Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-51-300-005 No. 5 Bearing Oil Jet, Filter, And Supply Tube - Related Parts - Replace The Damaged Helicoil Insert In The Oil Jet, Repair-005 (VRS5011)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Approved workshop equipment | LOCAL | Approved workshop equipment |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

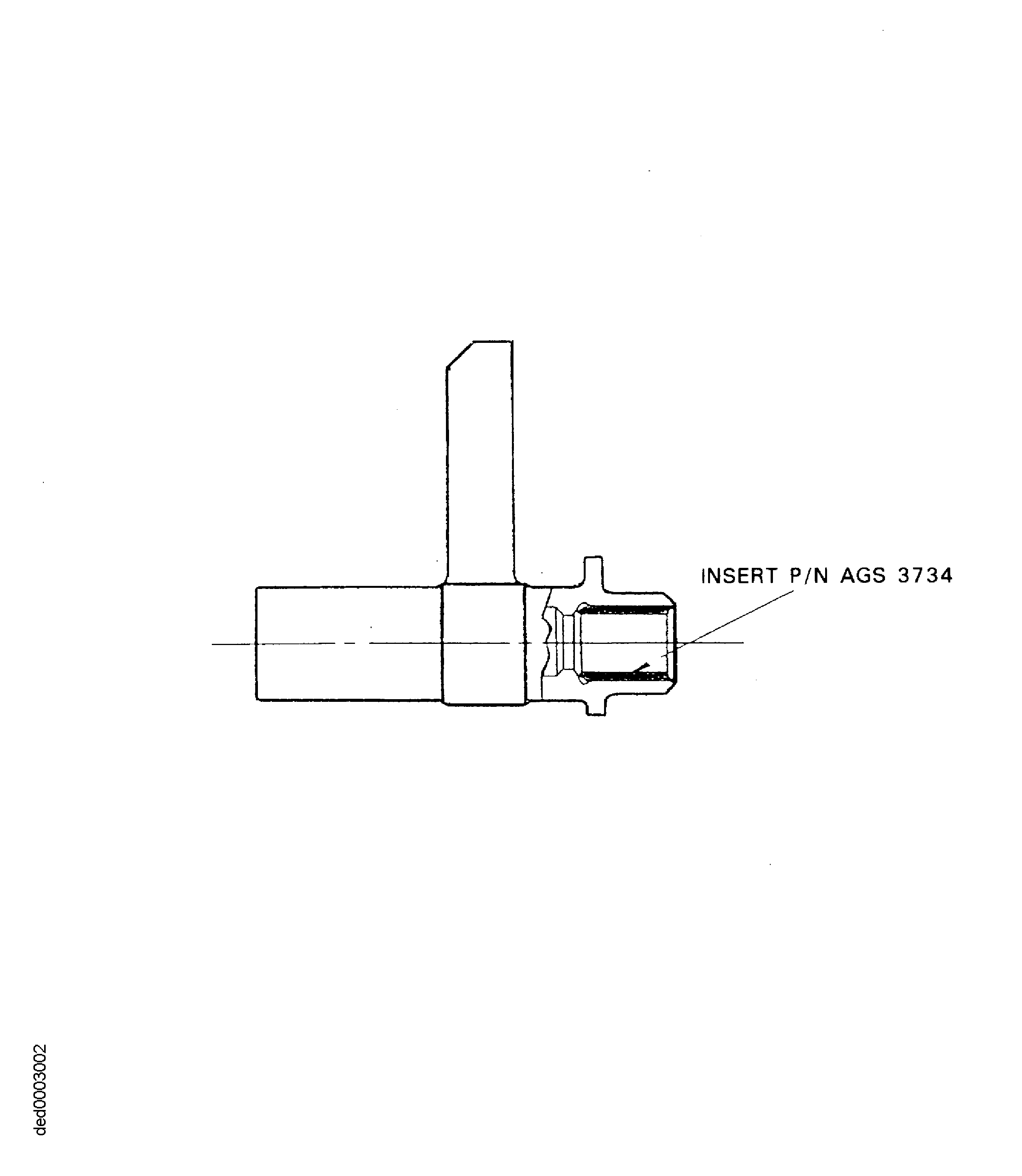

Refer to Figure.

Put the extracting tool into the insert at approximately a quarter of a coil from the end of the insert.

Put the extracting tool into the insert

Use a hammer

Hit the head of the tool lightly to dig blade into top of coil of the insert

Maintain hard pressure on handle as insert backs out.

Bearing down hard on handle of tool, turn it slowly counterclockwise.

SUBTASK 72-50-51-350-055 Remove the Damaged Helicoil Insert

Refer to Figure.

Put the new helicoil insert on the tip of the inserting tool

Put the tool with the insert above threaded hole

Refer to SPM TASK 70-35-08-300-501.

Install the helicoil 1 to 1.5 pitch below the surface

Install the helicoil insert into hole. Turn the handle clockwise

Use tang break-off tool. Remove broken tang

Break insert tang off at notch

SUBTASK 72-50-51-350-056 Install the New Helicoil Insert

Refer to SPM TASK 70-23-01-230-501.

Do a crack test in the repaired area

SUBTASK 72-50-51-230-055 Do a Crack Test on the Repaired Area

Refer to SPM TASK 70-35-08-300-501.

Examine the helicoil insert

SUBTASK 72-50-51-220-055 Do an Inspection of the Helicoil Insert

Figure: Repair Details and Dimension

Repair Details and Dimension