Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 78-11-11-420-001 Install the Common Nozzle Assembly (CNA), Installation-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL, unless other lubricants are referred to in the procedure.

The number for each radial location is identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must be removed immediately before installation of the components.

Make sure the upper strut recess of the Common Nozzle Assembly (CNA) is at the top center.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1N20001 Common nozzle fixture | 0AM53 | IAE 1N20001 | ||

| IAE 1N20004 Common nozzle dolly | 0AM53 | IAE 1N20004 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL | LOCAL | CoMat 10-094 | ||

| CoMat 10-039 ENGINE OIL | 0AM53 | CoMat 10-039 |

Spares

NONESafety Requirements

NONEProcedure

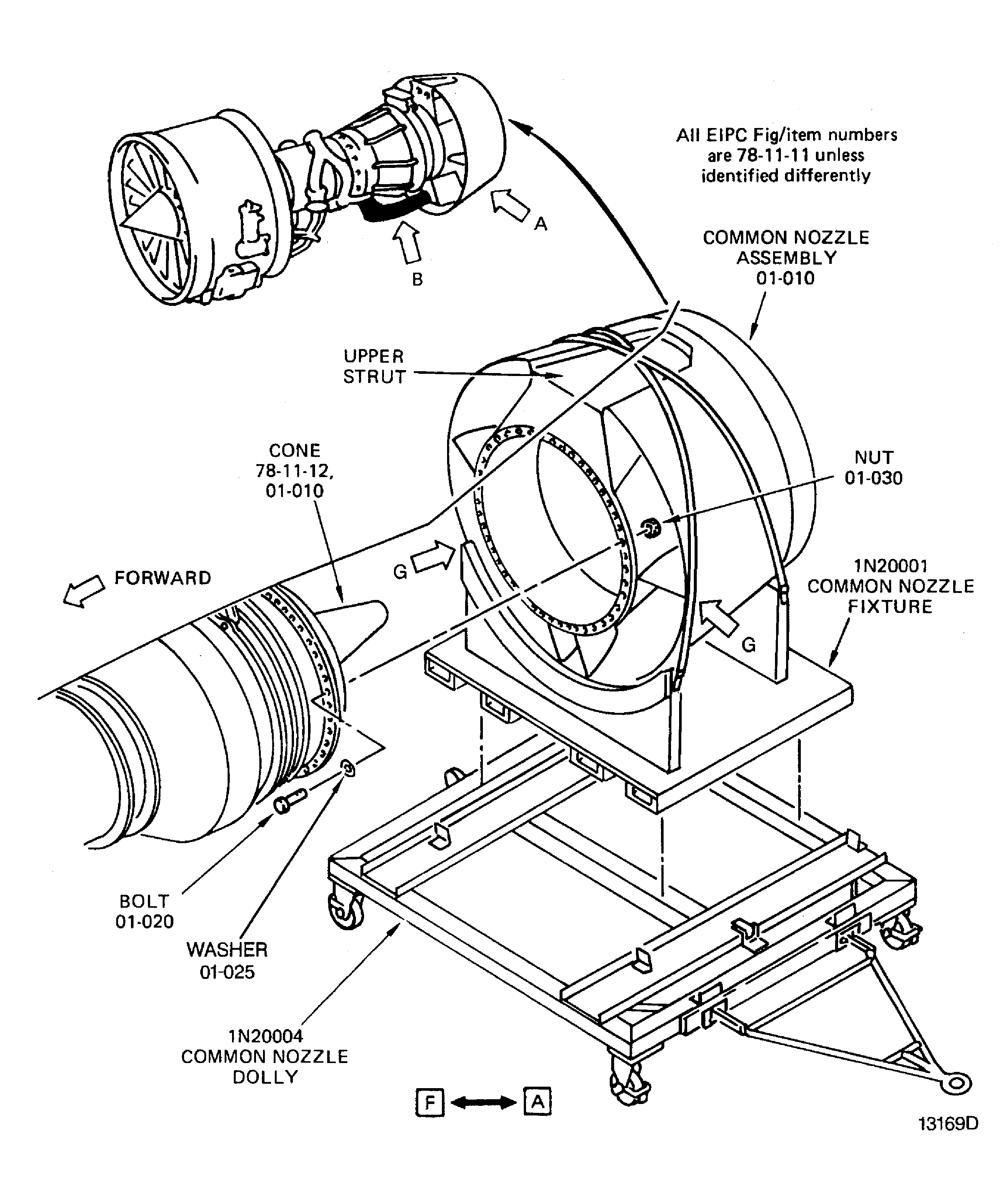

Remove the IAE 1N20001 Common nozzle fixture with the attached CNA Common Nozzle Assembly (CNA) (78-11-11,01-010) from the IAE 1N20004 Common nozzle dolly with a suitable lifting device.

NOTE

Access to some of the CNA fasteners is difficult. Access to these fasteners can be improved by the use of a standard 5/16 in. (7.93 mm) wrench modified to fit the contour of the CNA.Carefully move the CNA to the rear of the engine. Make sure that the CNA does not touch the exhaust cone Engine Exhaust Cone And Plug (78-11-12,01-010).

