Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-24-49-300-051 LPT ACC Connector Air Tube - Replace The Connector Tube, Repair-051 (VRS4484)

General

Price and availability - none.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 3M14523 Cut off and welding fixture | 0AM53 | IAE 3M14523 | 1 off |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-246 WELDING MATERIAL | LOCAL | CoMat 03-246 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CONNECTOR - TUBE, ASSEMBLY OF | 0AM53 | 3A2847 | 1 |

Safety Requirements

NONEProcedure

Use applicable machining equipment and IAE 3M14523 Cut off and welding fixture 1 off.

Machine to remove connector tube.

SUBTASK 75-24-49-326-003 Remove the Damaged Connector Tube

Refer to SPM TASK 70-11-34-300-503.

Aqueous decrease.

SUBTASK 75-24-49-110-103 Clean the Surfaces to be Welded

Refer to SPM TASK 70-31-13-310-501 andFigure and Figure.

Provide an argon gas backup.

Flow argon gas into the tube during weld repair.

Weld in a protective atmosphere.

Gas tungsten arc weld new 3A2847 CONNECTOR - TUBE, ASSEMBLY OF to connector tube assembly.

SUBTASK 75-24-49-310-074 Weld in the New Connector Tube

Refer to SPM TASK 70-31-13-310-501 and Figure and Figure.

Provide an argon gas backup.

Flow argon gas into the tube during weld repair.

Weld in a protective atmosphere.

Gas tungsten arc weld cut tube assembly to connector tube assembly.

SUBTASK 75-24-49-310-075 Weld in the Cut Tube Assembly

Refer to SPM TASK 70-23-05-230-501.

Use medium sensitivity level.

No cracks are permitted.

Do test for cracks.

SUBTASK 75-24-49-230-132 Examine the Repaired Areas for Cracks

Put the part in an oven for two hours at 887 deg F (475 deg C).

Use argon or vacuum.

Heat treat connector tube assembly.

SUBTASK 75-24-49-370-068 Heat Treatment After the Repair

Refer to SPM TASK 70-23-05-230-501.

Use medium sensitivity level.

No cracks are permitted.

Do test for cracks.

SUBTASK 75-24-49-230-133 Do the Test for Cracks

Refer to SPM TASK 70-11-34-300-503.

Aqueous decrease.

SUBTASK 75-24-49-110-104 Clean the Connector Tube Assembly

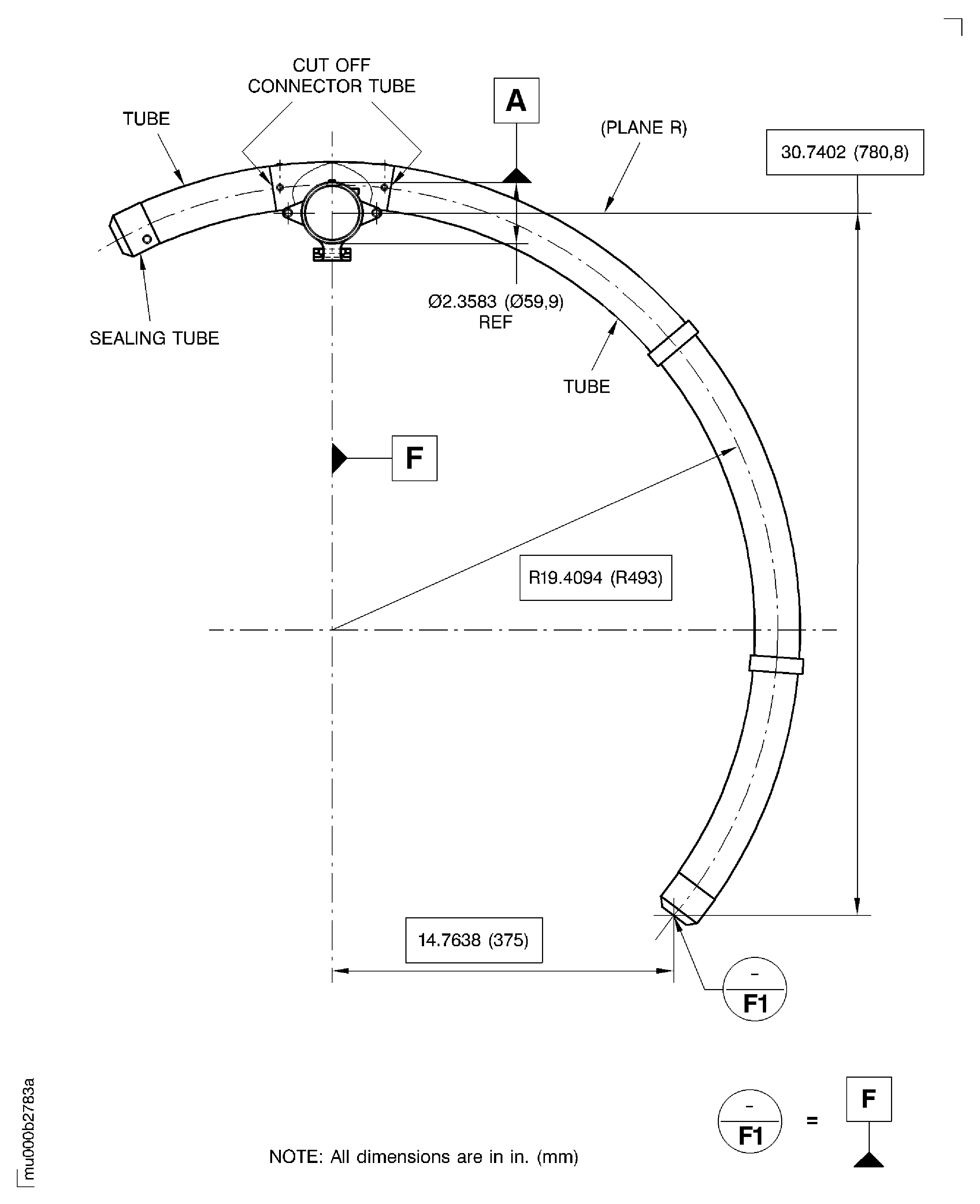

Figure: Replace The Connector Tube of the Connector Tube Assembly

Replace The Connector Tube of the Connector Tube Assembly

Replace The Connector Tube of the Connector Tube Assembly

Figure: Replace The Connector Tube of the Connector Tube Assembly

Replace The Connector Tube of the Connector Tube Assembly

Replace The Connector Tube of the Connector Tube Assembly