Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-24-49-300-006 LPT ACC Cooling Air Ducts - Replace the Front and Rear Supports, Nuts, and Rivets, Repair-006 (VRS4248)

Effectivity

FIG/ITEM | PART NO. |

02-010 | 3A0678 |

02-010 | 3A1501 |

02-010 | 3A1662 |

02-010 | 3A2656 |

02-010 | 3A2658 |

03-010 | 3A0698 |

03-010 | 3A1666 |

03-010 | 3A2657 |

03-010 | 3A2659 |

Material of component

DESCRIPTION | IAE SYMBOL | MATERIAL |

Upper/lower air cooling duct assembly | Ti6Al-4V | |

Upper/lower air cooling duct assembly | X10 |

General

Price and availability - none.

This TASK describes the repair of the upper and lower air cooling duct assemblies with subsequence separated items as follows:

Replacement of the anchor nuts, refer to Step .

Replacement of the clip nuts, refer to Step.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

Repair parts

FIG/ITEM | PART NO. | PART IDENT | QTY | ITEM |

02-200 | 4032806 | Anchor nut | 2 | 1 |

02-200 | 4W0043 | Clip Nut | 2 | 2 |

02-205 | 3A0622 | Countersink head solid rivet | 4 | 3 |

02-210 | AN123291 | Universal head solid rivet | 8 | 4 |

02-215 | 3A0165 | Front support | 1 | 5 |

02-215 | 3A2402 | Front support | 1 | 6 |

02-220 | 3A0164 | Rear support | 1 | 7 |

02-220 | 3A2421 | Rear support | 1 | 8 |

03-200 | 4032806 | Anchor nut | 2 | 1 |

03-200 | 4W0043 | Clip nut | 2 | 2 |

03-205 | 3A0622 | Countersink head solid rivet | 4 | 3 |

03-210 | AN123291 | Universal head solid rivet | 8 | 4 |

03-215 | 3A0165 | Front support | 1 | 5 |

03-215 | 3A2402 | Front support | 1 | 6 |

03-220 | 3A0164 | Rear support | 1 | 7 |

03-220 | 3A2421 | Rear support | 1 | 8 |

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Grinder, hand held pneumatic | LOCAL |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Do not damage the upper and lower air cooling duct assemblies.

Grind off formed rivet heads of the universal head solid rivets.

Use minimal of force to avoid damage of the upper and lower air cooling assemblies.

Hit lightly the remaining material of the shaft and dowel.

Maximum diameter should not be more than 0.169 in. (4.30 mm).

Examine the inner diameter of the holes dimensionally.

Refer to SPM TASK 70-23-05-230-501.

Use medium sensitivity level.

No cracks are permitted.

Do the test for cracks.

Refer to SPM TASK 70-39-03-390-501.

Install the new universal head solid rivets.