Pre SBN 78-0208: Install the bolts Common Nozzle Assembly (CNA) (78-11-11,01-020), washers Common Nozzle Assembly (CNA) (78-11-11,01-025) and nuts Common Nozzle Assembly (CNA) (78-11-11,01-030) to attach the CNA Common Nozzle Assembly (CNA) (78-11-11,01-010) to the engine flange. Do not fully torque the nuts until they are all installed. Do not install washers on the bolts which go through the EGT harness brackets on the engine flange.

SBN 78-0208: Install the bolts Common Nozzle Assembly (CNA) (78-11-11,01-020) and washers Common Nozzle Assembly (CNA) (78-11-11,01-025) to attach the CNA Common Nozzle Assembly (CNA) (78-11-11,01-010) to the engine flange. Do not fully torque the nuts until they are all installed. Do not install washers on the bolts which go through the EGT harness brackets on the engine flange.

Remove the IAE 1N20001 Common nozzle fixture from the CNA.

Pre SBN 78-0208: Torque the bolts Common Nozzle Assembly (CNA) (78-11-11,01-020) to between 180 and 220 lbfin (20.3 and 24.9 Nm). Begin at the 3 o'clock and 9 o'clock positions and torque the nuts in opposite pairs in a clockwise sequence.

SBN 78-0208: Torque the bolts Common Nozzle Assembly (CNA) (78-11-11,01-020) to between 150 and 160 lbfin (16.9 and 18.0 Nm). Begin at the 3 o'clock and 9 o'clock positions and torque the nuts in opposite pairs in a clockwise sequence.

SUBTASK 78-11-11-420-058-A00 V2500-A1 Install the Common Nozzle Assembly (CNA) (Pre SBN 78-0208 and SBN 78-0208)

Refer to Figure.

