Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

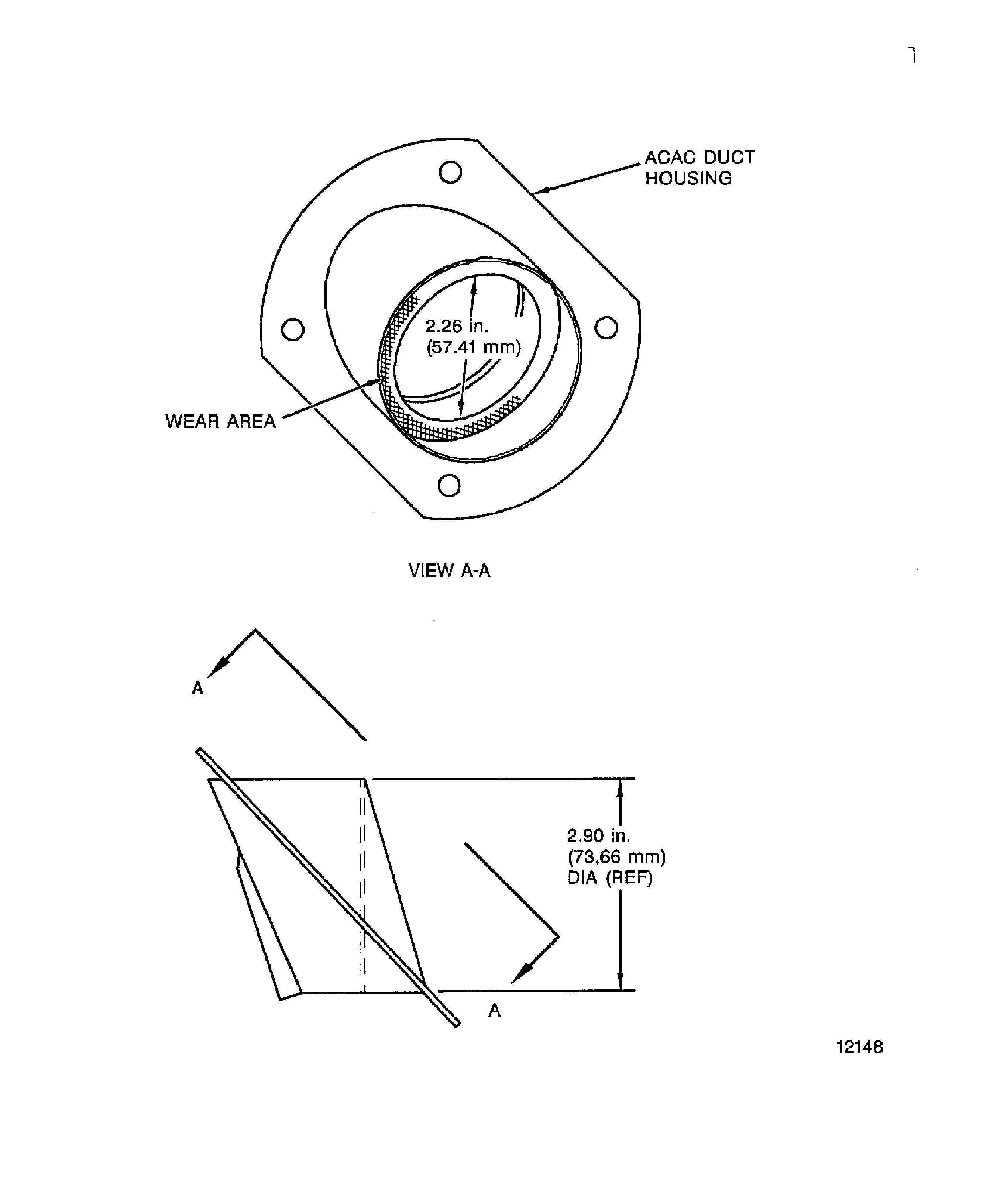

TASK 75-22-48-300-002 ACAC Exhaust Duct Housing - Weld Repair Or Replace The Flange, Repair-002 (VRS2209)

General

Price and availability - Refer to IAE.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

To do this procedure, welders must be certified. Refer to MIL-STD-1595 or equivalent.

