Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-40-440-001 Angle Gearbox Assembly - Assemble The Angle Gearbox, Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501, SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-039 ENGINE OIL, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings refer to SPM TASK 70-44-01-400-501.

After assembly apply CoMat 07-012 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. refer to SPM TASK 70-38-06-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must be removed immediately before the installation of the components.

Make sure that the outer race has the same serial number of the related bearing.

Lubricate the cages of the roller bearings with CoMat 10-039 ENGINE OIL before the installation.

Operate by hand the installed gearshafts to make easier subsequent installations.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Swivel vise | LOCAL | Swivel vise | ||

| Arbor Press | LOCAL | Arbor press | ||

| Hot Air Gun | LOCAL | Hot Air Gun | ||

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1F10082 Guide Pin | 0AM53 | IAE 1F10082 | 2 | |

| IAE 1F10087 Base | 0AM53 | IAE 1F10087 | 1 | |

| IAE 1F10098 Pusher | 0AM53 | IAE 1F10098 | 1 | |

| IAE 1F10100 Base holder | 0AM53 | IAE 1F10100 | 1 | |

| IAE 1F10102 Pusher | 0AM53 | IAE 1F10102 | 1 | |

| IAE 1F10104 Hand wrench | 0AM53 | IAE 1F10104 | 1 | |

| IAE 1F10105 Pusher | 0AM53 | 1F10105 | ||

| IAE 1F10110 Stud | 0AM53 | IAE 1F10110 | 3 | |

| IAE 1F10114 Hydraulic cylinder | 0AM53 | IAE 1F10114 | 1 | |

| IAE 1F10122 Pusher | 0AM53 | IAE 1F10122 | 1 | |

| IAE 1F10123 Puller | 0AM53 | IAE 1F10123 | 1 | |

| IAE 1F10128 Pusher | 0AM53 | IAE 1F10128 | 1 | |

| IAE 1F10129 Pusher | 0AM53 | IAE 1F10129 | 1 | |

| IAE 1F10130 Guide pins | 0AM53 | IAE 1F10130 | 2 | |

| IAE 1F10131 Base | 0AM53 | IAE 1F10131 | 1 | |

| IAE 1F10133 Pusher | 0AM53 | IAE 1F10133 | 1 | |

| IAE 1F10134 Ring | 0AM53 | IAE 1F10134 | 1 | |

| IAE 1F10135 Base | 0AM53 | IAE 1F10135 | 1 | |

| IAE 1F10136 Pusher | 0AM53 | IAE 1F10136 | 1 | |

| IAE 1F10201 Base | 0AM53 | IAE 1F10201 | 1 | |

| IAE 2F10132 Backlash fixture | 0AM53 | IAE 2F10132 | 1 | |

| IAE 2F10137 Clamping fixture | 0AM53 | IAE 2F10137 | 1 | |

| IAE 2F10138 Loading fixture | 0AM53 | IAE 2F10138 | 1 | |

| IAE 2F10139 Backlash fixture | 0AM53 | IAE 2F10139 | 1 | |

| IAE 2F10140 Loading fixture | 0AM53 | IAE 2F10140 | 1 | |

| IAE 2F10141 Clearance gage | 0AM53 | IAE 2F10141 | 1 | |

| IAE 2F10143 Clamping fixture | 0AM53 | IAE 2F10143 | 1 | |

| IAE 2F10144 Clamping fixture | 0AM53 | IAE 2F10144 | 1 | |

| IAE 2F10145 Rotating fixture | 0AM53 | IAE 2F10145 | 1 | |

| IAE 2F10147 Rotating fixture | 0AM53 | IAE 2F10147 | 1 | |

| IAE 2F10148 Clamping adapter | 0AM53 | IAE 2F10148 | 1 | |

| IAE 2F10217 Rotating handwheel | 0AM53 | IAE 2F10217 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-179 COMPOUND, GEAR MARKING | LOCAL | CoMat 02-179 | ||

| CoMat 07-012 AIR DRYING ENAMEL | 0AM53 | CoMat 07-012 | ||

| CoMat 10-039 ENGINE OIL | LOCAL | CoMat 10-039 |

Spares

Safety Requirements

NONEProcedure

Refer to Figure.

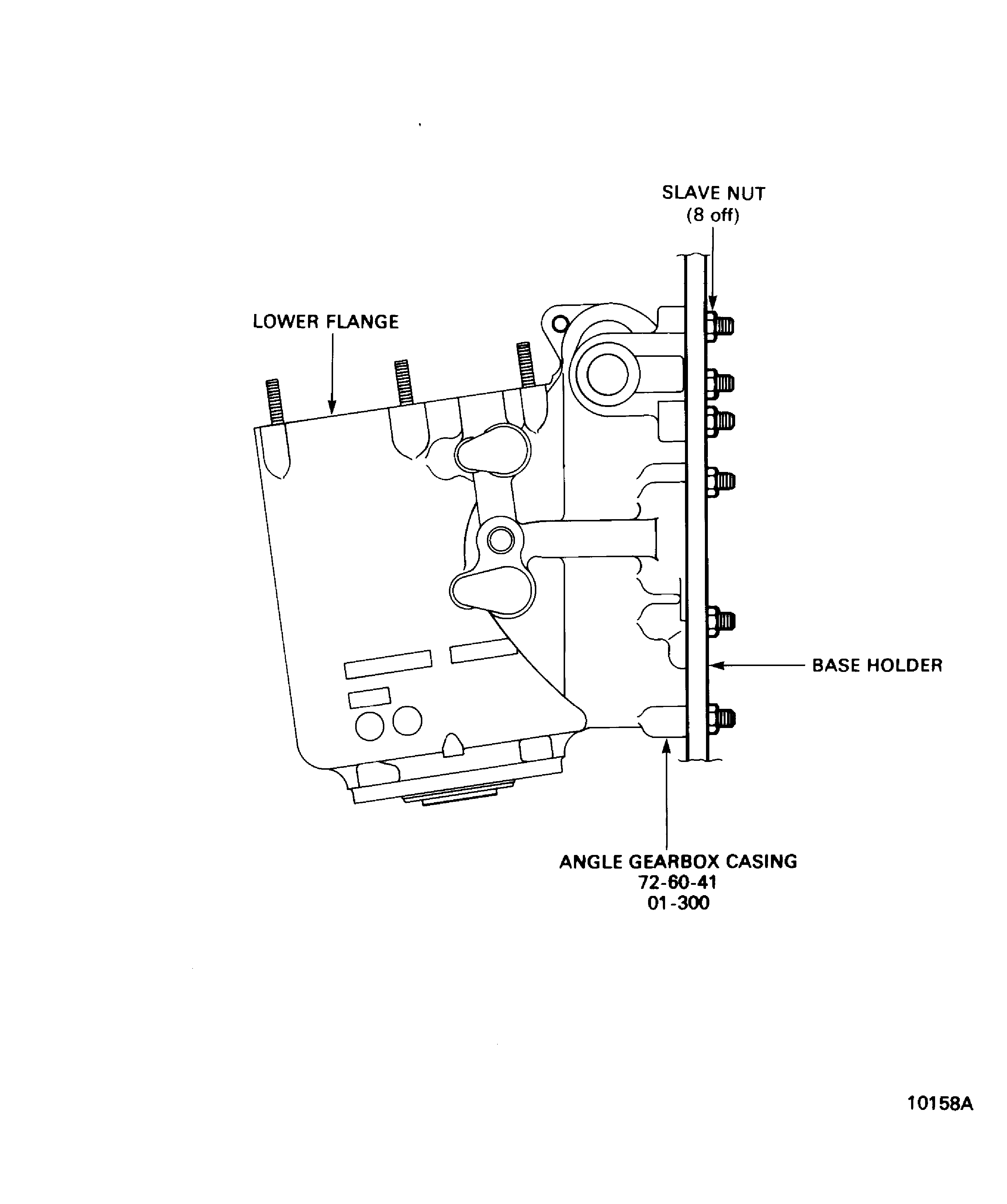

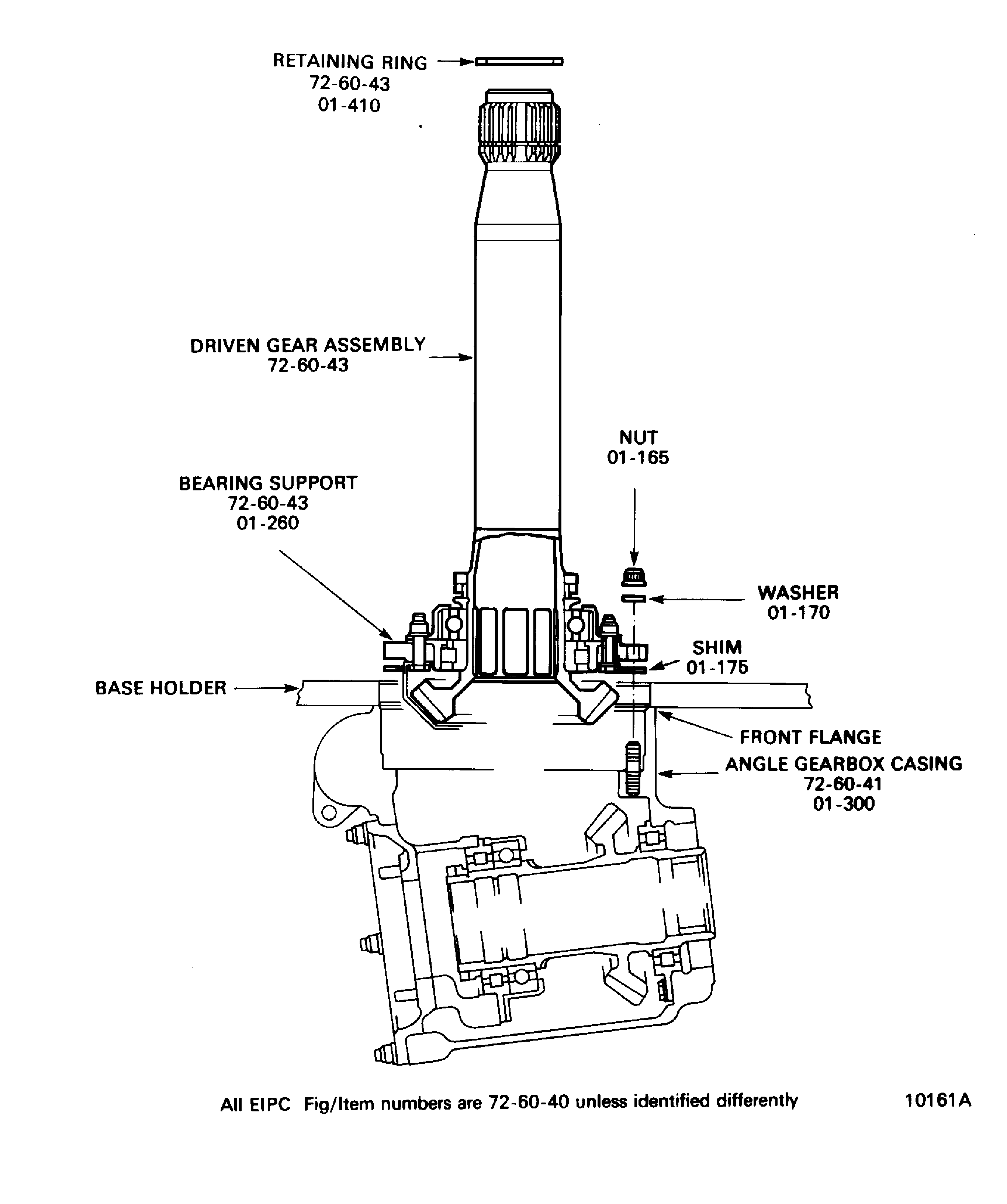

Align the guide pin and the studs in front face of the angle gearbox casing with the holes on IAE 1F10100 Base holder 1 off. Install the angle gearbox casing on the base holder.

SUBTASK 72-60-40-440-051 Install the Angle Gearbox Casing on the Base Holder

Refer to Figure.

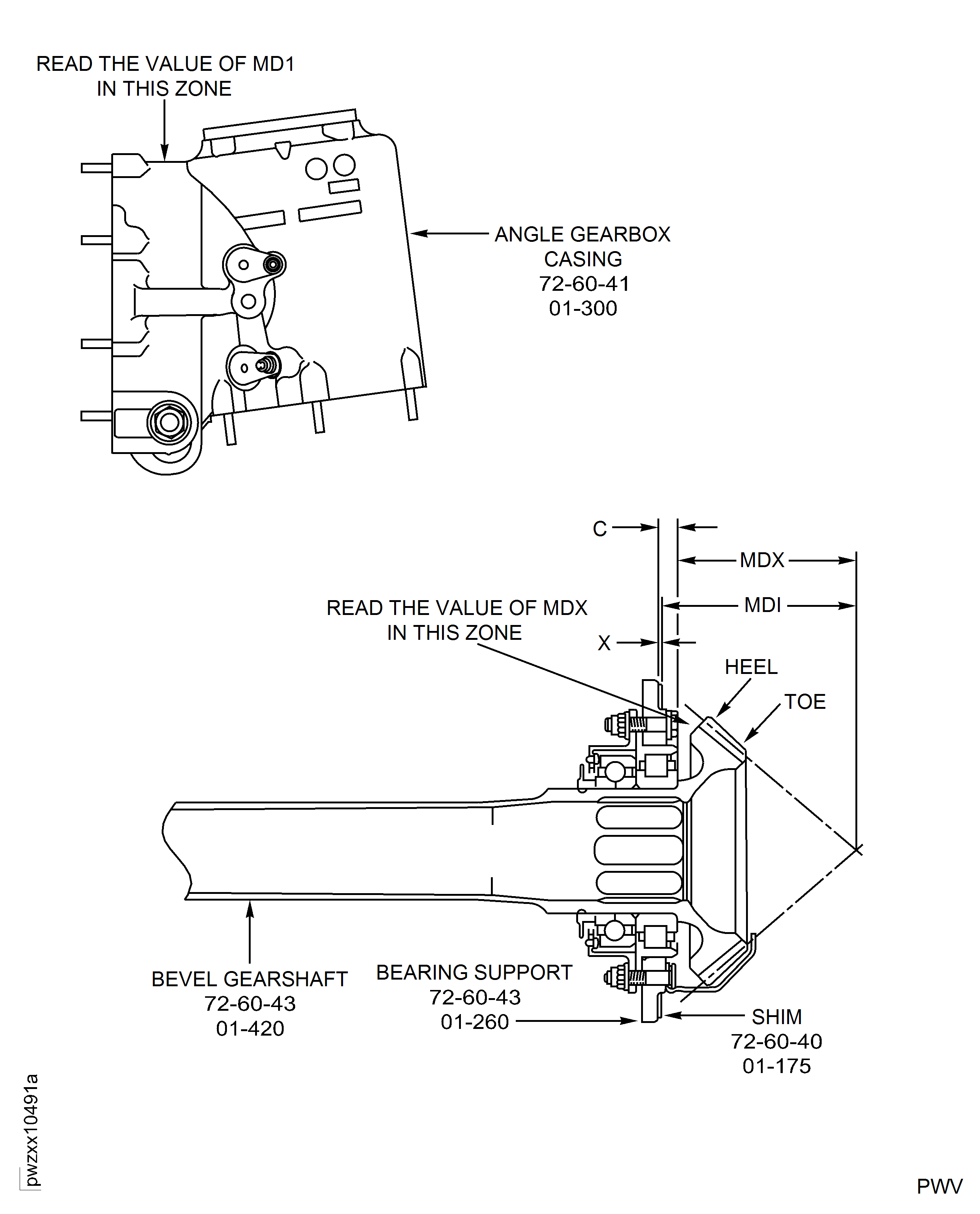

Calculate the thickness of the shim (01-175), Figure.

