Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-32-300-007 Angle Gearbox Support - Replace The Support Bushings, Repair-007 (VRS5116)

Material of component

PART IDENT | MATERIAL |

|---|---|

Casing | Aluminum alloy |

Bushing | Stainless steel |

Plug expansion and pin | Aluminum |

General

This Repair must only be done when the instruction to do so is given in the relevant Inspection/Check.

The TASK gives the procedure to replace the support bushes of the angle gearbox support.

Price and availability - none.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Arbor Press | LOCAL | Arbor press | ||

| Bore gage | LOCAL | Bore gage | ||

| Boring machine | LOCAL | Boring machine | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent Penetrant Inspection Equipment | ||

| Freezer | LOCAL | Freezer | ||

| Hot air gun | LOCAL | Hot air gun | ||

| Vibrating Marking Pencil | LOCAL | Vibrating Marking Pencil | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| BUSHING | A3460 | 4L0091 | ||

| BUSHING | 0AM53 | 4P0032 | 2 | |

| Pin | 0AM53 | AS3124-12 | 1 | |

| Plug Expansion | 0AM53 | AS3123-12 | 1 |

Safety Requirements

NONEProcedure

Machine diameter G to remove scratches and scores.

Keep machining to a minimum to remove the defects.

Make sure that the machined diameter is not more than 0.6048 in. (15.363 mm). Surface finish must be 1.6 microns.

Use a Boring machine.

Visually examine diameter G of the bores of the support.

SUBTASK 72-60-32-220-107 Examine the Support Bushes

Refer to the SPM TASK 70-23-01-230-501.

No cracks are permitted.

Do a penetrant crack test on the machined bores.

SUBTASK 72-60-32-230-066 Examine the Bores of the Support Bushes for Cracks

Refer to the SPM TASK 70-38-02-300-503.

Apply the chromate conversion coating to the machined surfaces.

SUBTASK 72-60-32-380-003 Apply the Chromate Conversion Coating

Use a Bore gage.

Measure and record diameter G.

If diameter G is between 0.5898 in. (14.982 mm) and 0.6048 in. (15.363 mm), install bush 4L0091. Before you install the bush, rework its fit diameter to make sure the fit interference with the bore diameter G is between 0.0010 and 0.0026 in. (0.025 and 0.065 mm).

Surface finish of the fit diameter of bush 4L0091 must be 1.6 microns.

Do a selection and rework the bushing.

SUBTASK 72-60-32-220-108 Do a Selection and Rework the Bushings

Make sure that the temperature of the bushing is not less than -58 deg F (-50 deg C).

Use the Hot air gun and/or the Freezer.

Increase the temperature of the housing and/or decrease the temperature of the bushing.

Use an Arbor Press, a drift and a guide pin.

Give sufficient back-up support at bushing bore area, to prevent housing distortion when you install the housing.

NOTE

The difference in temperature between the parts must be less than 250 deg F (120 deg C).Install the bushing into the machined bore.

SUBTASK 72-60-32-350-102 Install the Bushings

Refer to Figure.

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001 .

Vibro-engrave VRS5116 adjacent to part number.

