Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 73-11-41-300-001 Fuel Nozzle Supply Fuel Manifolds - Blend Repair Surface Damage, Repair-001 (VRS3378)

Effectivity

FIG/ITEM | PART NO. |

01-060 | 2A0504-01 |

01-160 | 2A0508-01 |

01-260 | 2A0509-01 |

02-060 | 2A0510-01 |

02-160 | 2A0511-01 |

02-260 | 2A0516-01 |

03-060 | 2A0515-01 |

03-160 | 2A1229-01 |

03-260 | 2A0513-01 |

03-360 | 2A1389-01 |

01-060 | 2A3229-001 |

01-160 | 2A3230-001 |

01-260 | 2A3231-001 |

02-060 | 2A3232-001 |

02-160 | 2A3233-01 |

02-260 | 2A3236-001 |

03-060 | 2A3235-01 |

03-160 | 2A3237-01 |

03-260 | 2A3234-01 |

03-360 | 2A3238-01 |

01-060 | 2A3256-01 |

01-160 | 2A3257-01 |

01-260 | 2A3258-01 |

02-060 | 2A3259-01 |

02-160 | 2A3260-01 |

02-260 | 2A3261-01 |

03-060 | 2A3263-01 |

03-160 | 2A3264-01 |

03-260 | 2A3265-01 |

03-360 | 2A3266-01 |

General

Price and availability - refer to IAE

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

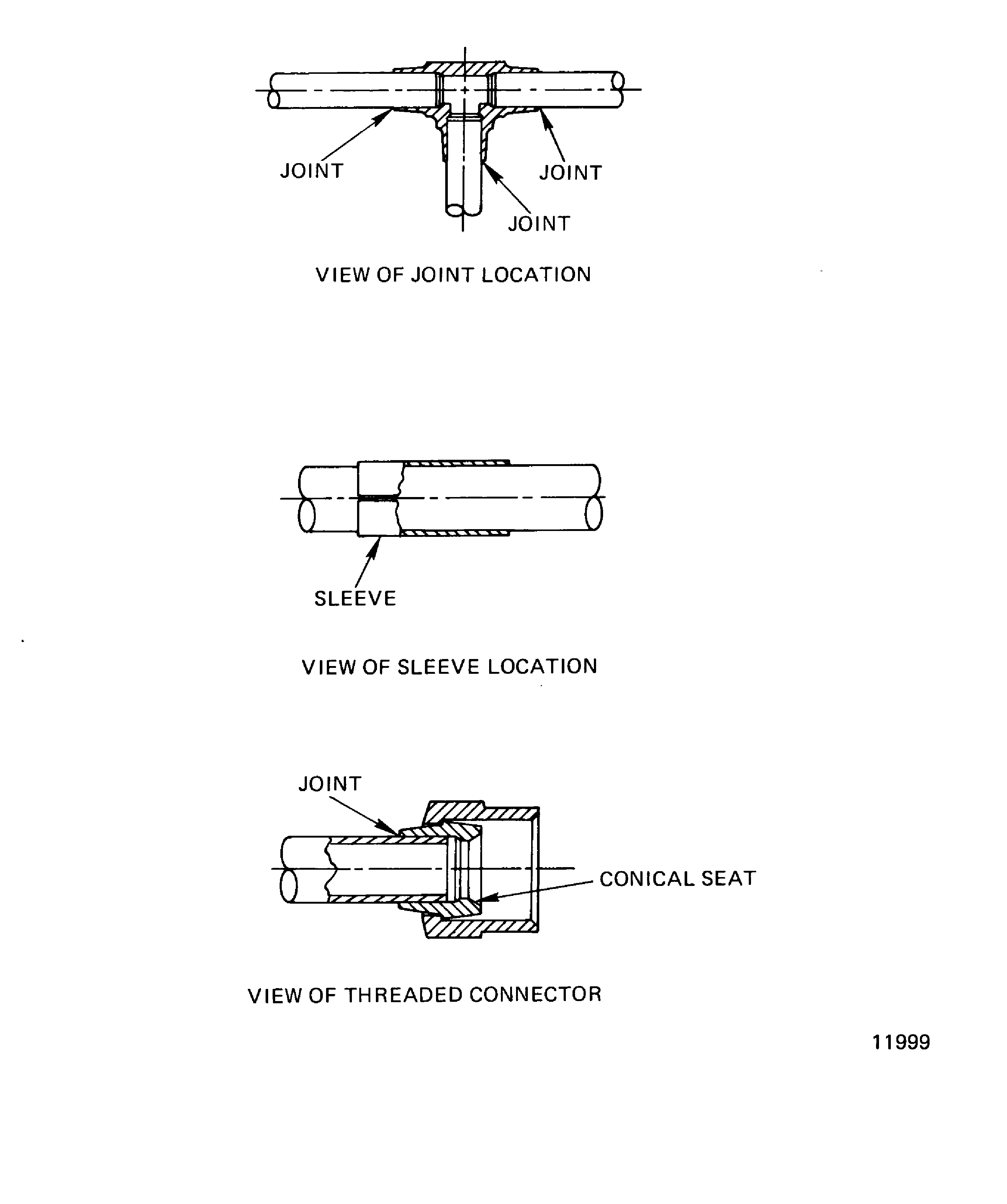

Refer to Figure.

Refer to the SPM TASK 70-35-03-300-501.

Blend damage in straight length areas that are 1.000 in. (25.4 mm) from ferrules.

The depth of the blends must not be more than 0.008 in. (0.203 mm) of the tube wall thickness.

Blend in all directions so there will be less stress concentration.

The blended area must not be more than 0.500 sq in. (323.0 sq mm). No more than one blend area is permitted circumferentially at a location.

Blends must be a minimum of 1.000 in. (25.4 mm) apart.

Blend nicks, chafing, pitting and scratches that are more than 0.003 in. (0.076 mm) in depth.

SUBTASK 73-11-41-350-051 Blend the Fuel Manifolds

Refer to Inspection-000 TASK 73-11-41-200-100.

Examine the blended areas

SUBTASK 73-11-41-220-053 Examine the Fuel Manifolds After Blend Repair

Refer to Inspection-001 TASK 73-11-41-200-101-A00, Step.

Do a pressure test to check for leaks.

SUBTASK 73-11-41-790-052 Examine the Fuel Manifold for Leaks

Figure: Fuel Manifold Blend Repair

Fuel Manifold Blend Repair