DMC:V2500-A1-72-32-8220-00A-933A-CIssue No:001.00Issue Date:2013-11-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-32-82-840-001 LPC Stage 2.0 Blade - Rework The Blade, Rework-001 - SBE 72-0001

General

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Refer to the indicated Service Bulletin for specific application requirements.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Hand held pneumatic grinder | LOCAL | Hand held pneumatic grinder | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

CAUTION

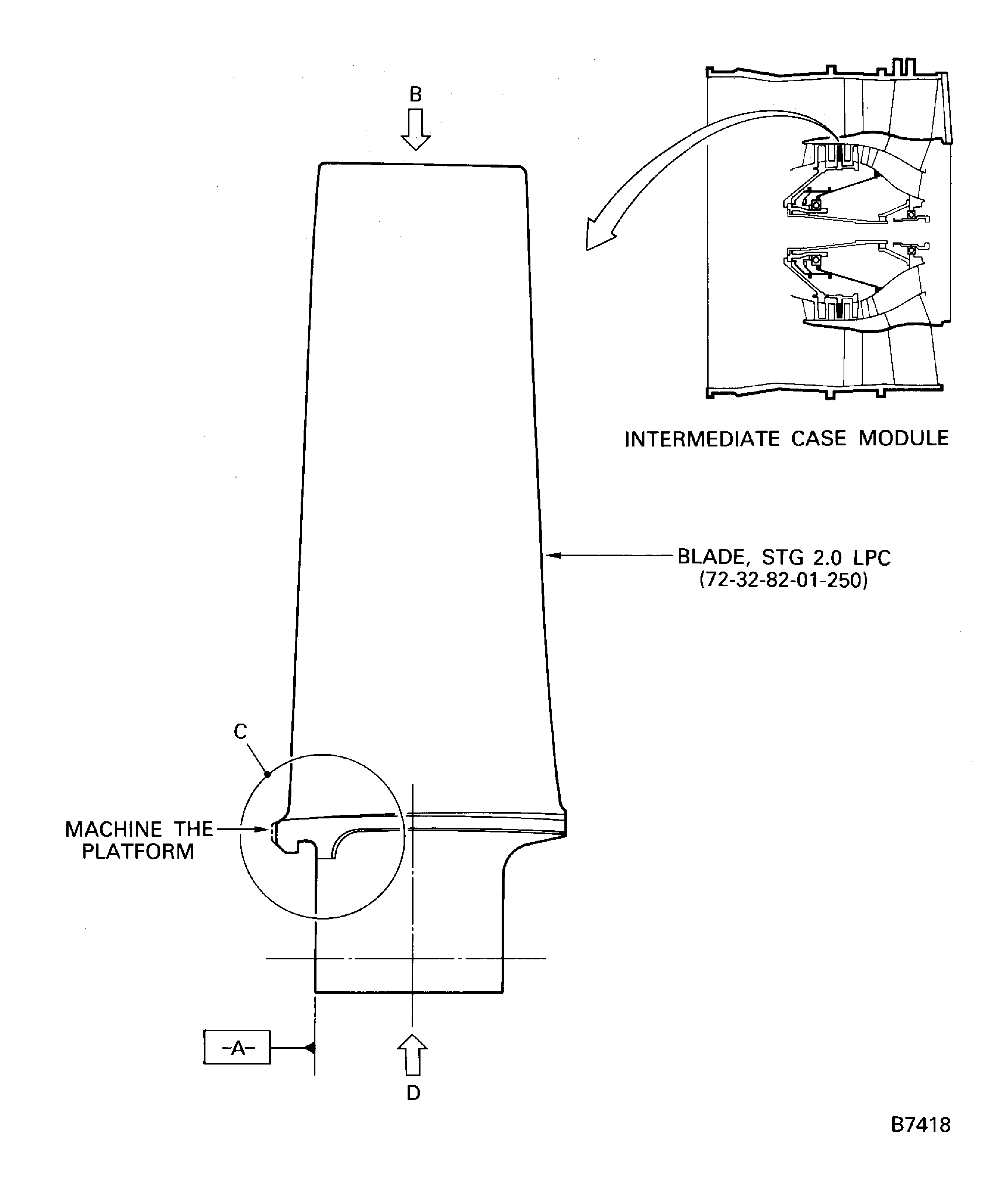

SPECIAL HANDLING OF TITANIUM COMPONENTS (REFER TO THE SPM TASK 70-03-00-300-503).Set-up and machine the platform of blade.

