Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-21-300-005 Main Gearbox Casing - Replace The Damaged Screw Thread Inserts, Repair-005 (VRS5256)

Material of component

DESCRIPTION | RR SYMBOL | MATERIAL |

|---|---|---|

Accessory gearbox casing | A357/T61 (AMS4219) | Aluminium alloy |

General

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| 5/16in. (7,937 mm) Drill, removal | LOCAL | 5/16in. (7,937 mm) Drill, removal | ||

| 29/64in. (11,506 mm) Drill, removal | LOCAL | 29/64in. (11,506 mm) Drill, removal | ||

| Square screw extractor, removal | LOCAL | Square screw extractor, removal | ||

| R1106W Wrench, installation | LOCAL | R1106W Wrench, installation | ||

| R1108W Wrench, installation | LOCAL | R1108W Wrench, installation | ||

| R206D Drive tool, installation | LOCAL | R206D Drive tool, installation | ||

| R208D Drive tool, installation | LOCAL | R208D Drive tool, installation |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-048 LUBRICANT | LOCAL | CoMat 10-048 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Lock ring | MS51990E106P | A/R | ||

| Screw insert | MS51991E206L | A/R | ||

| Lock ring | MS51990E108P | A/R | ||

| Screw insert | MS51991E208L | A/R | ||

| Lock ring | MS51990E106P | A/R | ||

| Screw insert | MS51991E206L | A/R | ||

| Lock ring | MS51990E106P | A/R | ||

| Screw insert | MS51991E206L | A/R | ||

| Lock ring | MS51990E108P | A/R | ||

| Screw insert | MS51991E208L | A/R | ||

| Lock ring | MS51990E106P | A/R | ||

| Screw insert | MS51991E206L | A/R | ||

| Lock ring | MS51990E106P | A/R | ||

| Screw insert | MS51991E206L | A/R |

Safety Requirements

NONEProcedure

