Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-32-83-300-008 LPC Front Case - Repair The Outside Diameter By Plasma Spray, Repair-008 (VRS1388)

General

Price and availability - none

The practice and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Vertical lathe | LOCAL | Vertical lathe | ||

| Abrasive blasting facility | LOCAL | Abrasive blasting facility | ||

| Plasma spray facility | LOCAL | Plasma spray facility | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| IAE 3J12755 Machining fixture | 0AM53 | IAE 3J12755 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | IE200 | CoMat 03-038 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

NONESafety Requirements

NONEProcedure

Use IAE IAE 3J12755 Machining fixture 1 off.

Set up the front case assembly on machine.

SUBTASK 72-32-83-320-051 Machine the Outside Diameter of the LPC Front Case Assembly

Refer to the SPM TASK 70-23-05-230-501.

Fluorescent penetrant examine machined area.

SUBTASK 72-32-83-230-060 Examine the LPC Front Case Assembly for Cracks

Refer to Figure.

Refer to the SPM TASK 70-34-01-340-501.

Abrasive blast the outside diameter.

Refer to the SPM TASK 70-34-01-340-501.

PLASMA SPRAY PARAMETER

Powder:

Metco 450 NS

Gun Model:

Metco 3 MB/7 MB/9 MB

Nozzle:

GH

Powder Port:

NO.2

Argon Pressure:

100 psi (700 Kpa)

Helium Pressure:

50 psi (350 Kpa)

Argon Flow Setting:

80 ft 3/Hr

Helium Flow Setting:

15

Carrier Flow Setting:

37

Spray Rate:

9 lbs/HOUR

Meter Wheel:

S

Meter Wheel Speed:

20 rpm.

Spray Distance:

4 - 7in. (102 - 177 mm)

Arc Volts:

64 - 70

Current:

500 amps

Plasma spray the outside diameters A or/and C.

SUBTASK 72-32-83-340-051 Plasma Spray the Outside Diameter of the Front Case Assembly

Refer to the SPM TASK 70-34-01-340-501.

Examine the outside diameter for adhesion, chipping and separation.

SUBTASK 72-32-83-220-088 Examine the Outside Diameter

Use vertical lathe and IAE IAE 3J12755 Machining fixture 1 off.

Set up the front case assembly on machine.

Refer to the SPM TASK 70-34-01-340-501.

Machine the coated area.

SUBTASK 72-32-83-220-089 Machine the Outside Diameter of the Front Case Assembly

No cracks are permitted.

Refer to the SPM TASK 70-34-01-340-501.

Visually and dimensionally examine the repaired area.

