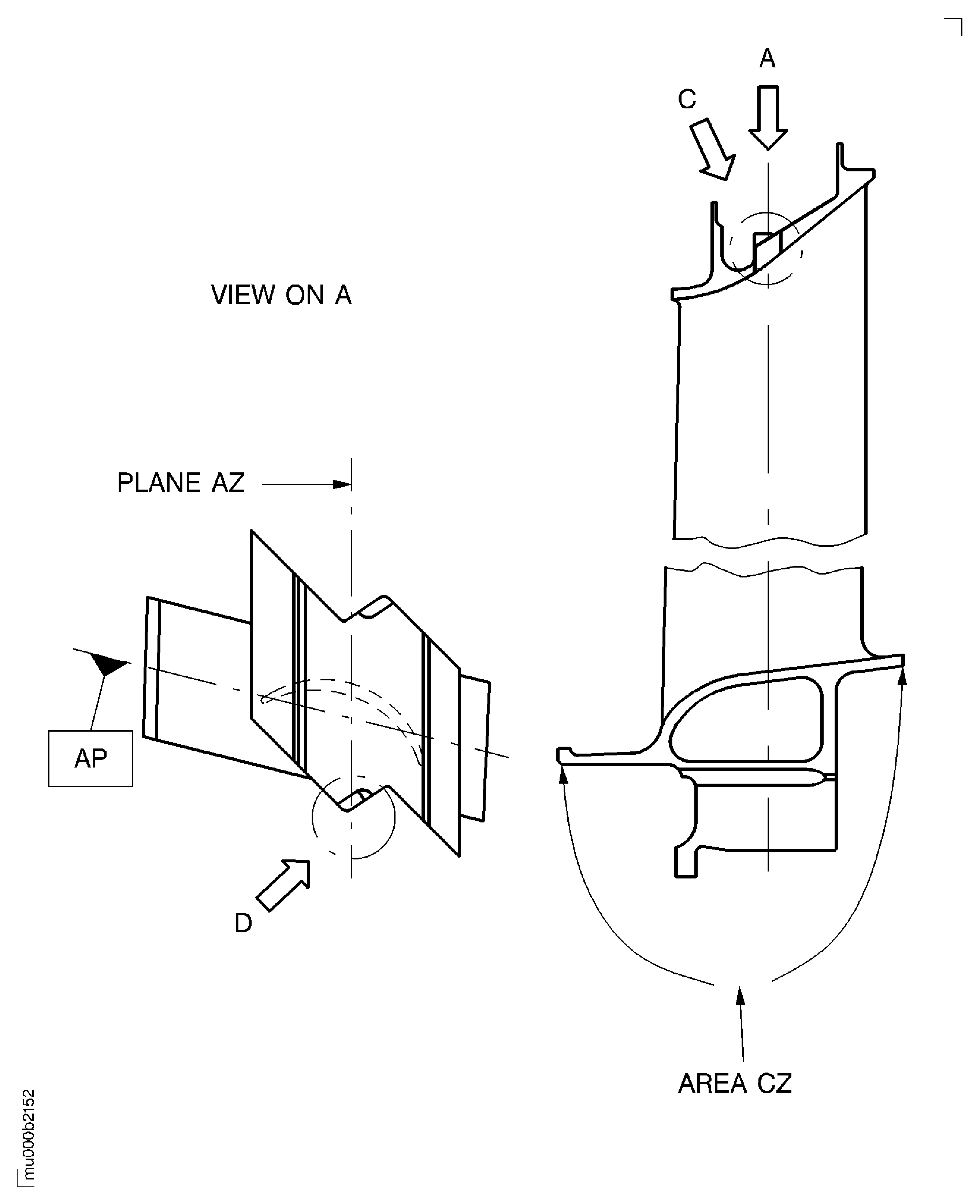

SUBTASK 72-50-32-350-113 General Instructions for the Rework of the Stage 3 LP Turbine Blades

Locally remove aluminide coating from shroud surface.

Refer to Figure.

Install the blade into IAE 3M14382 Welding fixture welding fixture 1 off.

Locally remove the aluminide coating.

SUBTASK 72-50-32-350-114 Prepare the Turbine Blade for Build Up Welding

Refer to the SPM TASK 70-31-08-310-501.

Use CoMat 03-283 COATING ALLOY to the dimensions given in Figure.

Electrical contact in area CZ is permitted.