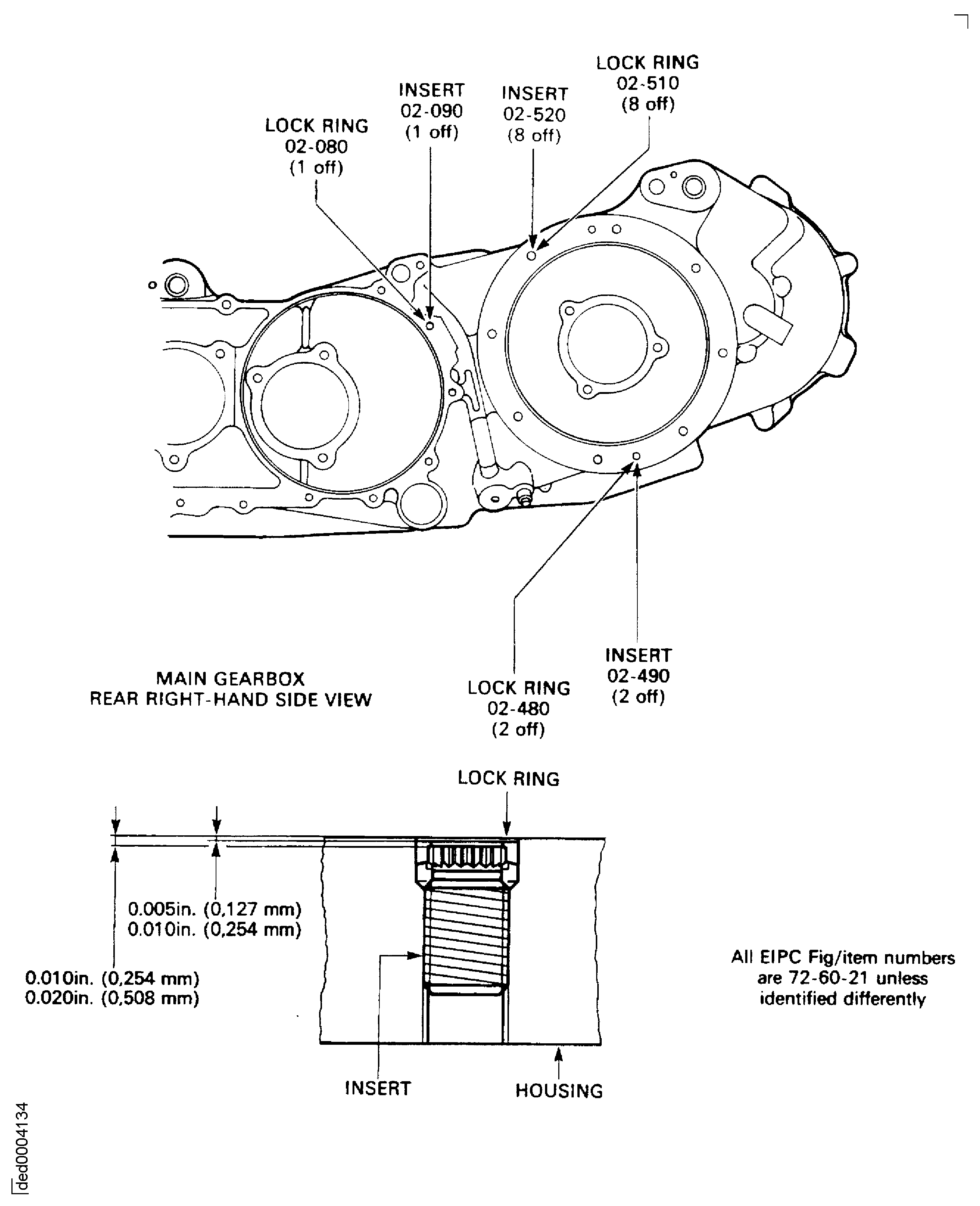

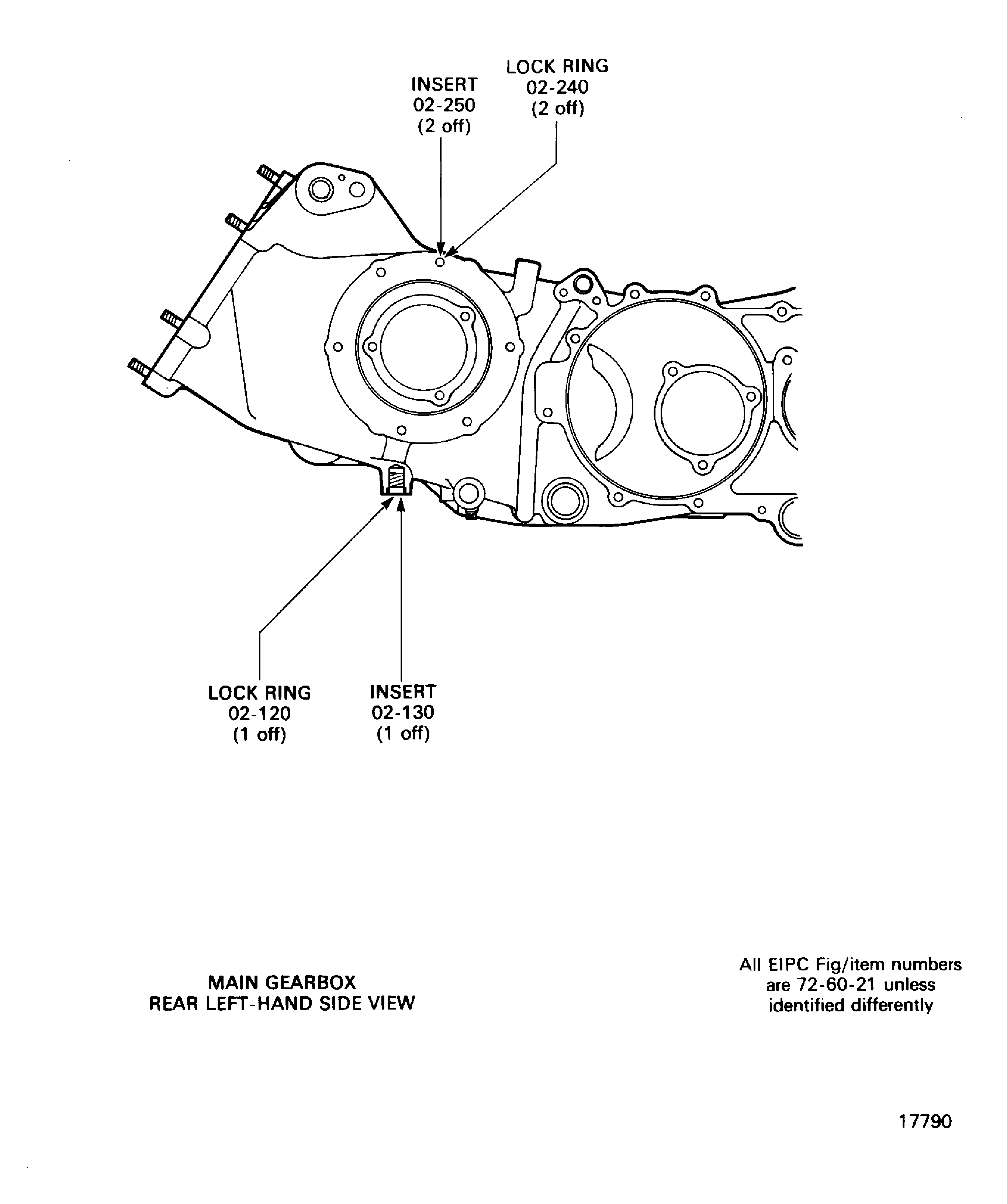

Use 5/16in. (7,937 mm) Drill, removal for lock ring 02-080, 02-240, 02-480, 02-560, 02-830.

Use 29/64in. (11,506 mm) Drill, removal for lock ring 02-120, 02-510.

Install the removal tool in drill press chuck.

SUBTASK 72-60-21-320-053 Mill the Lock Ring

SUBTASK 72-60-21-350-054 Remove the Insert

The depth is given in Figure.

Use R1106W Wrench, installation for insert 02-090, 02-250, 02-490, 02-570, 02-840.

Use R1108W Wrench, installation for insert 02-130, 02-520.

Install the insert.

For insert 02-520, refer to repair, VRS5707 TASK 72-60-21-300-056 (REPAIR-056).

If the threaded hole in the Main Gearbox Casing is damaged too much to adequately support the insert, refer to the following repair:

SUBTASK 72-60-21-350-055 Install the New Insert

Seat the new lock ring to depth given in Figure.

Use R206D Drive tool, installation for lock ring 02-080, 02-240, 02-480, 02-560, 02-830.

Use R208D Drive tool, installation for lock ring 02-120, 02-510.

Seat the new lock ring.

SUBTASK 72-60-21-350-056 Install the Lock Ring

Refer to SPM TASK 70-38-02-300-503.

Check the surface.

SUBTASK 72-60-21-330-054 Restore the Damaged Anodic Treatment

Refer to SPM TASK 70-23-01-230-501.

Do a crack test on the repaired area.

SUBTASK 72-60-21-230-054 Crack Test the Repaired Area

Figure: Replace damaged inserts and lock rings

Replace damaged inserts and lock rings

Figure: Replace damaged inserts and lock rings

Replace damaged inserts and lock rings

Figure: Replace damaged inserts and lock rings

Replace damaged inserts and lock rings

Figure: Replace damaged inserts and lock rings

Sheet 4