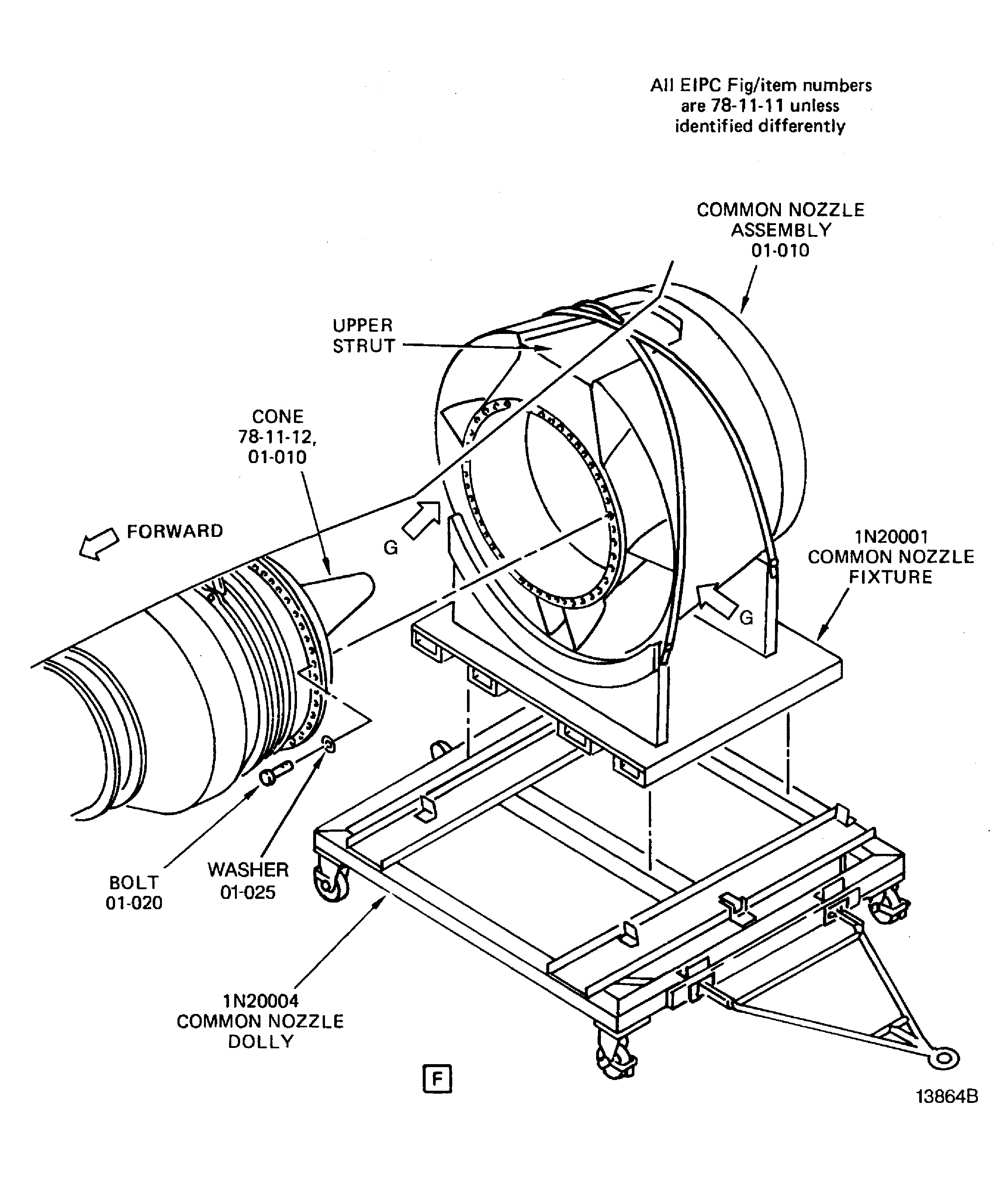

Remove the IAE 1N20001 Common nozzle fixture with the attached CNA Common Nozzle Assembly (CNA) (78-11-11,01-010) from the IAE 1N20004 Common nozzle dolly common nozzle dolly with a suitable lifting device.

Carefully move the CNA to the rear of the engine. Make sure that the CNA does not touch the exhaust cone Engine Exhaust Cone And Plug (78-11-12,01-010).

Apply the CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL to the threads of the bolts Common Nozzle Assembly (CNA) (78-11-11,01-020).

Install the bolts Common Nozzle Assembly (CNA) (78-11-11,01-020) and washers Common Nozzle Assembly (CNA) (78-11-11,01-025) to attach the CNA Common Nozzle Assembly (CNA) (78-11-11,01-010) to the engine flange. Do not fully torque the nuts until they are all installed. Do not install washers on the bolts which go through the EGT harness brackets on the engine flange.

Remove the IAE 1N20001 Common nozzle fixture from the CNA.

