Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-31-43-300-006 LPC Bleed Slave Actuator - Related Parts - Replace The LPC Bleed Slave Actuator Bracket Assembly Thin Wall Insert(s), Flanged Location Dowels, Repair-006 (VRS6668)

Material of Component

DESCRIPTION | RR SYMBOL | MATERIAL |

LP compressor, bleed master actuator | EEJ | Corrosion resistant steel |

bracket assembly | or | or |

ENH | Chrome cobalt molybdenum electro flux remelted steel |

General

Price and availability - Refer to International Aero Engines

This Repair must only be done when the instruction to do so is given in TASK 75-31-43-200-402.

This repair is to replace the thin wall insert(s), when they are broken, worn, cross-threaded or missing and flanged location dowel when damaged or missing.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard Workshop Equipment | LOCAL | Standard Workshop Equipment | ||

| Heat protection gloves | LOCAL | Heat protection gloves |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 |

Spares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-35-26-300-501, SUBTASK 70-35-26-350-001.

Remove damaged thin wall insert(s) and discard.

SUBTASK 75-31-43-350-060 Remove the Damaged Thin Wall Insert(s), Assembly A and Assembly B

Remove damaged flanged location dowel(s) and discard.

Remove sharp edges around location hole(s).

Use a soft clean cloth and blast with air.

Clean the holes

SUBTASK 75-31-43-350-061 Remove the Damaged Flanged Location Dowel(s), Assembly A and Assembly B

Visually examine dowel location holes

Make sure you can get an interference fit of 0.00008 inches to 0.00126 inches (0.002 mm to 0.032 mm) on the hole diameter.

Measure dimensions of the dowel location holes

SUBTASK 75-31-43-220-073 Examine the Dowel Holes, Assembly A and Assembly B

Use AS52761 insert, as necessary.

Refer to SPM TASK 70-35-26-300-501, SUBTASK 70-35-26-350-001.

Install replacement thin wall insert(s)

