Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-34-440-001-E00 HPC Variable Stator Vane Actuation System - Assemble The Front Bearing Housing To The Vane Actuating Crankshaft, Assembly-001 - SBE 72-0426

General

This TASK gives the procedure to assemble the front spherical bearing into the front bearing housing and install the front bearing assembly on to the VSV crankshaft (SBE 72-0426), refer to the sectional view Figure.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item numbers.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flange and attach parts. Use the correct color of the air drying enamel. Refer to SPM TASK 70-38-21-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine unless stated differently in the procedure.

The Fits and Clearances, NEW PART DIMENSION and REJECT IF MORE THAN columns will be used by most operators. This permits the full use of the maximum wear allowance and reduction in the number of parts which are rejected, is possible.

The column WORN PART DIMENSIONS (Non-select) is included for operators who want to have full interchangeability. If this column is used an increase in the number of parts which are rejected is possible.

After the part has been in service for some time the REJECT IF MORE THAN and WORN PART DIMENSIONS could be changed. The operator must tell IAE and if agreed the manual will be changed.

The abbreviation Intf shows an interference or tight fit. This causes REJECT IF MORE THAN to become REJECT IF LESS THAN.

The abbreviation clear shows a clearance fit.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Protective Gloves | LOCAL | Protective Gloves |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-110 HIGH TEMPERATURE ANTI-SEIZE COMPOUND | K6835 | CoMat 10-110 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Calculate the clearance at Location 1353.

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 1353

The spherical bearing

HPC Variable Stator Vane Actuation System (72-41-34, 01-634) location

on the crankshaft

HPC Variable Stator Vane Actuation System (72-41-34, 01-630)

Spherical Bearing Bore

2.8347

2.8354

Intf

0.0002

Crankshaft Diameter

2.8355

2.8361

0.0014

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 1353

The spherical bearing

HPC Variable Stator Vane Actuation System (72-41-34, 01-634) location

on the crankshaft

HPC Variable Stator Vane Actuation System (72-41-34, 01-630)

Spherical Bearing Bore

72.000

72.018

Intf

0.004

Crankshaft Diameter

72.022

72.036

0.036

SUBTASK 72-41-34-440-065 Make Sure That the Fits and Clearances of the HP Compressor Assembly are in the Limits given at Location 1353

Refer to Figure.

Lightly lubricate the surface of the outer diameter of the outer race of the spherical bearing with CoMat 10-110 HIGH TEMPERATURE ANTI-SEIZE COMPOUND using a clean brush.

Install the front spherical bearing HPC Variable Stator Vane Actuation System (72-41-34, 01-634) into the front bearing housing, align the pin location in the outer bearing with pin location slot on the housing.

Install the straight headless pin HPC Variable Stator Vane Actuation System (72-41-34, 01-638) into the front bearing housing/spherical bearing location slot.

Stake the pin in the housing, refer to view at A. Refer to the SPM TASK 70-42-06-400-501.

Install the retaining ring HPC Variable Stator Vane Actuation System (72-41-34, 01-636) in the front bearing housing groove to secure the front spherical bearing in the housing.

SUBTASK 72-41-34-440-066 Install the Front Spherical Bearing in the Front Bearing Housing

Refer to Figure.

Heat the front bearing housing assembly HPC Variable Stator Vane Actuation System (72-41-34, 01-631) to a temperature of 302 deg F (150 deg C) in a suitable oven for 15 minutes.

Remove the front bearing housing assembly from the oven and install on to the VSV crankshaft HPC Variable Stator Vane Actuation System (72-41-34, 01-630).

Install the retaining ring HPC Variable Stator Vane Actuation System (72-41-34, 01-623) to retain the front bearing housing assembly on the crankshaft.

Manually rotate the Crank Shaft within Bearing Housing Assembly, and ensure there is no relative rotational movement between shaft and inner race. Otherwise reject shaft.

SUBTASK 72-41-34-440-067 Install the Front Bearing Housing Assembly on to the VSV Crankshaft

WARNING

YOU MUST PUT ON THE CORRECT PROTECTIVE GLOVES BEFORE YOU REMOVE THE FRONT BEARING HOUSING ASSEMBLY FROM THE OVEN.

