Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-25-300-021 Fuel Pump Drive Gear Housing - Replace the Damaged or Loose Helicoil lnserts in the Fuel Pump Adapter, Repair-021 (VRS5670)

General

Standard equipment Extracting tool 1227-6 Breakoff tool 3695-4 Inserting tool 7552-4 Tools for removal and installation may be purchased from HeliCoil. Product Division/Mite Corporation, Danbury, Connecticut 06108, USA.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Helicoil Insert | 0AM53 | MS21209F4-20L | A/R | FIG/ITEM 01-270 |

Safety Requirements

NONEProcedure

Refer to Figure.

SUBTASK 72-60-25-350-001 Remove the Insert

Refer to SPM TASK 70-38-02-300-503.

Check the surface.

SUBTASK 72-60-25-330-001 Restore the Damaged Anodic Treatment

Refer to Figure.

Put the new MS21209F4-20L on the tip of the inserting tool.

Put the insert on the tool.

Put the tool with the new MS21209F4-20L into the threaded hole.

Put the tool with the insert.

Install the new MS21209F4-20L into the hole.

Turn the handle clockwise.

Install the helicoil 1 to 1.5 pitch below surface.

Install the insert into the hole.

SUBTASK 72-60-25-350-002 Install the New Insert

Do the touch up process if the anodic treatment has been damaged by insert installation.

Refer to the SPM TASK 70-38-02-300-503.

Check the surface.

SUBTASK 72-60-25-330-002 Restore the Damaged Anodic Treatment

Refer to the SPM TASK 70-23-01-230-501.

Do a crack test on the repaired area.

SUBTASK 72-60-25-230-001 Crack Test the Repaired Area

Refer to the SPM TASK 70-35-08-300-501.

Do an inspection of the new MS21209F4-20L .

SUBTASK 72-60-25-220-001 Inspect the Insert

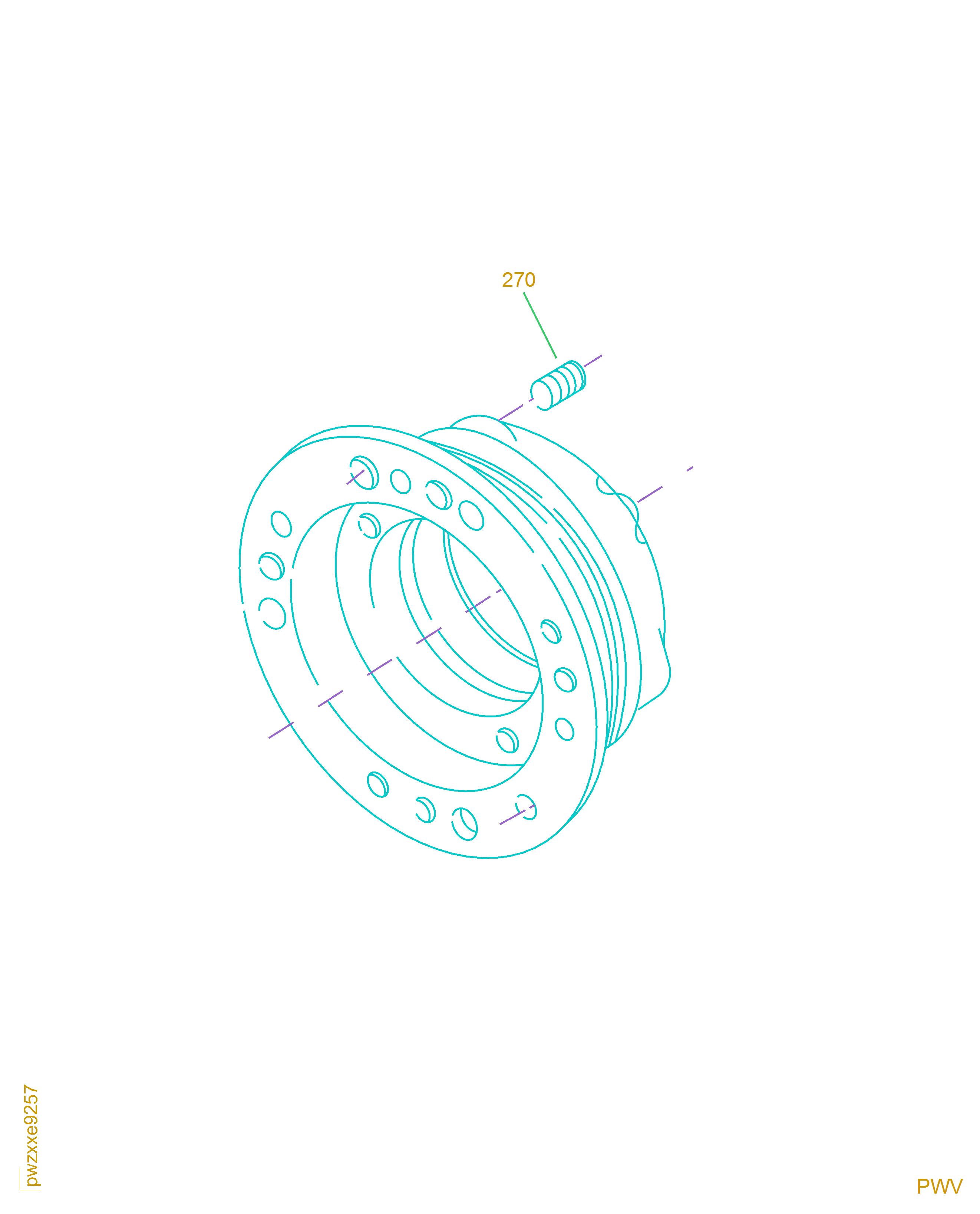

Figure: Replace damaged or loose helicoil inserts

Replace damaged or loose helicoil inserts