Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 79-21-42-840-001 Air Cooled Oil Cooler (ACOC) Inlet Duct - Add Drain Holes, Rework-001 - SBE 79-0010

General

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Files, rotating (Silicon carbide) | LOCAL | Files, rotating (Silicon carbide) | ||

| Grinder, Hand held pneumatic | LOCAL | Grinder, Hand held pneumatic | ||

| Marking pencil, vibrating | LOCAL | Marking pencil, vibrating | ||

| Drill Machine | LOCAL | Drill Machine |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-275 CHROMATE CONVERSION COATING FOR ALUMINIUM | LOCAL | CoMat 01-275 | ||

| CoMat 02-002 ADHESIVE TAPE GENERALPURPOSE PAPER | LOCAL | CoMat 02-002 |

Spares

NONESafety Requirements

NONEProcedure

WARNING

THE FILLERS REMOVED IN THIS PROCEDURE MAY BE SENSITIVE TO ALLERGIC RESPONSES BY BREATHING. A RESPIRATOR SHALL BE WORN BY THE OPERATORS.Attach the masking tape to prevent surface damage around the fillers.

Use suitable chisel, cutter and rotary files.

Remove the fillers carefully so as not to damage the surface of duct.

Use suitable vacuum cleaner.

Clean the surface that the fillers were removed from.

