Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-53-300-046 Turbine Exhaust Case (TEC) - Replace The Helical Coil Inserts Or Repair With Oversized Inserts, Repair-046 (VRS3014)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

21-300 | 2A1209-01 |

21-300 | 2A2620-01 |

21-300 | 2A3111-01 |

21-300 | 2A3183-01 |

21-300 | 2A3455-01 |

21-300 | 2A3183-101 |

21-300 | 2A4258-01 |

21-300 | 2A4263-01 |

General

Price and availability - refer to IAE.

The practices and processes referred to in the procedure by the TASK numbers are in SPM.

NOTE

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before the repair. | |

| Refer to Engine Manual, PN E-V2500-1IA, ATA 72-50-53 and Standard Practices Manual, PN SPM-V2500-1IA, Section 70-10-00. |

Support Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Installation tool | LOCAL | 7552-4 | Single Helical Coil Insert (Helicoil Products) | |

| Installation tool | LOCAL | 7552-4 | Double Helical Coil Insert (Helicoil Products) | |

| Outer helical wire thread insert tang removal tool | LOCAL | 4032-4 | Double Helical Coil Insert (Helicoil Products) | |

| Plug Tap | LOCAL | 3893-4 | Double Helical Coil Insert (Helicoil Products) | |

| Plug tap | LOCAL | 4FPB | Single Helical Coil Insert (Helicoil Products) | |

| Removal tool | LOCAL | 1227-6 | Single Helical Coil Insert (Helicoil Products) | |

| Removal tool | LOCAL | 1227-6 | Double Helical Coil Insert (Helicoil Products) | |

| Tang removal tool | LOCAL | 3695-4 | Single Helical Coil Insert (Helicoil Products) | |

| Tang removal tool | LOCAL | 3695-4 | Double Helical Coil Insert (Helicoil Products) | |

| Thread insert installation tool | LOCAL | 2705-4 | Double Helical Coil Insert (Helicoil Products) | |

| Thread plug gage | LOCAL | 1927-4 | Double Helical Coil Insert (Helicoil Products) | |

| Thread plug gage | LOCAL | 3694-4 | Single Helical Coil Insert (Helicoil Products) |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