SUBTASK 72-60-32-350-104 Identify the Repair

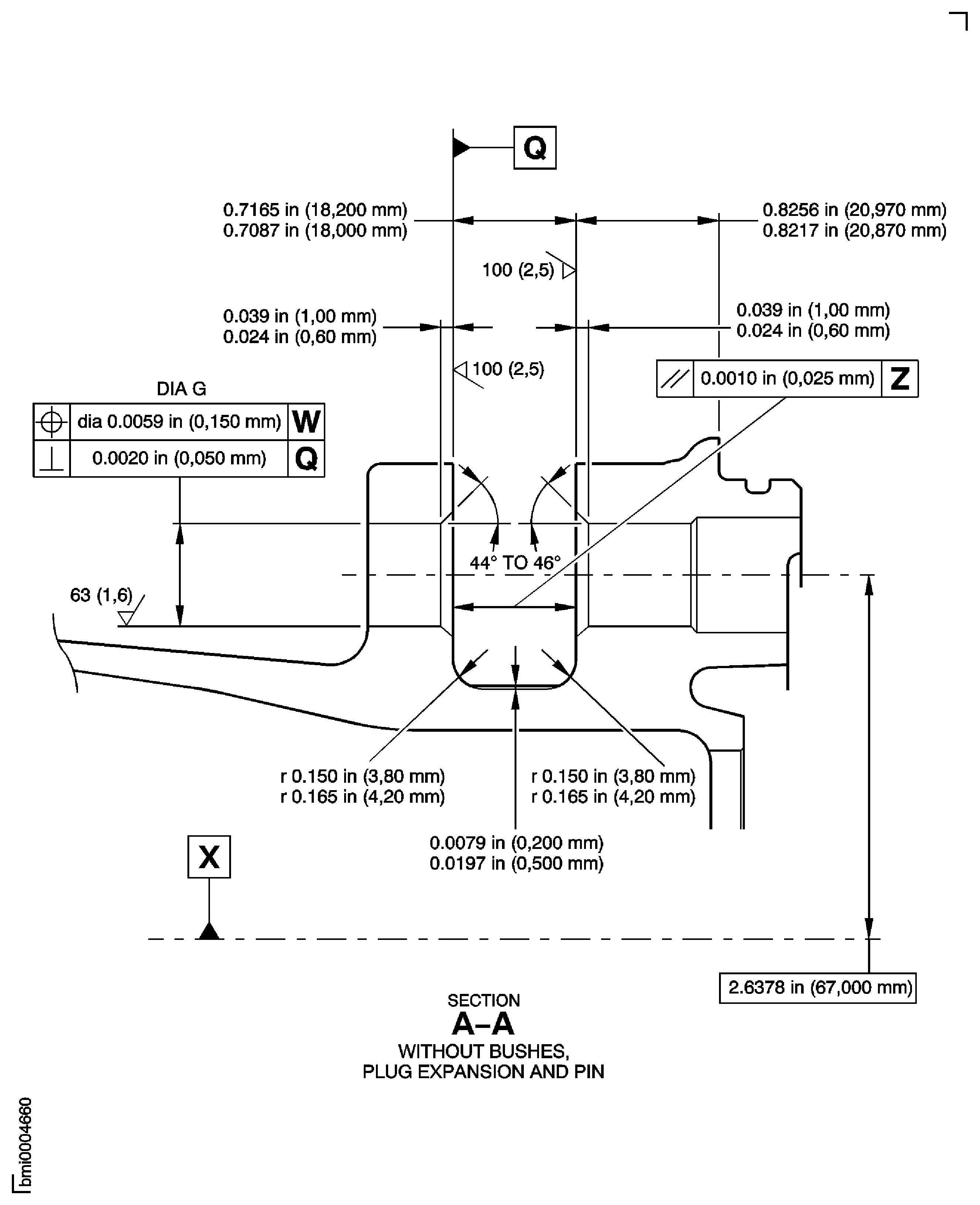

Figure: Repair Details and Dimensions

Sheet 1

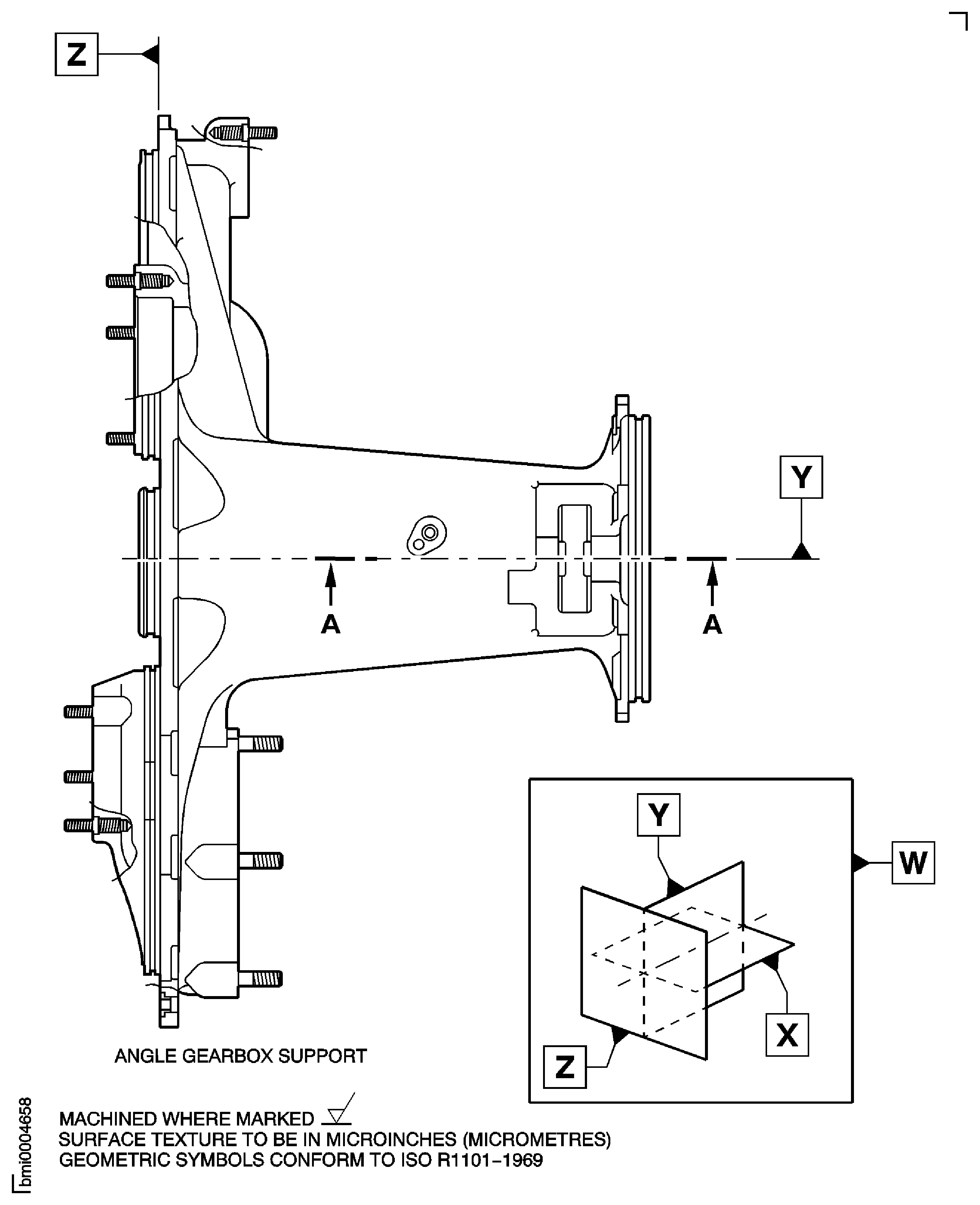

