Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 79-21-41-300-035 Replace The Identification Plate Of The Oil Pressure Pump Casing - Repair 035 (VRS5702)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

This repair procedure can be carried out once on each casing assembly.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent Penetrant Inspection Equipment | ||

| Drilling equipment | LOCAL | Drilling equipment | ||

| Vibrating Marking Pencil | LOCAL | Vibrating Marking Pencil | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| PLATE - IDENTIFICATION | 0AM53 | 4P7239 | 1 (Pre SB 79-0101) | Fig/Item 01-850 |

| PLATE - IDENTIFICATION | 0AM53 | 4P7374 | 1 (Post SB 79-0101) | Fig/Item 01-850A |

| Screw | LOCAL | MS21318-1 | 2 | Fig/Item 01-855 |

Safety Requirements

NONEProcedure

Drill or grind off heads.

Do not damage casing during this procedure.

Remove the screws with the use of standard tools.

Remove the identification plate.

NOTE

Record part number and serial number of the pump before identification plate disassembly.

SUBTASK 79-21-41-350-001 Remove the Identification Plate from the Oil Pressure Pump Casing

Accept

All quantity, length not more than 0.035 in. (0.889 mm) in depth is permitted.

Refer to VRS5305, TASK 79-21-41-300-003 (Repair-003).

More than Step.

Nicks, scores, dents or scratches.

SUBTASK 79-21-41-220-001 Visually Inspect Local Surfaces

Refer to Figure.

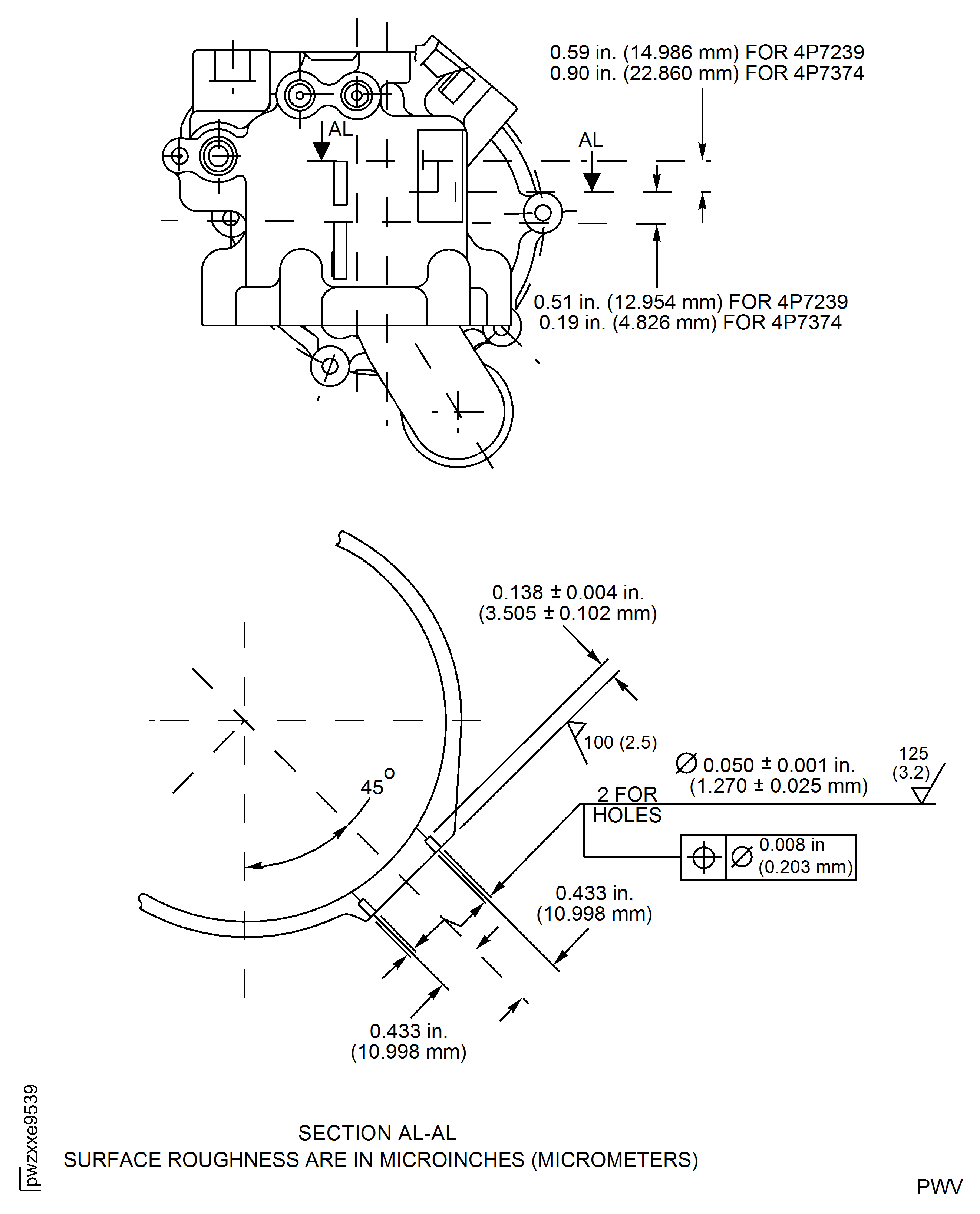

Use standard Drilling equipment. Make sure the diameter of each hole is not more than 0.060 in. (1.524 mm).

Drill the holes.

SUBTASK 79-21-41-320-001 Drill Holes in the New Identification Plate

Refer to Figure.

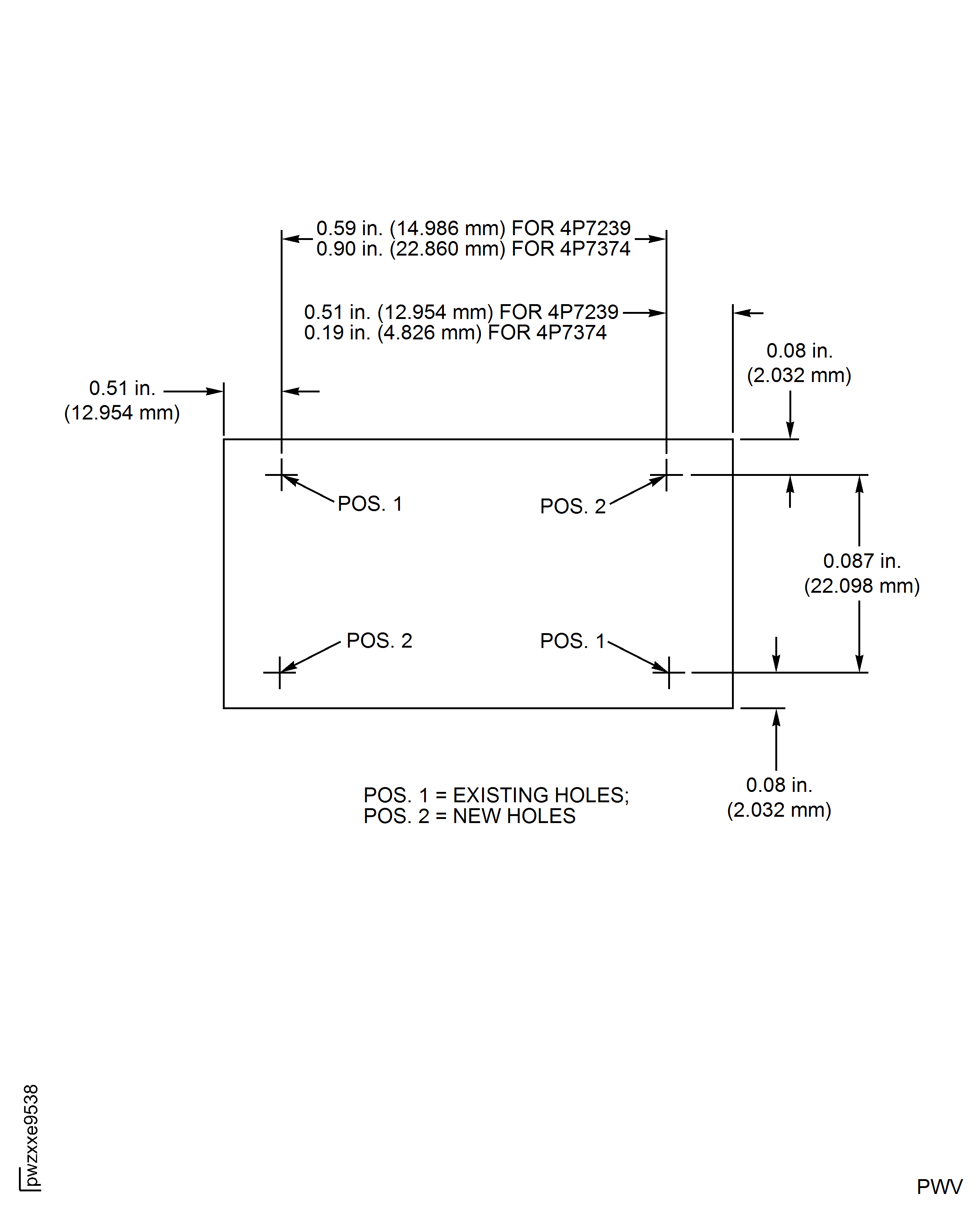

Use the identification plate as marking mask. Make sure the identification plate is aligned correctly before drilling new holes.

NOTE

Apply this step only if old screws can not be removed.

Mark the position of the holes.

Use standard Drilling equipment. Hole diameter is between 0.049 in. and 0.05 in. (1.245 mm and 1.270 mm). Hole depth is between 0.134 in. and 0.142 in. (3.404 mm and 3.607 mm).

WARNING

DRILLING BEYOND MAXIMUM DRILLING DEPTH CAN CAUSE SERIOUS DAMAGE TO THE PUMP HOUSING AND OIL LEAK.Drill the new holes.

SUBTASK 79-21-41-320-002 Drill New Holes in the Casing Assembly

Install new plate 4P7239 PLATE - IDENTIFICATION or 4P7374 PLATE - IDENTIFICATION with MS21318-1 .

Align the plate on the seat.

Use standard tools. Do not bend the screws. Do not damage the plate.

Press in the screws.

Make sure the plate is firmly seated.

Inspect the plate.

SUBTASK 79-21-41-350-003 Install the Identification Plate on the Casing Assembly

Refer to the SPM, SUBTASK 70-09-00-400-001.

Mark VRS5702 adjacent to the part number. Use Vibro-engraving equipment.

SUBTASK 79-21-41-350-004 Identify the Repair

Figure: Drill Holes In The New Identification Plate

Drill Holes In The New Identification Plate

Figure: Drill New Holes In The Casing Assembly

Drill New Holes In The Casing Assembly