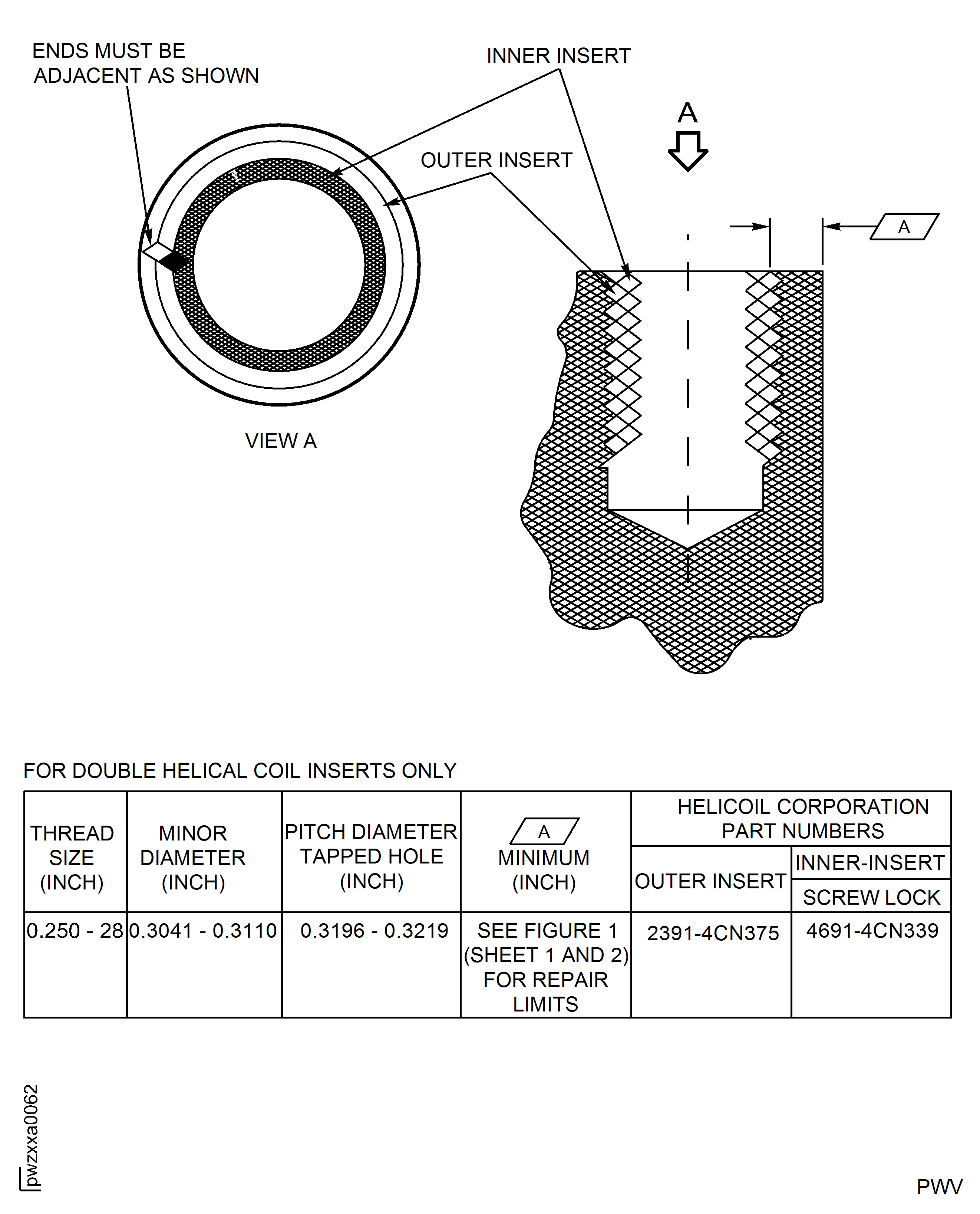

| Inner insert (screw locking) | LOCAL | 4691-4CN339 | AR | Double Helical Coil Insert |

| INSERT - SCREW THREAD | 96906 | MS21209F4-10 | AR | Screw thread insert |

| INSERT - SCREW THREAD, 0.250 - 28 X 0.375 | 96906 | MS21209F4-15 | AR | Single Helical Coil Insert |

| Outer insert (free running) | LOCAL | 2391-4CN375 | AR | Double Helical Coil Insert |

Safety Requirements

NONEProcedure

Refer to Figure.

Refer to SPM TASK 70-35-27-300-501. Use Removal tool.

Remove loose or damaged inserts from the turbine exhaust case.

SUBTASK 72-50-53-350-106 Remove the Inserts from the Turbine Exhaust Case

Use Thread plug gage for single helical coil or Thread plug gage for double helical coil.

Examine the threads after you remove the insert.

Do a dimensional inspection of the repair area at the Turbine Exhaust Case to make sure that there is sufficient minimum wall thickness for machining.

SUBTASK 72-50-53-220-194 Examine the Threads

Use Thread plug gage or Thread plug gage.

Examine the threads after you have tapped them.

SUBTASK 72-50-53-220-195 Examine the Threads

Refer to Figure.

Put the PN MS21209F4-15 insert onto the tip of the Installation tool.

Use Tang removal tool. Refer to SPM TASK 70-35-27-300-501.

Break the tang of the insert at the notch using the Tang removal tool.

SUBTASK 72-50-53-350-107 Install the New Single Helical Coil Inserts

Put the PN 2391-4CN375 outer insert onto the tip of the Thread insert installation tool.

Put the insert into the threaded hole.

Turn the handle clockwise so the top of the insert is one to one and a half pitch below the face of the boss.

Refer to SPM TASK 70-35-27-300-501.

Break off and remove tang using the Tang removal tool.

SUBTASK 72-50-53-420-001 Install the Outer Double Helical Coil Inserts

Put the PN 4691-4CN339 inner insert onto the tip of the insertion tool Installation tool.

Put the insert into the threaded hole.

Align the ends of the inner insert and the outer insert.

Refer to SPM TASK 70-35-27-300-501.

Break off and remove tang using the Tang removal tool.

SUBTASK 72-50-53-420-002 Install the Inner Double Helical Coil Inserts

Refer to TASK 72-50-53-200-000 (INSPECTION-000).

Examine the new inserts.