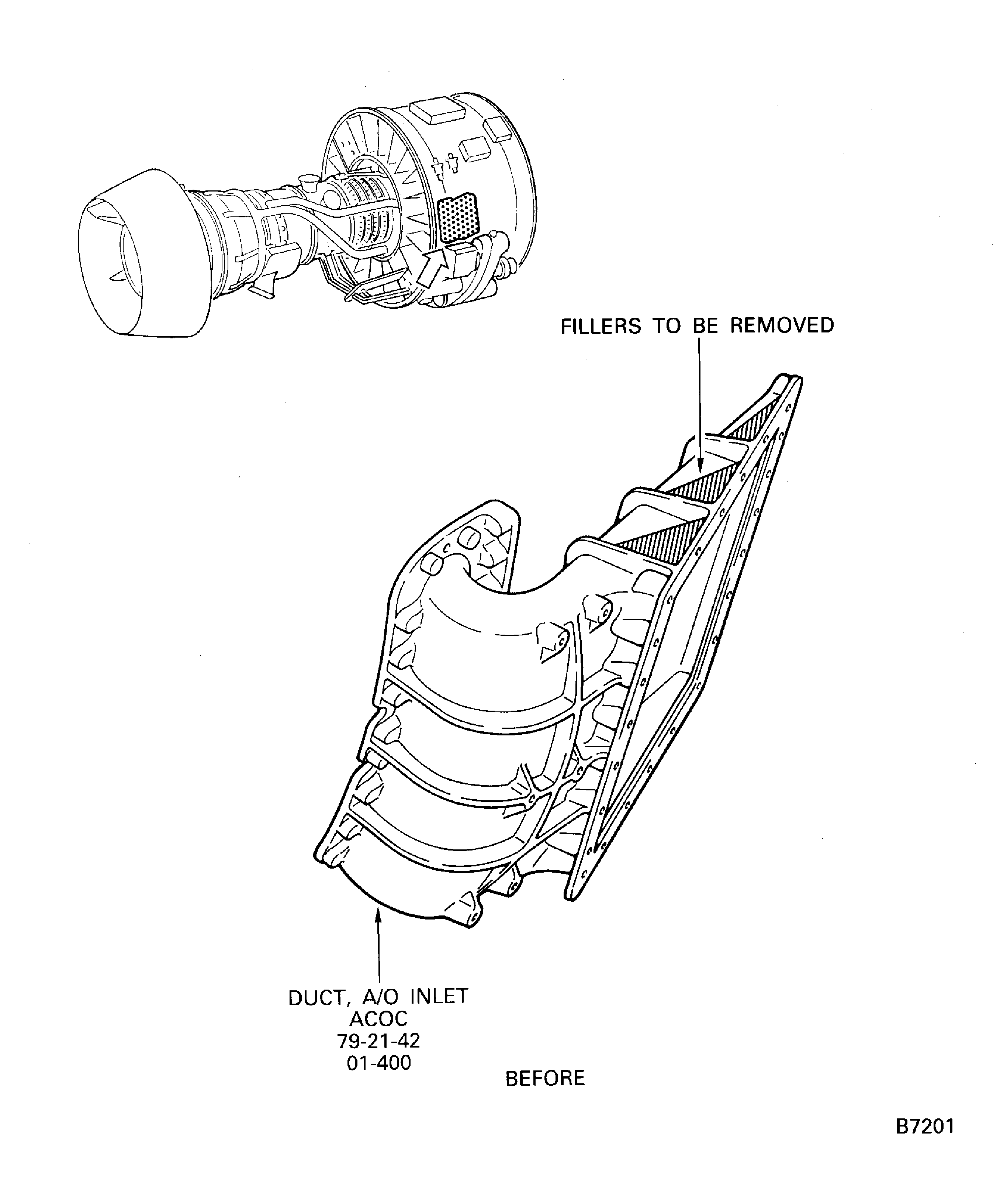

SUBTASK 79-21-42-350-053 Remove the Fillers

