Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-21-300-055 Repair The Drain Ports Of Main Gearbox Casing With Aluminum Bush, Repair-055 (VRS5706)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Main Gearbox Casing | A357/T61 (AMS4219) | Aluminum alloy |

Bushing | AA2024-T3 (AMS4152/AMS4165/AMS4120) | Aluminum alloy |

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 04-009 ANAEROBIC COMPOUND | 05972 | CoMat 04-009 | ||

| CoMat 04-010 ACTIVATOR/PRIMER | LOCAL | CoMat 04-010 | ||

| DELETED | X111X | DELETED | ||

| DELETED | X111X | DELETED |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Remove the damaged bush from the gearbox port(s).

If present, remove the bush(es) from the Gearbox drain port(s).

SUBTASK 72-60-21-350-160 If Present, Remove the Damaged Bush(es) from the Main Gearbox Drain Port(s)

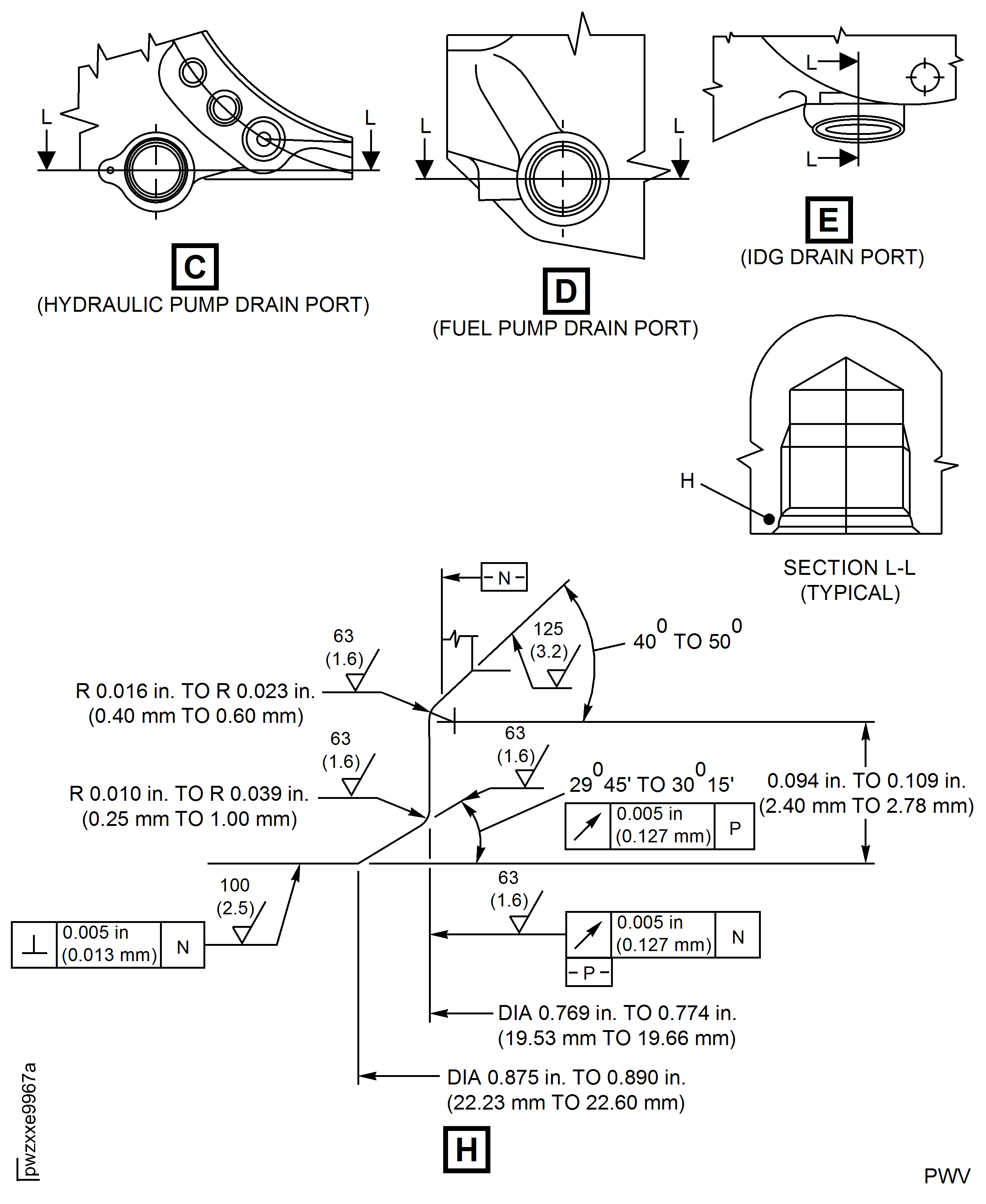

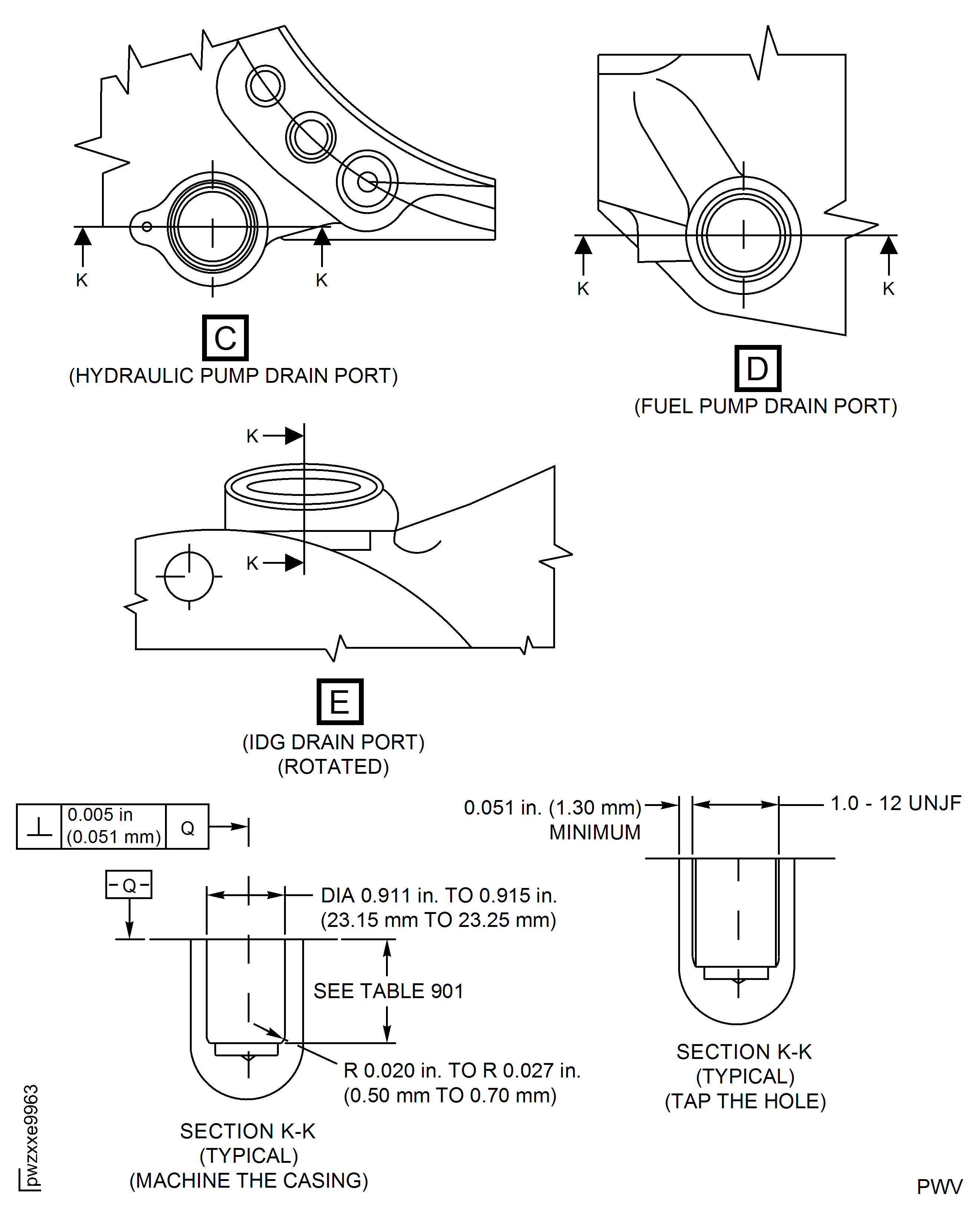

Diameter of the drain port(s) to be 0.911 in. - 0.915 in. (23.15 mm - 23.25 mm) and for depth, see Figure, Table 901.

New machining must be concentric within 0.0050 in. (0.127 mm) of the sealing diameter of the original drain port.

Use a boring machine.

Machine the diameter of the drain port(s).

The thread must be 1.000 - 12 UNJF.

Use tapping tool.

Tap the hole(s).

SUBTASK 72-60-21-320-142 If the Repair is Performed for the First Time, Machine the Main Gearbox Drain Port(s)

Refer to SPM TASK 70-11-03-300-503.

Clean the part.

Refer to SPM TASK 70-23-01-230-501.

Cracks are not allowed.

Inspect the casing for cracks in the area of the machined drain port(s).

Damage less than one half of one full thread.

Accept.

Do a visual inspection of the thread of the machined drain port(s).

Ensure the minimum wall thickness of the damaged location(s) is at least 0.051 in. (1.30 mm). If less, the repair cannot be done.

Do a dimensional inspection of the thread of the machined drain port(s).

SUBTASK 72-60-21-220-171 Examine the Machined Drain Port(s)

Refer to Figure.