Figure: Repair Details and Dimensions

Repair Details and Dimensions

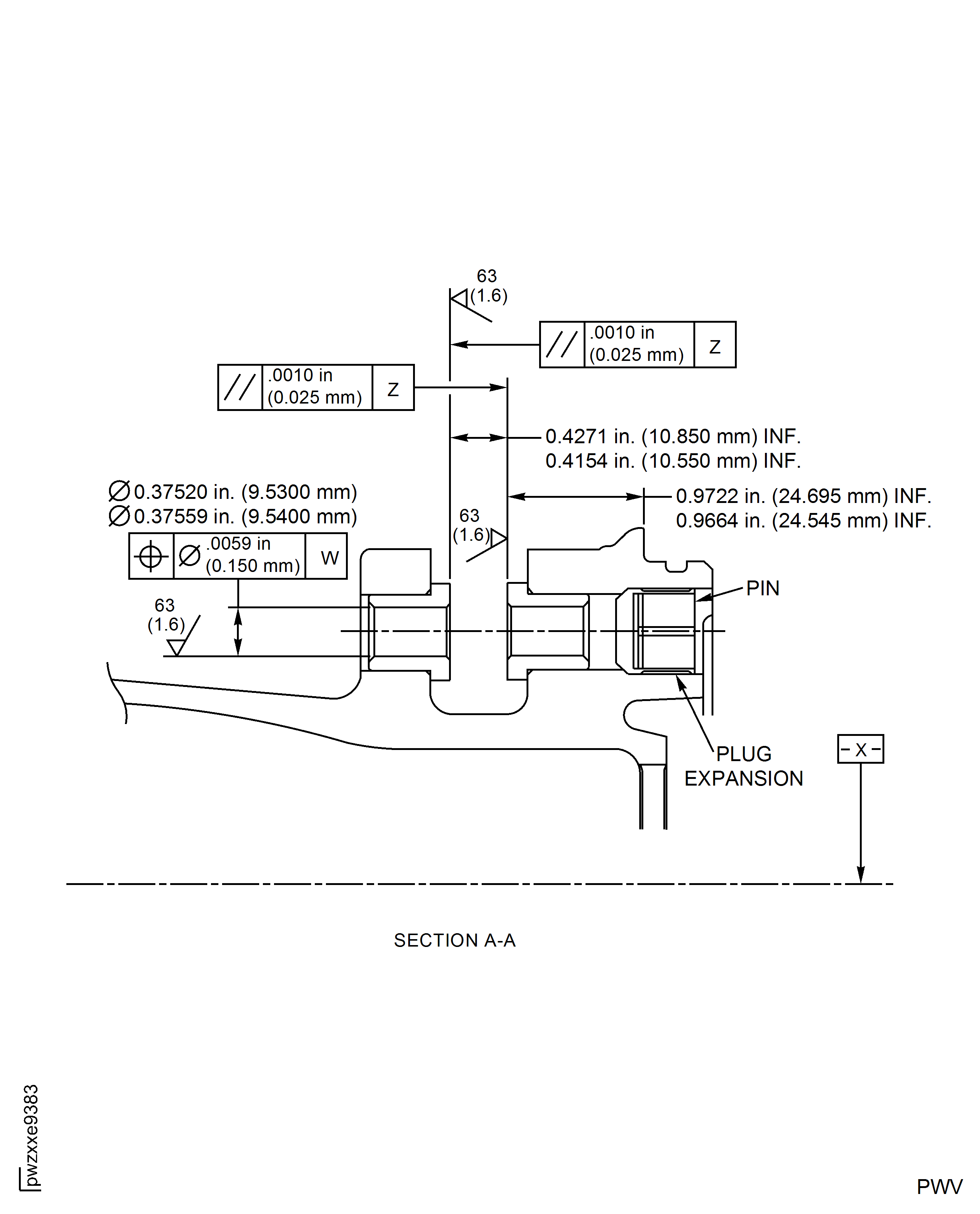

Figure: Repair Details and Dimensions

Sheet 3