SUBTASK 72-32-83-220-090 Examine the Outside Diameter of the Front Case Assembly

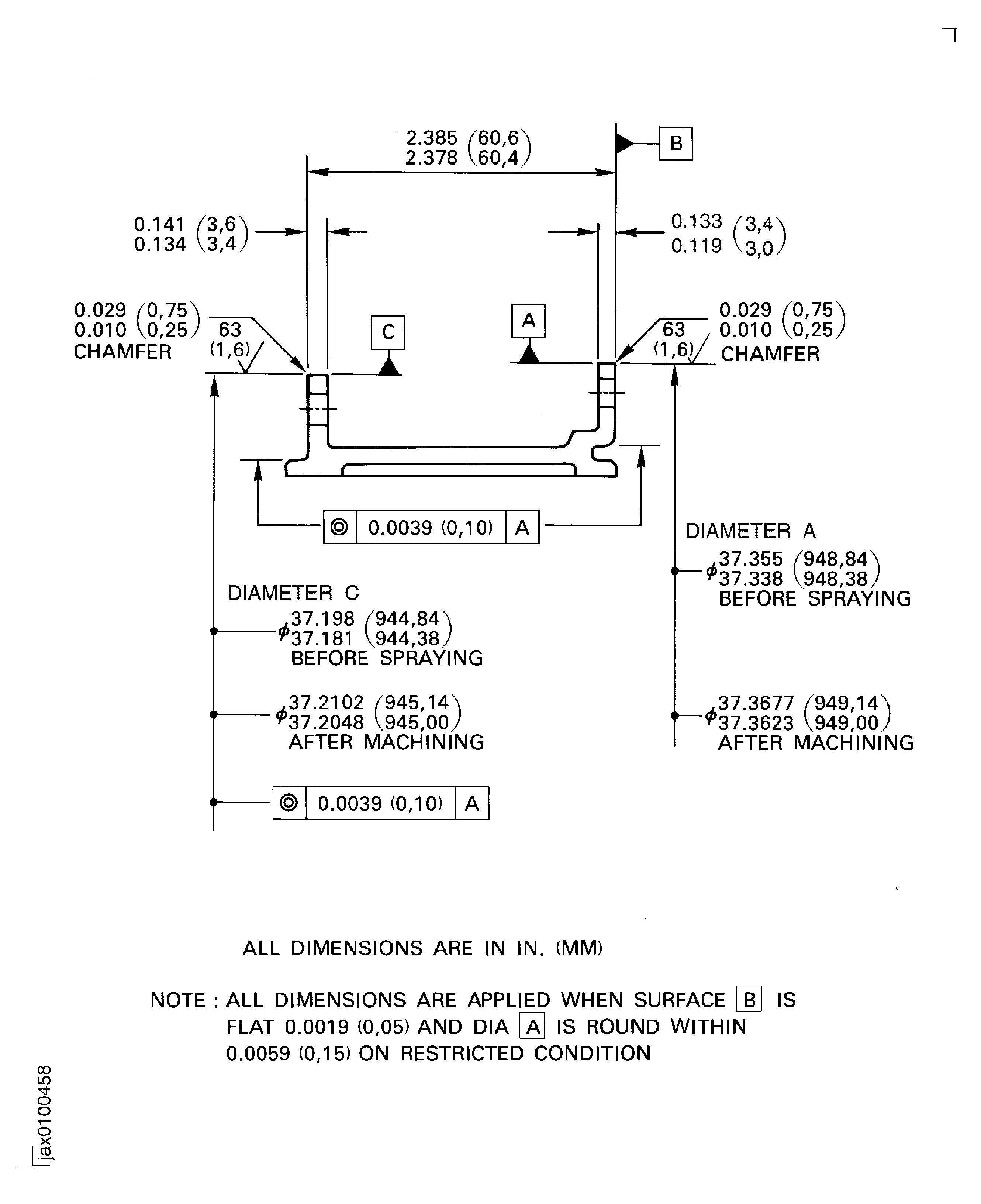

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

