Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-32-83-300-009 LPC Front Case - Repair The Snap Diameter By Plasma Spray, Repair-009 (VRS1389)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Non-metallic scraper | LOCAL | Non-metallic scraper | ||

| Vertical lathe | LOCAL | Vertical lathe | ||

| Abrasive blasting facility | LOCAL | Abrasive blasting facility | ||

| Plasma spray facility | LOCAL | Plasma spray facility | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| IAE 3J12755 Machining fixture | 0AM53 | IAE 3J12755 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | IE200 | CoMat 03-038 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 |

Spares

NONESafety Requirements

NONEProcedure

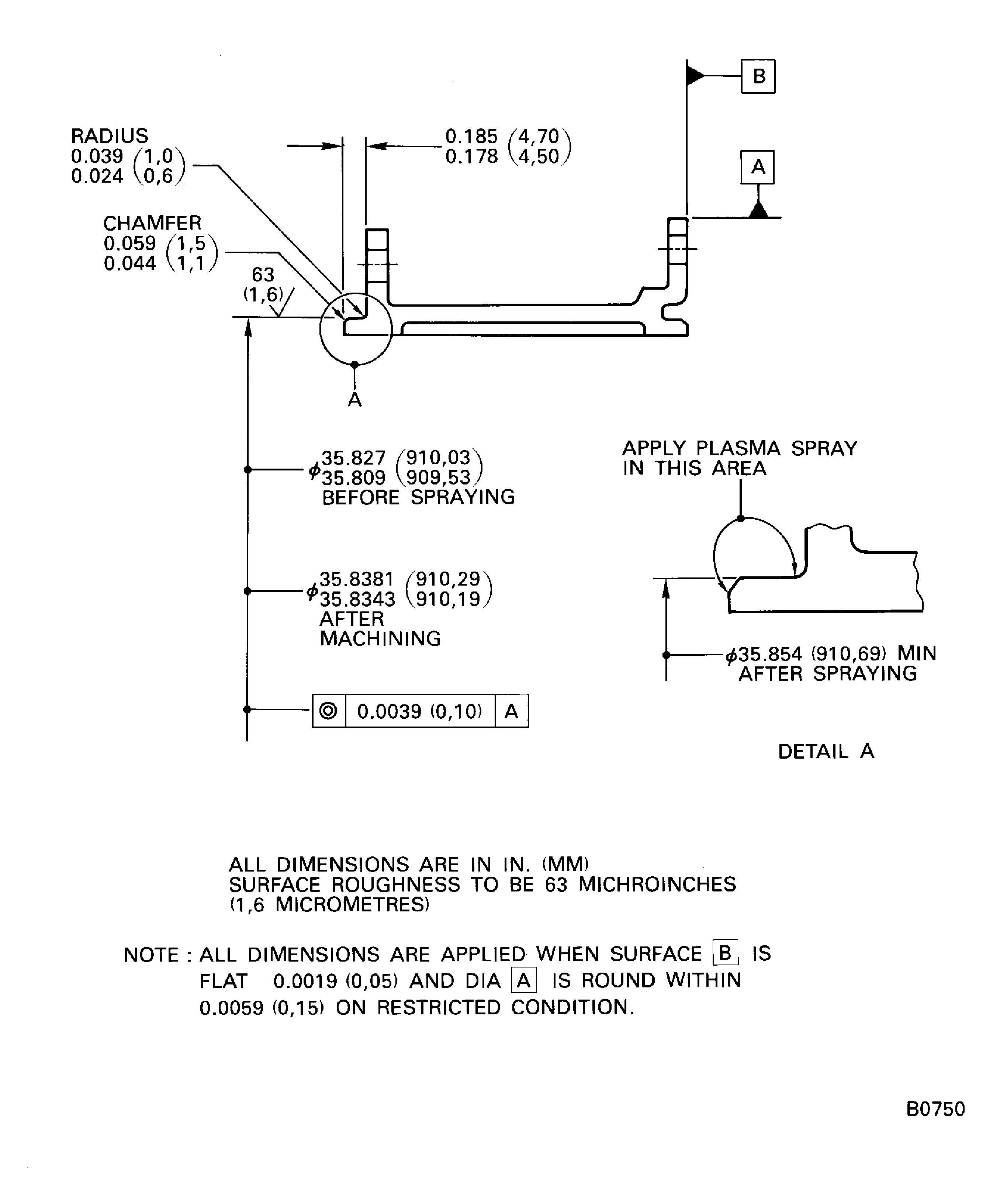

Refer to Figure.

Use vertical lathe and IAE IAE 3J12755 Machining fixture 1 off.

Set up the front case assembly on machine.

SUBTASK 72-32-83-320-052 Machine the Snap Diameter of the LPC Front Case Assembly

Refer to Figure.

Measure and record the snap diameter.

SUBTASK 72-32-83-220-091 Examine the Snap Diameter

Refer to the SPM TASK 70-23-05-230-501.

Fluorescent penetrant examine machined area.

SUBTASK 72-32-83-230-061 Examine the LPC Front Case Assembly for Cracks

Refer to Figure.

Refer to the SPM TASK 70-34-01-340-501.

Abrasive blast the snap diameter.

Refer to the SPM TASK 70-34-01-340-501.

PLASMA SPRAY PARAMETER

Powder .. .. .. ..

Metco 450 NS

Gun Model .. .. .. ..

Metco 3 MB / 7 MB / 9 MB

Nozzle .. .. .. ..

GH

Powder Port .. .. ..

No.2

Argon Pressure .. .. ..

100 psi (690 Kpa)

Helium Pressure .. .. ..

50 psi (344 Kpa)

Argon Flow Setting .. ..

80 ft 3/Hr

Helium Flow Setting .. ..

15

Carrier Flow Setting .. ..

37

Spray Rate .. .. .. ..

9 lbs / HOUR

Meter Wheel .. .. ..

S

Meter Wheel Speed .. ..

20 rpm

Spray Distance .. .. ..

4 - 7in. (102 - 177 mm)

Arc Volts .. .. .. ..

64 - 70

Current .. .. .. ..

500 amps

Plasma spray the front snap diameter to a diameter 35.854in. (910.69 mm) min.

SUBTASK 72-32-83-340-052 Plasma Spray the Snap Diameter of the Front Case Assembly

Refer to the SPM TASK 70-34-01-340-501.

Examine the snap diameter for adhesion, chipping and separation.

SUBTASK 72-32-83-220-092 Examine the Snap Diameter

Refer to Figure.

Use vertical lathe and IAE IAE 3J12755 Machining fixture 1 off.

Set up the front case assembly on machine.

Refer to the SPM TASK 70-34-01-340-501.

Machine the coated area.

SUBTASK 72-32-83-220-093 Machine the Snap Diameter of the Front Case Assembly

Refer to Figure.

No cracks are permitted.

Refer to the SPM TASK 70-34-01-340-501.

Visually and dimensionally examine the repaired area.

SUBTASK 72-32-83-220-094 Examine the Snap Diameter of the Front Case Assembly

Figure: Repair details and dimensions

Repair details and dimensions