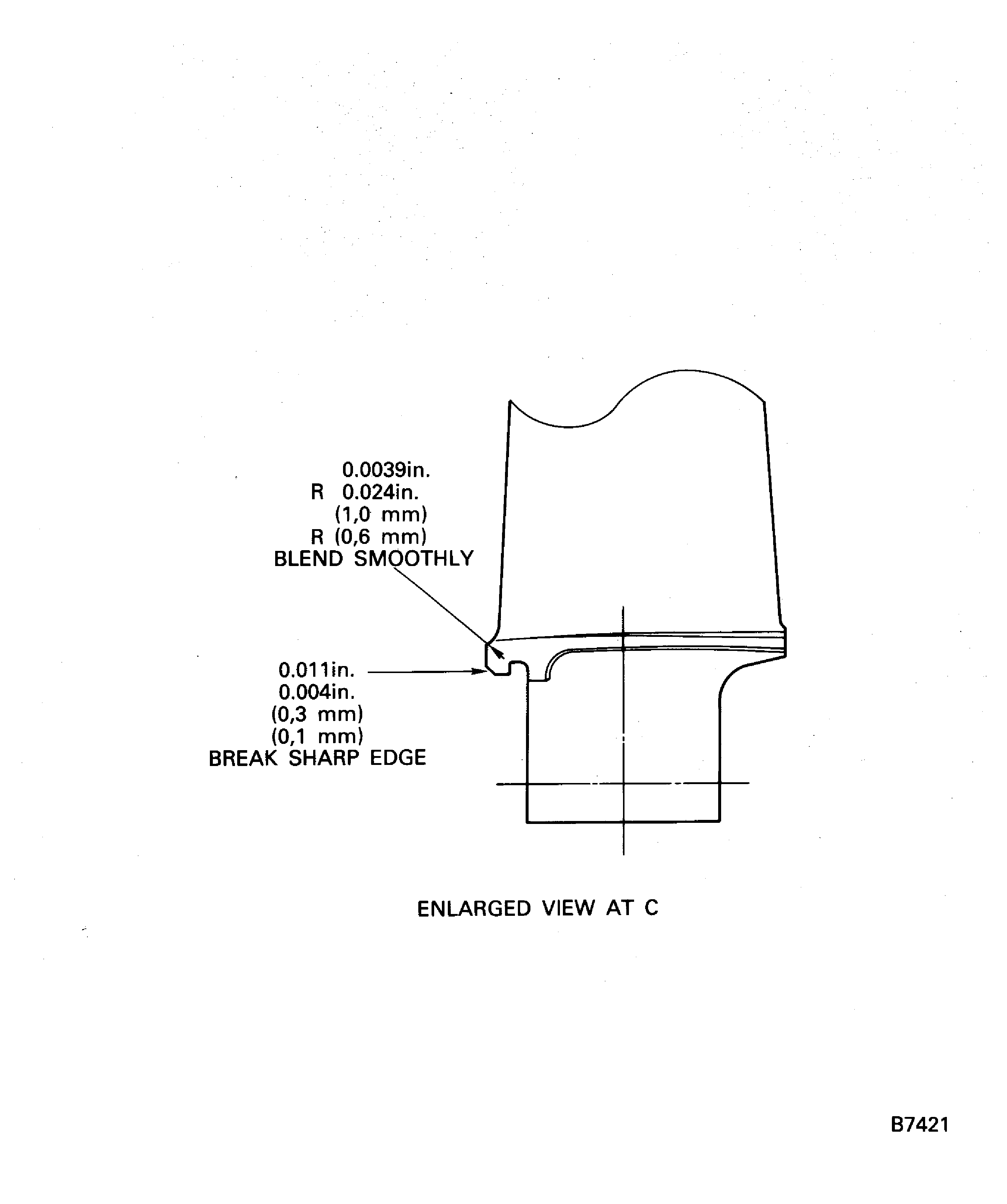

SUBTASK 72-32-82-350-064 Rework the Blade, Stage 2.0 LP Compressor