No burring, no selective attack are permitted.

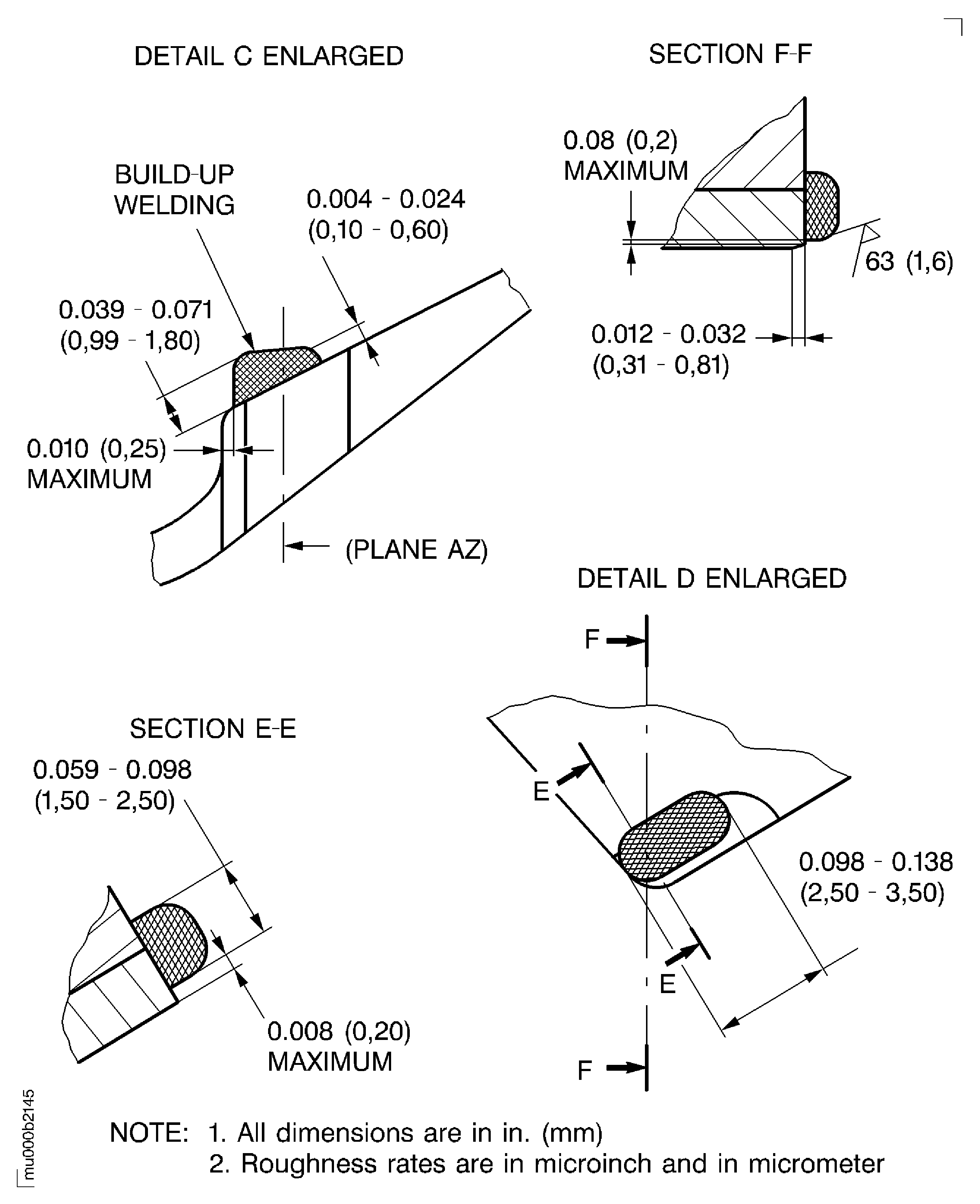

Build up weld the shingling stop.

SUBTASK 72-50-32-310-060 Weld the Stage 3 Turbine Blade

Refer to requirements given in Figure.

Check dimensions.

SUBTASK 72-50-32-220-215 Dimensionally Inspect the Reworked Stage 3 Turbine Blades

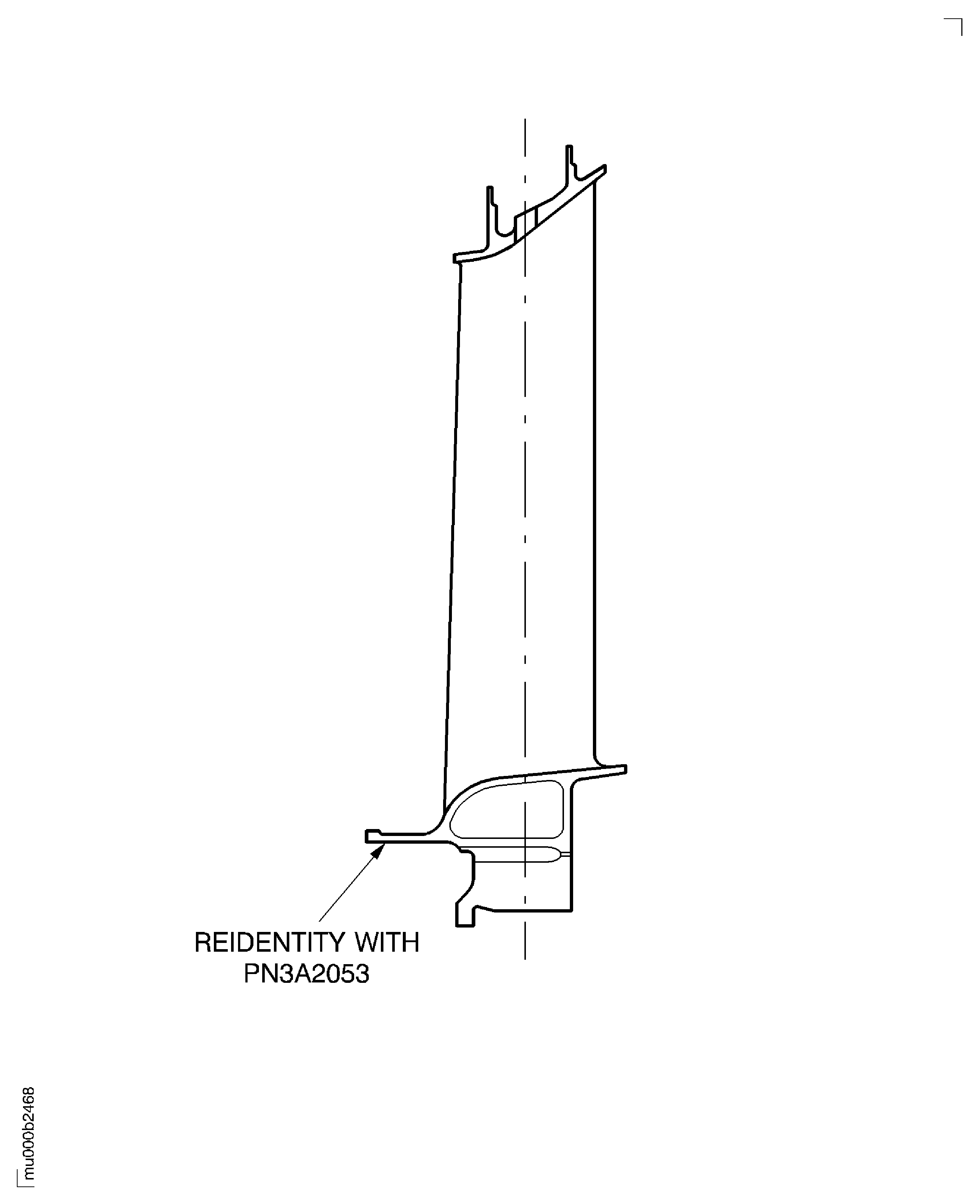

PART NUMBER BEFORE - 3A0883.

NEW PART NUMBER - 3A2053.

Refer to the SPM TASK 70-09-00-400-501.

Refer to Fig. 72-50-32-990-130.

Reidentify with new part number. Use roller stamp method or vibropeen method.

SUBTASK 72-50-32-850-052 Reidentify the Stage 3 Turbine Blade with the New Part Number

Figure: Shingling of LP turbine stage 3 rotor blades - preparation for build up welding

Shingling of LP turbine stage 3 rotor blades - preparation for build up welding

Figure: LP turbine stage 3 rotor blades - build up welding dimensions

LP turbine stage 3 rotor blades - build up welding dimensions

Figure: Reidentification of LP turbine stage 3 rotor blades

Reidentification of LP turbine stage 3 rotor blades