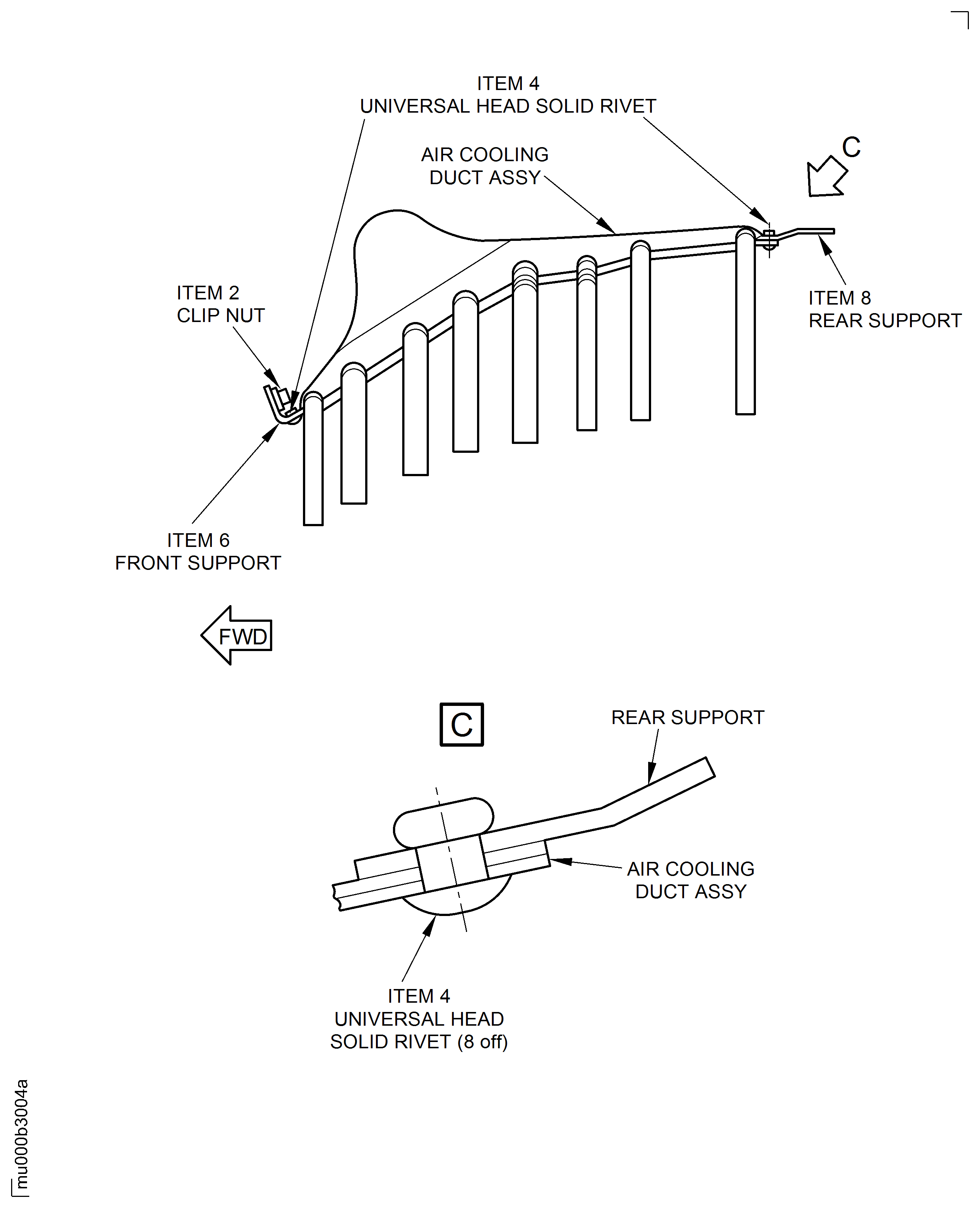

SUBTASK 75-24-49-350-059 Replace the Universal Head Solid Rivets (ITEM 4)

Refer to Figure.

Do not damage the anchor nuts and the front support.

Grind off the formed rivet heads of the countersink head solid rivets.

Use minimal of force to avoid damage of the anchor nuts and the front support.

Hit lightly the remaining material of the shaft and dowel.

Maximum diameter should not be more than 0.169 in. (4.30 mm).

Examine the diameter of the holes dimensionally.

Refer to SPM TASK 70-23-05-230-501.

Use medium sensitivity level.

No cracks are permitted.

Do the test for cracks.

Refer to SPM TASK 70-39-03-390-501.

The head surfaces of the countersink head rivets must be below of the front support surface.

Install the new universal head solid rivets.