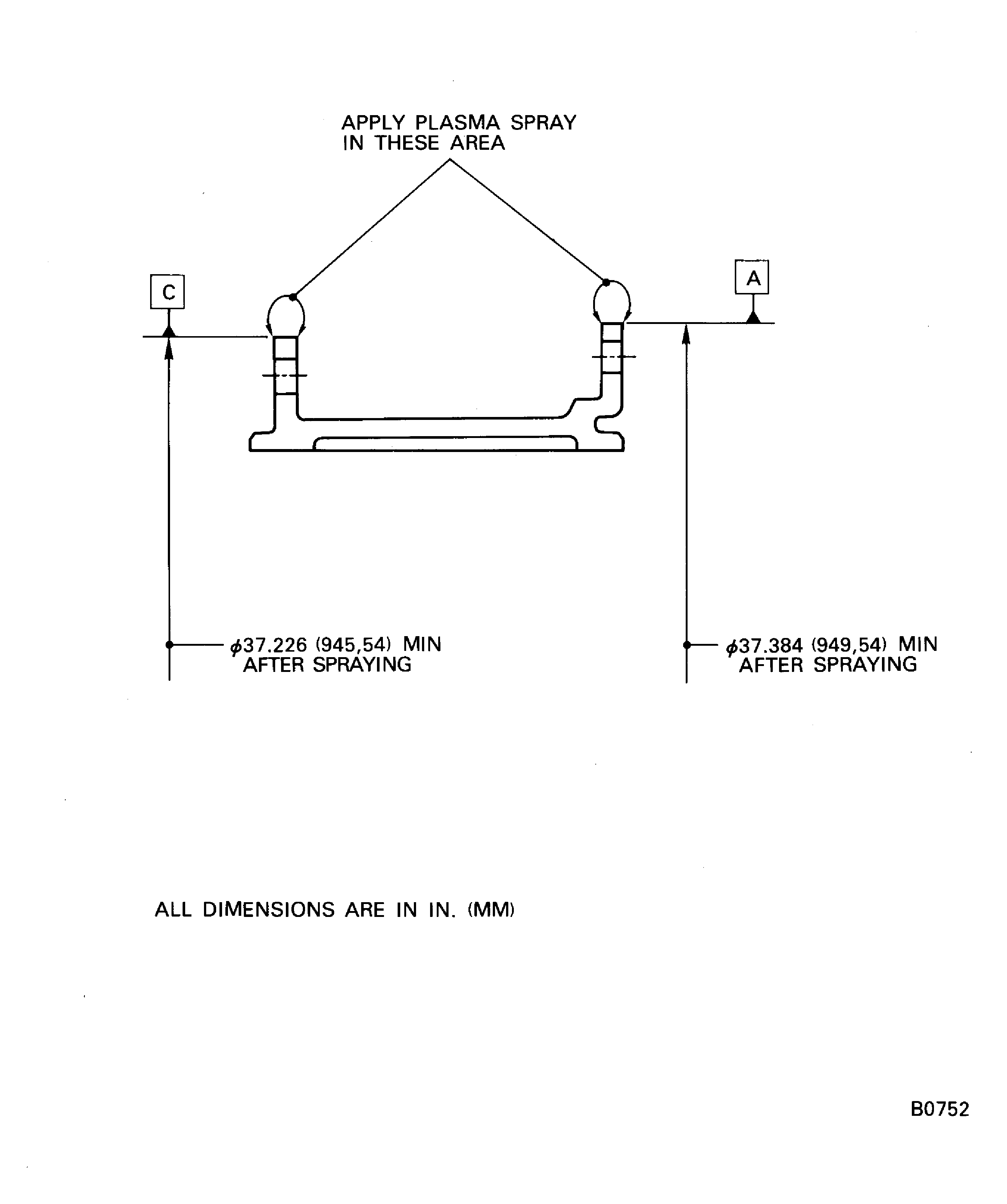

Figure: Repair details and dimensions

Repair details and dimensions

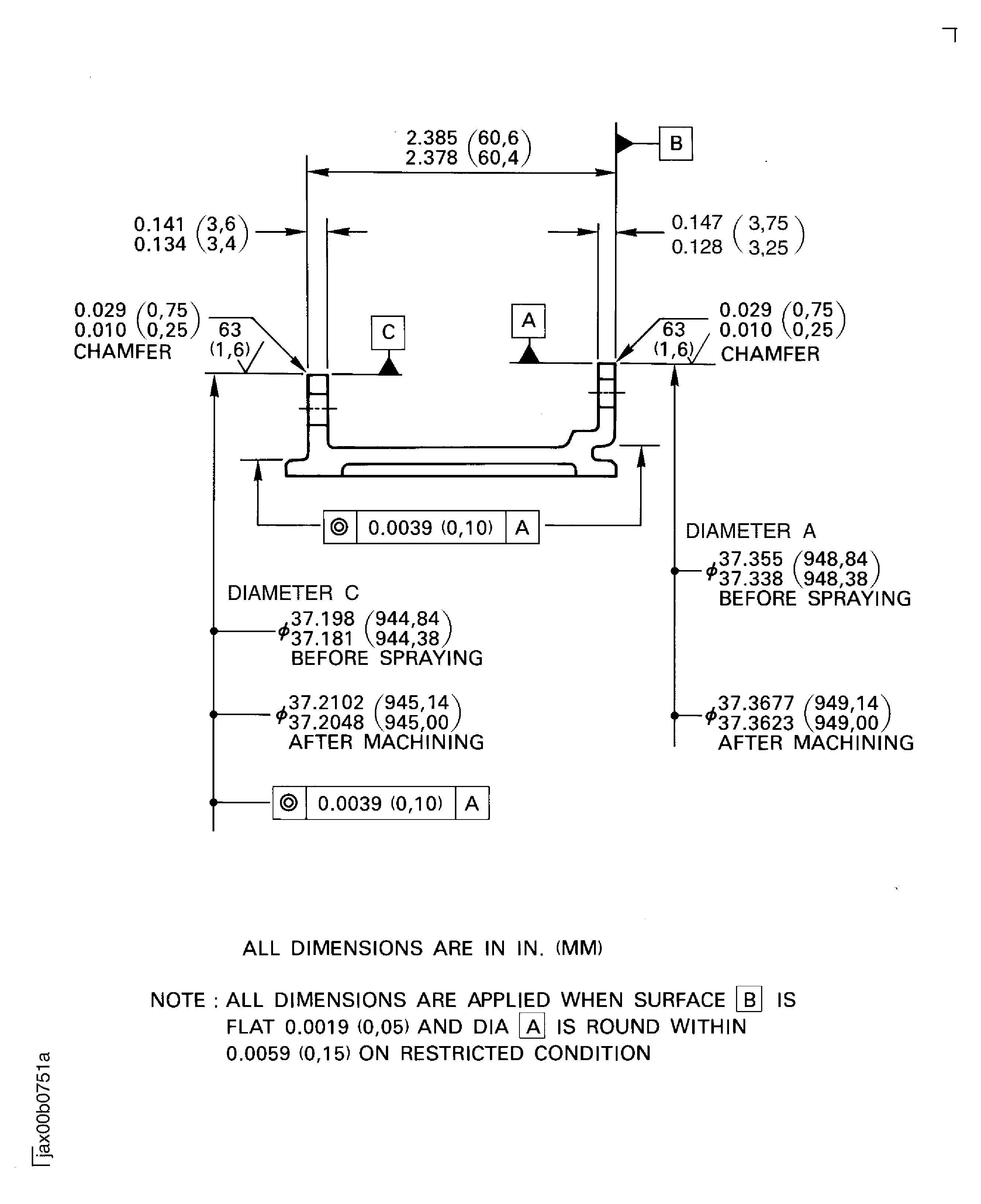

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B