Special tools - Locally manufactured.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Gas tungsten arc weld (GTAW) system | LOCAL | Gas tungsten arc weld (GTAW) system | ||

| Hand Held Pneumatic Grinder | LOCAL | Hand Held Pneumatic Grinder | ||

| Hand held rotary grinder | LOCAL | Hand held rotary grinder | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent Penetrant Inspection Equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 03-287 WELDING FILLER WIRE | LOCAL | CoMat 03-287 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 06-131 MARKING PEN | 0AM53 | CoMat 06-131 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Flange | 51563 | 740-1085-5 | 1 | FIG/ITEM 01-055 |

Safety Requirements

NONEProcedure

Refer to Figure.

Refer to Cleaning-001 TASK 75-22-48-100-101.

Wipe the surface dry before the solvent evaporates.

NOTE

Position the copper back-up plate behind the flange during welding, so that it can absorb the heat and prevent the flange from buckling.

Clean the repair area.

Refer to SPM TASK 70-31-02-310-501-001.

Use the welding procedure to build-up the material in the worn area of the flange.

Refer to SPM TASK 70-23-02-230-501.

No cracks are permitted.

Fluorescent penetrant inspect the repaired area for cracks.

Use a Hand Held Pneumatic Grinder to grind the weld surface down to +0.005 in. (+0.127 mm) above the adjacent surface

Remove the unwanted weld material and make the weld surface area smooth with the adjacent surface area.

Refer to SPM TASK 70-23-02-230-501.

No cracks are permitted.

Fluorescent penetrant inspect the repaired area for cracks.

Put the mark, VRS2209, adjacent to the part number.

Use a CoMat 06-131 MARKING PEN of a color that contrasts.

Identify the repair.

SUBTASK 75-22-48-350-055 Weld Repair the Worn Areas on the ACAC Duct Housing Flange

WARNING

PUT ON PROTECTIVE GLOVES WHEN YOU USE THE DEGREASER.USE THE DEGREASER ONLY IN AREAS WITH GOOD AIRFLOW.THE DEGREASER IS VERY FLAMMABLE, KEEP IT AWAY FROM IGNITION SOURCES.Refer to Figure.

Use a Hand held rotary grinder to carefully remove the worn flange.

Remove the worn flange from the duct housing.

Use a Hand Held Pneumatic Grinder to grind the surface down to +0.005 in. (+0.127 mm) above the adjacent surface.

Remove the unwanted material.

Refer to SPM TASK 70-23-02-230-501.

No cracks are permitted.

Fluorescent penetrant inspect the repair area for cracks.

Refer to Cleaning-001 TASK 75-22-48-100-101.

Wipe the surface dry before the solvent evaporates.

Clean the repair area.

The distance between the 740-1085-5 (flange) 1 off and the lower edge of the duct housing should be 0.78 in. (19.812 mm).

Position the tool and the copper back-up plate in the duct housing.

Refer to SPM TASK 70-31-02-310-501-001.

Use the welding procedure to weld the spare flange into the duct housing.

Put the mark, VRS2209, adjacent to the assembly number.

Use a CoMat 06-131 MARKING PEN of a color that contrasts.

Identify the repair.

SUBTASK 75-22-48-350-056 Replace the ACAC Duct Housing Flange

WARNING

PUT ON PROTECTIVE GLOVES WHEN YOU USE THE DEGREASER.USE THE DEGREASER ONLY IN AREAS WITH GOOD AIRFLOW.THE DEGREASER IS VERY FLAMMABLE, KEEP IT AWAY FROM IGNITION SOURCES.

Figure: ACAC Exhaust Duct Housing Flange Worn Area Repair

ACAC Exhaust Duct Housing Flange Worn Area Repair

Figure: ACAC Exhaust Duct Housing Flange Replacement Repair

ACAC Exhaust Duct Housing Flange Replacement Repair