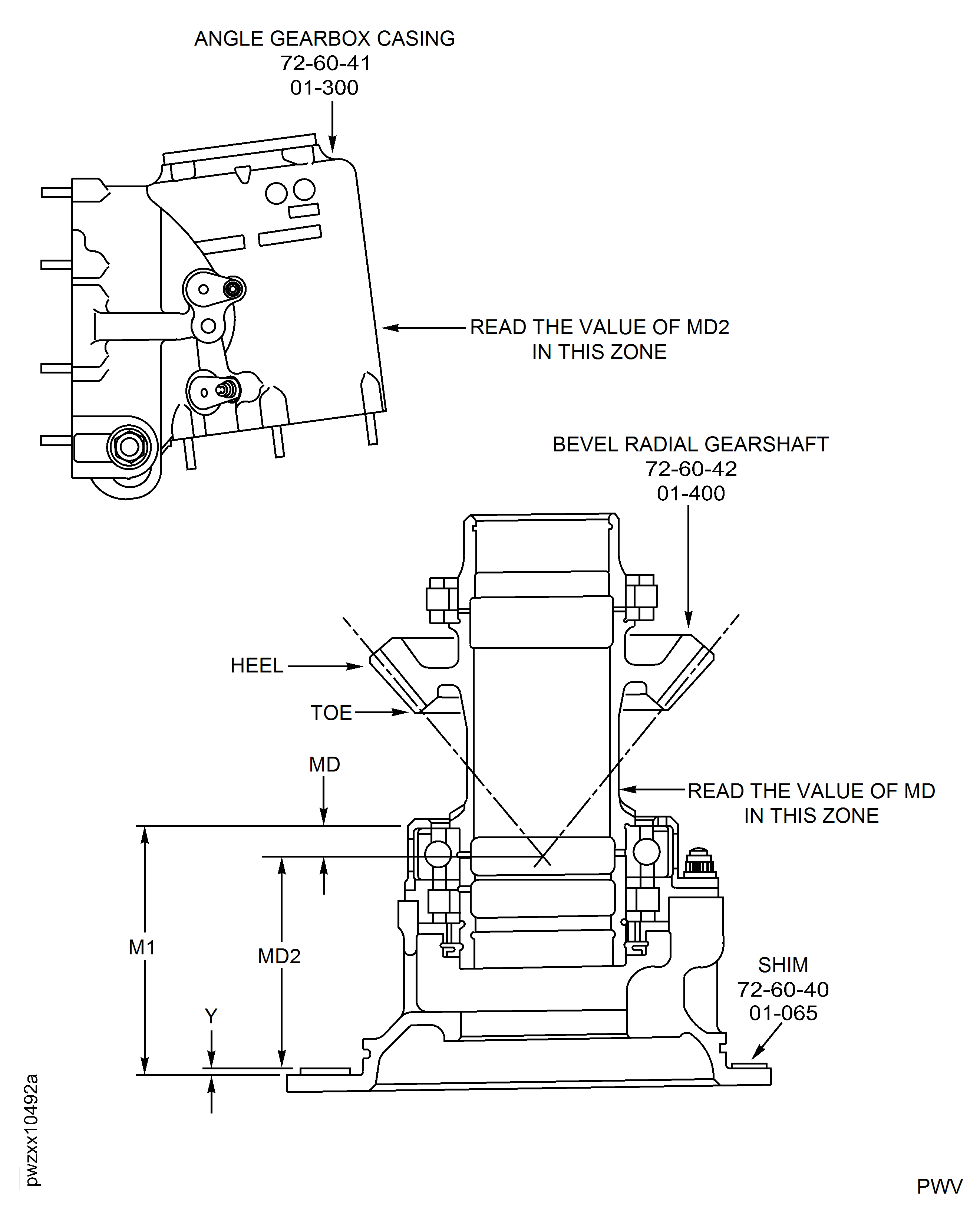

Calculate the thickness of the shim (01-165), Figure.

SUBTASK 72-60-40-440-052 Calculate the Thickness of the Shims

NOTE

It is only required to calculate the thickness of the shims if any of the following statements are true,1. The shim thickness for Dimension X or Dimension Y are not recorded during disassembly of the Angle Gearbox.2. One or more of the following parts have been replaced since disassembly of the Angle Gearbox: Driving Bevel Gearshaft, Driven Bevel Gearshaft, Angle Gearbox Casing, Roller Bearing (Driven Bevel Gearshaft), Roller Bearing (Driving Bevel Gearshaft), Ball Bearing (Driving Bevel Gearshaft).Refer to Figure.

WARNING

DO NOT TOUCH THE HOT PARTS WITHOUT PROTECTIVE GLOVES.

WARNING

HOT PARTS CAN CAUSE REDDENING AND BLISTERING OF THE SKIN IF THE HANDS ARE NOT PROTECTED.

WARNING

IMMERSE THE CONTACTED AREA IN COLD WATER FOR 10 MINUTES IF THE SKIN IS BURNED. IMMEDIATELY GET MEDICAL ATTENTION IF PAIN OR BLISTERING PERSISTS.NOTE

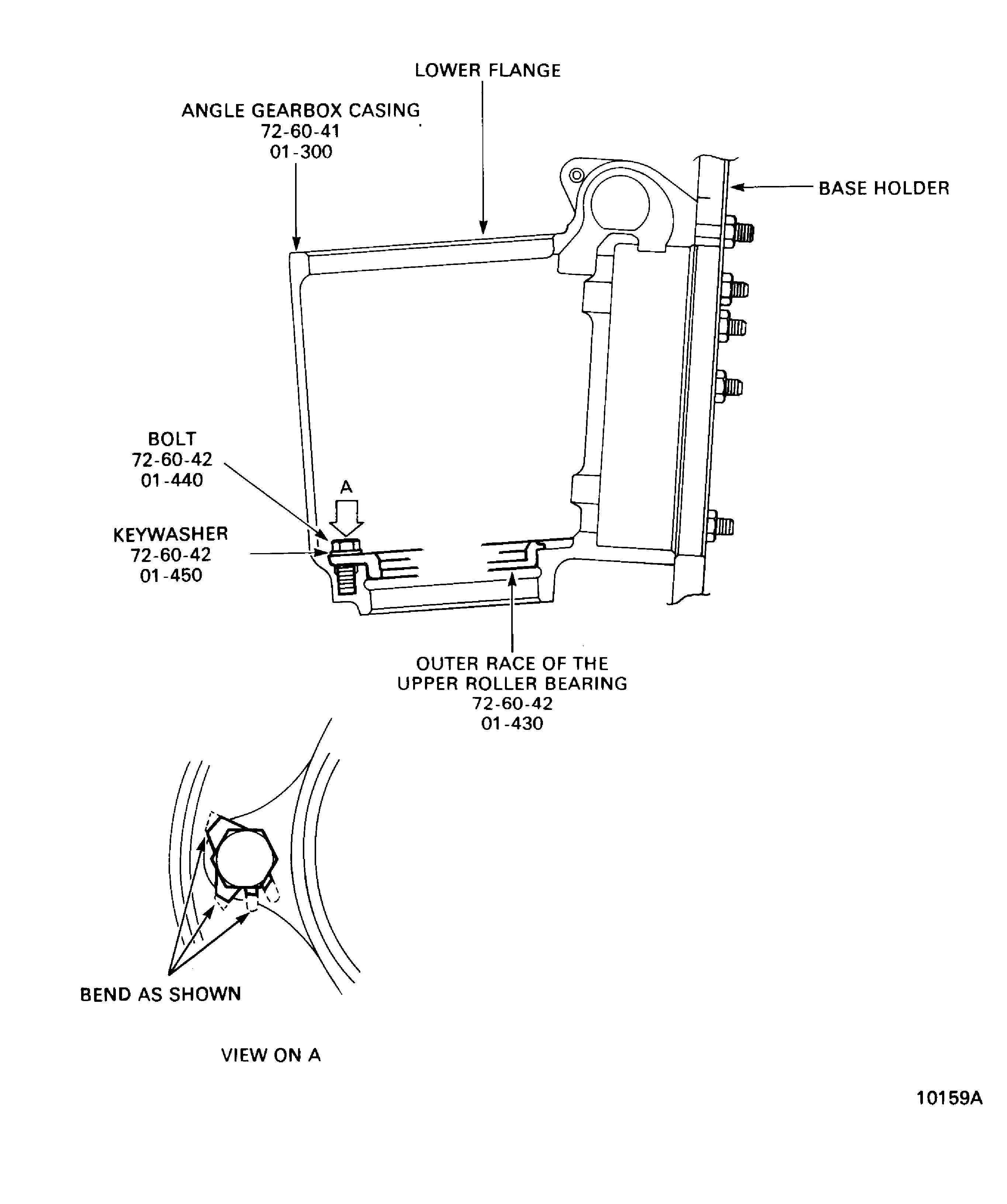

If the subsequent operation is not easy, locally increase the temperature of the angle gearbox casing to 250 °F (121 °C) maximum. Use a hot air gun.Install IAE 1F10082 Guide Pin 2 off in to the bolt holes near the seat of the outer race.

Align the holes on the outer race flange with the guide pins. Install the outer race in to the seat in the internal of the angle gearbox casing. Use IAE 1F10098 Pusher 1 off to easy the installation. Remove the two guide pins.

SUBTASK 72-60-40-440-053 Install the Outer Race of the Upper Roller Bearing

Refer to Figure.

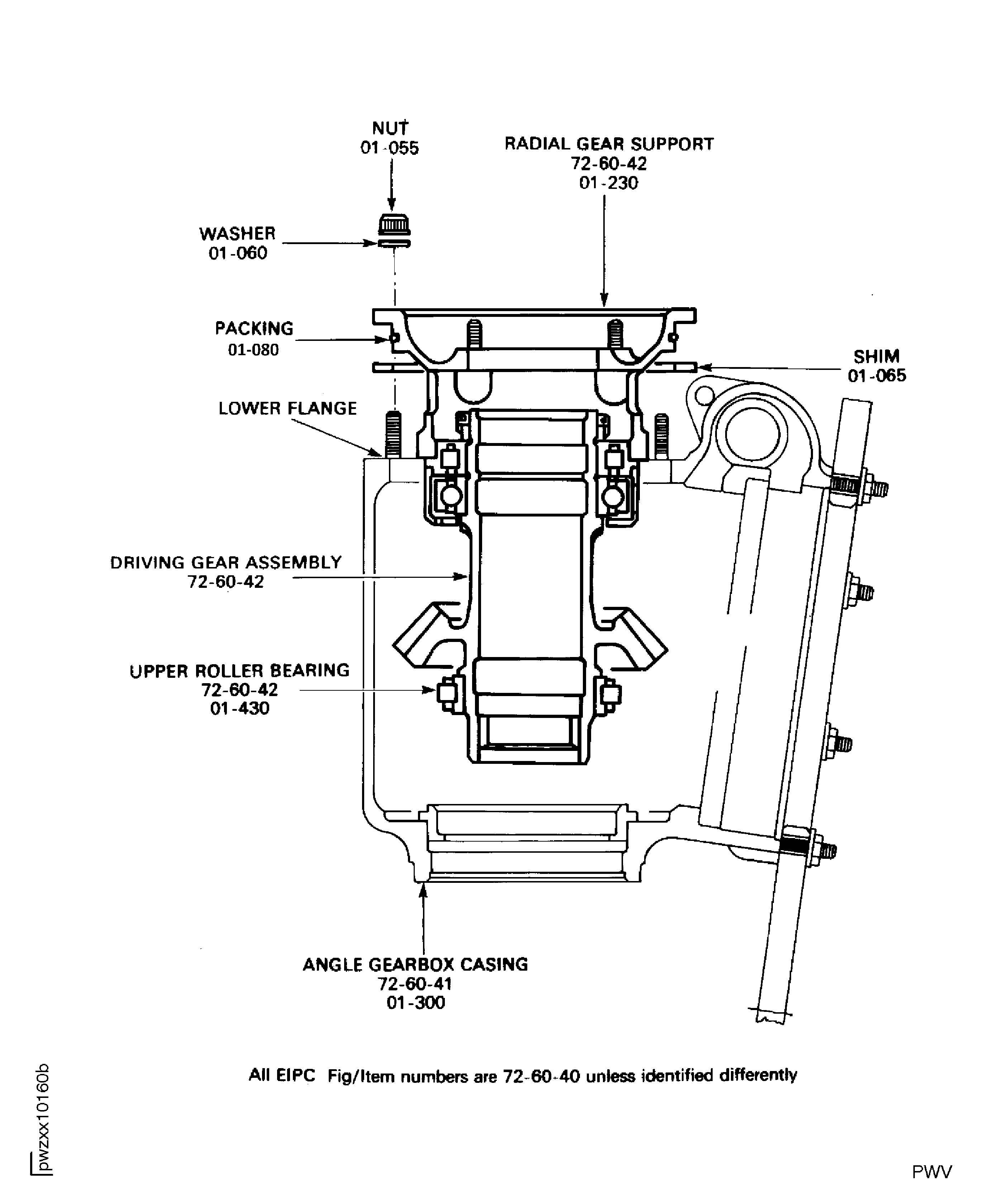

Install Angle Gearbox Assembly (72-60-40, 01-080) packing 1 off in to the groove on the radial gear support.

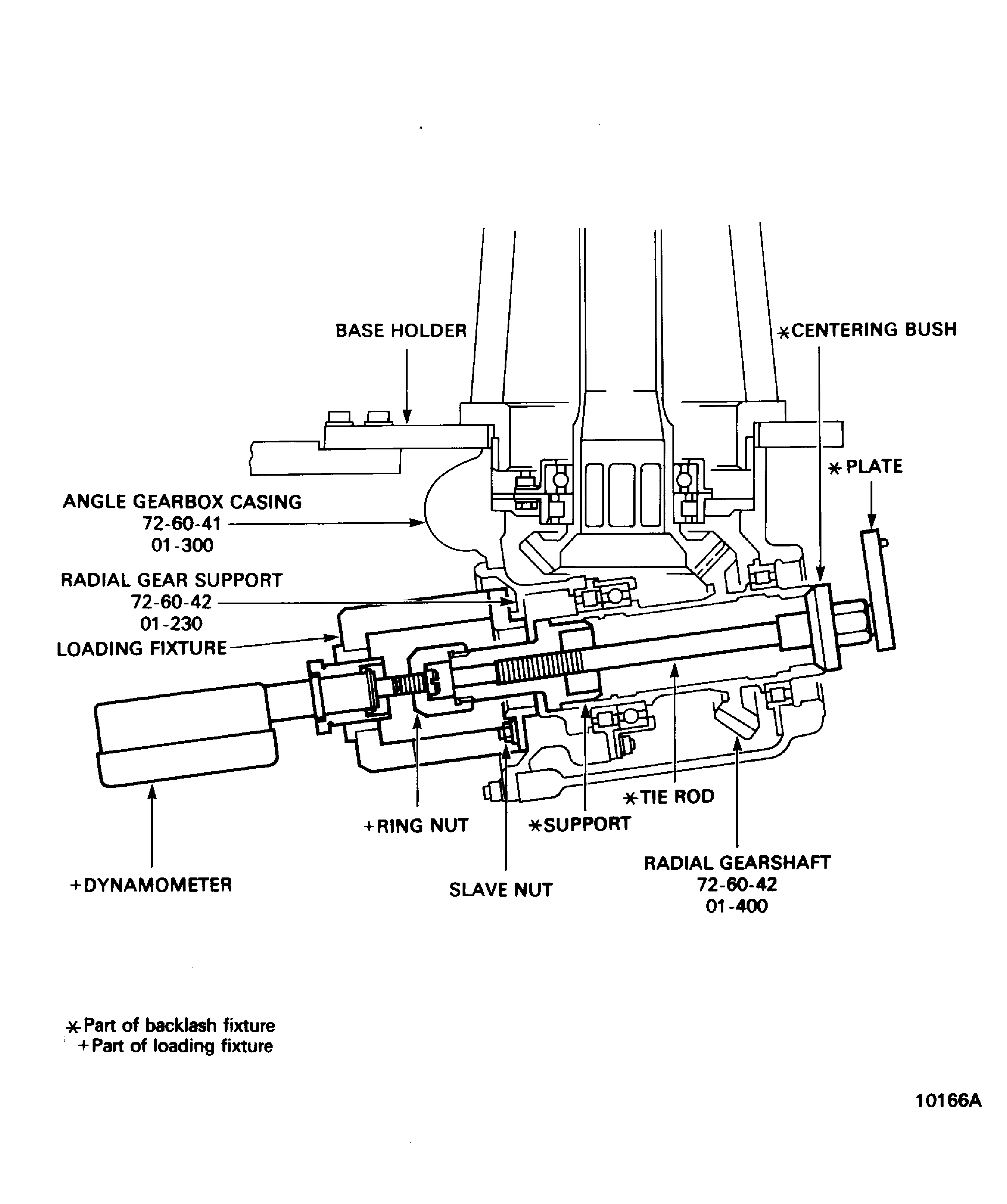

Apply CoMat 02-179 COMPOUND, GEAR MARKING on the teeth of the radial gearshaft.

SUBTASK 72-60-40-440-054 Install the Driving Gear Assembly for the Contact and the Backlash Checks

Refer to Figure.

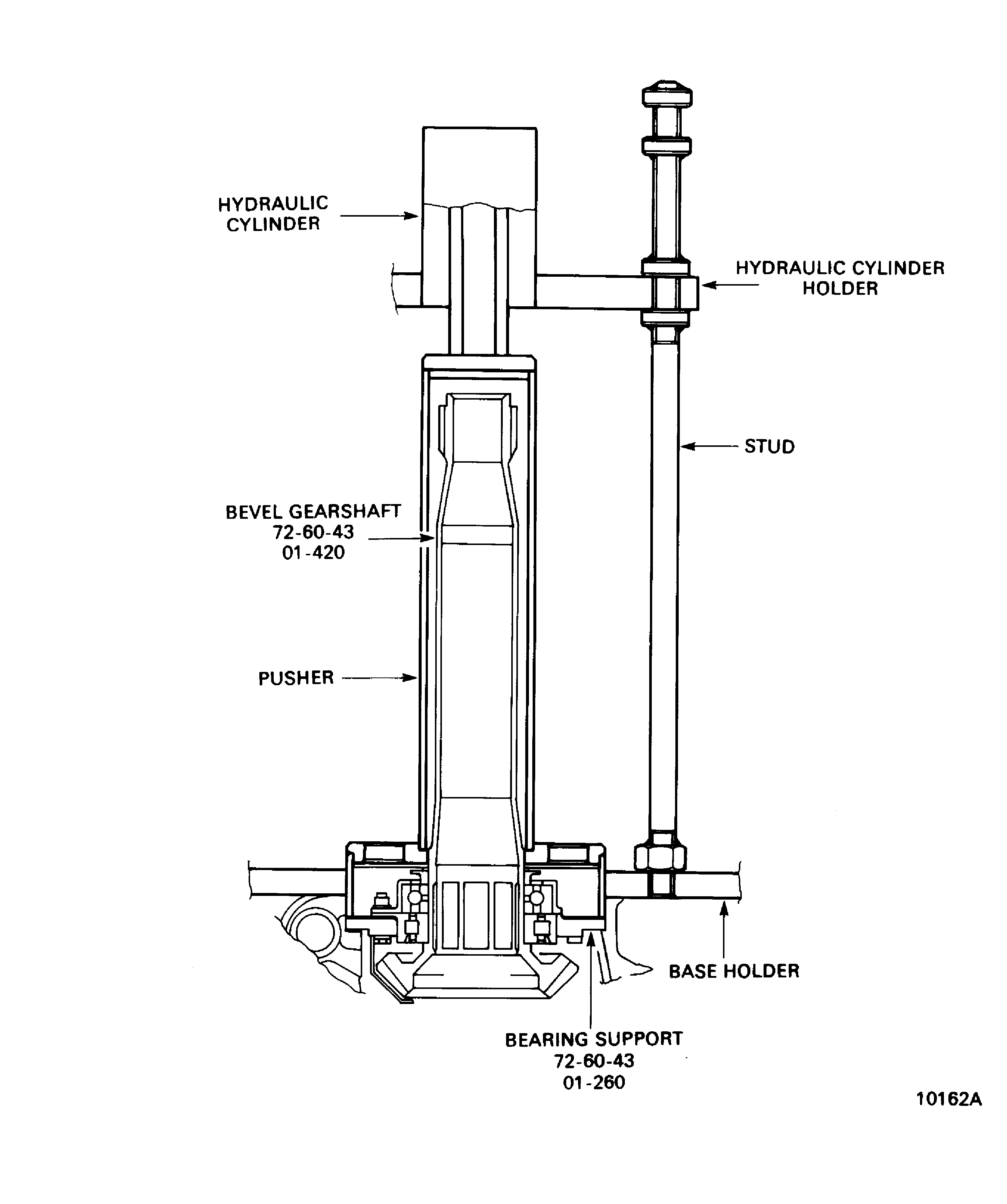

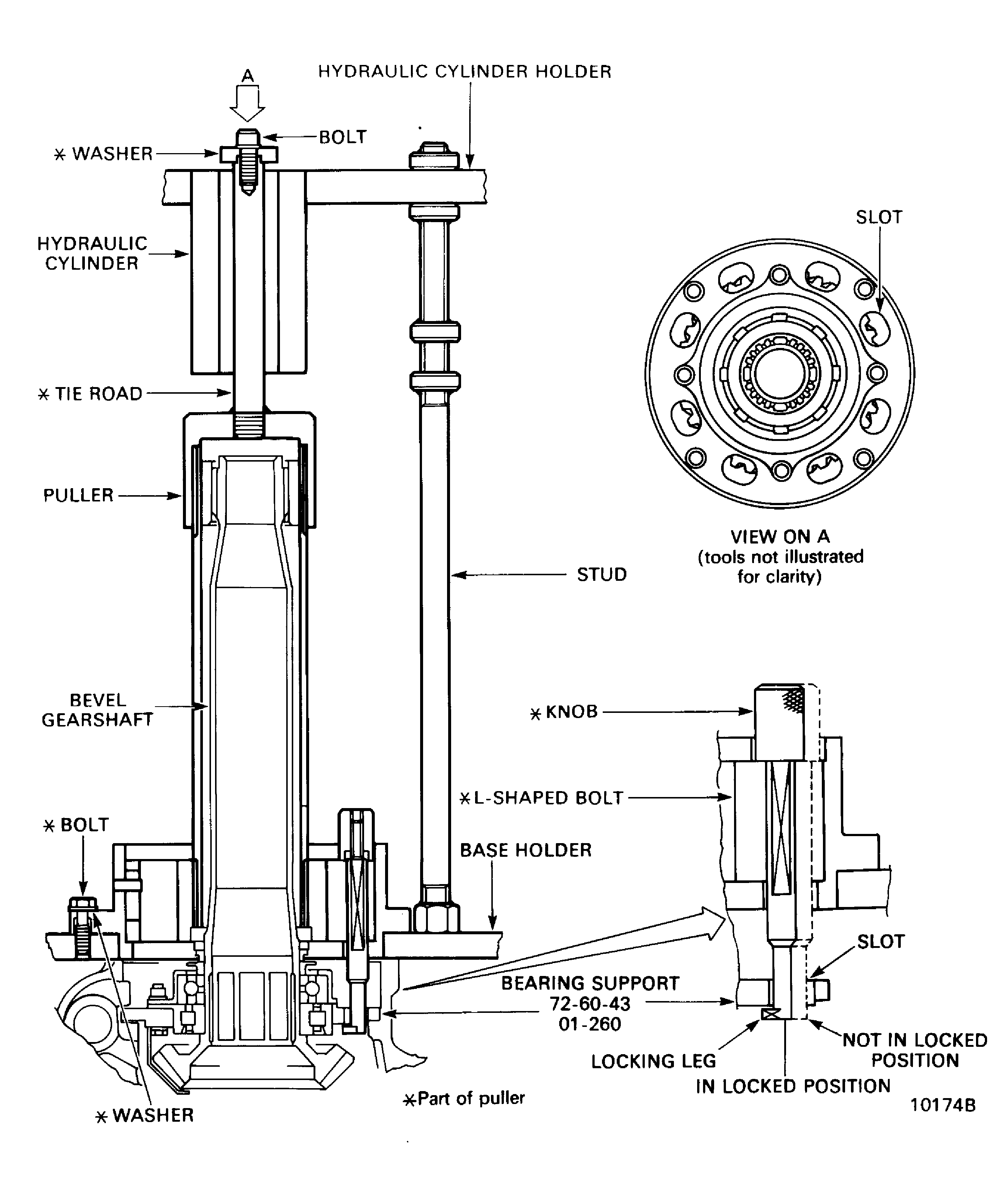

Apply CoMat 02-179 COMPOUND, GEAR MARKING on the teeth of the bevel gearshaft.

Install IAE 1F10110 Stud 3 off on the base holder.

Install IAE 1F10122 Pusher 1 off over the bevel gearshaft and put on the bearing support.

Install IAE 1F10114 Hydraulic cylinder 1 off on the three studs. Make sure that the hydraulic cylinder is seated to push.

Attach IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic cylinder. Operate the hydraulic pump until the driven gear assembly is fully installed on the angle gearbox casing.

SUBTASK 72-60-40-440-055 Install the Driven Gear Assembly for the Contact and the Backlash Checks

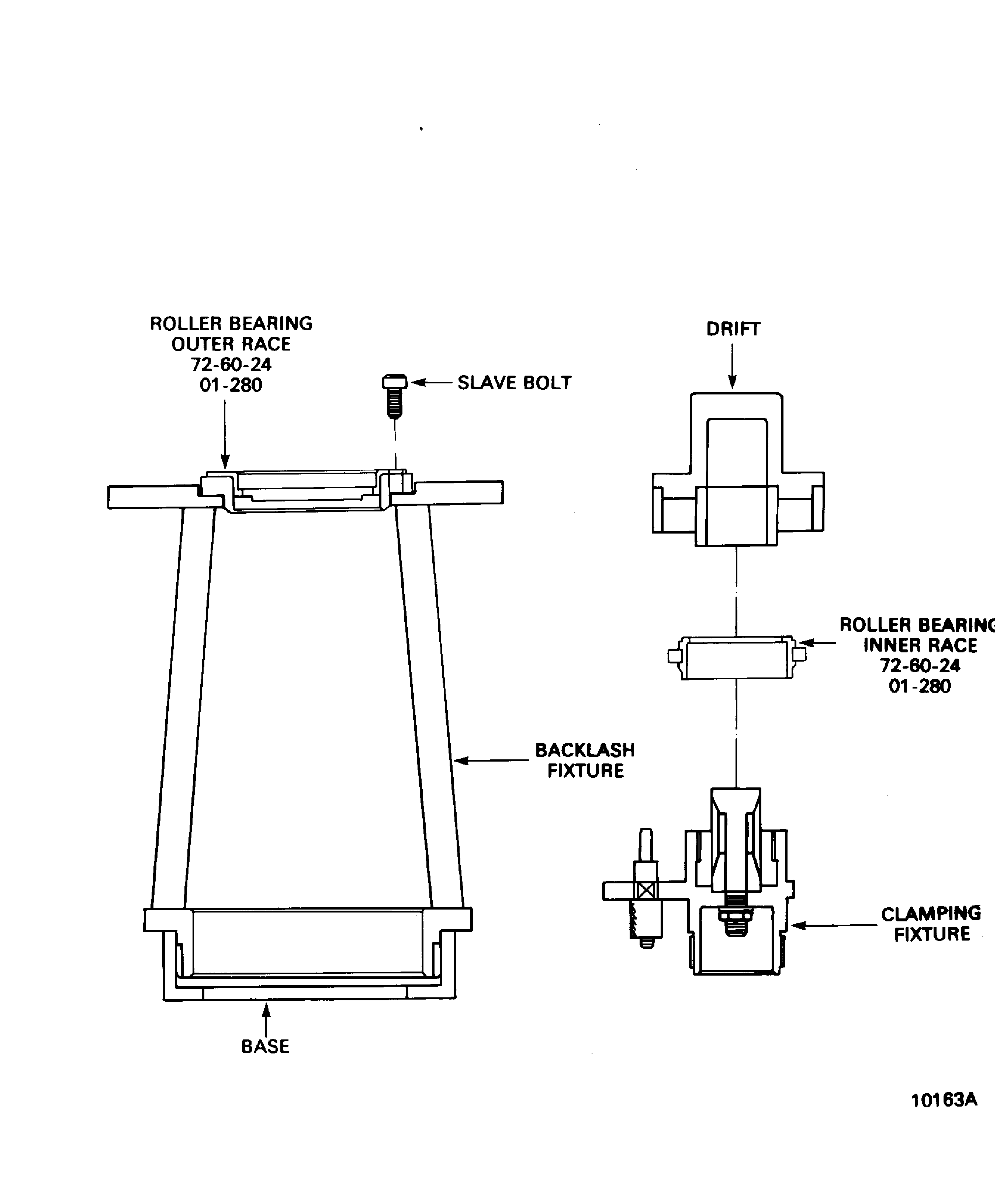

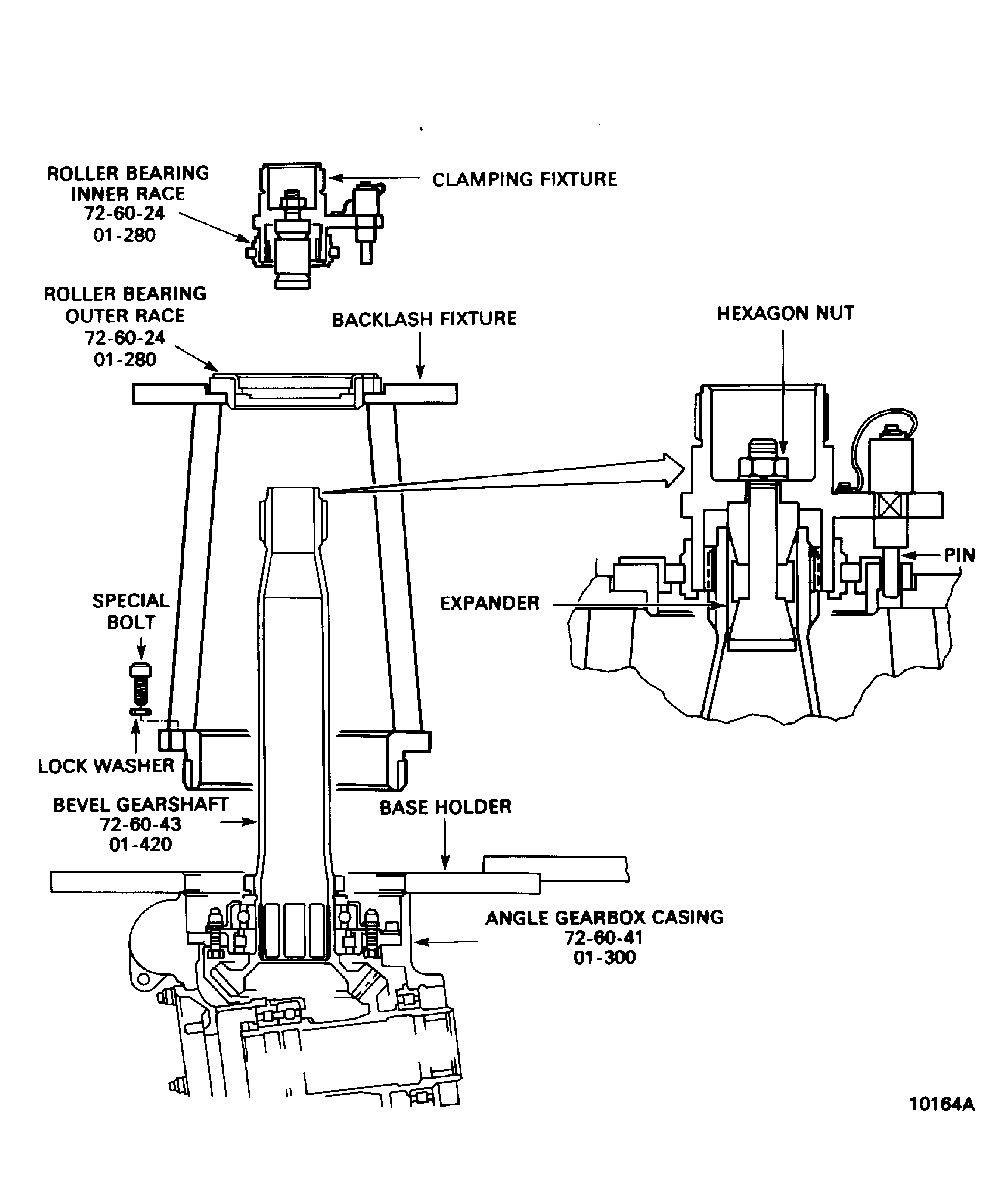

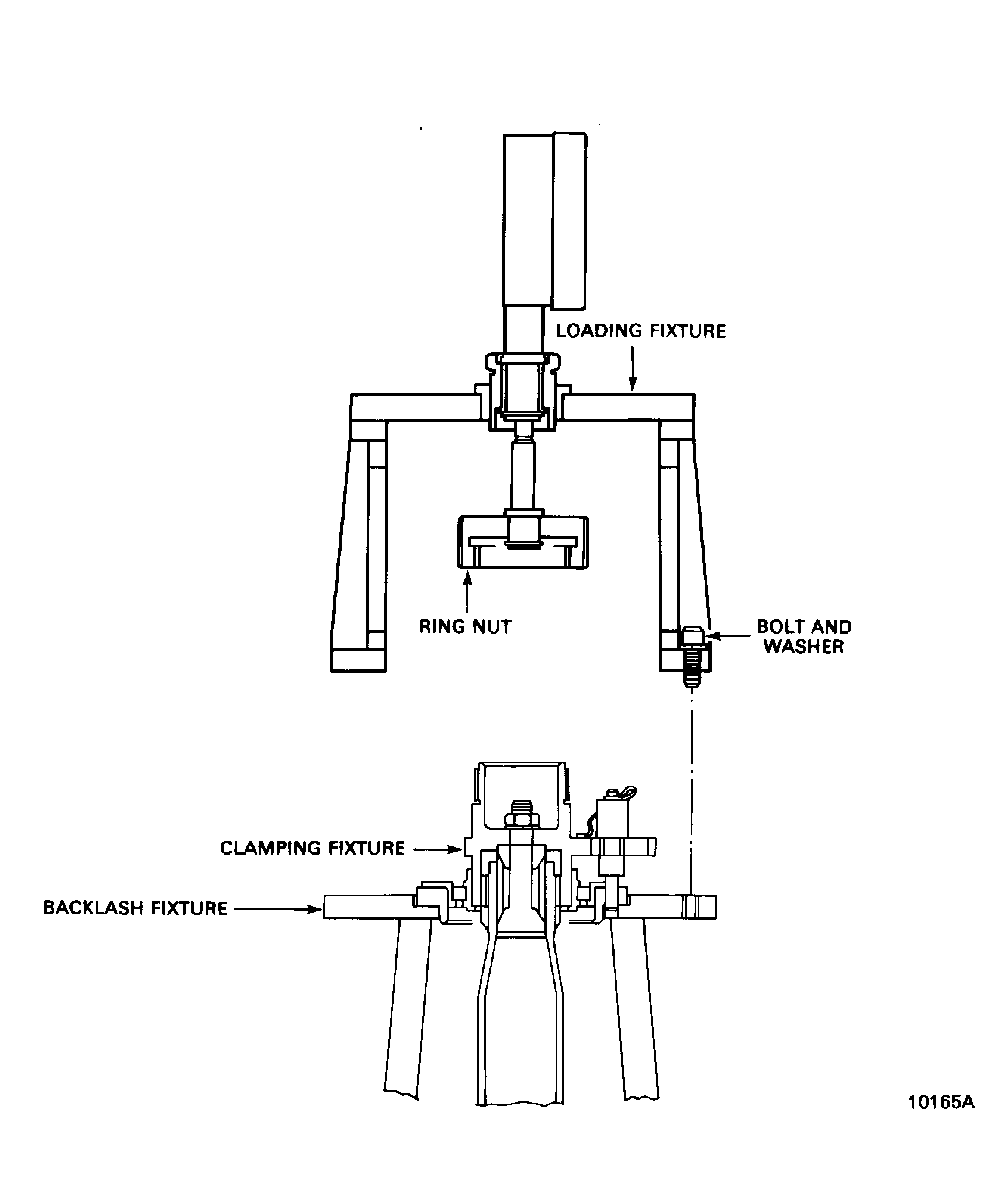

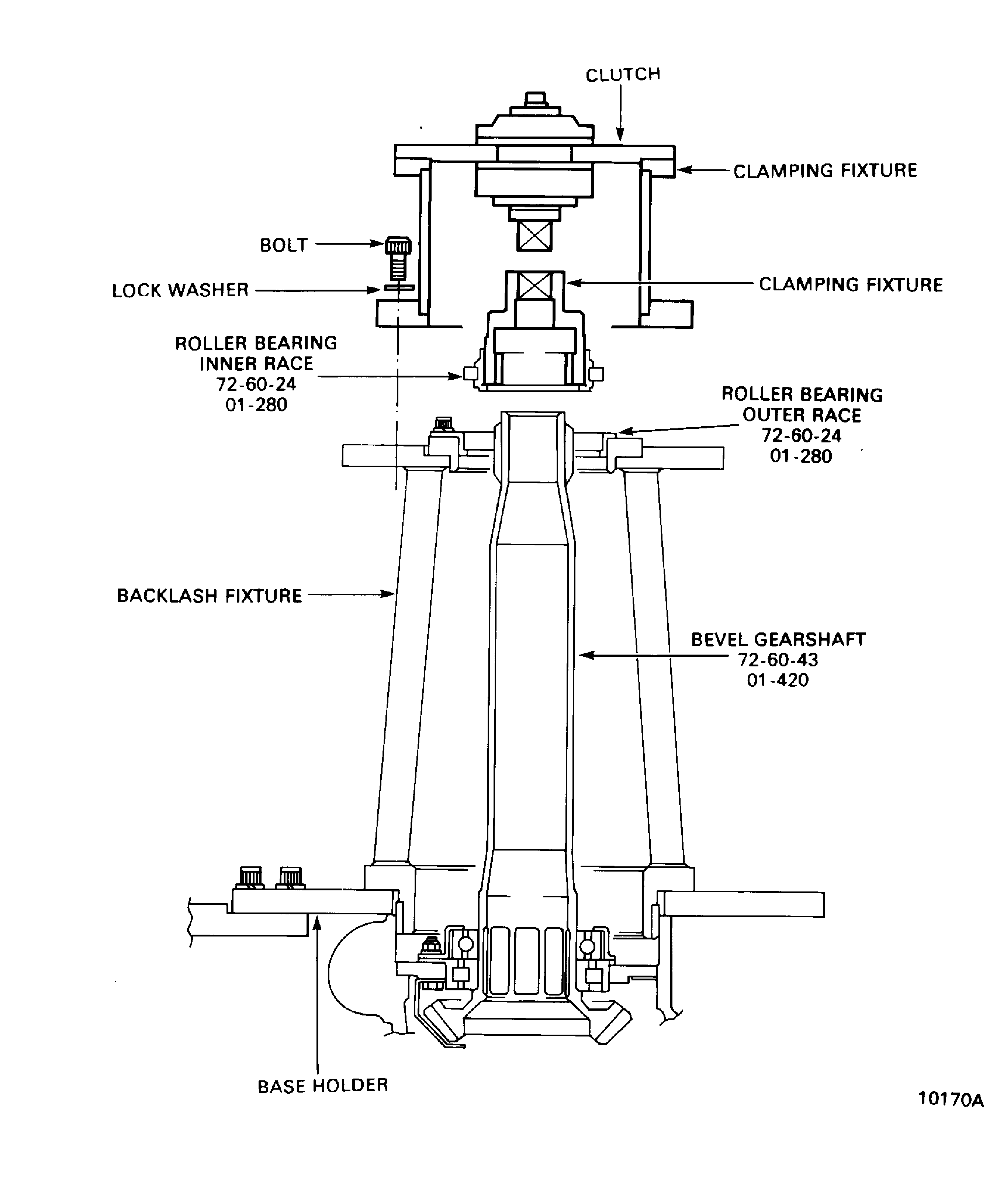

Install IAE 2F10132 Backlash fixture 1 off on IAE 1F10131 Base 1 off.

Install IAE 1F10130 Guide pins 2 off on the top flange of the backlash fixture.

Align the holes on the outer race flange with the guide pins. Install the outer race on the backlash fixture. Use IAE 1F10128 Pusher 1 off to easy the installation.