Torque the bolts Common Nozzle Assembly (CNA) (78-11-11,01-020) to between 150 and 160 lbfin (16.9 and 18.0 Nm). Begin at the 3 o'clock and 9 o'clock positions and torque the nuts in opposite pairs in a clockwise sequence.

SUBTASK 78-11-11-420-058-B00 V2500-A5 Install the Common Nozzle Assembly (CNA)

Refer to Figure.

Remove the IAE 1N20001 Common nozzle fixture from the CNA Engine Exhaust Cone And Plug (78-11-12, 01-010).

Lower the IAE 1N20001 Common nozzle fixture on to the IAE 1N20004 Common nozzle dolly.

SUBTASK 78-11-11-420-059 Remove the Support Equipment

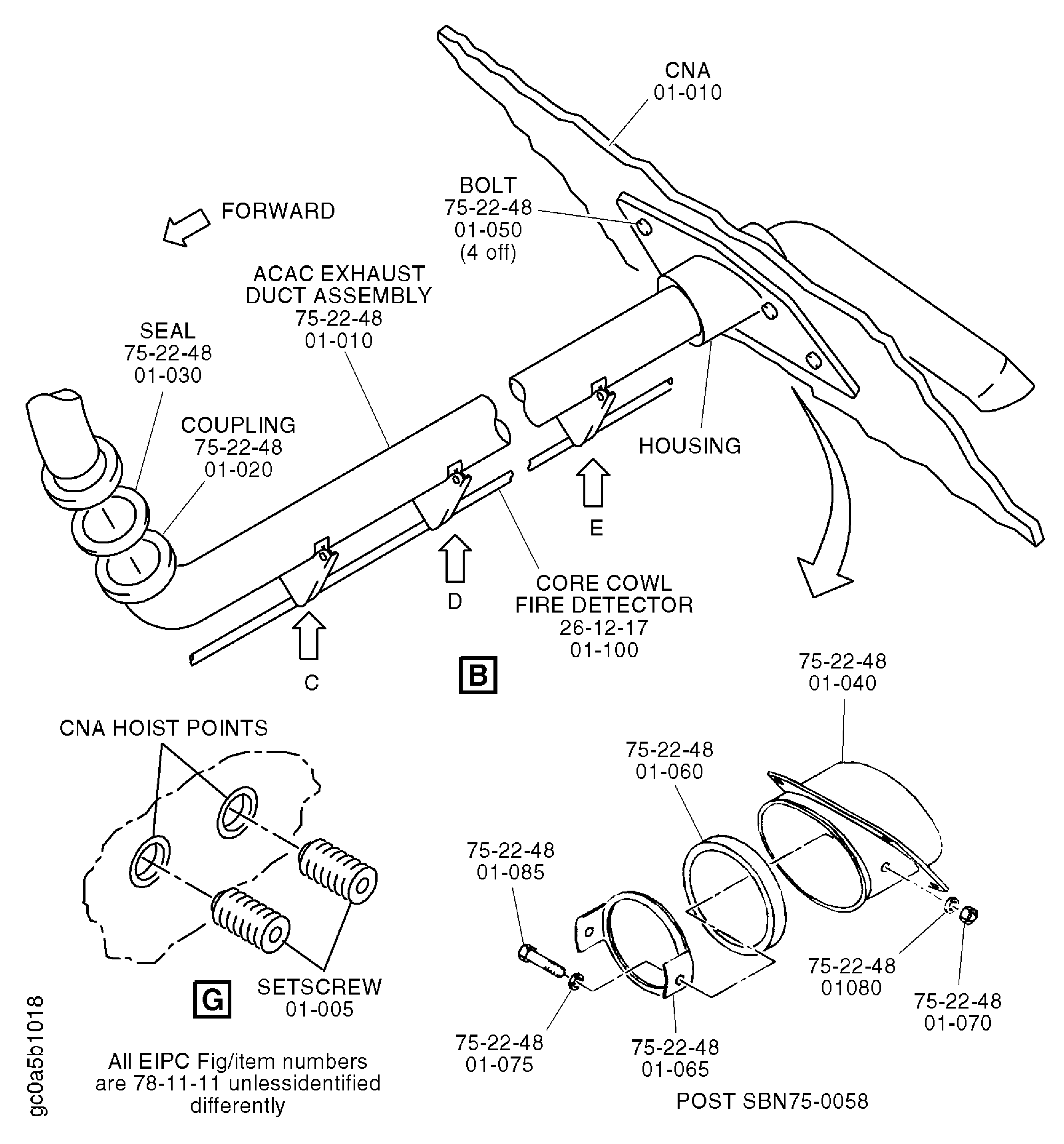

SBN 75-0058: Replacement of the ACAC exhaust duct seal

Refer to Figure.

Position the lower segment ACAC Exhaust Duct And Housing (75-22-48, 01-010) on the CNA Engine Exhaust Cone And Plug (78-11-12, 01-010).

Pre SBN 75-0058: Install the four bolts ACAC Exhaust Duct And Housing (75-22-48, 01-050) and the seal ACAC Exhaust Duct And Housing (75-22-48, 01-030) which attach the ACAC exhaust duct lower segment to the upper segment.

SBN 75-0058: Put the support ring ACAC Exhaust Duct And Housing (75-22-48, 01-060) and the backup ring ACAC Exhaust Duct And Housing (75-22-48, 01-065) in the housing ACAC Exhaust Duct And Housing (75-22-48, 01-040). Attach with two bolts ACAC Exhaust Duct And Housing (75-22-48, 01-085), two radius blocks ACAC Exhaust Duct And Housing (75-22-48, 01-075) and ACAC Exhaust Duct And Housing (75-22-48, 01-080) and two nuts ACAC Exhaust Duct And Housing (75-22-48, 01-070). Attach the housing ACAC Exhaust Duct And Housing (75-22-48, 01-040) to the CNA Common Nozzle Assembly (CNA) (78-11-11, 01-010).

Install the coupling ACAC Exhaust Duct And Housing (75-22-48, 01-020) and the seal ACAC Exhaust Duct And Housing (75-22-48, 01-030) which attach the ACAC exhaust duct lower segment to the upper segment.

Torque the four bolts ACAC Exhaust Duct And Housing (75-22-48, 01-050) to between 50 and 70 lbfin. (5.6 and 7.9 Nm).

Torque the coupling ACAC Exhaust Duct And Housing (75-22-48, 01-020).

SUBTASK 78-11-11-420-060 Install the Lower Segment of the ACAC Exhaust Duct (Pre SBN 75-0058 and SBN 75-0058)

Refer to Figure.

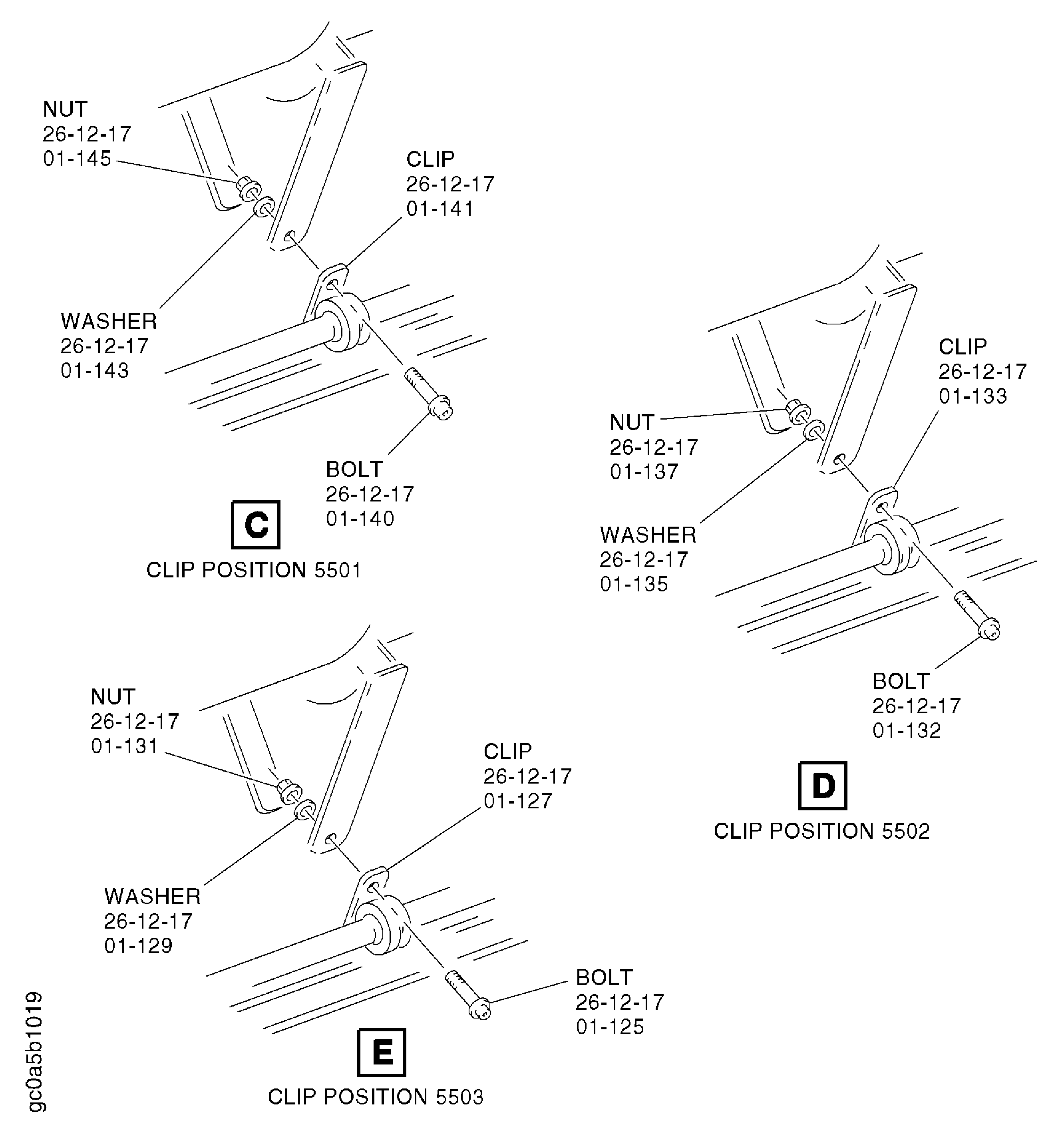

Apply the CoMat 10-039 ENGINE OIL to the threads of the bolts FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-125), FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-132), FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-140).

Install the clip FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-127) at clip position 5503 on the ACAC exhaust duct ACAC Exhaust Duct And Housing (75-22-48, 01-010) with the washer FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-129), bolt FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-125), and nut FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-131).

Install the clip FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-133) at clip position 5502 on the ACAC exhaust duct ACAC Exhaust Duct And Housing (75-22-48, 01-010) with the washer FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-135), bolt FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-132), and nut FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-137).

Install the clip FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-141) at clip position 5501 on the ACAC exhaust duct ACAC Exhaust Duct And Housing (75-22-48, 01-010) with the washer FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-143), bolt FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-140), and nut FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-145).

Torque the nuts FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-131), FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-137), FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-145) to 40 lbfin. (4.5 Nm).

SUBTASK 78-11-11-420-061 Install the Core Cowl Fire Detector on the ACAC Exhasut Duct

NOTE

Make sure that the fire detector has a minimum clearance of 0.25 in. (6.35 mm) with adjacent pipes and structure.

Figure: Common Nozzle Assembly, Fixture and Dolly

Sheet 1

Figure: Common Nozzle Assembly, Fixture and Dolly

Sheet 2

Figure: ACAC Exhaust Duct

ACAC Exhaust Duct

Figure: Core Cowl Fire Detector

Core Cowl Fire Detector