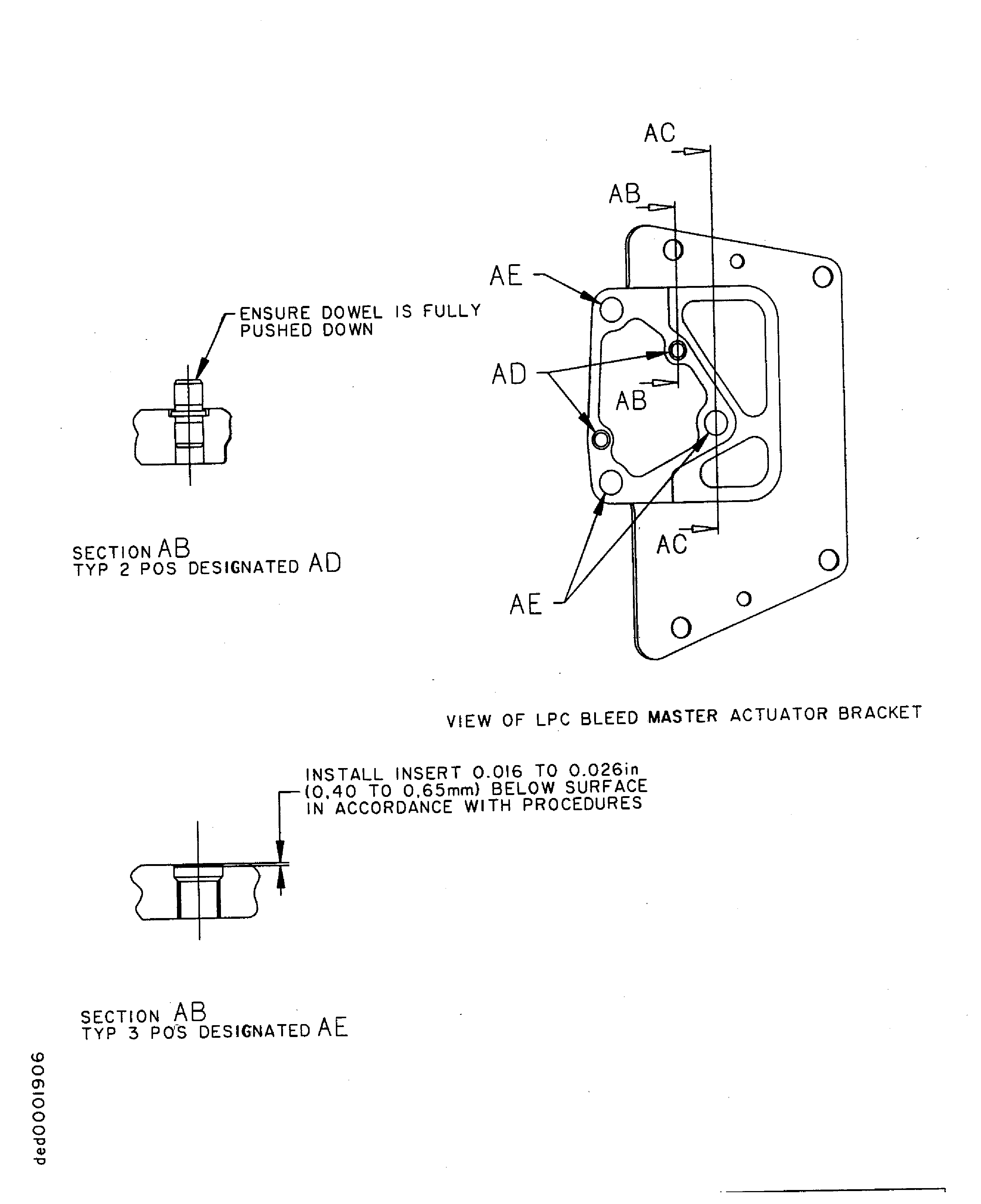

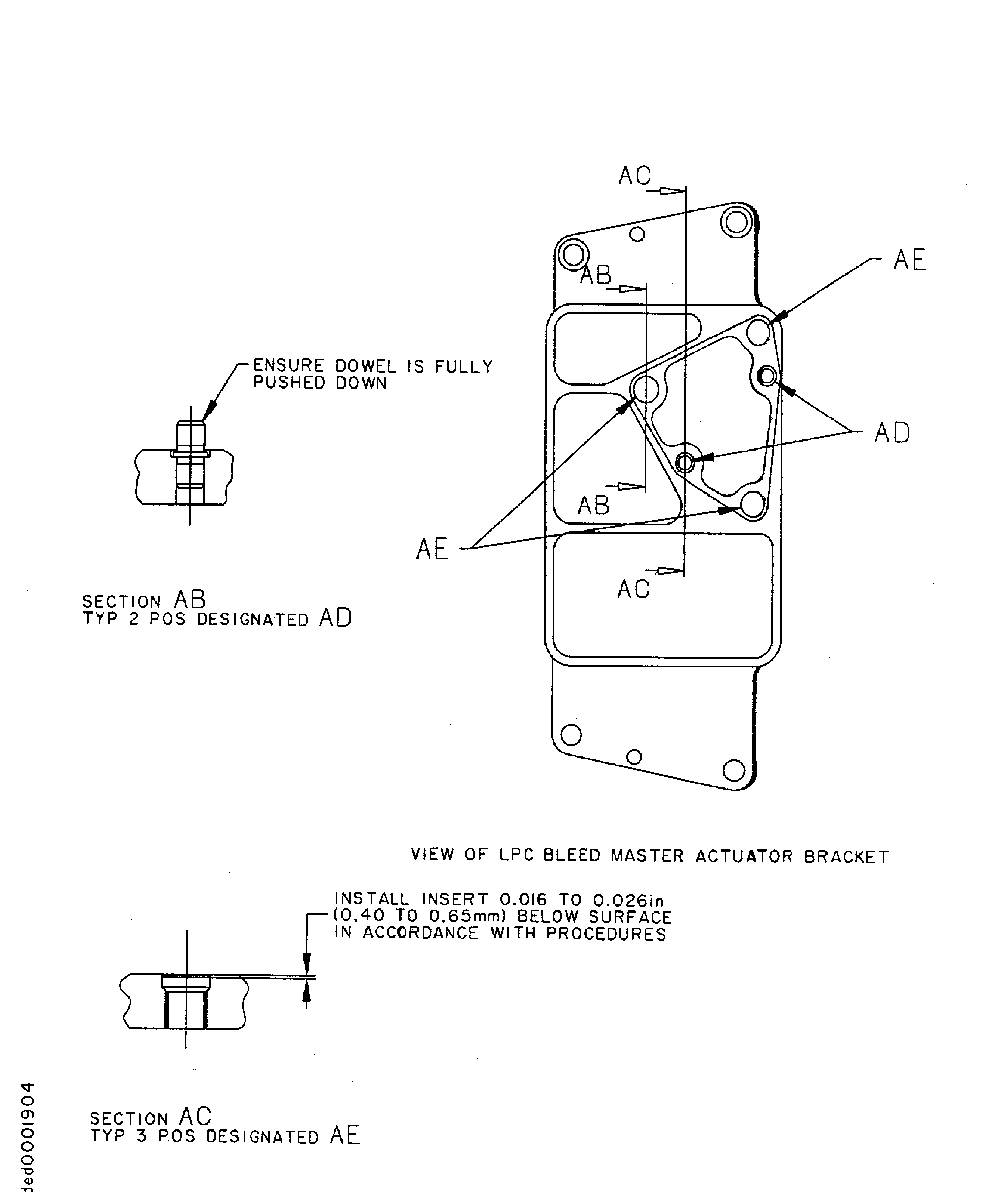

SUBTASK 75-31-43-350-062 Install the Replacement Thin Wall Insert(s), Assembly A and Assembly B

Use CoMat 03-026 LIQUID NITROGEN. Use AS44806 flanged location dowel.

Ensure dowel(s) are pushed hard down.

Freeze and install replacement flanged location dowel(s)

SUBTASK 75-31-43-350-063 Install the Replacement Flanged Location Dowel(s), Assembly A and Assembly B

Refer to SPM TASK 70-35-26-300-501, SUBTASK 70-35-26-350-001.

Examine thin wall insert(s)

SUBTASK 75-31-43-220-074 Examine the Thin Wall Insert(s), Assembly A and Assembly B

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions