Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-53-300-057 Turbine Exhaust Case (TEC) - Nickel Plate The Cover Bore, Repair-057 (VRS3111)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

21-300 | 2A1209-01 |

21-300 | 2A2620-01 |

21-300 | 2A3111-01 |

21-300 | 2A3183-01 |

21-300 | 2A3455-01 |

21-300 | 2A3183-101 |

21-300 | 2A4258-01 |

21-300 | 2A4263-01 |

General

Price and availability - refer to IAE

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before this repair. Refer to Engine Manual section 72-50-53 and Standard Practices Manual section 70-10-00. | |

| Remove all the details from the Turbine Exhaust Case by applicable Engine Manual repairs. Refer to Engine Manual section 72-50-53 and Standard Practices Manual section 70-35-08. |

Support Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Magnifying Glass, 4x | LOCAL |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-067 STRIPPABLE COATING | 71410 | CoMat 02-067 |

Spares

NONESafety Requirements

NONEProcedure

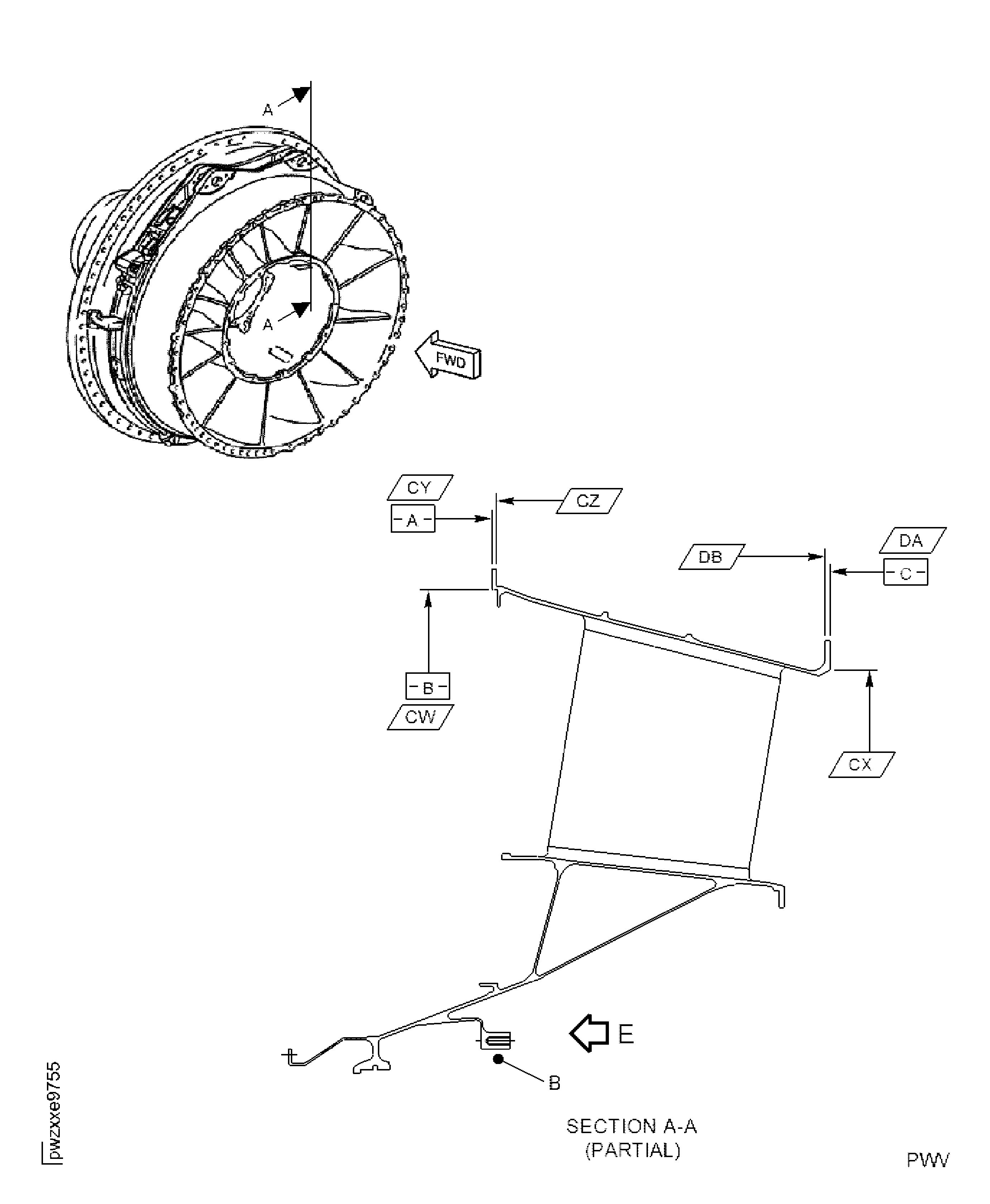

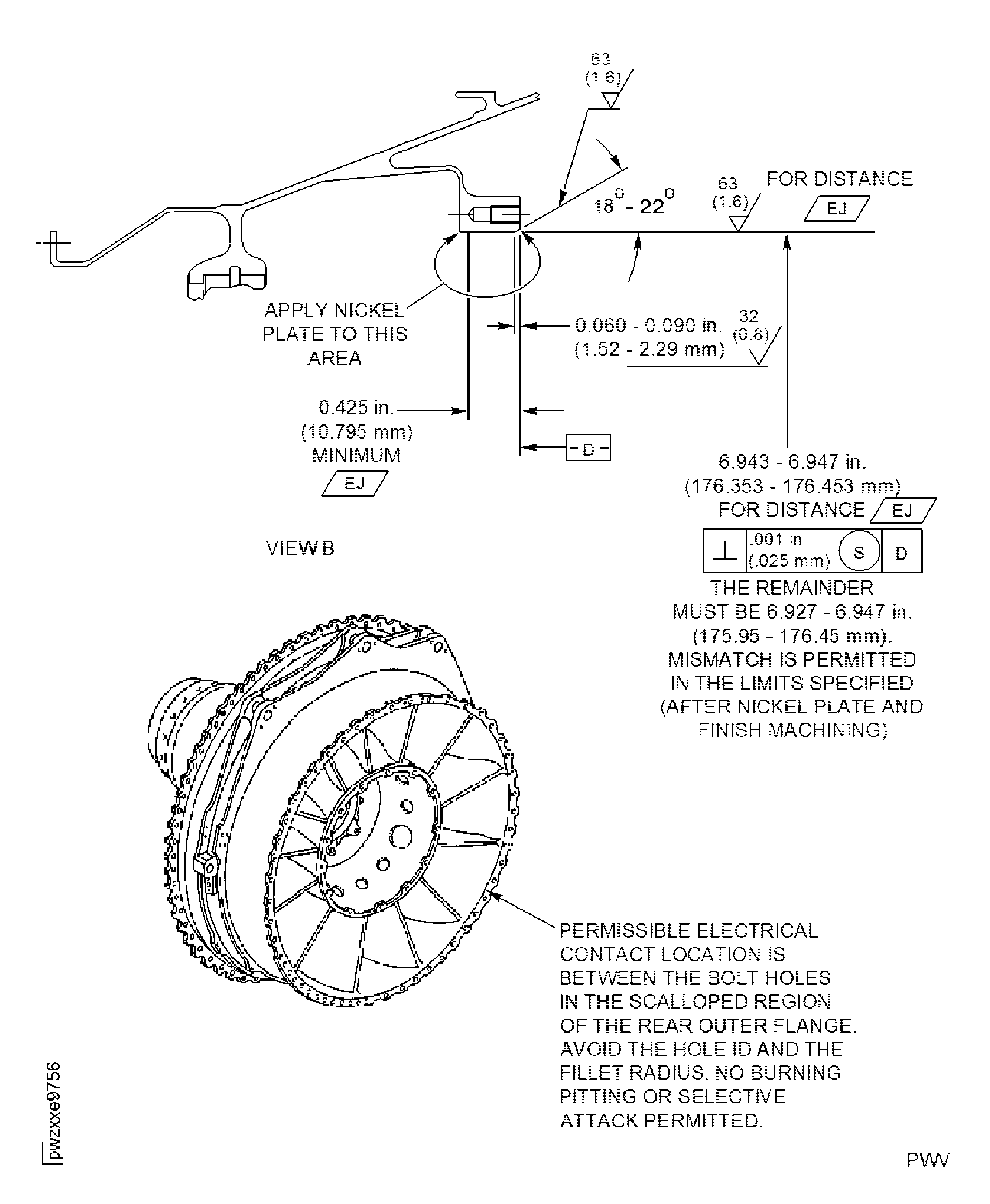

Refer to Figure.

Machine the diameter of the cover bore. Keep material removal to a minimum so the plating will be 0.002 in. to 0.012 in. (0.05 mm to 0.30 mm) thick after finish machining.

Part is steel with a hardness is greater than 25 HRC and less than 40 HRC.

Remove nickel plate by SPM TASK 70-33-06-300-503. Mask other non-nickel strip region. See Figure.

Prepare the cover bore diameter for nickel plate to the limits in Figure by one or more of the methods that follow.

SUBTASK 72-50-53-320-101 Prepare the Cover Bore Diameter for Nickel Plating

Refer to SPM TASK 70-11-03-300-503.

Clean the part.

SUBTASK 72-50-53-110-212 Clean the Turbine Exhaust Case (TEC)

Refer to SPM TASK 70-23-05-230-501 (High Sensitivity). No indications permitted.

Do a local fluorescent penetrant inspection of the repair area.

SUBTASK 72-50-53-230-091 Examine the Surfaces to be Plated

Refer to SPM TASK 70-38-24-300-503.

Apply a mask to the areas of the Turbine Exhaust Case that are not to be plated.

SUBTASK 72-50-53-380-064 Apply a Mask to the Turbine Exhaust Case

Refer to Figure.

Part is stainless steel with a hardness greater than 25 HRC and less than 40 HRC.

Part cannot be damaged if heated to 375 deg F (190 deg C) or greater.

Apply the plating to a sufficient thickness to permit finish machining. Plating outside the repair area is permitted but must be removed.

Refer to SPM TASK 70-33-06-300-503 (Nickel Plating on Stainless Steel, Cobalt, and Nickel Base Alloys).

Part is 400 series stainless steel with a hardness greater than 25 HRC and less than 40 HRC.

Part cannot be damaged if heated to 375 deg F (190 deg C) or greater.

Apply the plating to a sufficient thickness to permit finish machining. Plating outside the repair area is permitted but must be removed.

Refer to SPM TASK 70-33-28-300-503 (Brush Nickel Plating).

Nickel plate the diameter by one of the following processes.

SUBTASK 72-50-53-330-066 Nickel Plate the Diameter of the Cover Bore

Refer to Figure.

SUBTASK 72-50-53-320-102 Machine the Diameter of the Cover Bore after Nickel Plate

Refer to SPM TASK 70-11-03-300-503.

Clean the part.

SUBTASK 72-50-53-110-213 Clean the Turbine Exhaust Case (TEC)