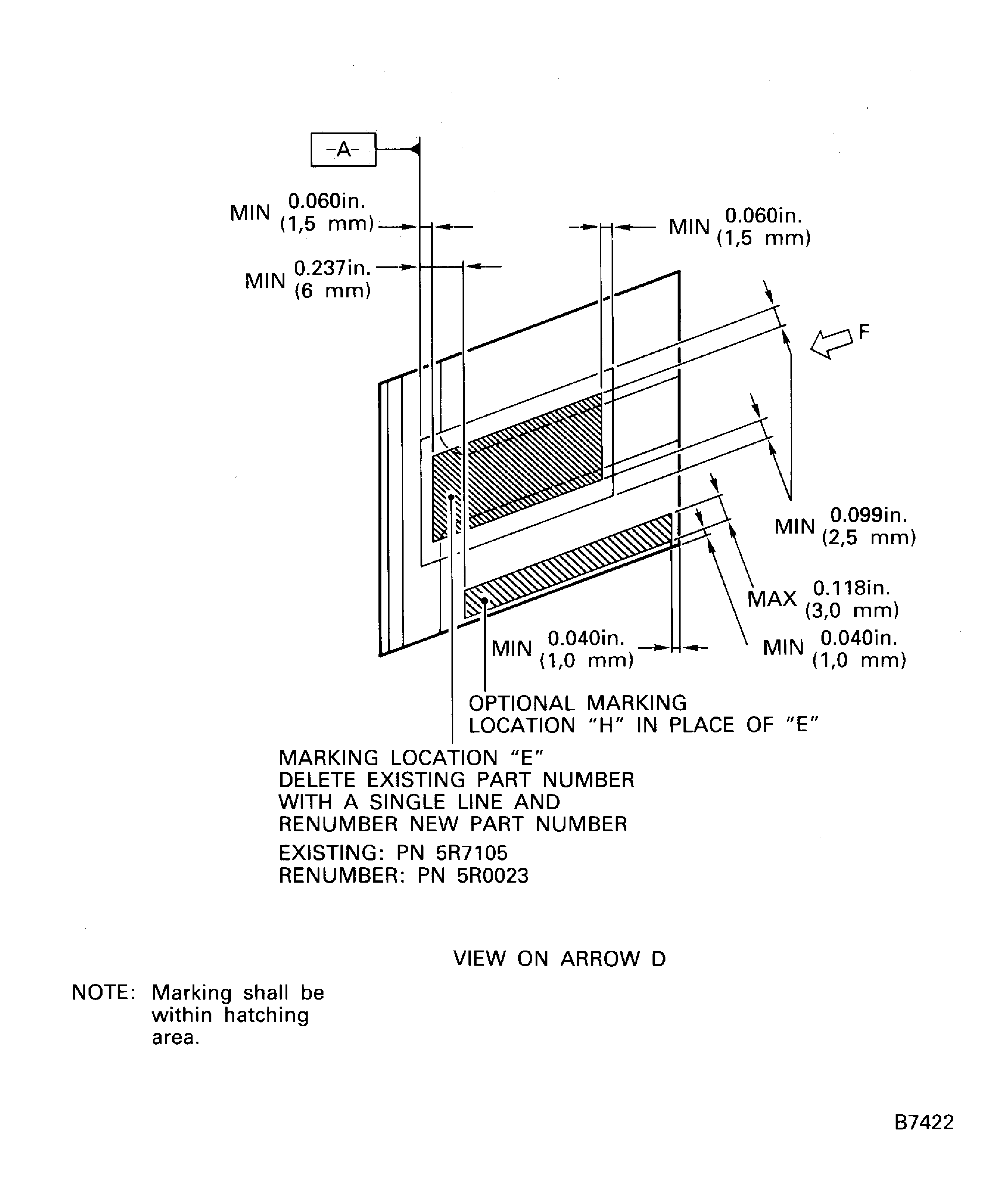

Existing - 5R7105

Renumber - 5R0023

Refer to the SPM TASK 70-09-00-400-501.