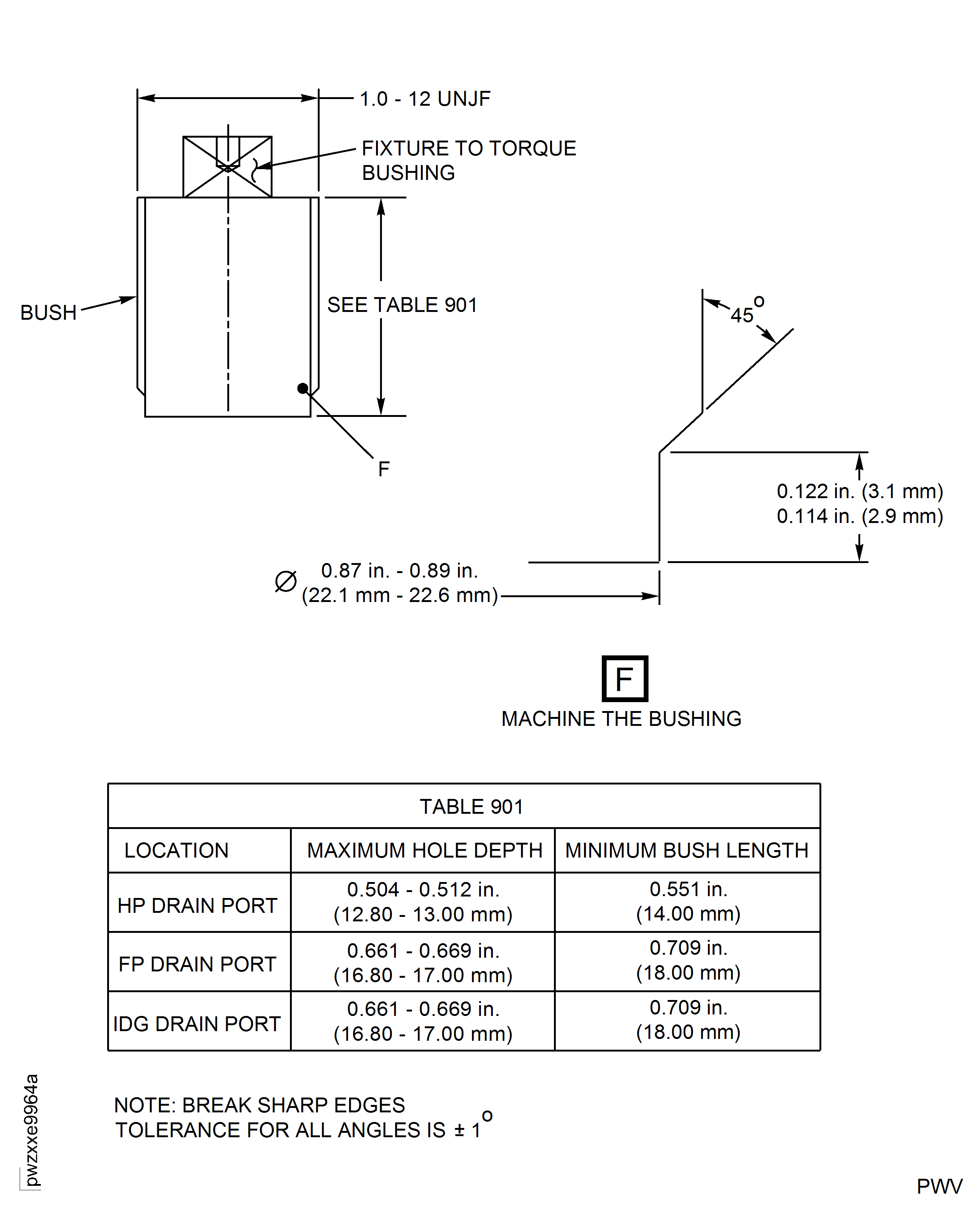

Use only aluminium alloy AA2024-T3 per spec AMS4152 or AMS4165 or AMS4120. Do not use other materials.

See Figure, Table 901 for bush depth. Bush(es) should contain 1.000 - 12 UNJF cut threads.

Use a grinding machine or a lathe.

Produce bush(es).

SUBTASK 72-60-21-320-143 Produce Bush(es)

Refer to SPM TASK 70-38-02-300-503.

Apply the chromate conversion coating to the machined drain port(s) and bush(es).

SUBTASK 72-60-21-380-001 Apply the Chromate Conversion Coating on the Machined Drain Port(s) and the Bush(es)

