Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-24-49-300-019 LPT ACC Support Assemblies - Weld Repair, Repair-019 (VRS4364)

General

Price and availability - none.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-204 WELDING FILLER WIRE | LOCAL | CoMat 03-204 |

Spares

NONESafety Requirements

NONEProcedure

SUBTASK 75-24-49-310-054 Prepare the Support Assembly for the Welding Procedure

NOTE

Before trying repair, remove inserts, refer to VRS4366 (Repair-021) TASK 75-24-49-300-021 and clip nuts, refer to VRS4365 (Repair-020) TASK 75-24-49-300-020.Before trying a repair to half loop clamp or in a area adjacent to a half loop clamp, remove half loop clamp and clip nuts, refer to VRS4365 (Repair-020) TASK 75-24-49-300-020.After repair, assemble half loop clamp and clip nuts, refer to VRS4365 (Repair-020) TASK 75-24-49-300-020 and put in new inserts where applicable, refer to VRS4366 (Repair-021) TASK 75-24-49-300-021.It is permitted to vee-groove cracks before weld repair.

Vee-groove the cracks.

SUBTASK 75-24-49-322-052 Remove the Cracks

Refer to SPM TASK 70-31-13-310-501.

Clean the areas around the cracks on both sides of the support assembly if possible.

SUBTASK 75-24-49-110-071 Clean the Support Assembly

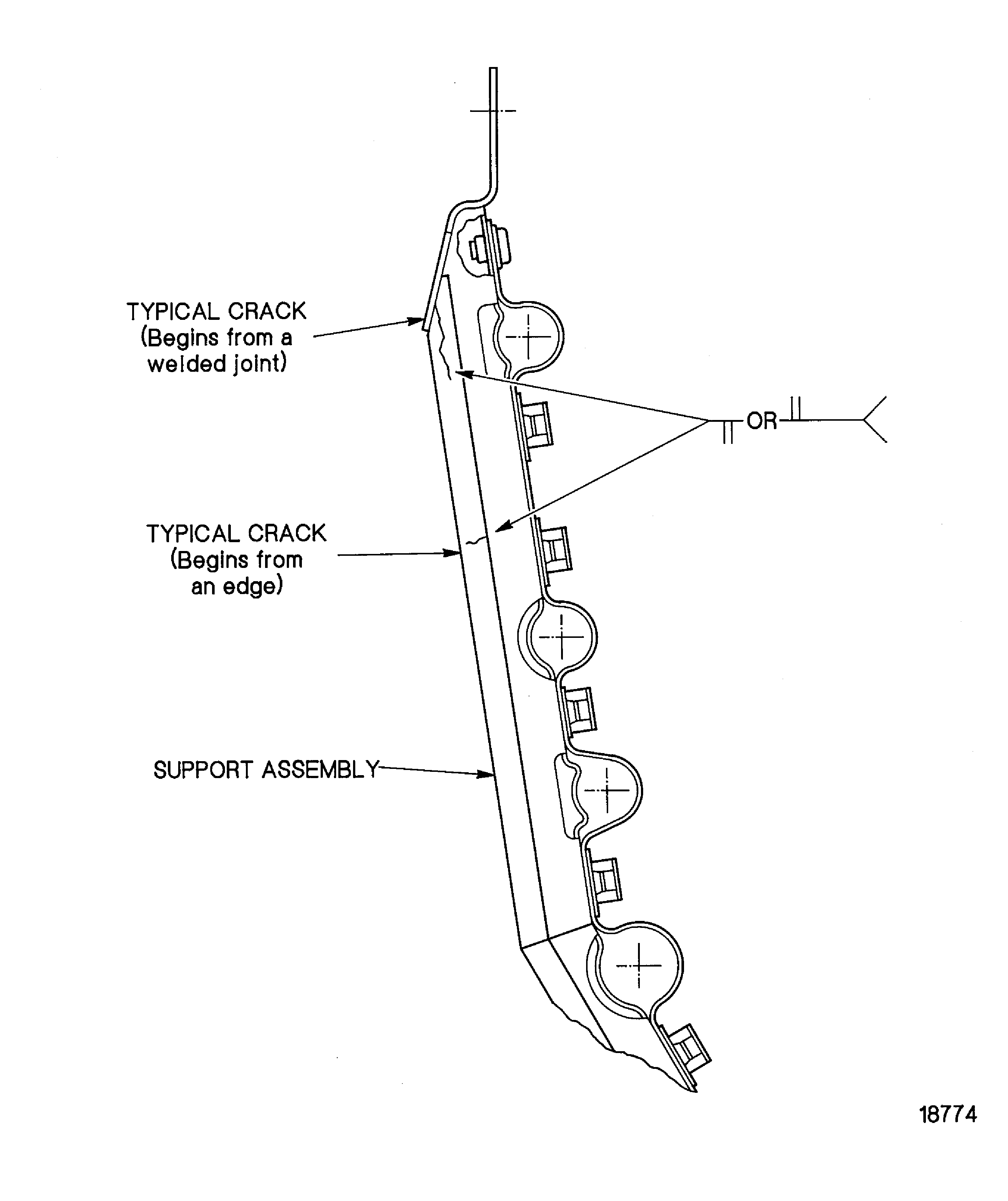

Refer to Figure.

Refer to SPM TASK 70-31-13-310-501.

Tungsten inert gas weld cracks on the two sides.

SUBTASK 75-24-49-310-055 Weld Repair the Support Assembly

Refer to SPM TASK 70-23-05-230-501.

No cracks are permitted.

Do the test for cracks.

SUBTASK 75-24-49-230-080 Examine the Welded Areas for Cracks

No raised material is permitted on functional or connecting faces.

Use hand held pneumatic grinder.

If necessary dress the welds on functional or connecting faces until they make a continuous surface with the adjacent areas.

SUBTASK 75-24-49-320-057 Dress the Welded Areas

CAUTION

DO NOT OVERHEAT THE AREAS WHICH ARE TO BE DRESSED.Refer to SPM TASK 70-23-01-230-501 or to SPM TASK 70-23-02-230-501.

No cracks are permitted.

Do the test for cracks.

SUBTASK 75-24-49-230-081 Do the Post Repair Inspection

Figure: Weld Repair of the Support Assemblies

Weld Repair of the Support Assemblies