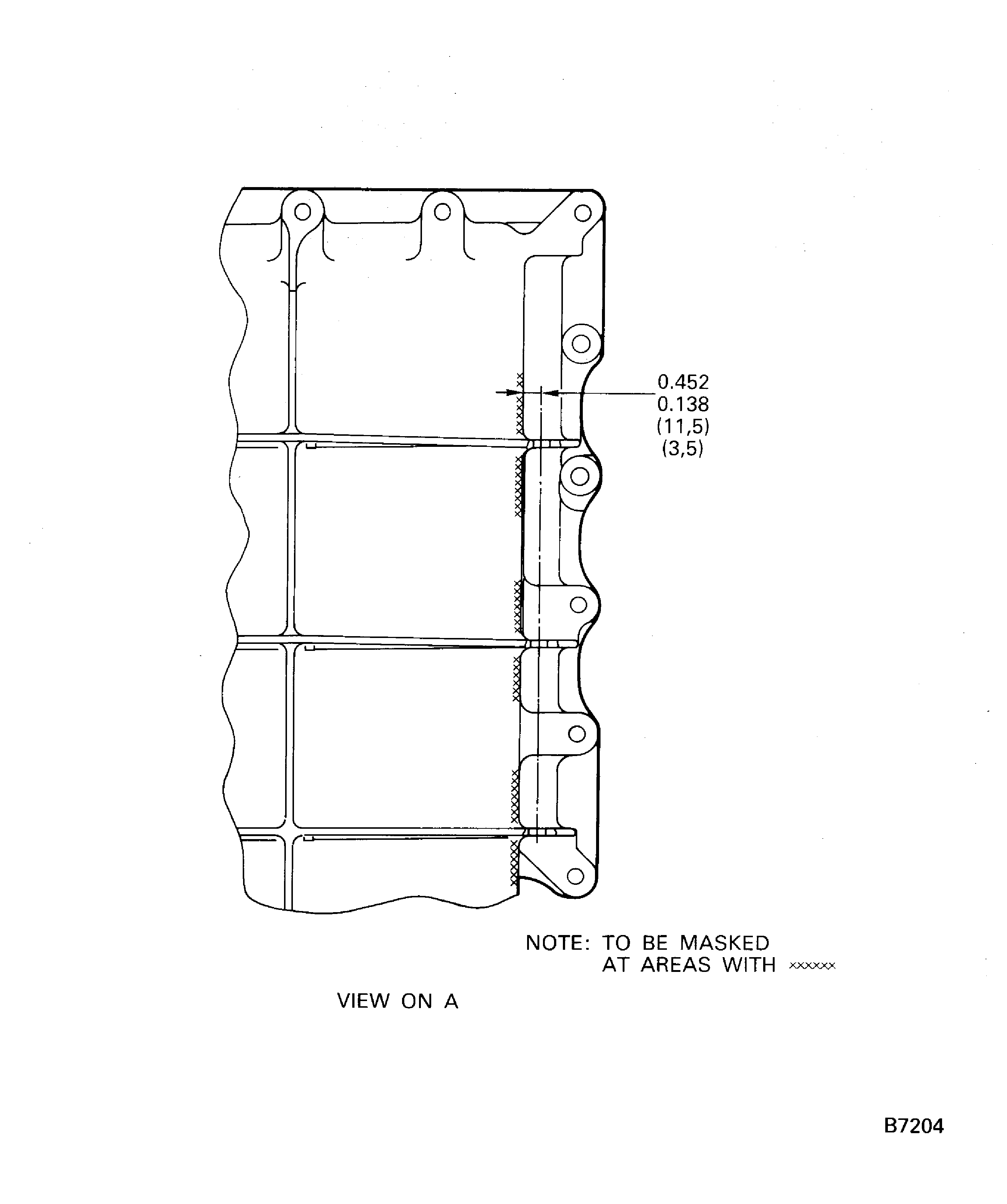

Add the masking tape to prevent the surface damage at the reworked area.

