Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 73-22-15-700-401 P3/T3 Sensor - Related Parts - Do A Test On The P3/T3 Sensor, Testing-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants, refer to the IPC.

All test pressures referred to in the procedure are gage pressures.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Heat Gun | LOCAL | Heat Gun | ||

| Megohmmeter | LOCAL | Megohmmeter | ||

| Microammeter | LOCAL | Microammeter | ||

| Ohmmeter | LOCAL | Ohmmeter | ||

| Pressure jig | LOCAL | Pressure jig |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Set the Ohmmeter to zero.

SUBTASK 73-22-15-750-051 Do a Loop Resistance Test on the P3/T3 Sensor

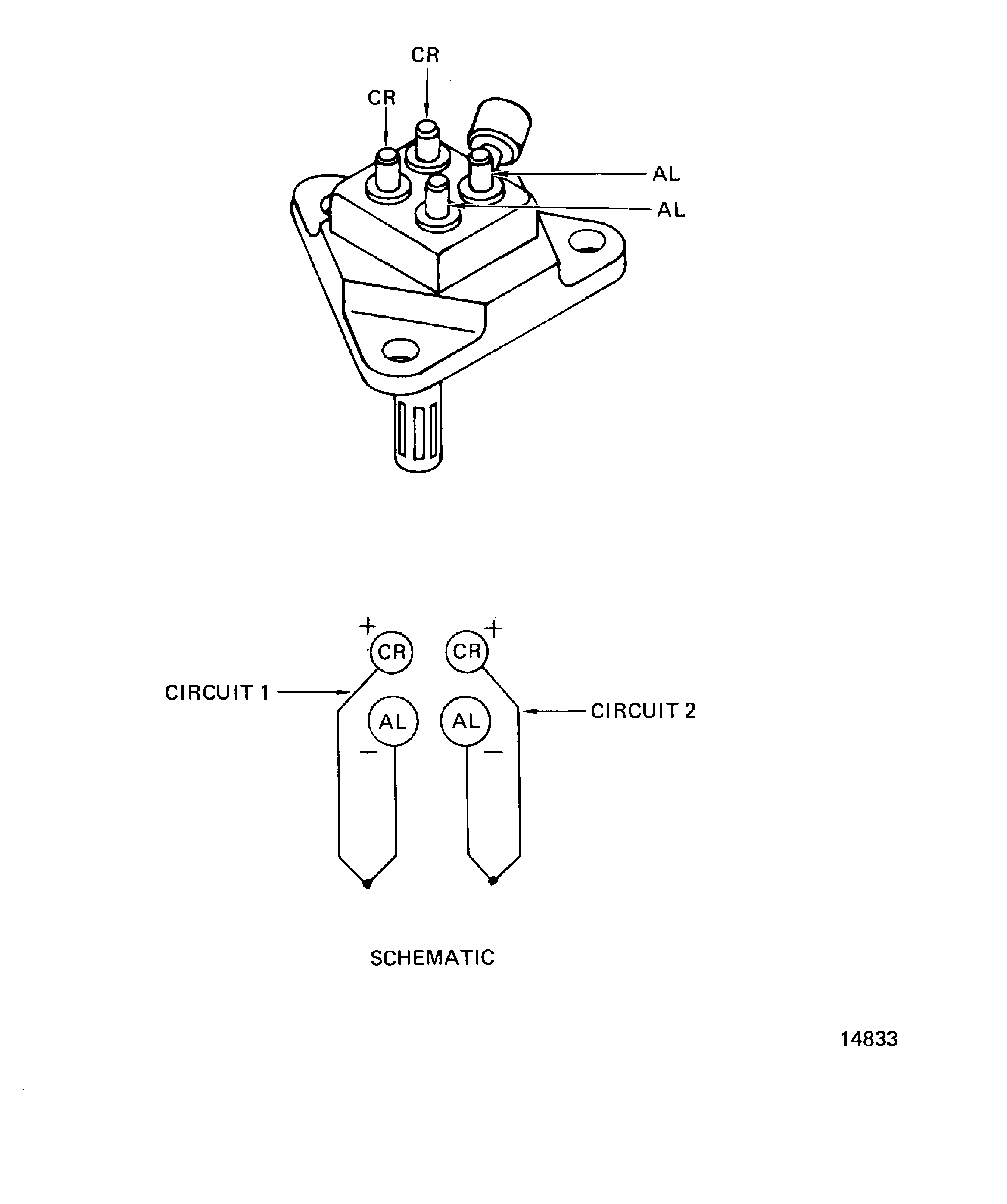

Refer to Figure.

Set the Megohmmeter to zero. Set the scale to get values of 20 megohms at 600 VDC.

Do a test for the insulation resistance between Circuit No. 1 and the diffuser case.

Do a test for the insulation resistance between Circuit No. 2 and the diffuser case.

Do a test for the insulation resistance between Circuit No. 1 and Circuit No. 2.

Do a test of all circuits against each other and against non-circuit components.

The minimum insulation resistance permitted is 20 megohms at 600 VDC. If you do not get this value, clean the sensor and/or bake the sensor at 225 deg F (107.2 deg C) until the insulation is dry. Refer to Cleaning-001 TASK 73-22-15-100-401. Do the test again.

SUBTASK 73-22-15-750-052 Do an Insulation Resistance Test on the P3/T3 Sensor

Refer to Figure.

Connect the negative lead of the Microammeter to the alumel stud (larger diameter).

Connect the positive lead to the chromel stud.

Connect the Microammeter to the terminal studs of Circuit No. 1 with test leads.

CAUTION

DO NOT APPLY HEAT TO THE TERMINAL STUDS. THIS CAN CAUSE INCORRECT VALUES TO SHOW ON THE MICROAMMETER.Apply heat to the thermocouple junction with the heat gun. Point the hot air through the slots in the lower part of the protective housing.

A positive deflection of the Microammeter indicates correct polarity and correct operation of the part.

Do the test for Circuit No. 2.

If you get a negative deflection on the Microammeter, reject the sensor.

SUBTASK 73-22-15-750-053 Do a Response Test on the P3/T3 Sensor

Close the sensor pressure outlet with a cap.

Install the sensor in the Pressure jig.

Apply air at 20 to 30 psig (137.895 to 206.843 kPa) pressure to the fixture for one minute. The pressure must not decrease. If the pressure decreases, reject the sensor.

Bleed the pressure from the jig and remove the sensor.

SUBTASK 73-22-15-780-051 Do a Pressure Test on the P3/T3 Sensor

Figure: P3/T3 Sensor Testing

P3/T3 Sensor Testing