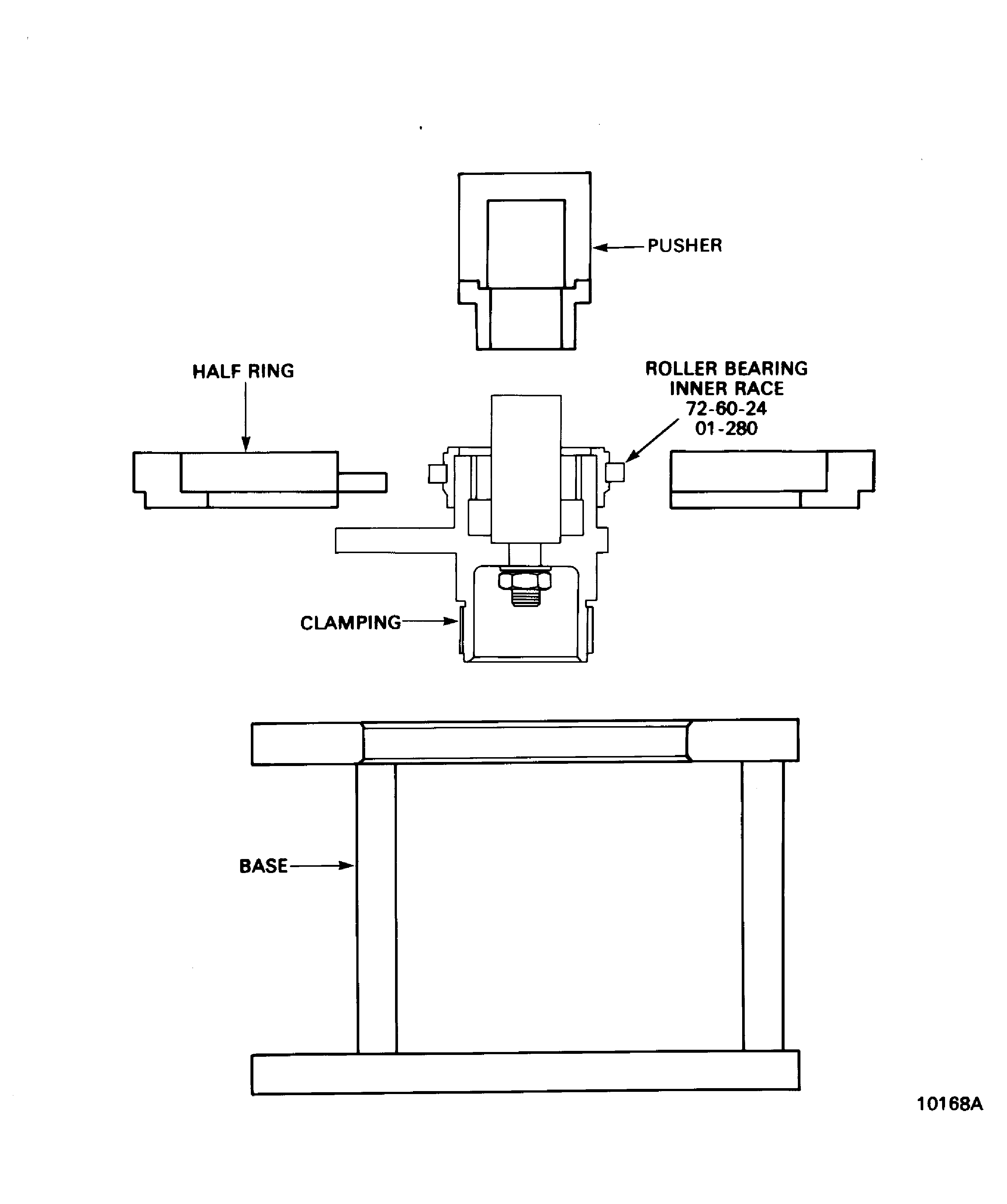

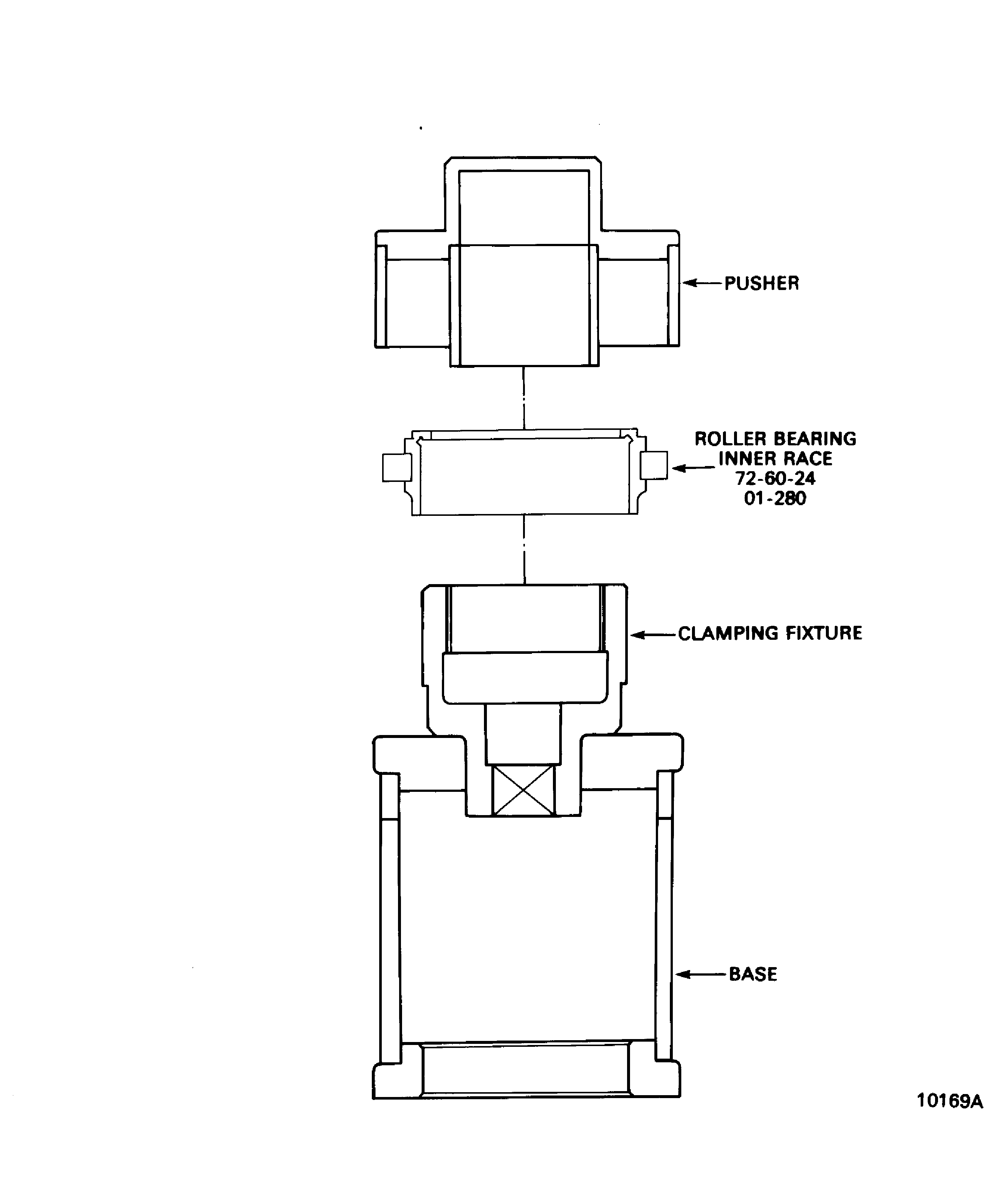

Install the outer race of the roller bearing Extension Layshaft Gear And Bearing Assembly (72-60-24, 01-280) on the backlash fixture, Figure.

Install the backlash fixture on the base holder. Safety with the four lockwashers and special bolts, Figure.

WARNING

DO NOT TOUCH THE HOT PARTS WITHOUT PROTECTIVE GLOVES.HOT PARTS CAN CAUSE REDDENING AND BLISTERING OF THE SKIN IF THE HANDS ARE NOT PROTECTED.IMMERSE THE CONTACTED AREA IN COLD WATER FOR 10 MINUTES IF THE SKIN IS BURNED. IMMEDIATELY GET MEDICAL ATTENTION IF PAIN OR BLISTERING PERSISTS.Put the inner race of the roller bearing in to the oven and increase the temperature to 250 °F (121 °C) maximum.

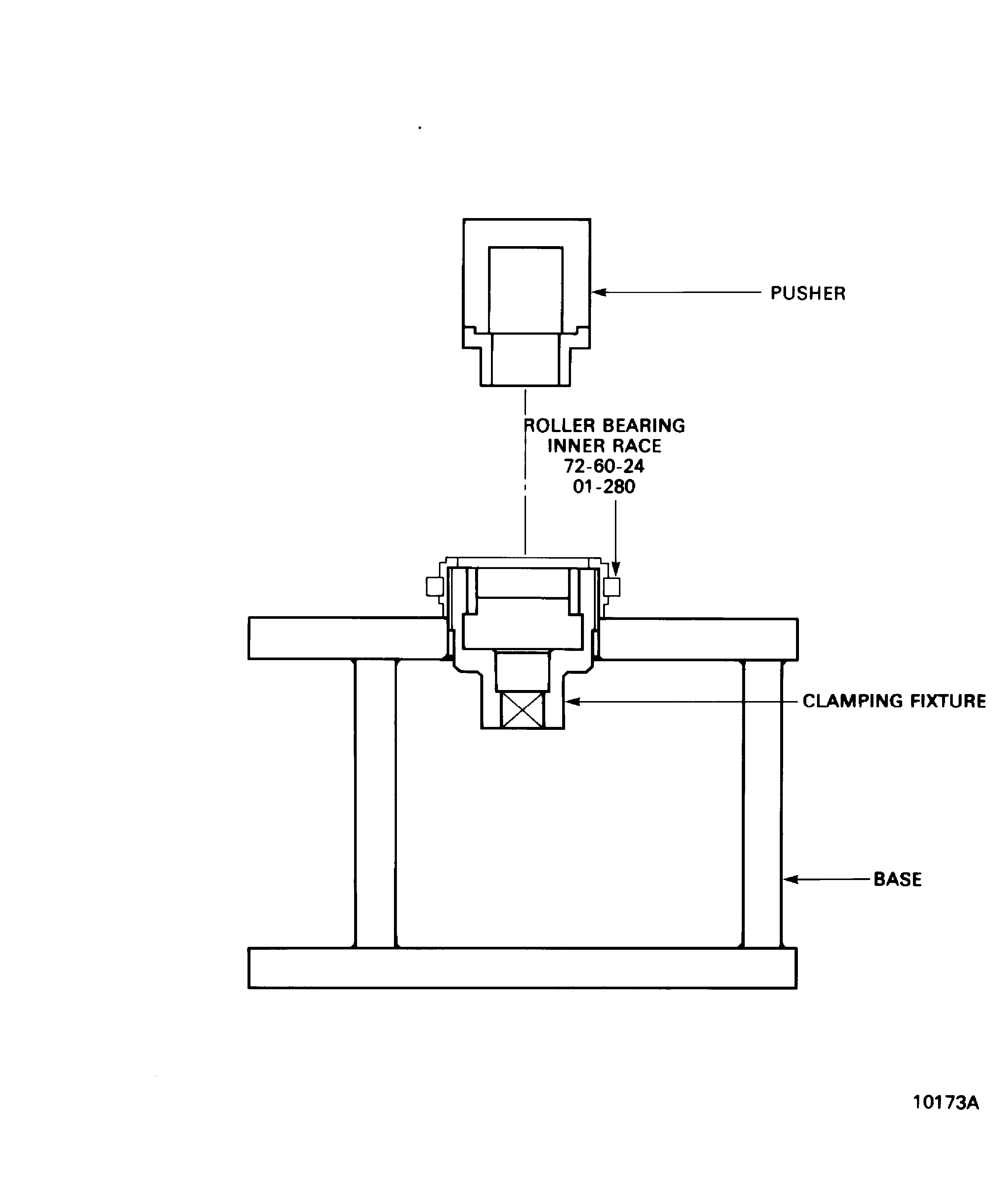

Install the inner race on the clamping fixture. Use IAE 1F10133 Pusher 1 off and the Arbor Press ram or equivalent.

Install the inner race of the roller bearing Extension Layshaft Gear And Bearing Assembly (72-60-24, 01-280) on the IAE 2F10137 Clamping fixture 1 off, Figure.

Install the clamping fixture, Figure.

Install IAE 2F10138 Loading fixture 1 off on the backlash fixture and attach with the bolts and washers. Attach the ring nut to the clamping fixture, Figure.

Install IAE 2F10139 Backlash fixture 1 off, Figure.

Install IAE 2F10140 Loading fixture 1 off, Figure.

SUBTASK 72-60-40-440-056 Install the Tools for the Backlash Check of the Angle Gearbox Gears

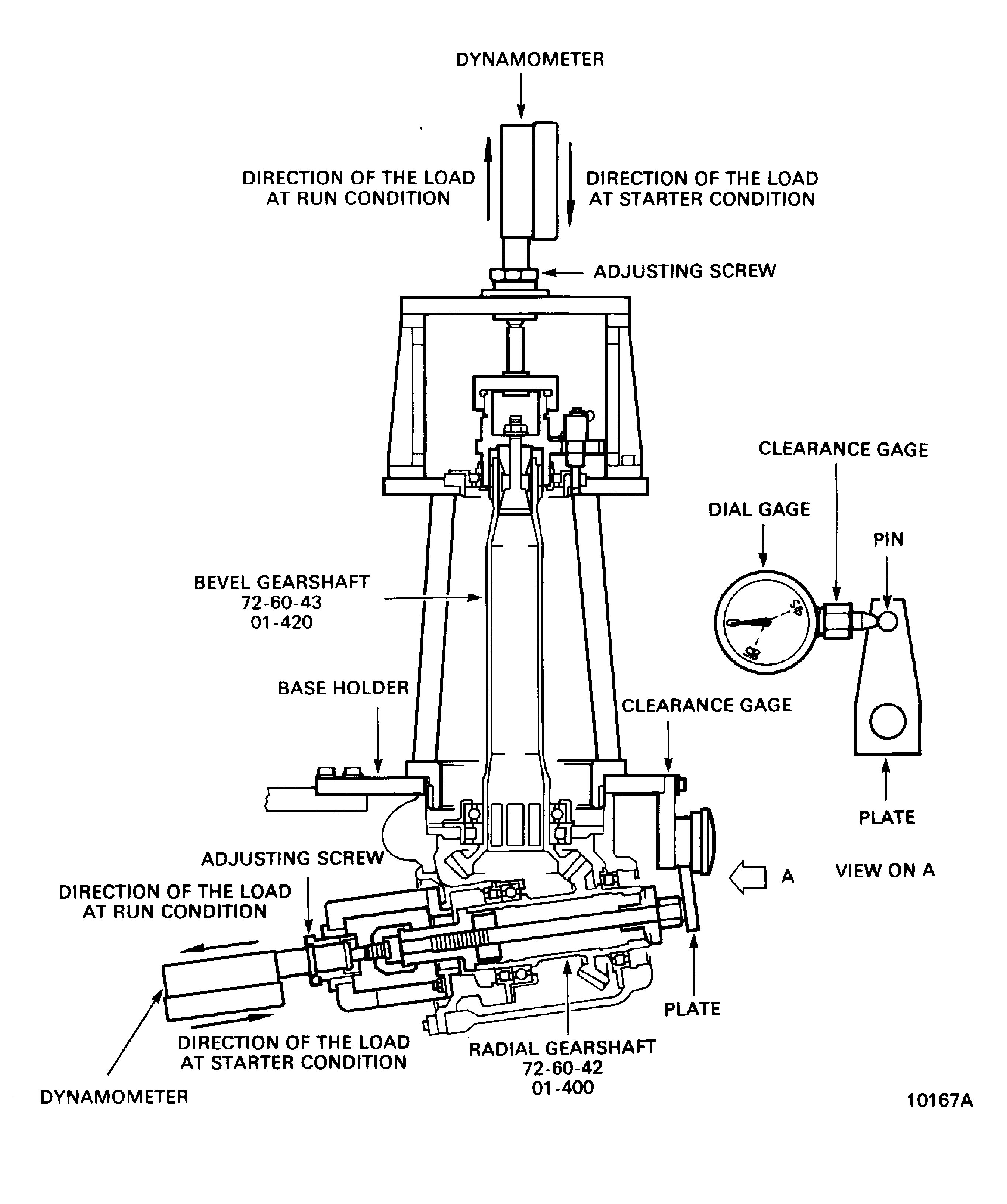

Refer to Figure.