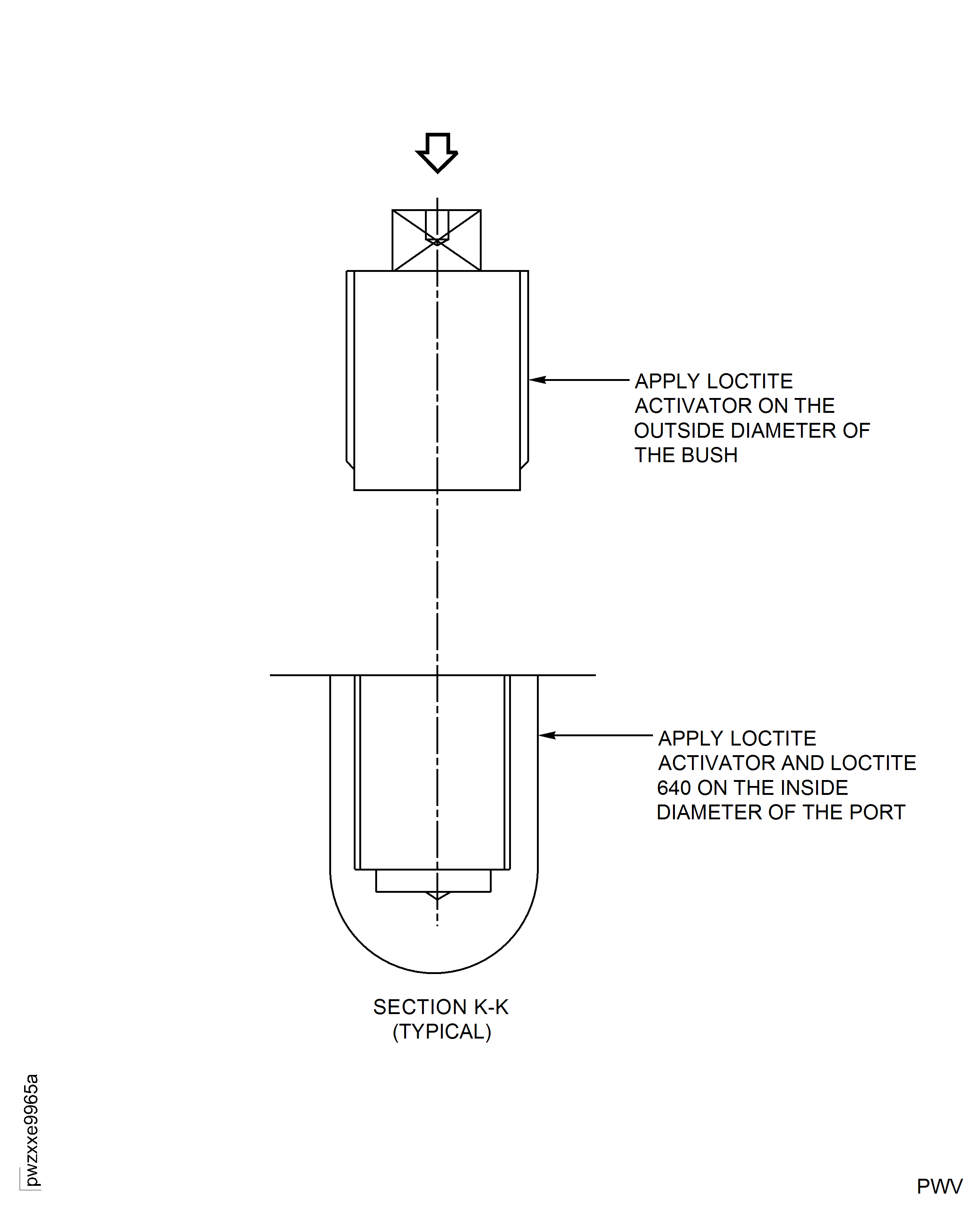

Use CoMat 04-010 ACTIVATOR/PRIMER. primer T.

Apply Loctite activator to threads of machined drain port(s) and bush(es).

Use CoMat 04-009 ANAEROBIC COMPOUND Loctite 640.

Apply Loctite 640 to the thread of the bush.

Screw the bush(es) full bottom into the machined drain port(s).

Torque must not exceed 220 lbfin. (25 Nm).

Use torque tool.

Install the bush(es) into the drain ports(s).

Let the compound cure at room temperature at least for 24 hours.

Cure the compound.

SUBTASK 72-60-21-380-002 Prepare the Machined Areas and Install the Bush(es)

