Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

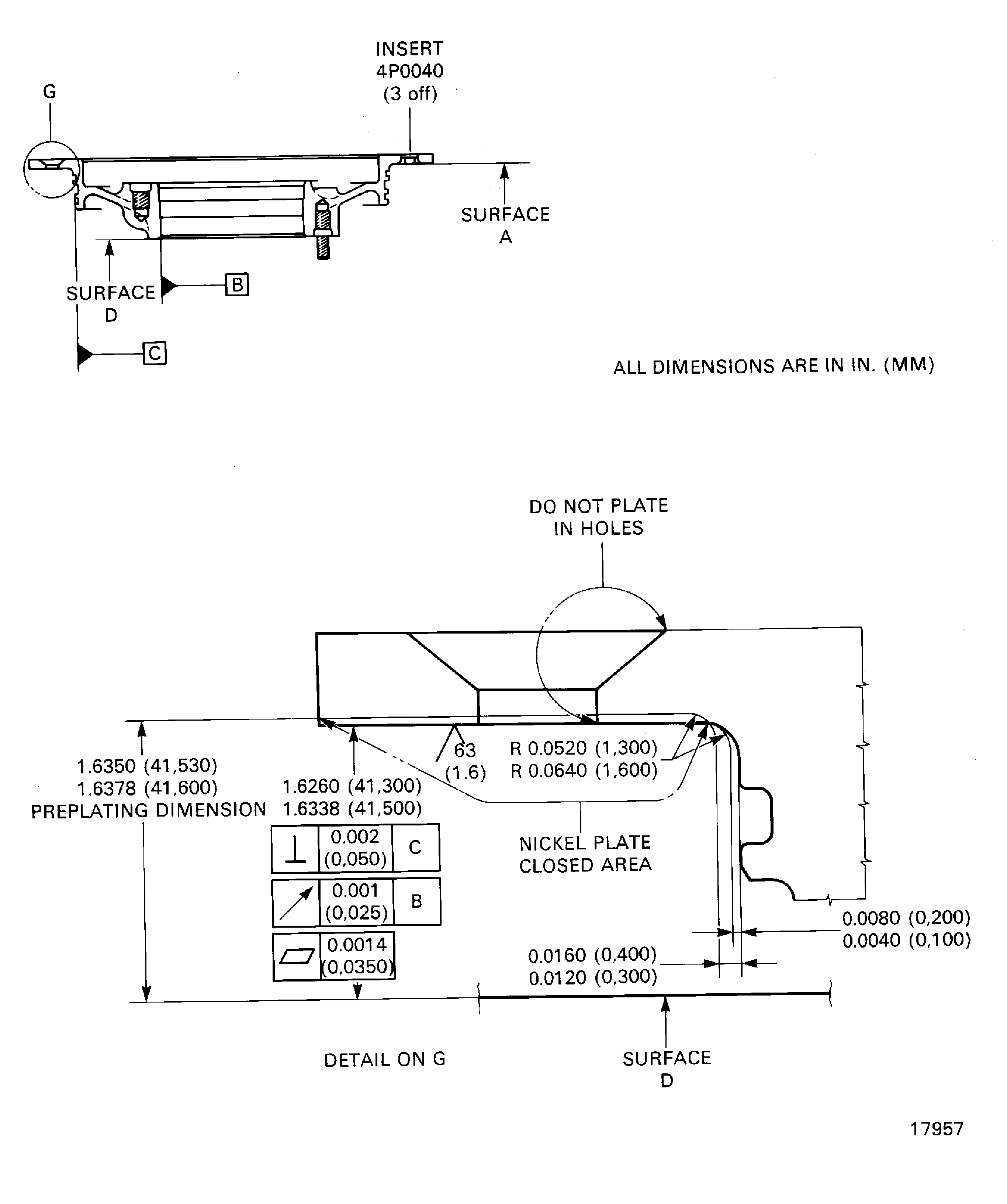

TASK 72-60-28-300-013 Generator Drive Gear Housing - Nickel Plate The Mounting Face, Repair-013 (VRS5067)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPP.

NOTE

To identify the consumable materials refer to PCI.

Consumable materials are given in SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Hot air gun | LOCAL | Hot air gun | ||

| Grinding machine | LOCAL | Grinding machine | ||

| FPI inspection station | LOCAL | FPI inspection station | ||

| Basket | LOCAL | Basket | ||

| Vapor degreaser | LOCAL | Vapor degreaser | ||

| Process Plating Tanks | LOCAL | Process plating tanks | ||

| Oven | LOCAL | Oven | ||

| Magnifying glass, 4x | LOCAL | Magnifying glass, 4x | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-027 HYDROFLUORIC ACID | LOCAL | CoMat 01-027 | ||

| CoMat 01-058 NITRIC ACID HNO3 | LOCAL | CoMat 01-058 | ||

| CoMat 01-112 ALKALINE SILICATE DEGREASER | 23373 | CoMat 01-112 | ||

| DELETED | LOCAL | DELETED | ||

| CoMat 02-067 STRIPPABLE COATING | 71410 | CoMat 02-067 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| INSERT | 4P0040 | 3 |

Safety Requirements

NONEProcedure

Refer to Figure.

Use the Hot air gun.

Heat the housing adjacent to the insert.

For pre Service Bulletin 72-0492 parts, remove the inserts as follows:

For post Service Bulletin 72-0492 and 70-0950 parts, remove the inserts. Refer to Repair, VRS5673 TASK 72-60-28-300-028 (Repair-028).

SUBTASK 72-60-28-350-073 Remove the Inserts

Refer to Figure.

SUBTASK 72-60-28-320-077 Machine the Mounting Face of the Housing

Refer to the SPM TASK 70-23-01-230-501.

No cracks are permitted.

Do the fluorescent penetrant inspection for cracks.

SUBTASK 72-60-28-230-060 Examine the Housing

Refer to Figure.

Refer to the SPM TASK 70-33-08-300-503.

Plate to a sufficient thickness to permit the machining to the last dimensions.

The plating out of the mounting face is permitted but must be removed.

Do the nickel plating.

SUBTASK 72-60-28-330-067 Nickel Plate the Mounting Face of the Housing

Refer to Figure.

SUBTASK 72-60-28-320-078 Machine the Mounting Face of the Housing

Refer to Figure.

Use a Magnifying glass, 4x.

The natural network crack, emphasized by grinding, is permitted.

Do the visual inspection of the plated area for cracks and adhesion.

SUBTASK 72-60-28-220-107 Examine the Nickel Plated Area

Refer to Figure.

Use the Hot air gun.

Heat the housing adjacent to the hole.

For pre Service Bulletin 72-0492 parts, install the inserts as follows:

For post Service Bulletin 72-0492 and 70-0950 parts, install the inserts. Refer to Repair, VRS5673 TASK 72-60-28-300-028 (Repair-028).

SUBTASK 72-60-28-350-074 Install the New Inserts

Figure: Repair Details and Dimensions

Repair Details and Dimensions