NOTE

Marking locations G and H are permissible to mark if location E does not have a sufficient area for marking.All raised metal which exceeds 0.0009 in. (0.025 mm) must be removed.Delete existing part number with a single line and renumber new part number.

SUBTASK 72-32-82-350-065 Reidentify the 5R7105 Blade, Stage 2.0 LP Compressor

Figure: Outline of rework

Outline of rework

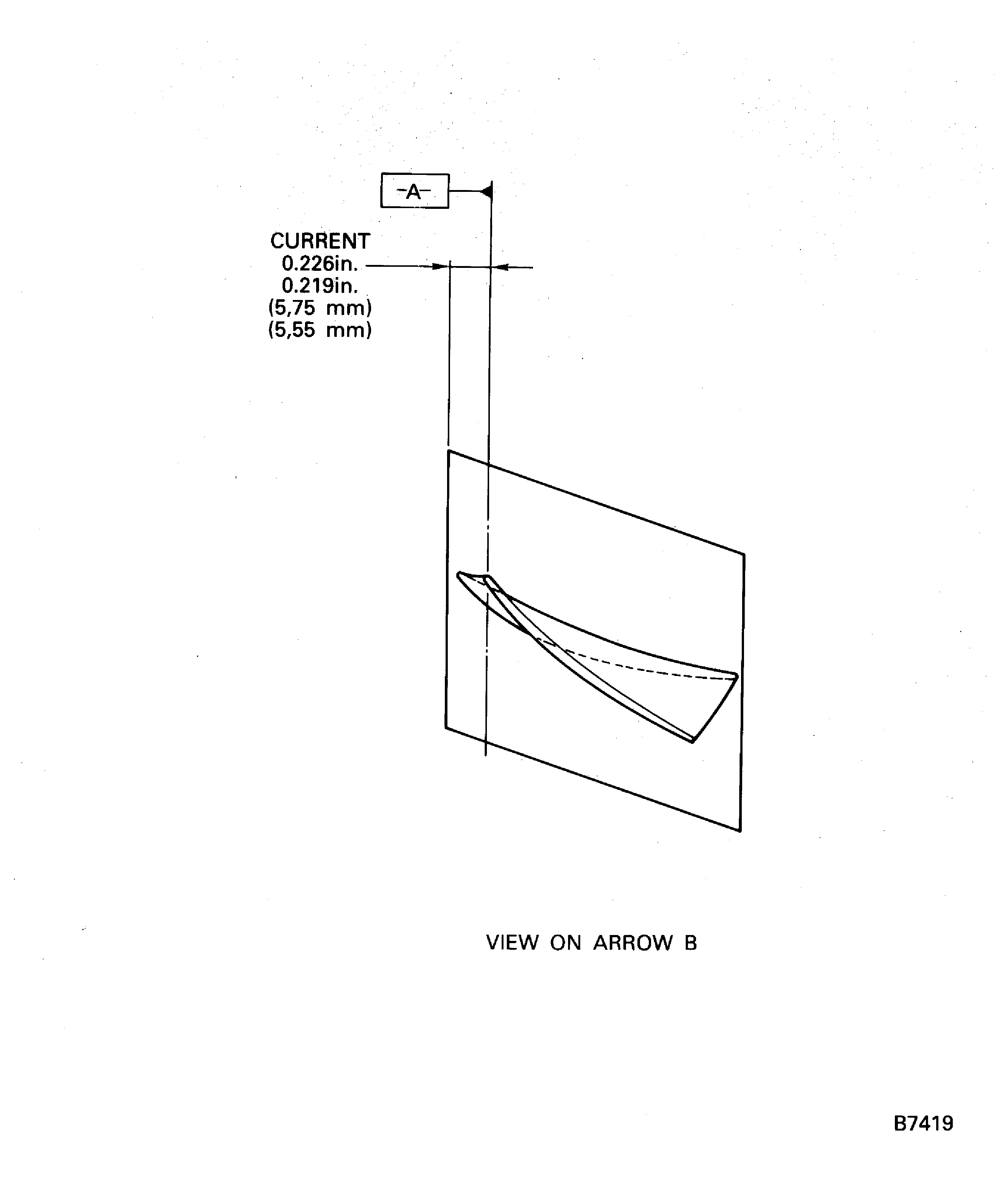

Figure: Before accomplishment of rework

Before accomplishment of rework

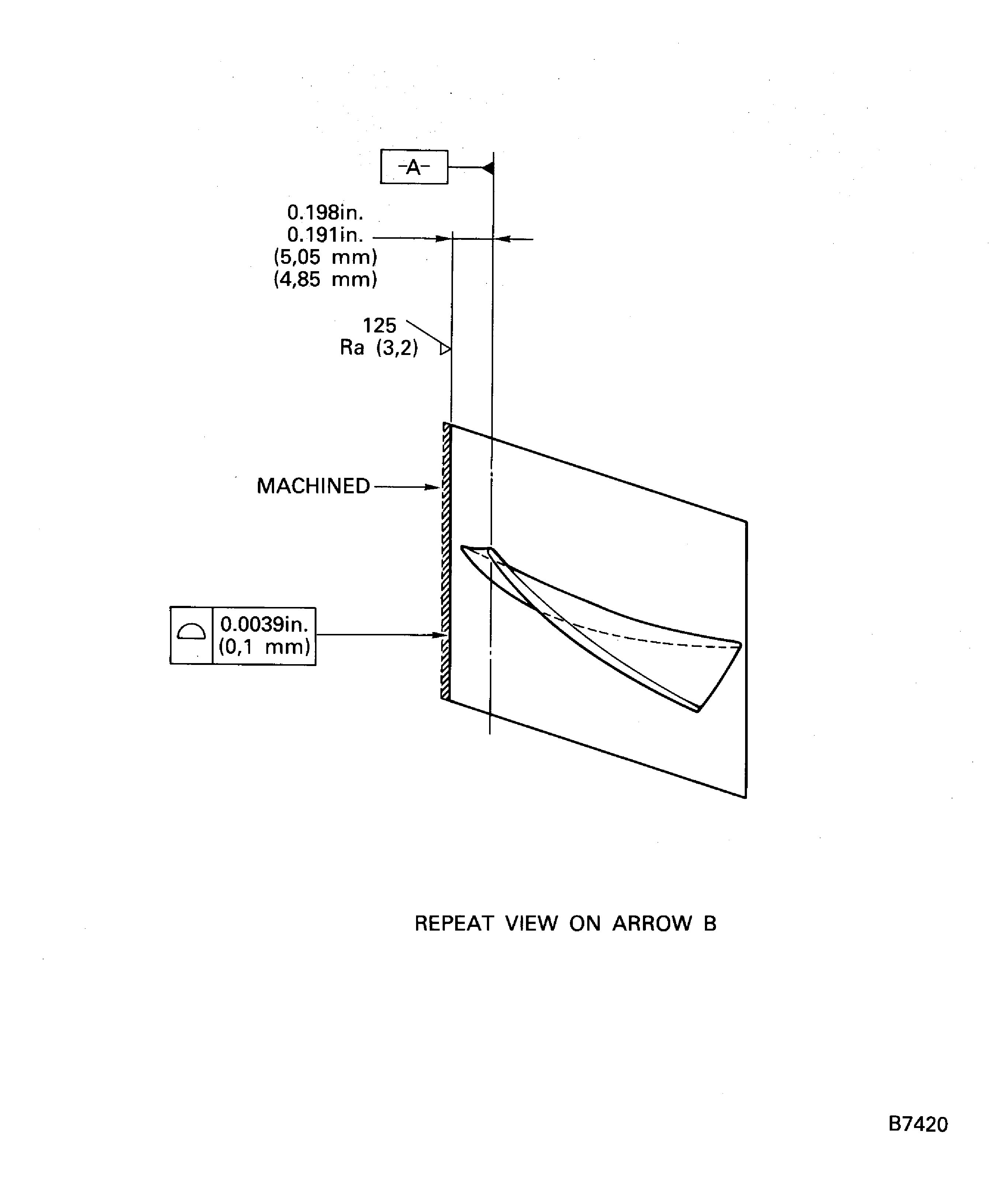