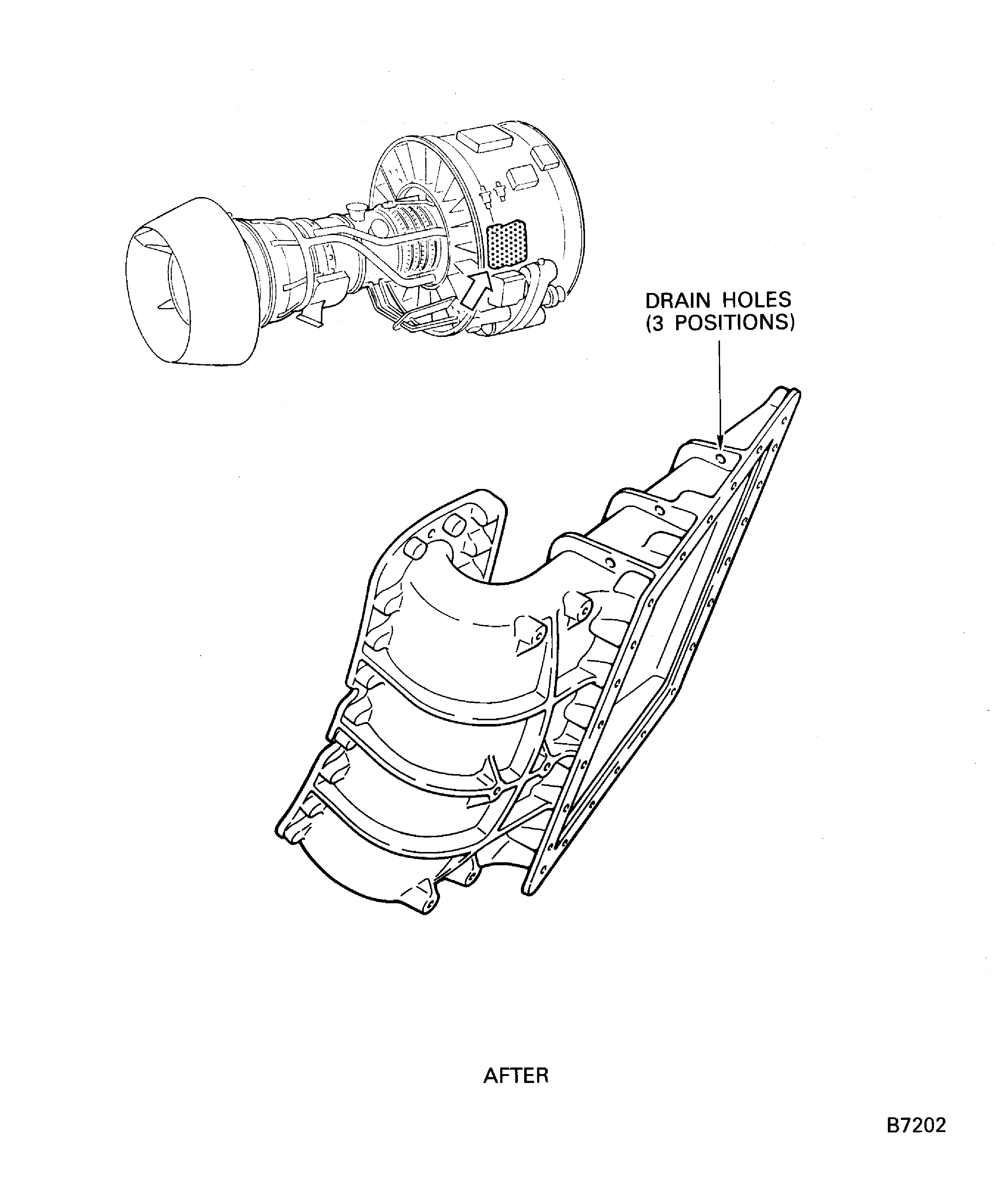

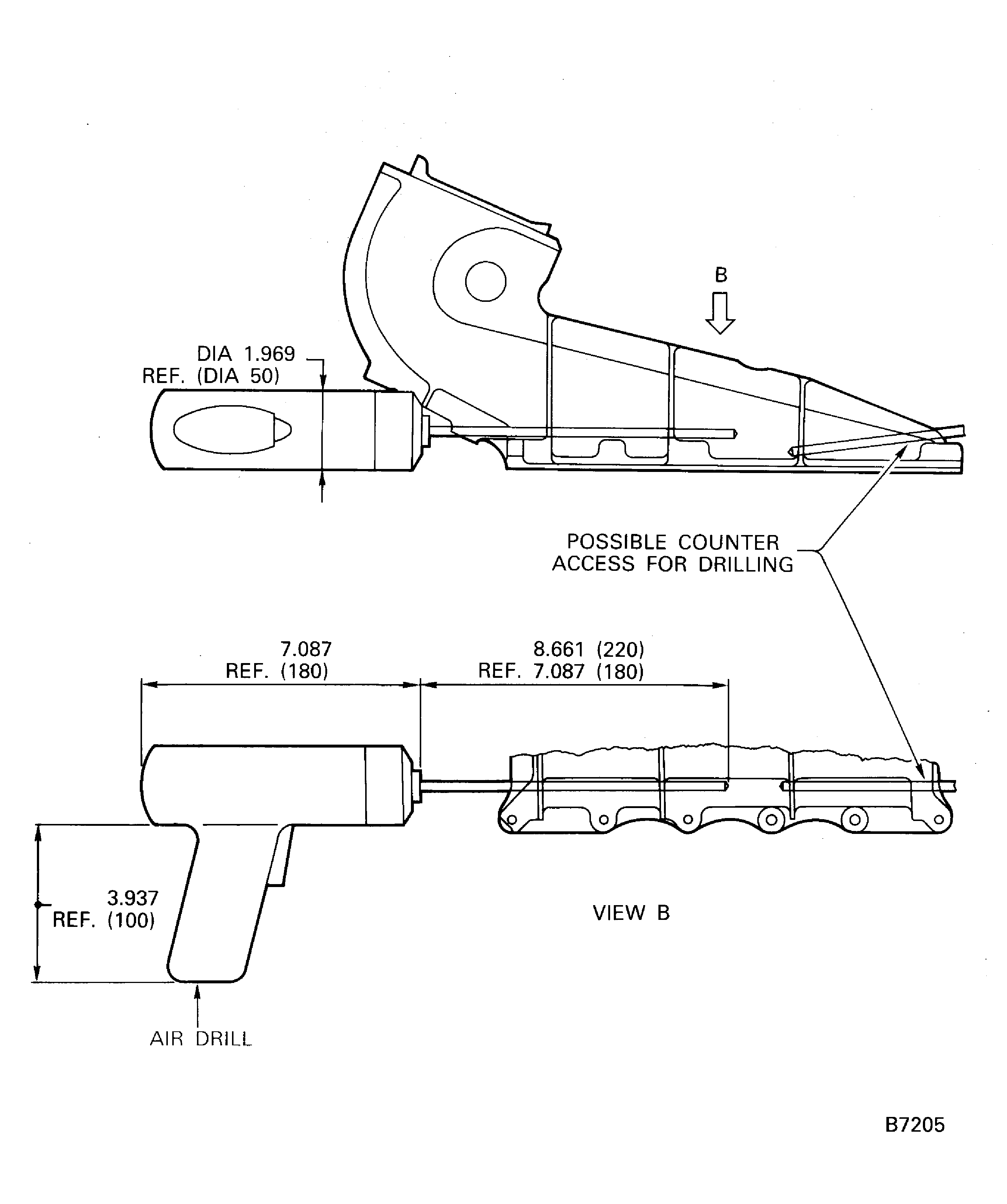

Use Drill Machine.