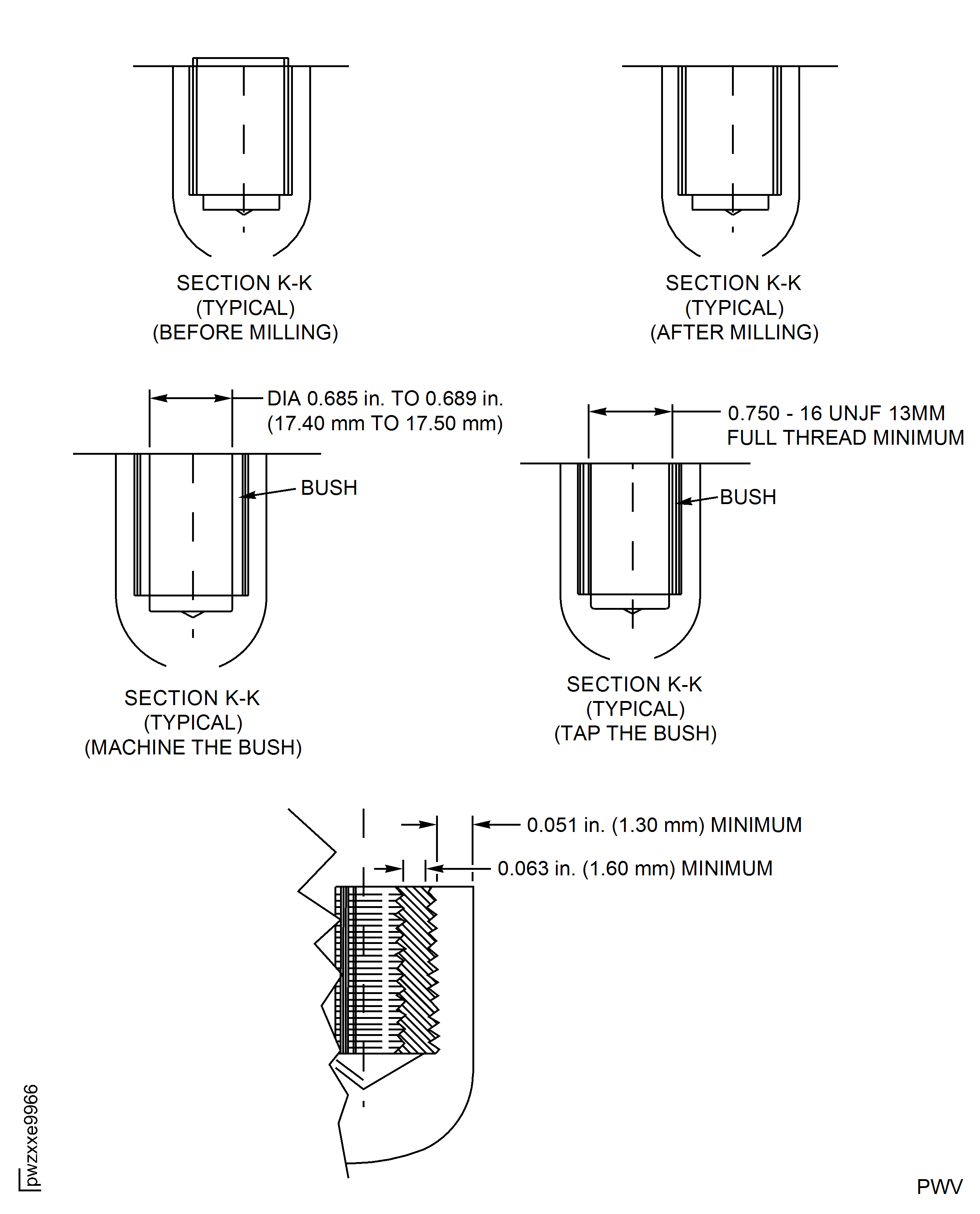

Use milling machine to flush the bush(es) top land with casing contour.

Surface finish is 100 microinches (2.5 micrometer).

Machine the top land of the bush(es) with the casing contour.

Machine the inner diameter of the bush(es) to be 0.685 in. - 0.689 in. (17.40 mm - 17.50 mm) and depth until bottom of original drain hole(s).

Use a boring machine.

Machine the inner diameter of the bush(es).

The thread must be 0.750 - 16 UNJF 13 mm full thread minimum.

Use tapping tool.

Tap the drain hole(s).

Use a grinding machine.

Machine the chamfer of the bush(es).

SUBTASK 72-60-21-320-144 Machine the Bush(es)

Refer to SPM TASK 70-11-03-300-503.

Make sure the drain passage(s) are open and clean.

Clean the machined area and the drain port(s).

SUBTASK 72-60-21-110-058 Clean the Machined Area and the Drain Port(s)

Refer to SPM TASK 70-38-02-300-503.

Apply the chromate conversion coating to the machined areas.

SUBTASK 72-60-21-380-003 Apply the Chromate Conversion Coating

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Used method 3 (vibration peen).

Make a mark VRS5706 (if not already marked) adjacent to the part number.

Refer to SPM TASK 70-38-02-300-503.

Apply the chromate conversion coating to areas affected by marking.