SUBTASK 72-50-53-220-196 Examine the Repair

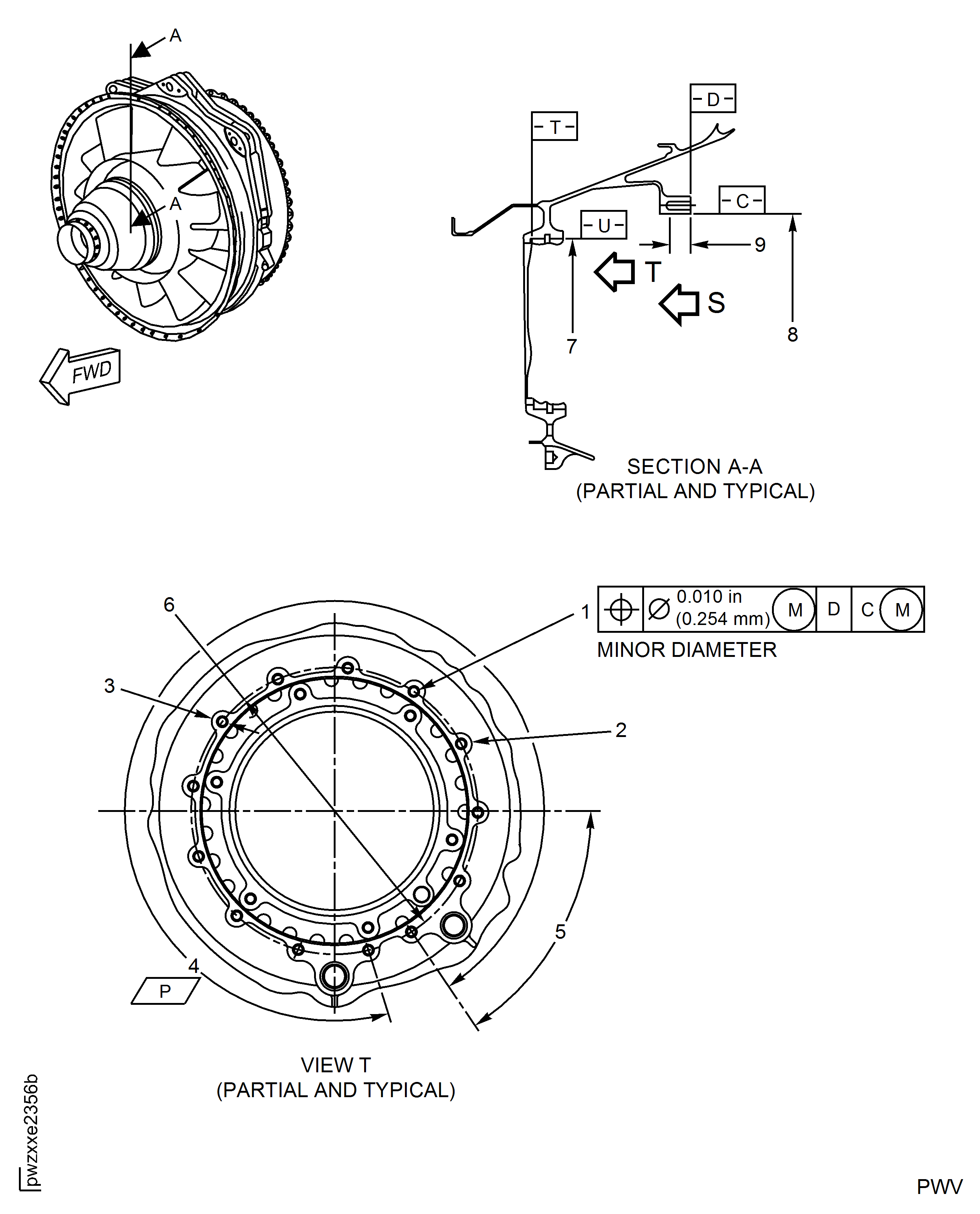

Figure: Turbine Exhaust Case Assembly - No. 5 Bearing Housing Single And Double Helical Coil Inserts Repair

(1) Repair Areas On The No. 5 Bearing Compartment Cover Mating Flange Bolt Holes At 13 Locations Equally Spaced Over Arc P.