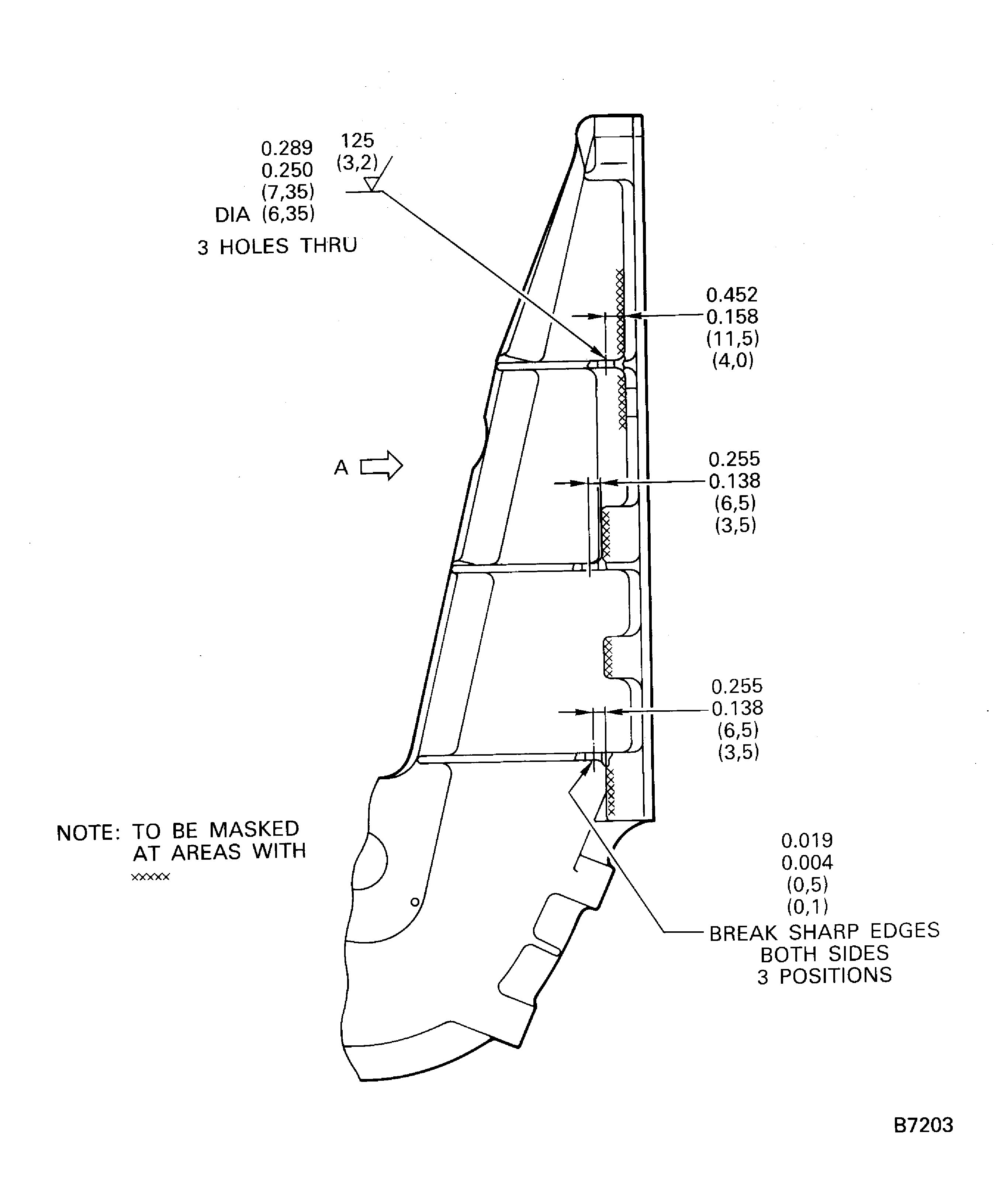

Set-up the reworked positions and make small holes initially less than specified dimensions as a guide. Then make specified holes (3 positions).

Refer to Figure.

Remove the burrs around the holes.

Refer to Figure.

Finish the surface of the holes.

SUBTASK 79-21-42-323-051 Drill the Holes in the Ribs of the Duct

Refer to SPM TASK 70-09-00-400-501.

Refer to Figure.

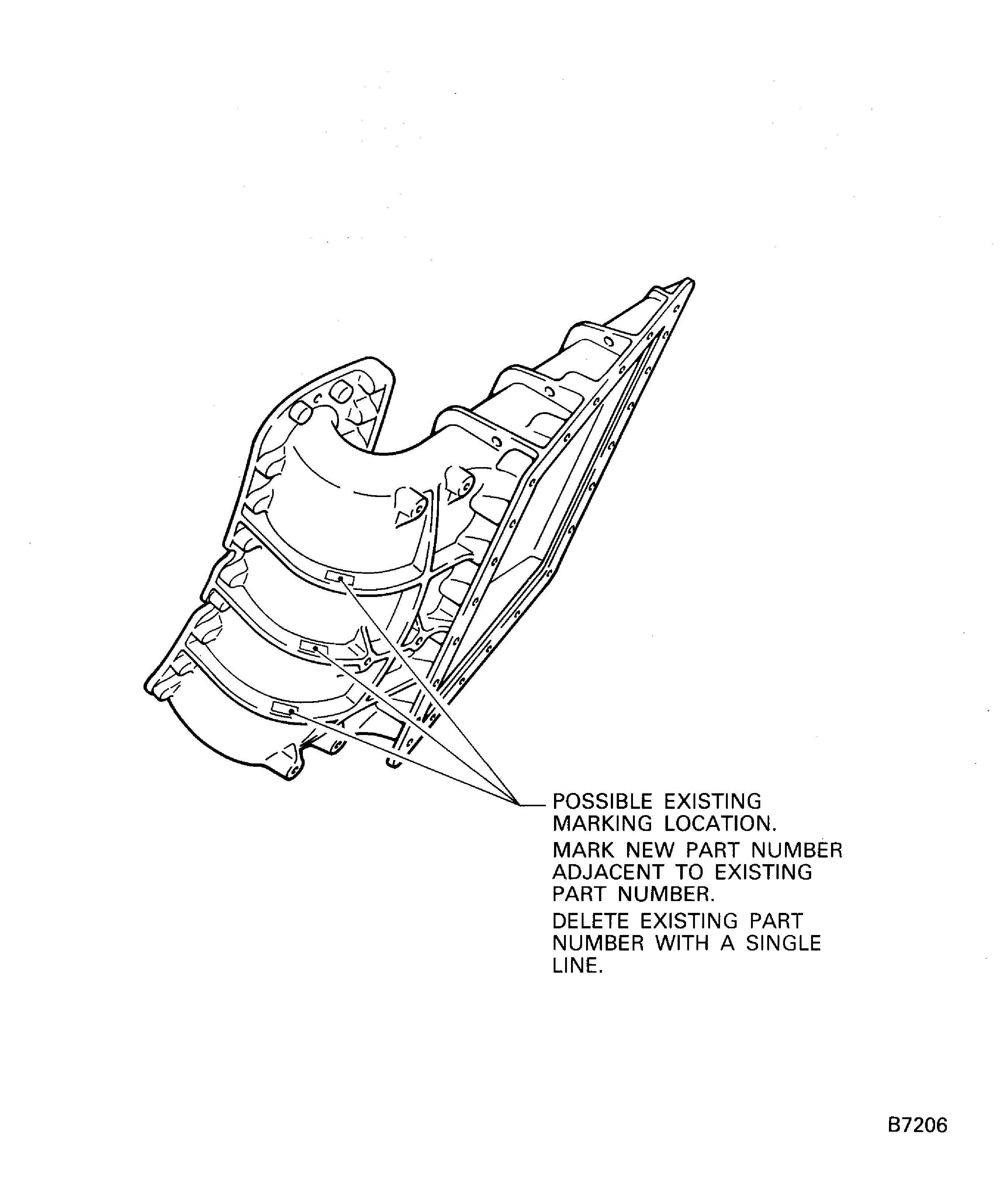

Renumber 5T0056 adjacent to existing part number. Delete 5T0061 with a single line.

SUBTASK 79-21-42-850-051 Identify the Reworked Duct with the New Part Number

Refer to SPM TASK 70-38-02-300-503

Coat inner surfaces of newly drilled holes, new and deleted part numbers and other scratched places with chromate conversion coatings

SUBTASK 79-21-42-380-051 Apply the Surface Protection

Figure: Before And After Views Of Configuration Changes

Before And After Views Of Configuration Changes

Before And After Views Of Configuration Changes

Figure: Rework Of The Duct, A/O Inlet ACOC

Rework Of The Duct, A/O Inlet ACOC

Figure: Rework Of The Duct, A/O Inlet ACOC

Rework Of The Duct, A/O Inlet ACOC

Figure: Rework Of The Duct, A/O Inlet ACOC

Rework Of The Duct, A/O Inlet ACOC

Figure: Rework Of The Duct, A/O Inlet ACOC

Rework Of The Duct, A/O Inlet ACOC