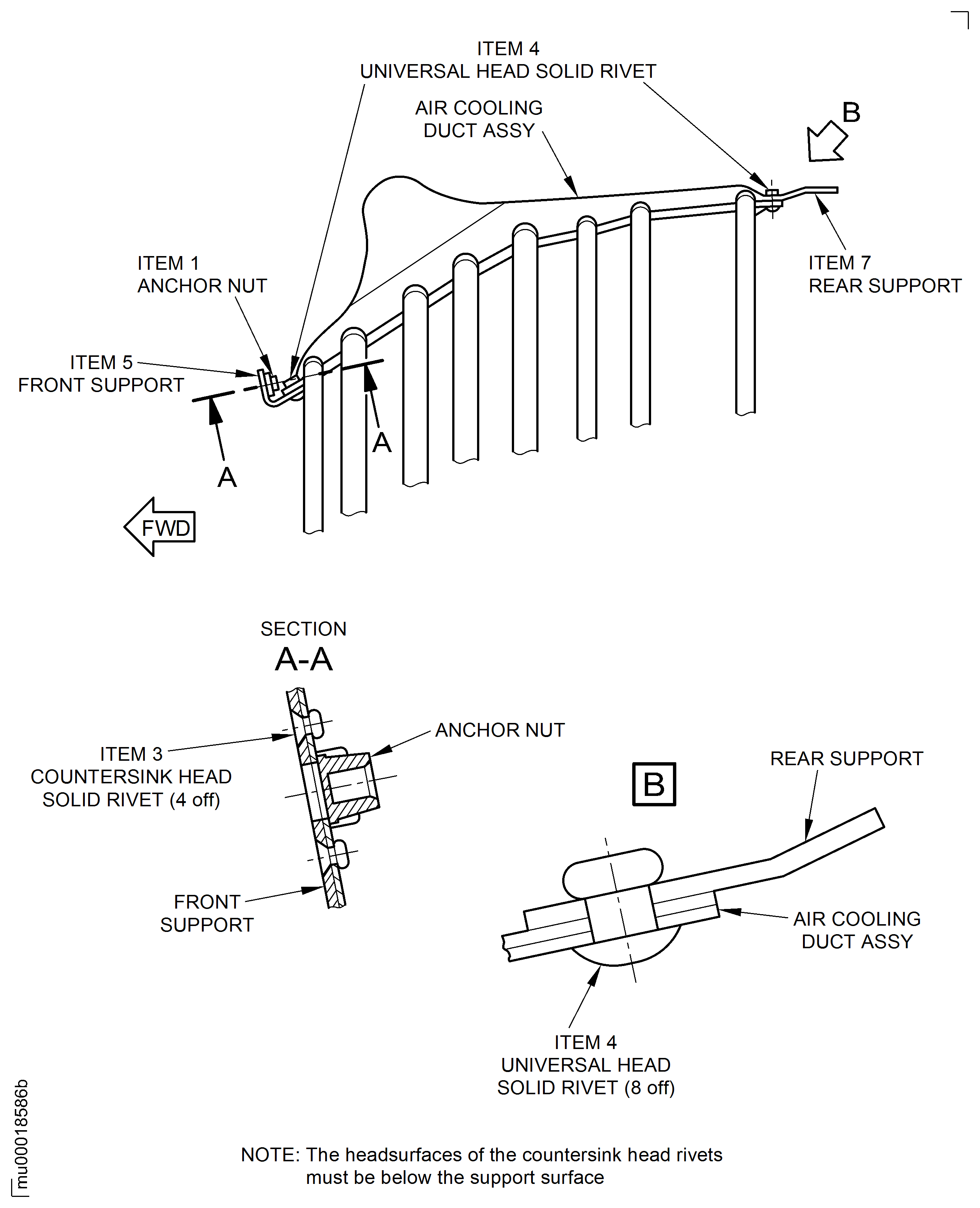

SUBTASK 75-24-49-350-060 Replace the Countersink Head Solid Rivets (ITEM 3)

Refer to Figure .

Refer to theStep.

Remove the countersink head solid rivets.

Remove the anchor nut.

Refer to SPM TASK 70-39-03-390-501.

The head surfaces of the countersink head rivets must be below of the front support surface.

Install the new anchor nuts with the countersink head solid rivets on to the front support.

SUBTASK 75-24-49-350-061 Replace the Anchor Nuts (ITEM 1)

Refer toFigure.

Remove the clip nuts.

Install the new clip nuts on to the front support.

SUBTASK 75-24-49-350-146 Replace the Clip Nuts (ITEM 2)

Refer to Step.

Remove the universal head solid rivets.

Remove the front support.

Refer to SPM TASK 70-39-03-390-501.

Install the front support with the universal head solid rivets on to the upper and lower air duct cooling assemblies.

Refer to Step.

Install the new anchor nuts on to the front support.

SUBTASK 75-24-49-350-062 Replace the Front Support (ITEM 5)

Refer to Figure.

Refer to Step.

Remove the universal head solid rivets.

Remove the front support.

Refer to SPM TASK 70-39-03-390-501.

Install the front support with the universal head solid rivets on to the upper and lower air duct cooling assemblies.

Refer to Step.

Install the new clip nuts on to the front support.

SUBTASK 75-24-49-350-147 Replace the Front Support (ITEM 6)

Refer toFigure .

Refer to the Step.

Remove the universal head solid rivets.

Remove the rear support.

Refer to SPM TASK 70-39-03-390-501.

Install the rear support with the universal head solid rivets on to the upper and lower air duct cooling assemblies.

SUBTASK 75-24-49-350-063 Replace the Rear Support (ITEM 7 or ITEM 8)

Refer to SPM TASK 70-39-03-390-501.

The head surfaces of the countersink head rivets must be below of the front support surface.

Examine the quality of the riveting and the safety of the joints.

For dimensions refer to SPM TASK 70-39-03-390-501.

Examine the formed heads of the universal and countersink head solid rivets.

SUBTASK 75-24-49-210-051 Do the Post Repair Inspection

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions