Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-32-35-300-004 Front Bearing Compartment Rear Air Seal Assembly - Repair The Snap Diameter By Plasma Spraying, Repair-004 (VRS1253)

General

Price and availability

Refer to IAE for any of the following:

Tools

Engine parts

Repair of spares

The practices and processes referred to in the procedure by the TASK number are in the SPM.

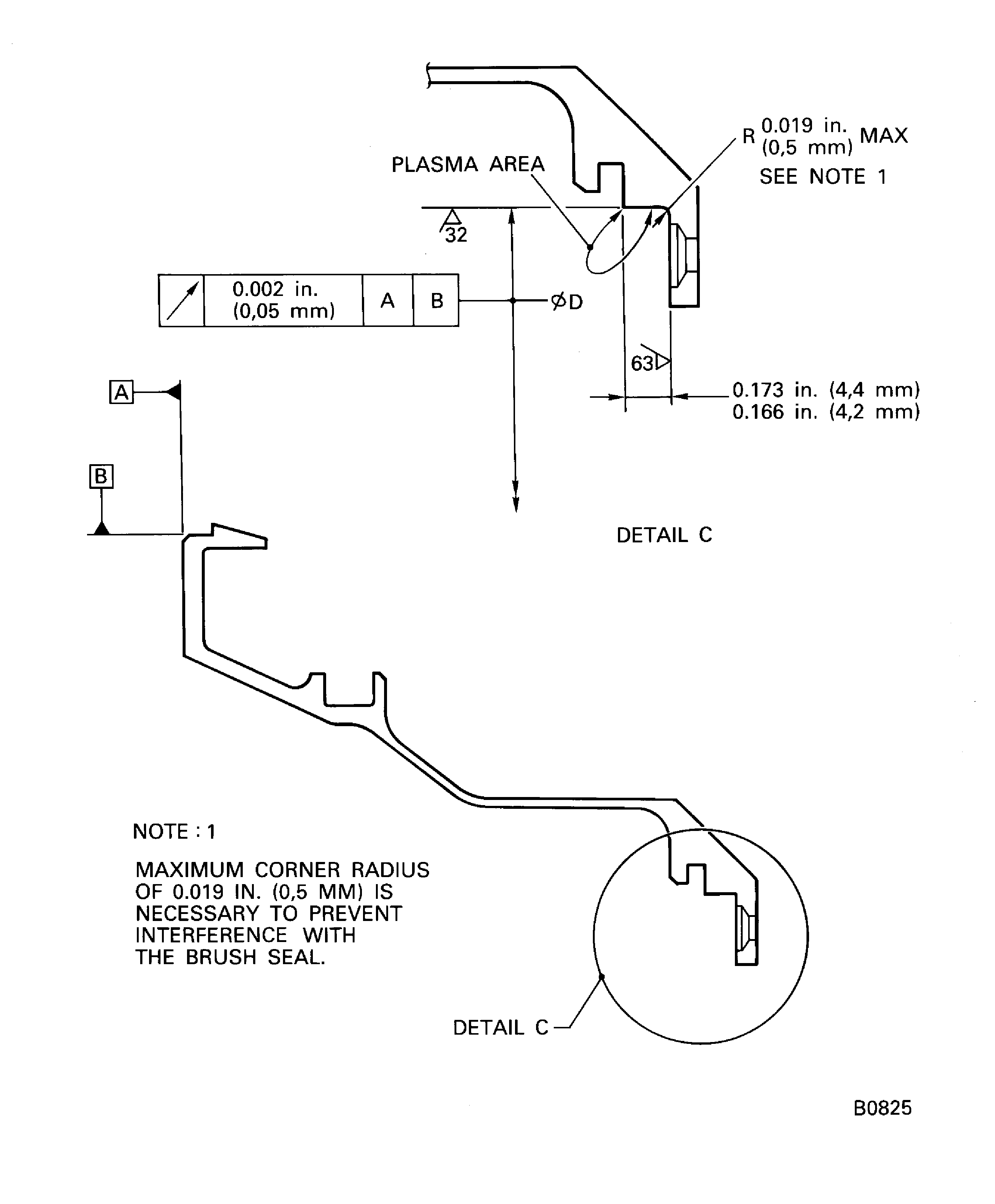

This Repair scheme gives the procedure for plasma spraying the snap diameter of the rear air seal assembly.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Lathe | LOCAL | Lathe | ||

| Grinding machine | LOCAL | Grinding machine | ||

| Abrasive blasting facility | LOCAL | Abrasive blasting facility | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-051 HIGH TEMPERATURE GLASS CLOTH TAPE | 0AM53 | CoMat 02-051 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | IE200 | CoMat 03-038 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

SUBTASK 72-32-35-325-051 Machine the Worn Snap Diameter

Refer to the SPM TASK 70-21-01-220-501.

Do a visual inspection for the machined area.

SUBTASK 72-32-35-220-058 Inspect the Rear Air Seal

Refer to the SPM TASK 70-23-01-230-501.

Do a crack test. Cracks are not permitted.

SUBTASK 72-32-35-230-053 Examine the Rear Air Seal for Cracks

Refer to the SPM TASK 70-12-02-120-501.

Abrasive blast the rear air seal surface to be plasma sprayed.

SUBTASK 72-32-35-120-051 Abrasive Blast the Rear Air Seal

Refer to Figure.

Refer to the SPM TASK 70-34-03-340-501.

Apply plasma spray. Maximum diameter of 8.960 in. (227.59 mm) is required after plasma spraying.

SUBTASK 72-32-35-340-051 Apply Plasma Spray on the Snap Diameter

Refer to Figure.

SUBTASK 72-32-35-324-052 Grind the Snap Diameter

Refer to the SPM TASK 72-32-35-200-000.

Do a visual inspection.

SUBTASK 72-32-35-220-059 Examine the Rear Air Seal

Figure: Rear air seal

Rear air seal