Install IAE 2F10141 Clearance gage 1 off on the base holder. Safety with the two washers and bolts. Make sure that the dial gage points the pin on the plate.

0.0177 in. (0.45 mm) Minimum.

0.0334 in. (0.85 mm) Maximum.

Refer to Step if the backlash is out of these limits.

Turn counterclockwise the plate by hand and read the value of the backlash on the dial gage. The value of the backlash must be:

Do the backlash check at starter condition.

0.0177 in. (0.45 mm) Minimum.

0.0334 in. (0.85 mm) Maximum.

Refer to Step if the backlash is out of these limits.

Turn counterclockwise the plate by hand and read the value of the backlash on the dial gage. The value of the backlash must be:

Do the backlash check at run condition.

SUBTASK 72-60-40-440-057 Do the Backlash Check of the Angle Gearbox Gears

Remove the loading fixture from the angle gearbox, Figure.

Remove the loading fixture from the slave support, Figure.

NOTE

Do not remove the backlash fixture with the outer race of the roller bearing from the angle gearbox.Release the clamping fixture from the bevel gearshaft. Remove the clamping fixture with the inner race of the roller bearing, Figure.

Adjust the two half of IAE 1F10134 Ring 1 off under the lower flange of the inner race. Install the clamping fixture and the ring on IAE 1F10135 Base 1 off with the inner race to the top.

Install IAE 1F10136 Pusher 1 off on the clamping fixture.

Remove the inner race from the clamping fixture. Use the Arbor Press ram or equivalent.

Remove the inner race of the roller bearing from the clamping fixture, Figure.

SUBTASK 72-60-40-440-058 Remove the Tools used for the Backlash Check of the Angle Gearbox Gears

Install the clamping fixture on IAE 1F10201 Base 1 off. Put the small diameter of the clamping fixture in to the smaller hole of the base.

WARNING

DO NOT TOUCH THE HOT PARTS WITHOUT PROTECTIVE GLOVES.HOT PARTS CAN CAUSE REDDENING AND BLISTERING OF THE SKIN IF THE HANDS ARE NOT PROTECTED.IMMERSE THE CONTACTED AREA IN COLD WATER FOR 10 MINUTES IF THE SKIN IS BURNED. IMMEDIATELY GET MEDICAL ATTENTION IF PAIN OR BLISTERING PERSISTS.Put the inner race of the roller bearing in to the oven and increase the temperature to 250 °F (121 °C) maximum.

Install the inner race on the clamping fixture. Use IAE 1F10133 Pusher 1 off and the Arbor Press ram or equivalent.

Install the inner race of the roller bearing Extension Layshaft Gear And Bearing Assembly (72-60-24, 01-280) on IAE 2F10144 Clamping fixture 1 off, Figure.

Install the clamping fixture over the splined end of the bevel gearshaft. Put the inner race of the roller bearing in to the outer race installed on the backlash fixture, Figure.

Align the square end of the clutch with the square hole on the clamping fixture. Install IAE 2F10143 Clamping fixture 1 off on the backlash fixture and attach with the bolts, Figure.

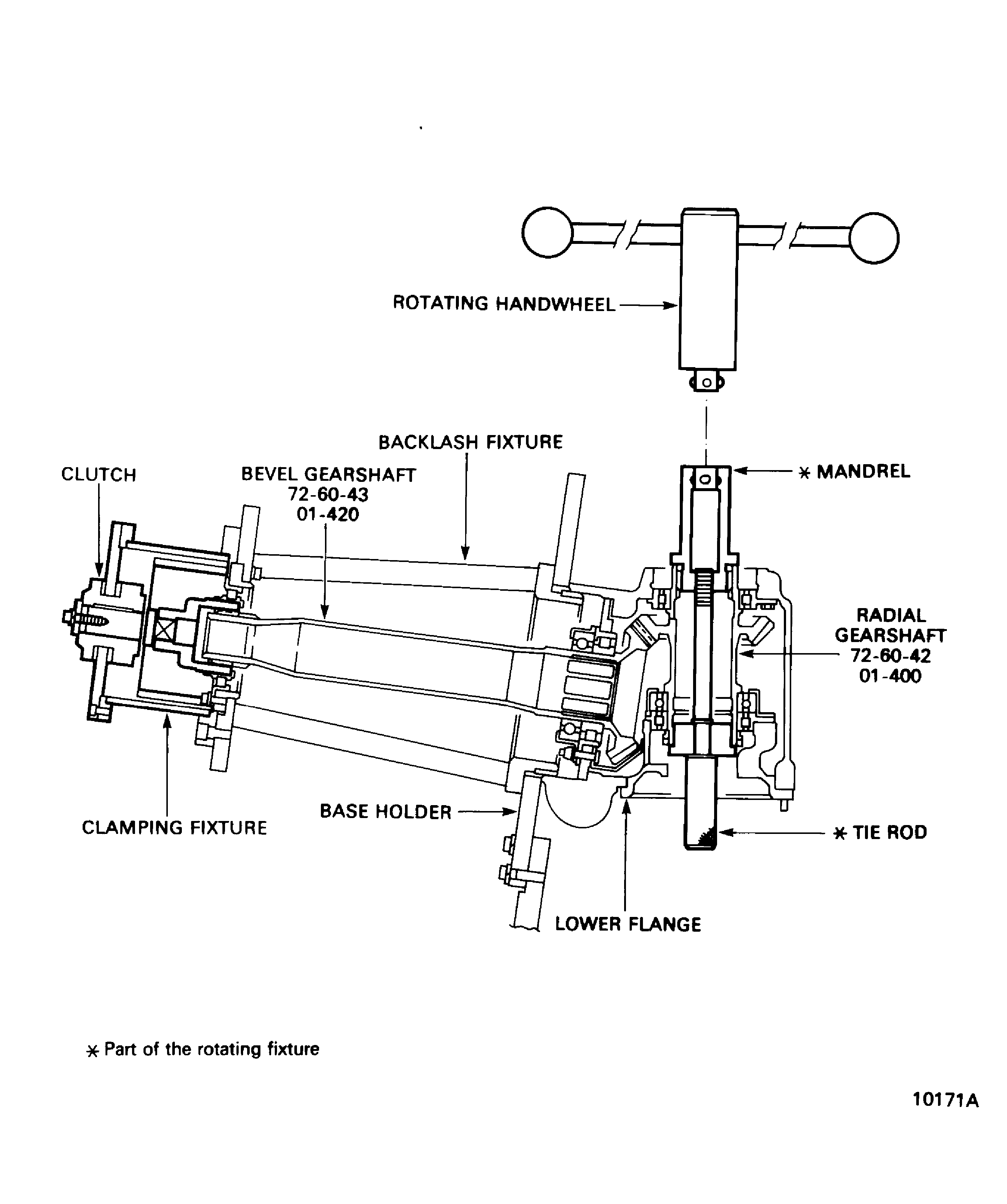

Install IAE 2F10145 Rotating fixture 1 off on the radial gearshaft, Figure.

SUBTASK 72-60-40-440-059 Install the Tools for the Contact Check at Run Condition of the Angle Gearbox Gears

Refer to Figure.

Install IAE 2F10217 Rotating handwheel 1 off on the mandrel.

SUBTASK 72-60-40-440-060 Do the Contact Check of the Angle Gearbox Gears at Run Condition

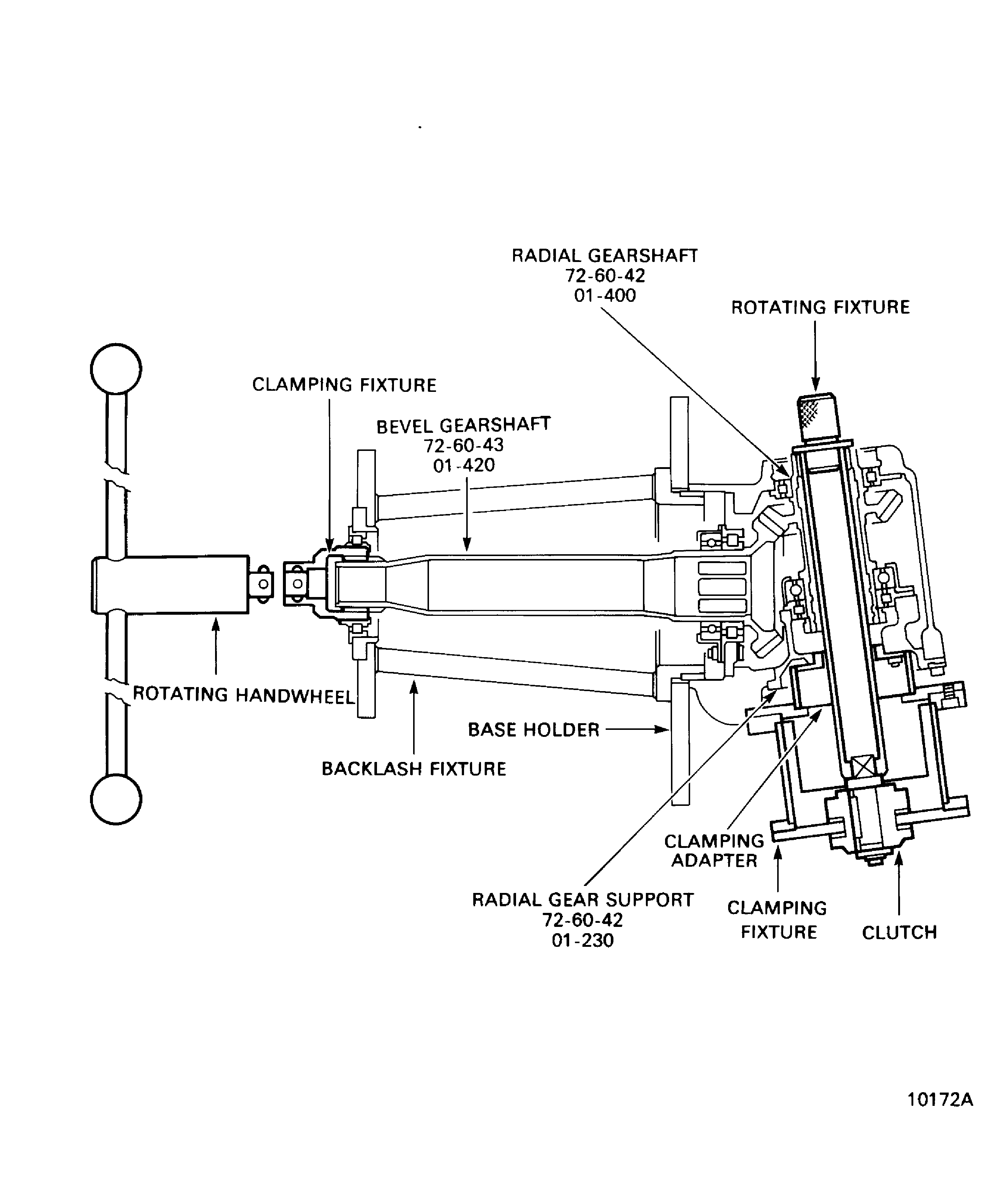

Refer to Figure.

Install IAE 2F10148 Clamping adapter 1 off on the radial gear support. Attach with the slave nuts.

Install IAE 2F10143 Clamping fixture 1 off on the clamping adapter and secure with the bolts.

Install IAE 2F10147 Rotating fixture 1 off through the radial gearshaft and attach to the clutch.

SUBTASK 72-60-40-440-061 Install the Tools for the Contact Check at Starter Condition

Refer to Figure.

Install IAE 2F10217 Rotating handwheel 1 off on the clamping fixture.

SUBTASK 72-60-40-440-062 Do the Contact Check of the Angle Gearbox Gears at Starter Condition

Refer to Figure.

Put the backlash fixture with the outer race to the bottom on IAE 1F10131 Base 1 off.

Remove the outer race from the backlash fixture. Use IAE 1F10129 Pusher 1 off.

Remove the outer race of the roller bearing from the backlash fixture.

Install the clamping fixture on the smaller diameter of IAE 1F10201 Base 1 off with inner race of the roller bearing to the top.

Remove the inner race from the clamping fixture. Use IAE 1F10136 Pusher 1 off and the Arbor Press ram or equivalent.

Remove the inner race of the roller bearing from the clamping fixture, Figure.

SUBTASK 72-60-40-440-063 Remove the Tools used for the Contact Check of the Angle Gearbox Gears

Refer to Figure.

Remove the four nuts and washers which attach the driven gear assembly to the angle gearbox casing. Refer to Figure.

Install IAE 1F10123 Puller 1 off on the driving gear assembly.

Install IAE 1F10110 Stud 3 off on the base holder.

Install IAE 1F10114 Hydraulic cylinder 1 off.

Attach IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic cylinder. Operate the hydraulic pump until the driving gear assembly is disengaged from the angle gearbox casing.

Examine the contact on the teeth of the bevel gearshaft. Refer to Step.

SUBTASK 72-60-40-440-064 Remove the Drive Gear Assembly from the Angle Gearbox Casing

Do the subsequent steps if the backlash is more than the maximum limits specified in the Step.

Do the subsequent steps if the backlash is less than the minimum limits specified in the Step.

Do the procedure from the Step again until the contact bearing patter is satisfactory.

Examine the contact bearing pattern on the convex side of the teeth of the driving gear assembly and on the concave side of the driven gear assembly (Run condition). The bearing pattern must be as much as possible on the center of the tooth side. Do the subsequent steps if this condition is not satisfactory.

SUBTASK 72-60-40-220-051 Examine the Radial Gearshaft and the Bevel Gearshaft for the Correct Installation

NOTE

Go to step C. if the backlash is in the limits specified in the Step.Refer to Figure.