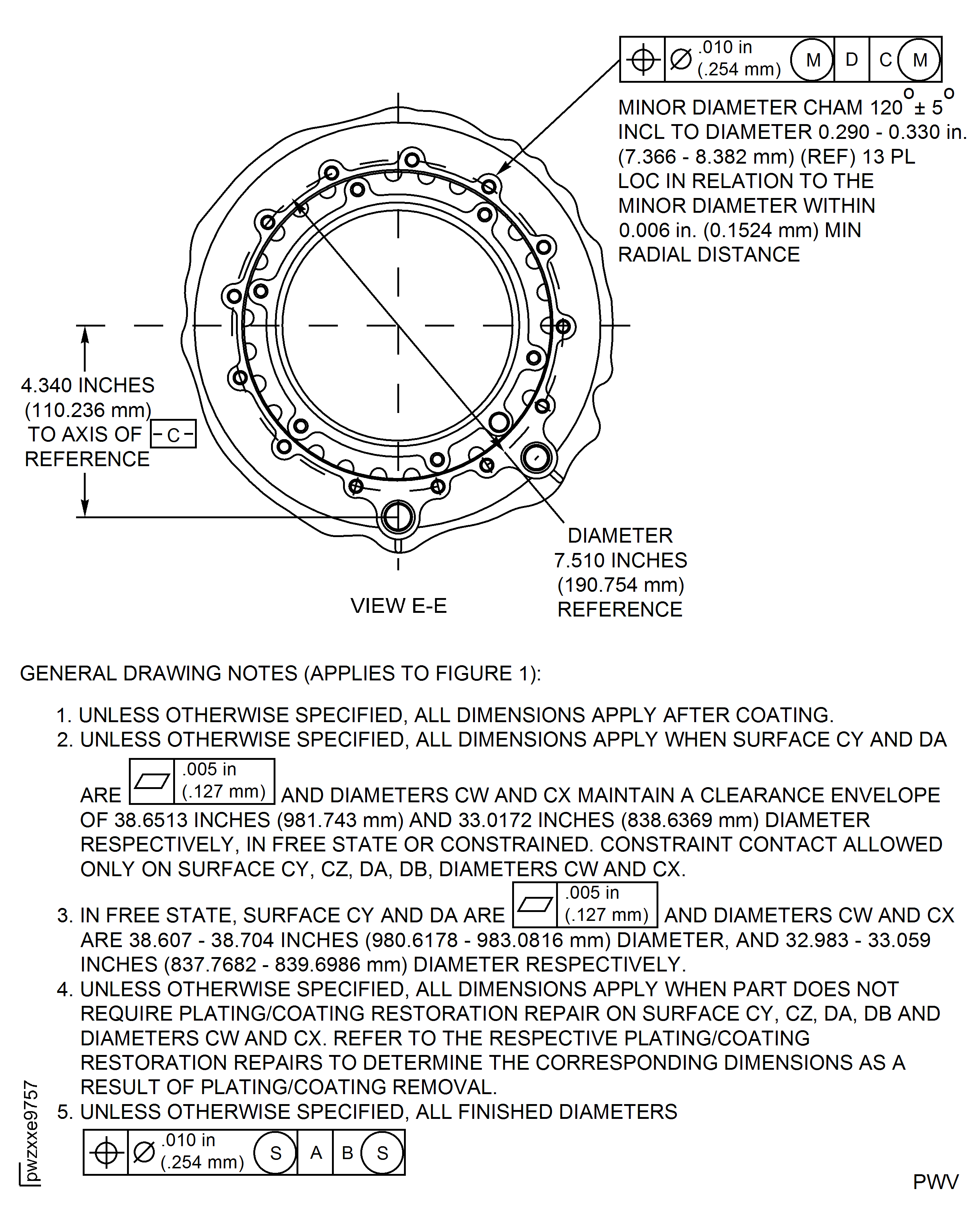

Do a visual and dimensional inspection of the repair location. Refer to Figure.

SUBTASK 72-50-53-220-202 Examine the Repair

Mark VRS3111 on the repaired Turbine Exhaust Case adjacent to the part number.

Use vibration peen marking method.

Remove high metal caused by marking the number.

If the VRS repair number is already marked on the part, do not mark the repair number again.

Make a permanent mark by the procedure given in the SPM TASK 70-09-00-400-501.

SUBTASK 72-50-53-350-224 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

Requirements After Job Completion

Follow-On Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Install all the details to the Turbine Exhaust Case by applicable Engine Manual repairs. Refer to Engine Manual section 72-50-53 and Standard Practices Manual section 70-35-08. | |

| Do a dimensional inspection of the part per lnspection-003. Refer to Engine Manual section 72-50-53. |