Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-32-80-040-001-A00 LPC Assembly - Disassemble The LPC Cases And Vanes From The Rotor Assembly, Disassembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

Discard all rubber seal rings and tab washers removed in this procedure.

The LP compressor booster stage assembly is installed on to IAE 1J13111 LPC storage stand in the TASK 72-32-00-030-006-A00 (DISASSEMBLY-006, CONFIG-001).

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1J12139 Puller bolt set | 0AM53 | IAE 1J12139 | 1 | |

| IAE 1J13210 LPC holding block | 0AM53 | IAE 1J13210 | 1 | |

| IAE 1J13111 LPC storage stand | 0AM53 | IAE 1J13111 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Move IAE 1J13210 LPC holding block 1 off to the work area.

SUBTASK 72-32-80-040-051 Remove the Stage 1.5 LP Compressor Blades

Use the four puller bolts (part of IAE 1J12139 Puller bolt set 1 off) to release the front LP compressor case from the rear LP compressor case and the stage 2.0 LP compressor vane assembly.

SUBTASK 72-32-80-040-052 Remove the Front LP Compressor Case and the Stage 1.5 LP Compressor Vane from the Rear LP Compressor Case and the Stage 2.0 LP Compressor Vane Assembly

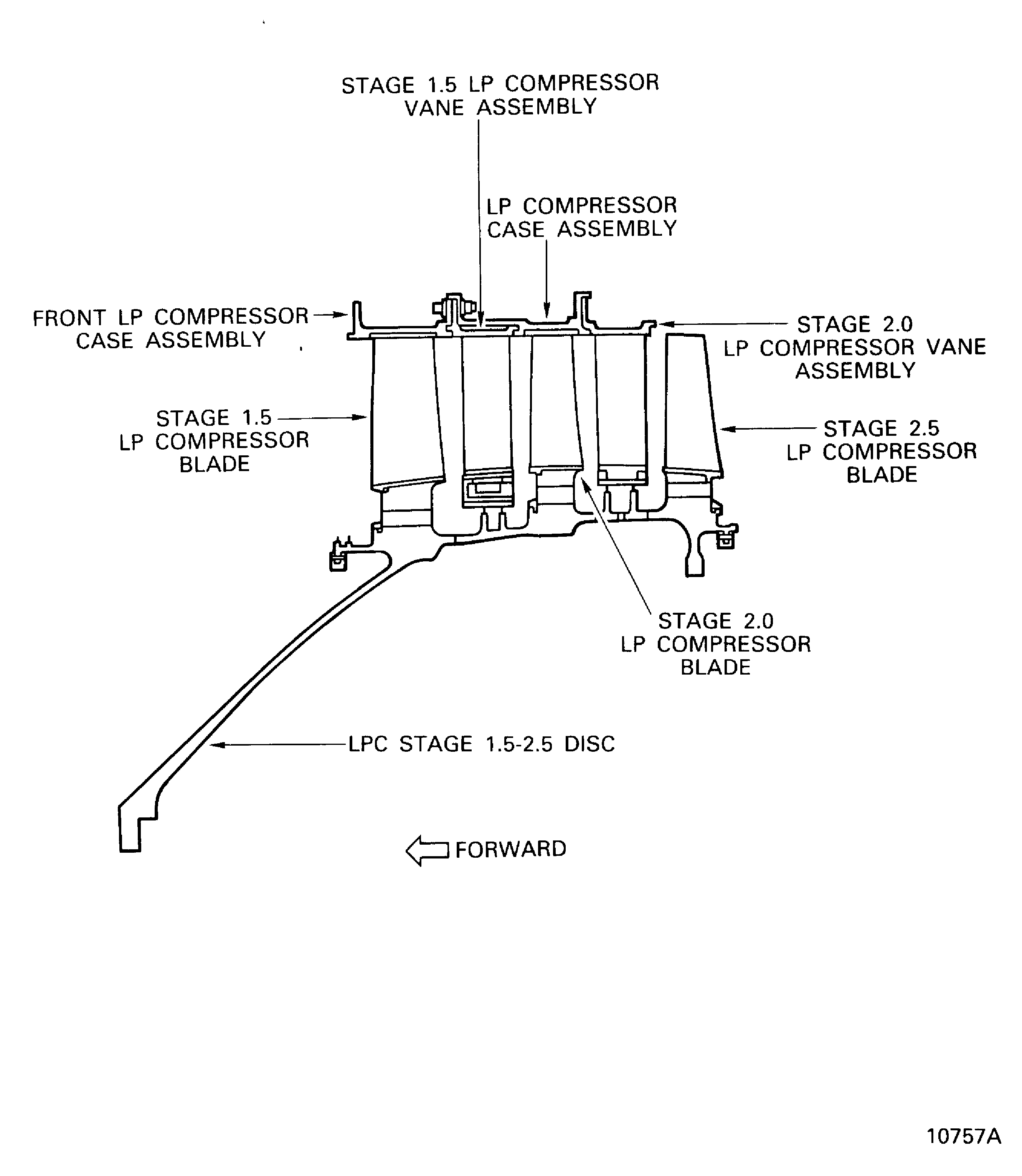

Figure: Sectional view of the LP Compressor Stage 1.5, 2 and 2.5 Assembly

Sectional view of the LP Compressor Stage 1.5, 2 and 2.5 Assembly

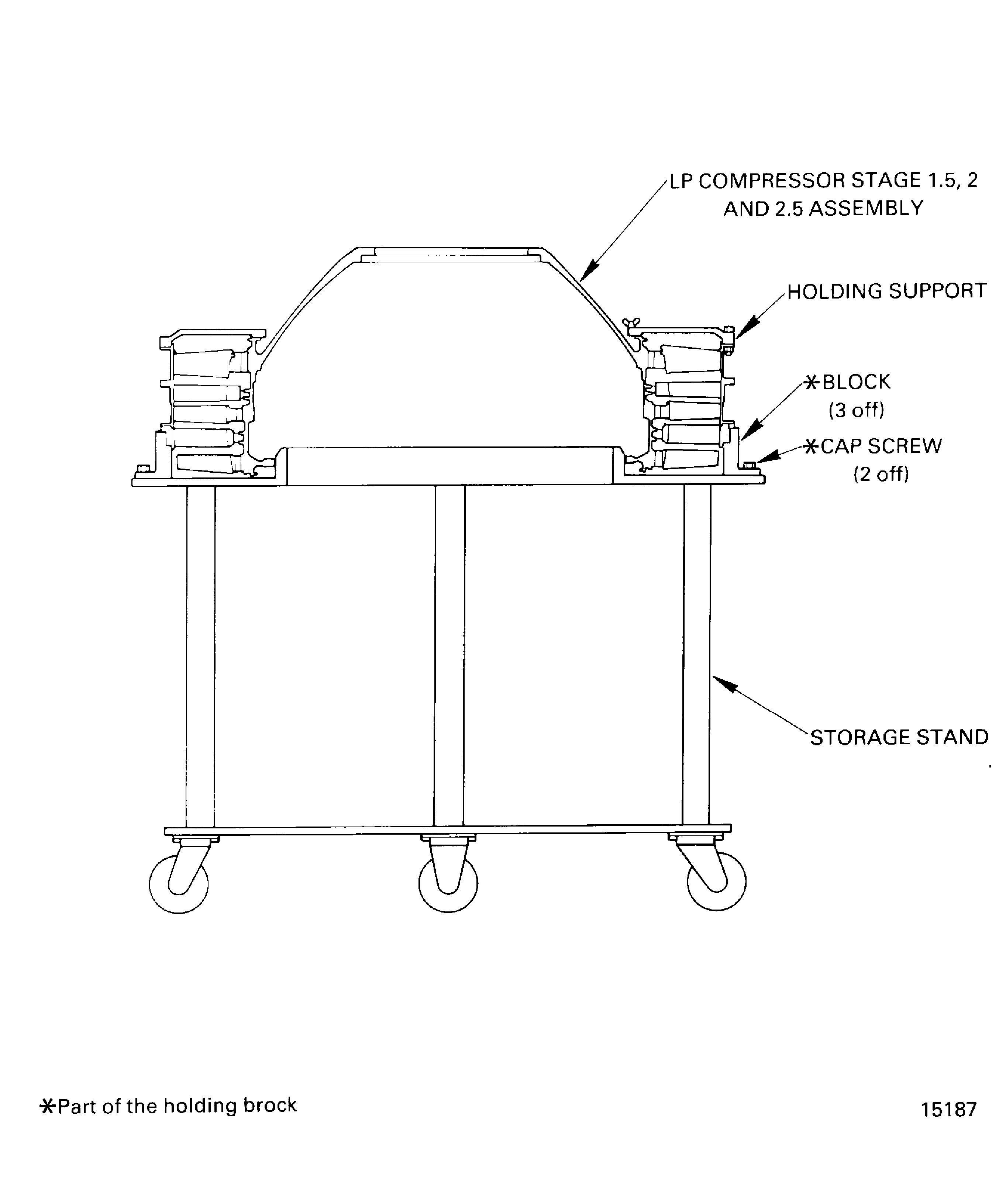

Figure: Install the LP Compressor Booster Stage Assembly on to the LPC Holding Block

Install the LP Compressor Booster Stage Assembly on to the LPC Holding Block

Figure: Remove the Stage 1.5 and Stage 2 Blades

Sheet 1

Figure: Remove the Stage 1.5 and Stage 2 Blades

Sheet 2

Figure: Remove the Stage 2.5 Blades

Sheet 1

Figure: Remove the Stage 2.5 Blades

Sheet 2