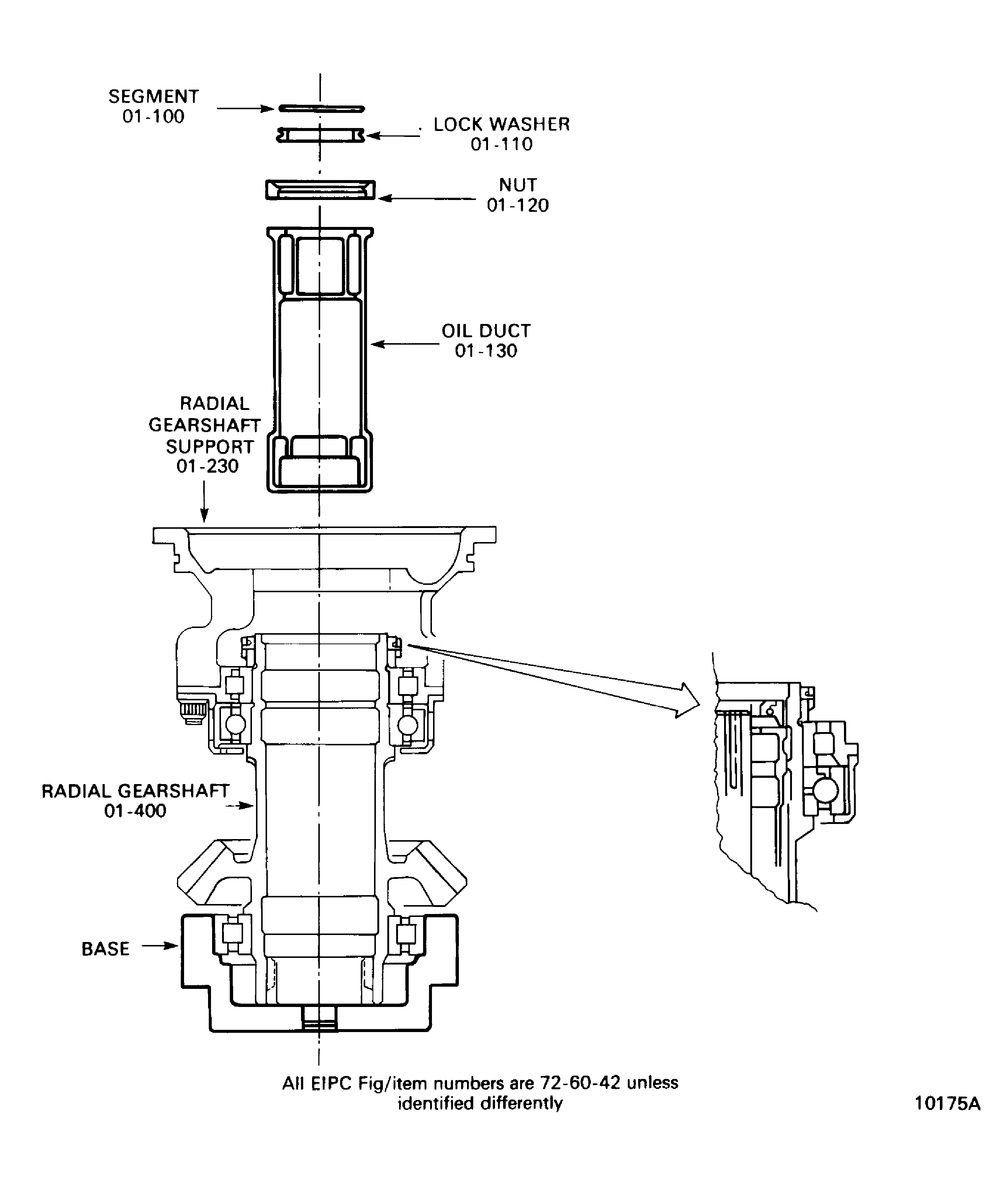

Put the driving gear assembly in to IAE 1F10087 Base 1 off with the radial gear support to the top.

Install the oil duct in to the radial gearshaft. Use IAE 1F10102 Pusher 1 off.

Install the nut which attach the oil duct to the radial gearshaft. Torque to 619.560 lbfin to 796.577 lbfin (70 Nm to 90 Nm). Use IAE 1F10104 Hand wrench 1 off.

Install the lock washer and the segment to lock the nut. Use IAE 1F10105 Pusher 1 off.

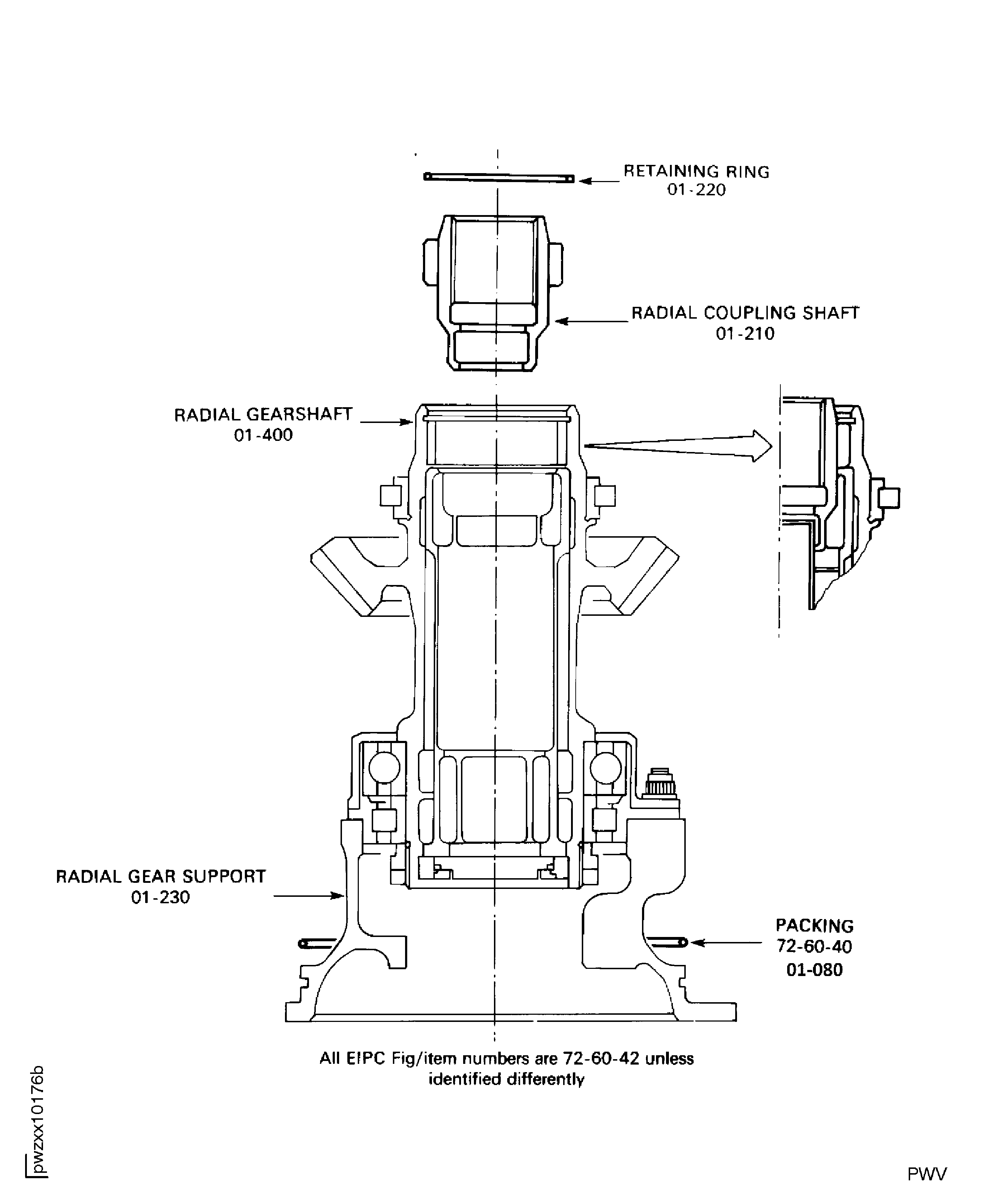

If not installed, install Angle Gearbox Assembly (72-60-40, 01-080) packing 1 off in to the groove of the radial gear support.

SUBTASK 72-60-40-440-066 Assemble the Driving Gear Assembly Before the Installation

Refer to Figure.

Install the shim with the thickness calculated after the contact and the backlash checks (Refer to Step), on the lower flange of the angle gearbox casing. Align the holes on the shim with the studs on the angle gearbox casing.

SUBTASK 72-60-40-440-067 Install the Driving Gear Assembly on the Angle Gearbox Casing

Refer to Figure.

Install the shim, with the thickness calculated after the contact and the backlash checks (Refer to Step), on the internal flange of the angle gearbox casing. Align the holes on the shim with the studs on the angle gearbox casing.

Install IAE 1F10110 Stud 3 off on the base holder.

Install IAE 1F10122 Pusher 1 off over the bevel gearshaft and put on the bearing support.

Install IAE 1F10114 Hydraulic cylinder 1 off on the three studs. Make sure that the hydraulic cylinder is seated to push.

Attach IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic cylinder. Operate the hydraulic pump until the driven gear assembly is fully installed on the angle gearbox casing.

SUBTASK 72-60-40-440-068 Install the Driven Gear Assembly on the Angle Gearbox Casing

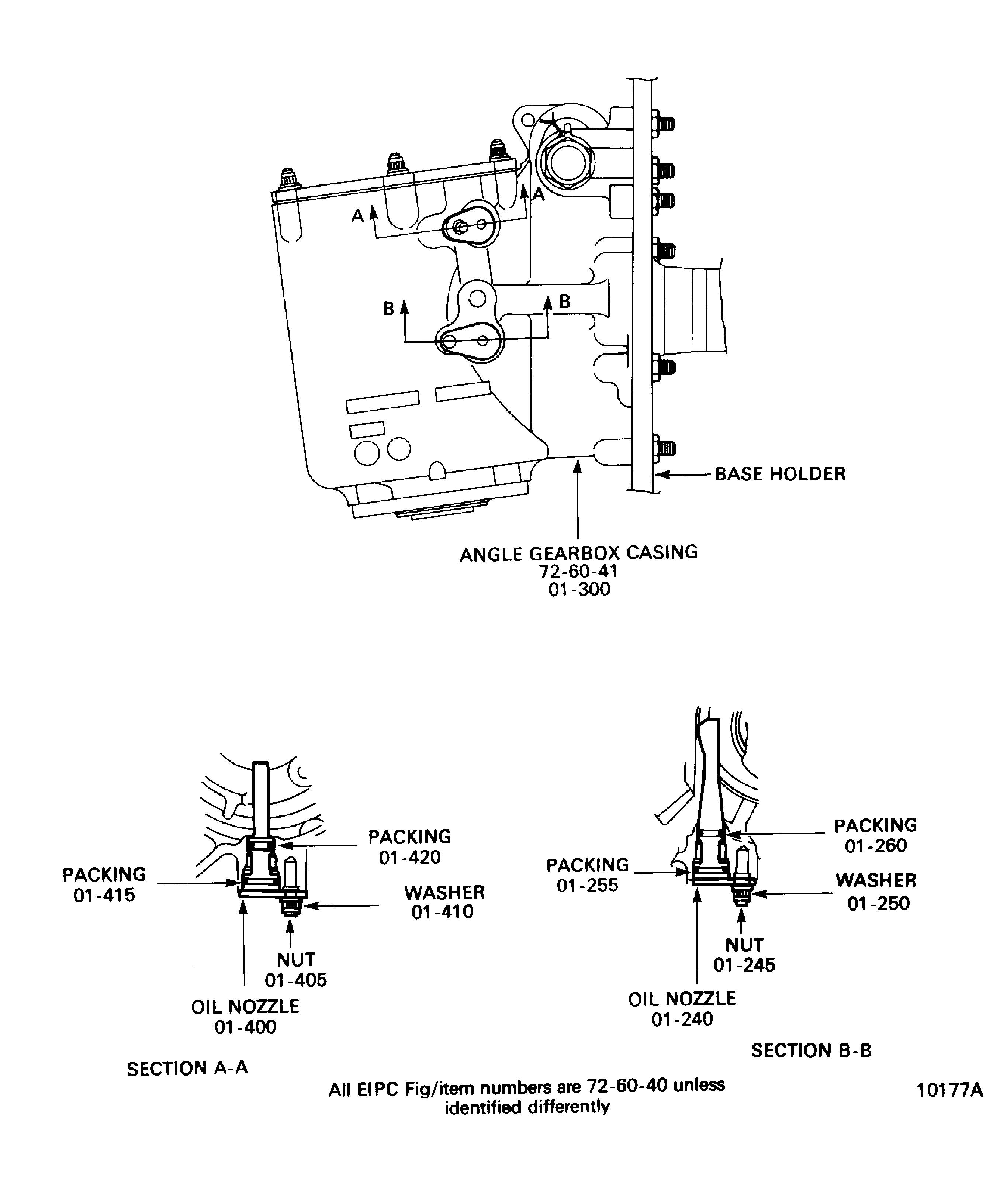

Refer to Figure.

Install Angle Gearbox Assembly (72-60-40, 01-420) packing 1 off and Angle Gearbox Assembly (72-60-40, 01-415) packing 1 off in to the grooves of the oil nozzle.

Install the oil nozzle of the driving gear assembly.

Install Angle Gearbox Assembly (72-60-40, 01-260) packing 1 off and Angle Gearbox Assembly (72-60-40, 01-255) packing 1 off in to the grooves of the oil nozzle.

Install the oil nozzle of the driven gear assembly.

SUBTASK 72-60-40-440-069 Install the Oil Nozzles on the Angle Gearbox

Refer to Figure.

Remove the eight slave nuts which attach the angle gearbox casing to the base holder.

Remove the angle gearbox casing from the base holder.