SUBTASK 72-60-21-350-144 Identify the Repair

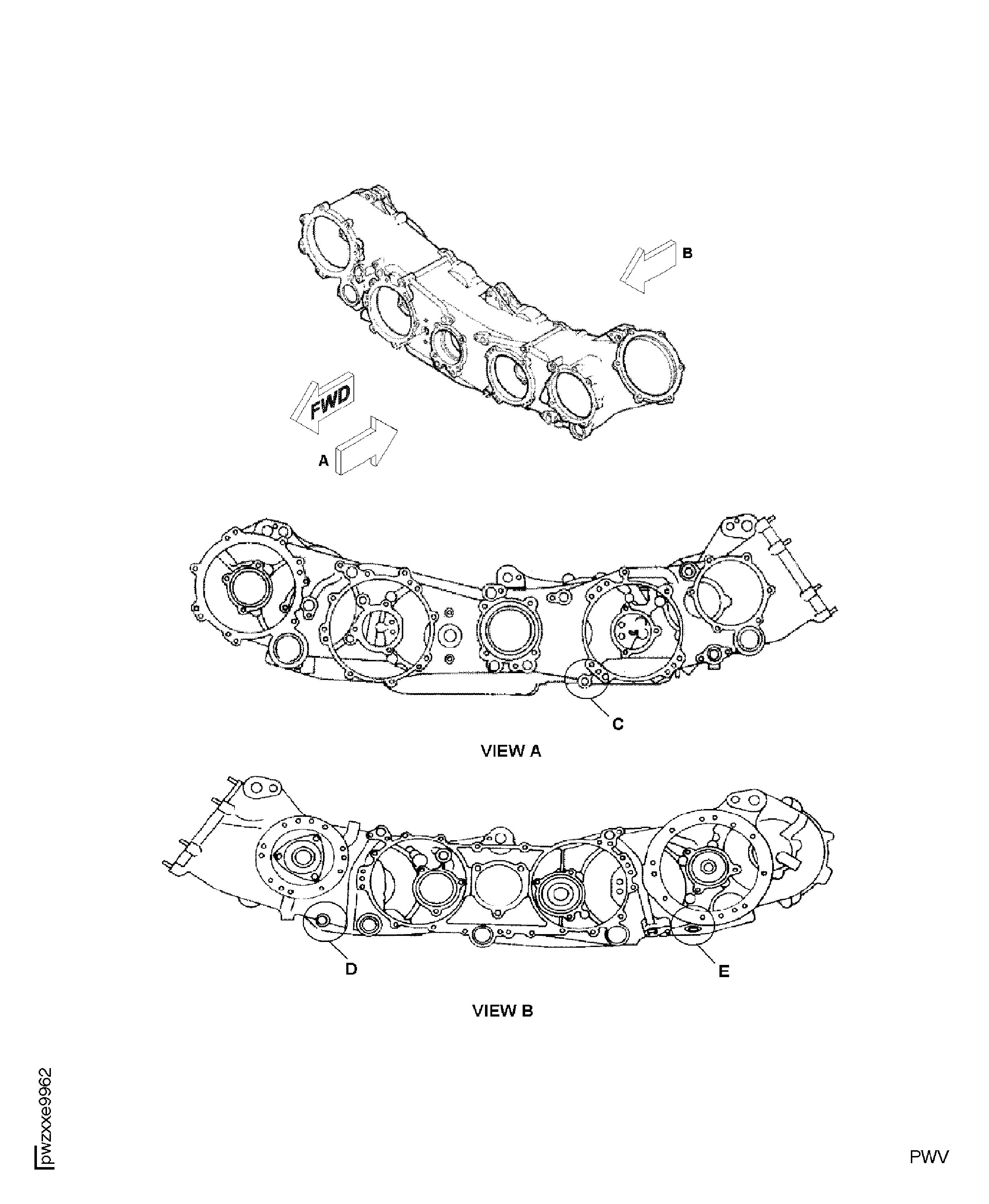

Figure: Main Gearbox Casing - Repair Location(s)

Main Gearbox Casing - Repair Location(s)

Main Gearbox Casing - Repair Location(s)

Main Gearbox Casing - Repair Location(s)

Main Gearbox Casing - Repair Location(s)

Main Gearbox Casing - Repair Location(s)

Main Gearbox Casing - Repair Location(s)