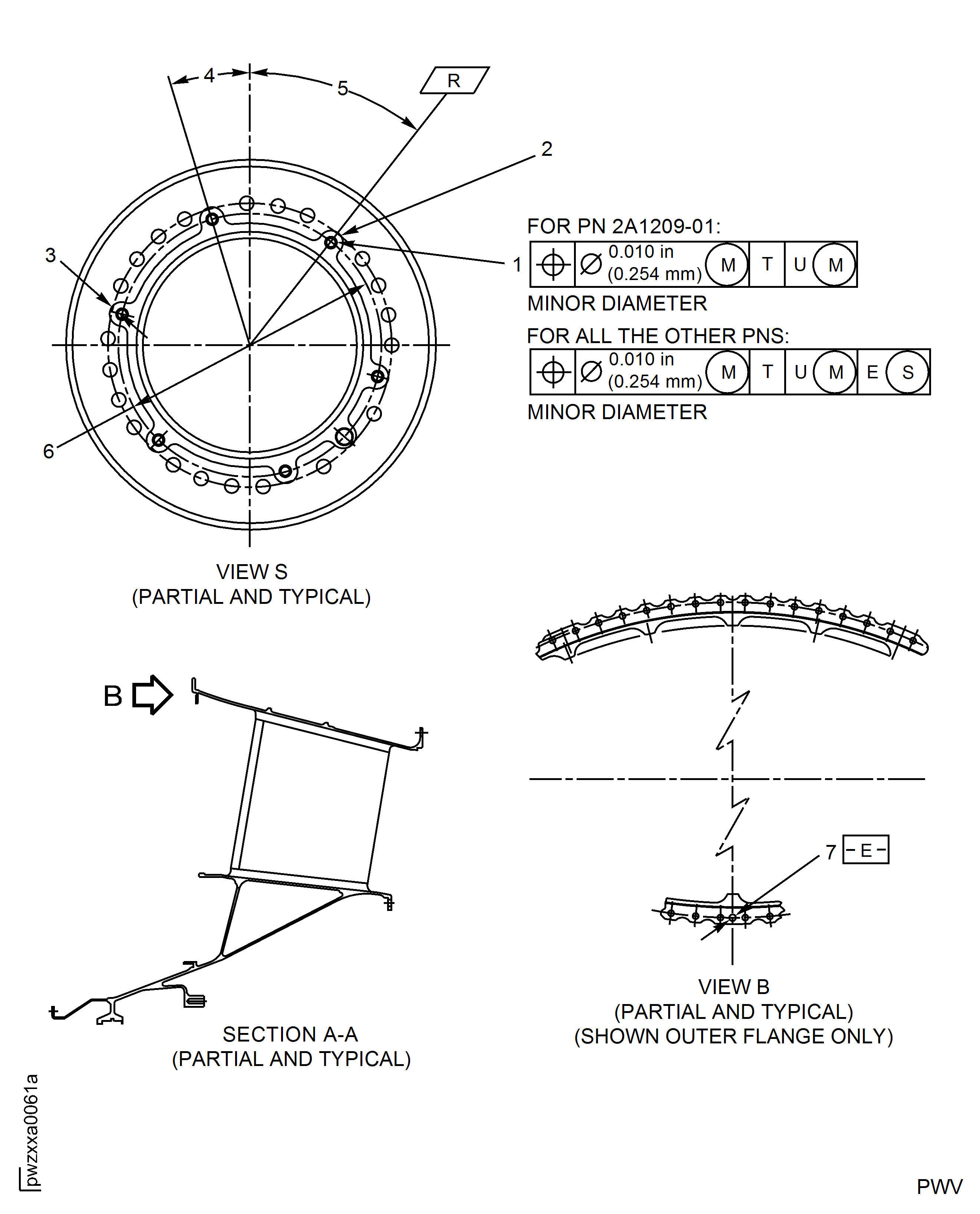

Figure: Turbine Exhaust Case Assembly - No. 5 Bearing Housing Single And Double Helical Coil Inserts Repair

(1) Repair Areas On The No. 5 Bearing Retaining Plate Mating Flange Bolt Holes On The Turbine Exhaust Case Assembly At Six Locations. FIve Locations On The Basis Of Six Equally Spaced Locations And One Location Offset At R.

Figure: Turbine Exhaust Case Assembly - No. 5 Bearing Housing Double Helical Coil Inserts Repair

Turbine Exhaust Case Assembly - No. 5 Bearing Housing Double Helical Coil Inserts Repair