SUBTASK 72-60-40-440-072 Remove the Angle Gearbox Casing from the Base Holder

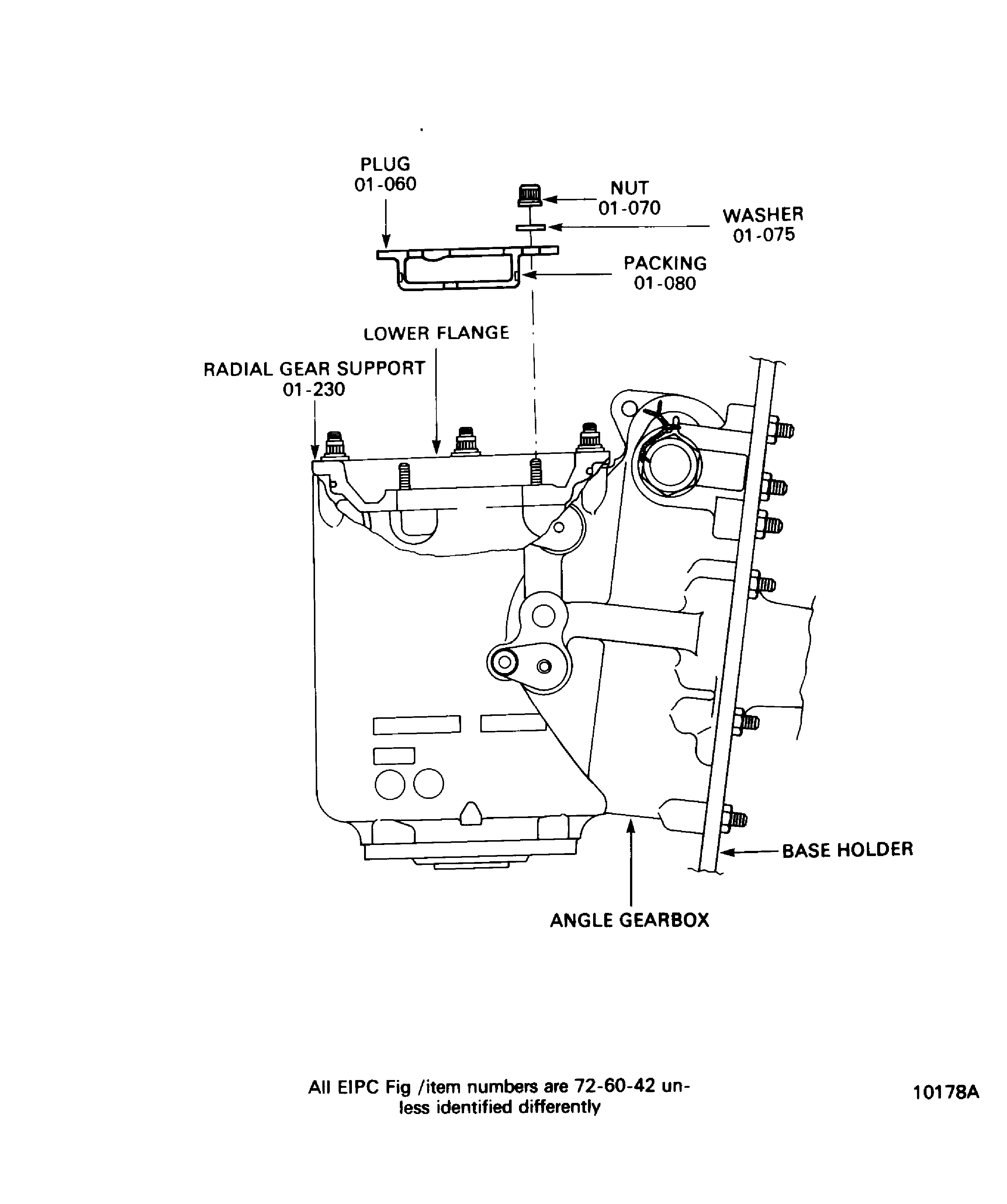

Refer to Figure.

Install Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-080) packing 1 off in to the groove of the plug.

SUBTASK 72-60-40-440-070 Install the Plug on the Lower Flange of the Angle Gearbox

Refer to Figure.

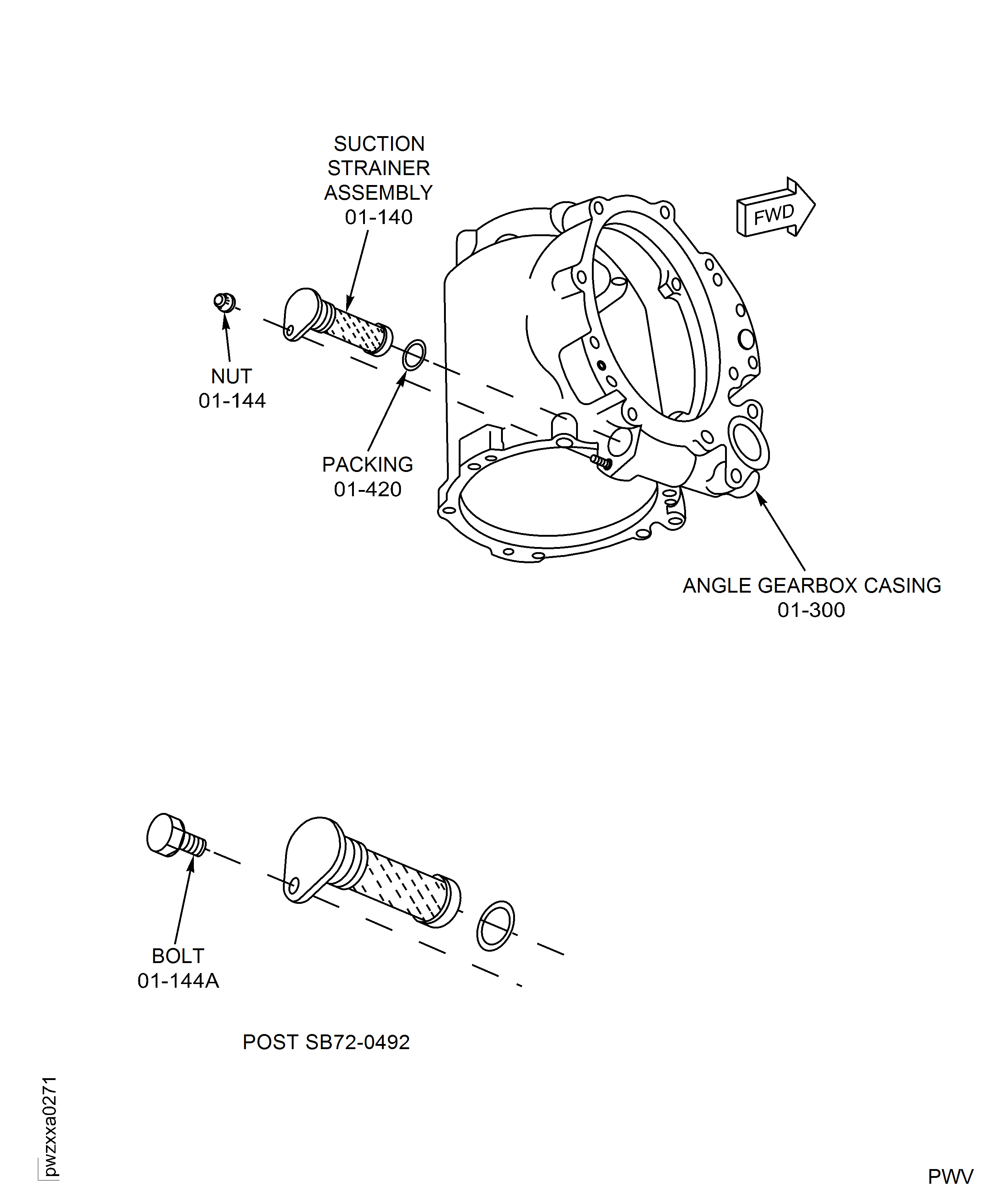

Install ENGINE-ANGLE GEARBOX CASE (72-60-41, 01-146) packing 1 off to the groove of the suction strainer assembly ENGINE-ANGLE GEARBOX CASE (72-60-41, 01-140).

Install the suction strainer assembly to the seat on the angle gearbox casing. Align the hole on the strainer flange with the adjacent stud.

Install the nut/bolt and torque to 85 lbfin to 95 lbfin (9.604 Nm to 10.734 Nm).

SUBTASK 72-60-40-440-073 Install the Suction Strainer Assembly on the Angle Gearbox

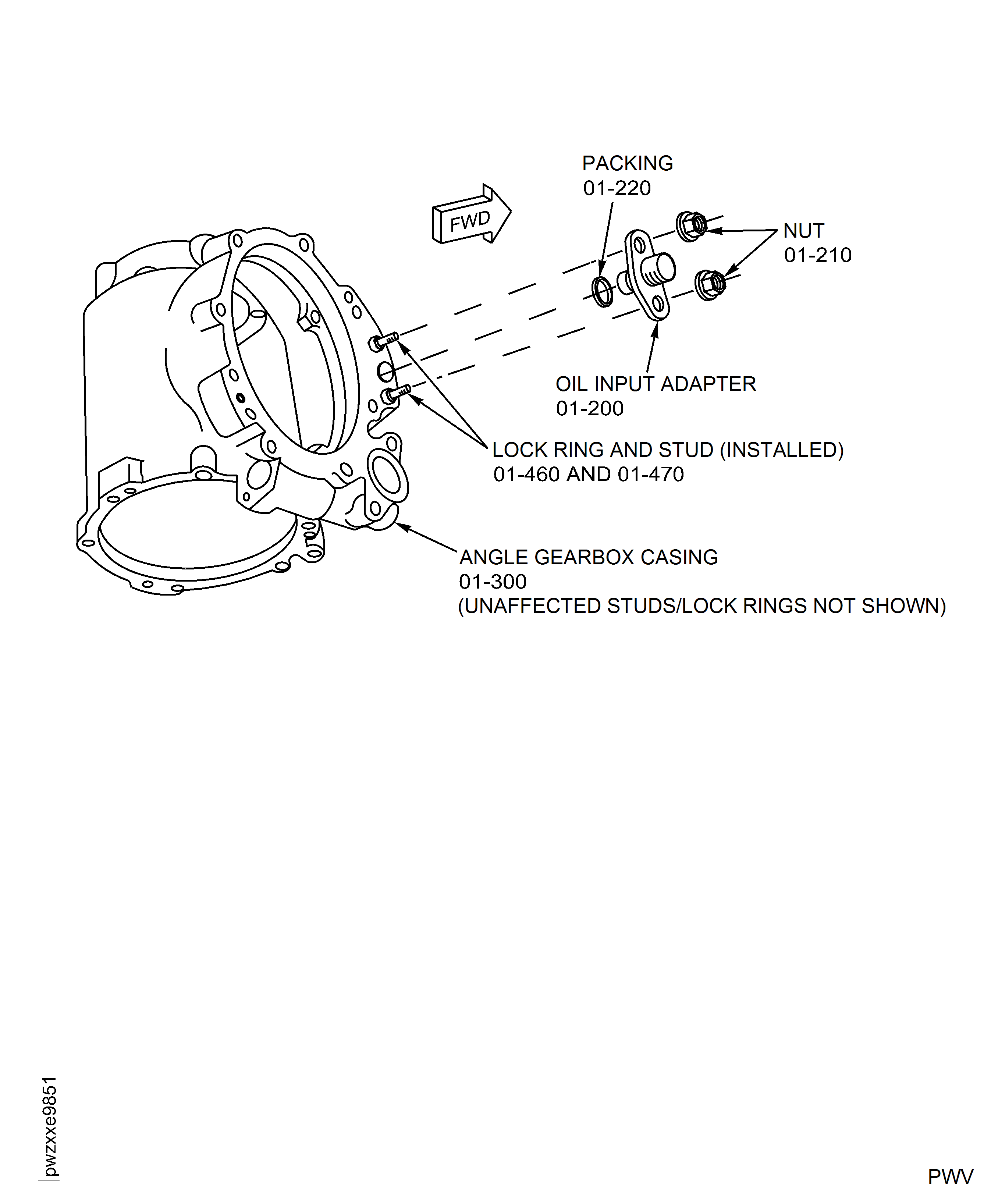

Refer to Figure.

Install ENGINE-ANGLE GEARBOX CASE (72-60-41, 01-220) packing 1 off to the groove of the oil input adapter ENGINE-ANGLE GEARBOX CASE (72-60-41, 01-200).

Install the oil input adapter to the seat on the angle gearbox casing. Align the holes in the adapter flange with the adjacent studs.

Install the nuts and torque to 85 lbfin to 95 lbfin (9.604 Nm to 10.734 Nm).

SUBTASK 72-60-40-440-071 Install the Oil Input Adapter on the Angle Gearbox

Figure: Installation of the Angle Gearbox on the Base Holder

Installation of the Angle Gearbox on the Base Holder

Figure: Installation of the Outer Race of the Upper Roller Bearing

Installation of the Outer Race of the Upper Roller Bearing

Figure: Installation of the Driving Gear Assembly

Installation of the Driving Gear Assembly

Figure: Installation of the Driven Gear Assembly

Installation of the Driven Gear Assembly

Figure: Installation of the Driven Gear Assembly

Installation of the Driven Gear Assembly

Figure: Installation of the Roller Bearing on the Tools

Installation of the Roller Bearing on the Tools

Figure: Installation of the Backlash Fixture and the Clamping Fixture on the Angle Gearbox

Installation of the Backlash Fixture and the Clamping Fixture on the Angle Gearbox

Figure: Installation of the Loading Fixture on the Backlash Fixture

Installation of the Loading Fixture on the Backlash Fixture

Figure: Installation of the Backlash Fixture and the Loading Fixture on the Radial Gearshaft

Installation of the Backlash Fixture and the Loading Fixture on the Radial Gearshaft

Figure: Backlash Check

Backlash Check

Figure: Removal of the Inner Race from the Clamping Fixture

Removal of the Inner Race from the Clamping Fixture

Figure: Installation of the Inner Race of the Roller Bearing on the Clamping Fixture

Installation of the Inner Race of the Roller Bearing on the Clamping Fixture

Figure: Installation of the Clamping Fixture and the Clutch

Installation of the Clamping Fixture and the Clutch

Figure: Contact Check at Run Condition

Contact Check at Run Condition

Figure: Contact Check at Starter Condition

Contact Check at Starter Condition

Figure: Removal of the Roller Bearing from the Clamping Fixture

Removal of the Roller Bearing from the Clamping Fixture

Figure: Removal of the Driven Gear Assembly

Removal of the Driven Gear Assembly

Figure: Installation of the Oil Duct on the Driving Gear Assembly

Installation of the Oil Duct on the Driving Gear Assembly

Figure: Installation of the Radial Coupling Shaft on the Driving Gear Assembly

Installation of the Radial Coupling Shaft on the Driving Gear Assembly

Figure: Oil Nozzles on the Angle Gearbox

Oil Nozzles on the Angle Gearbox

Figure: Installation of the Plug on the Lower Flange of the Angle Gearbox

Installation of the Plug on the Lower Flange of the Angle Gearbox

Figure: Calculate The Value Of X To Find The Shim Thickness

Calculate The Value Of X To Find The Shim Thickness

Figure: Calculate The Value Of Y To Find The Shim Thickness

Calculate The Value Of Y To Find The Shim Thickness

Figure: Installation of the Oil Input Adapter

Installation of the Oil Input Adapter

Figure: Installation of the Suction Strainer Assembly

Installation of the Suction Strainer Assembly