Figure: After accomplishment of rework

After accomplishment of rework

Figure: After accomplishment of rework

After accomplishment of rework

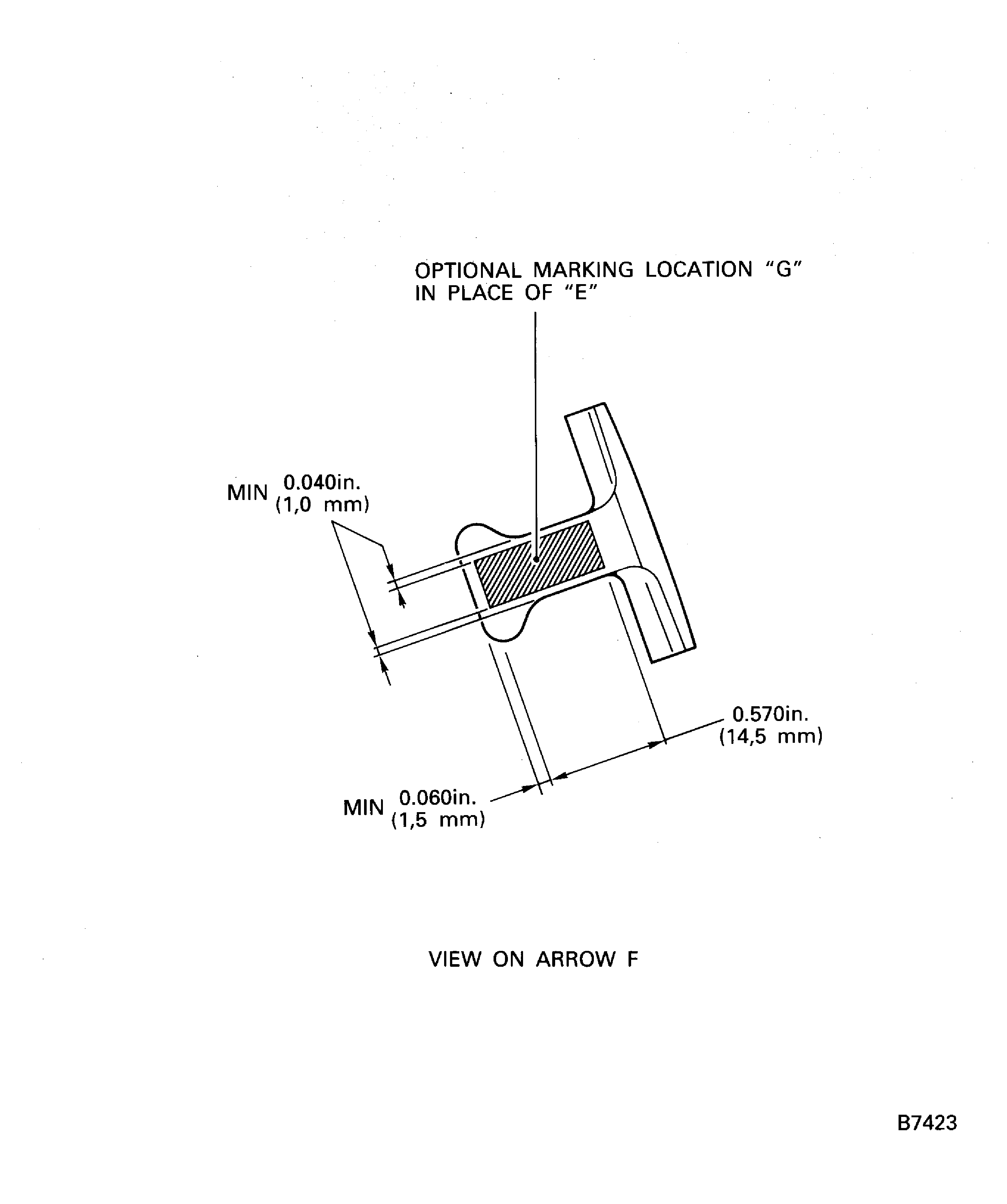

Figure: Marking location

Marking location

Figure: Marking location

Marking location