CAUTION

YOU MUST MAKE SURE THE FRONT BEARING HOUSING ASSEMBLY IS INSTALLED CORRECTLY ON TO THE VSV CRANKSHAFT.

CAUTION

YOU MUST MAKE SURE THE FRONT BEARING HOUSING ASSEMBLY IS INSTALLED HARD AGAINST THE SHOULDER OF THE VSV CRANKSHAFT.

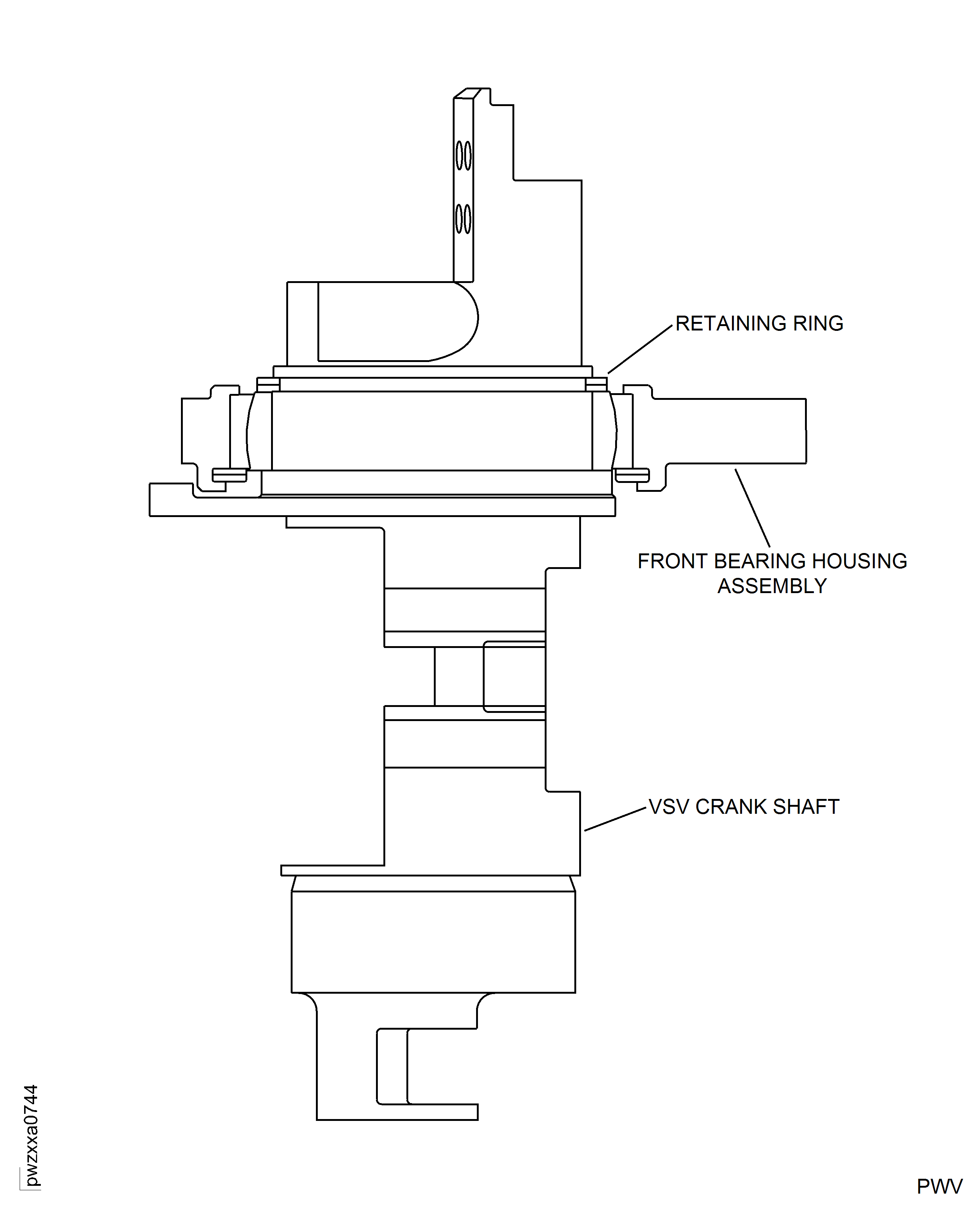

Figure: Sectional View Of VSV Crankshaft Assembly

Sectional View Of VSV Crankshaft Assembly

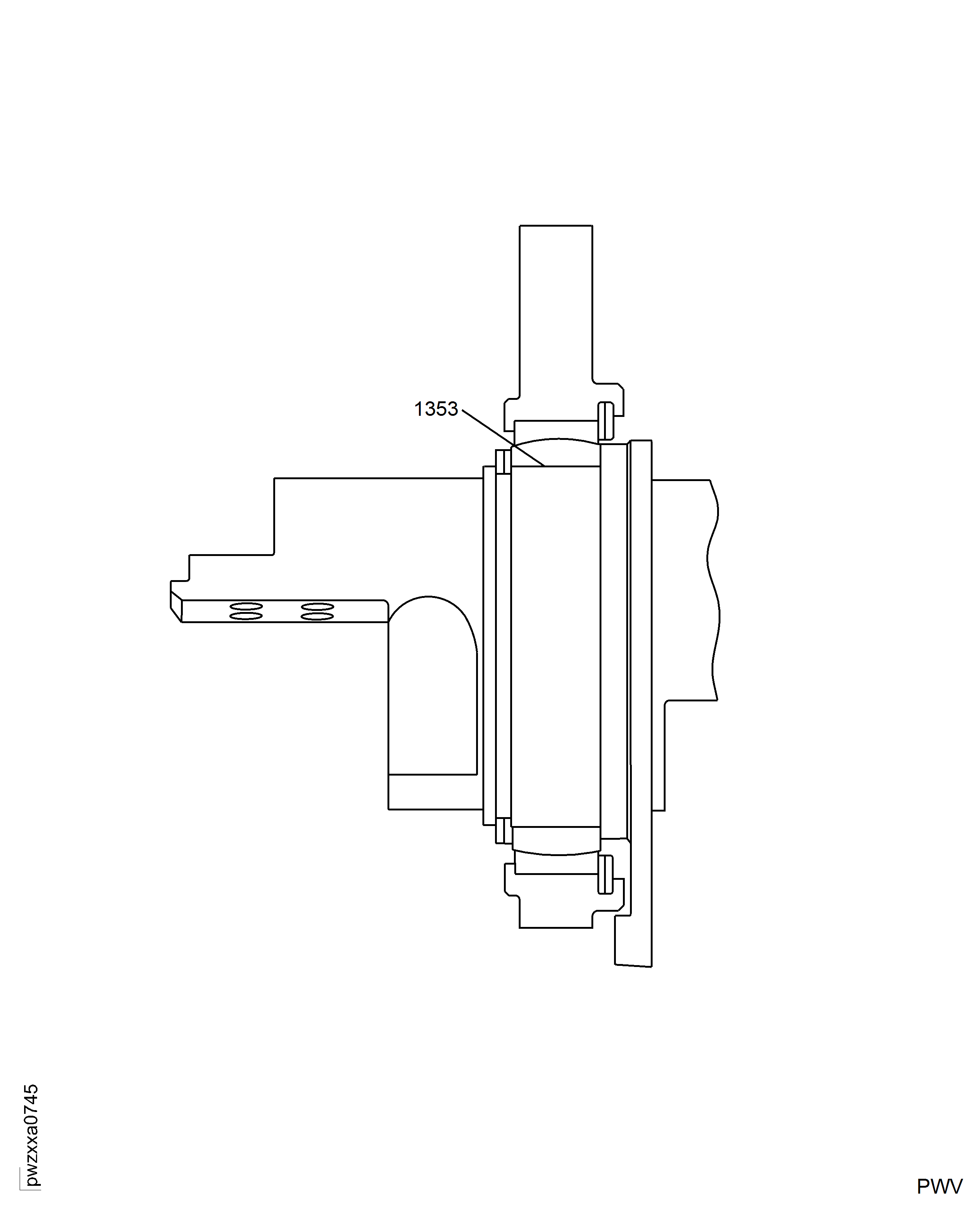

Figure: Location For Fits And Clearances

Location For Fits And Clearances

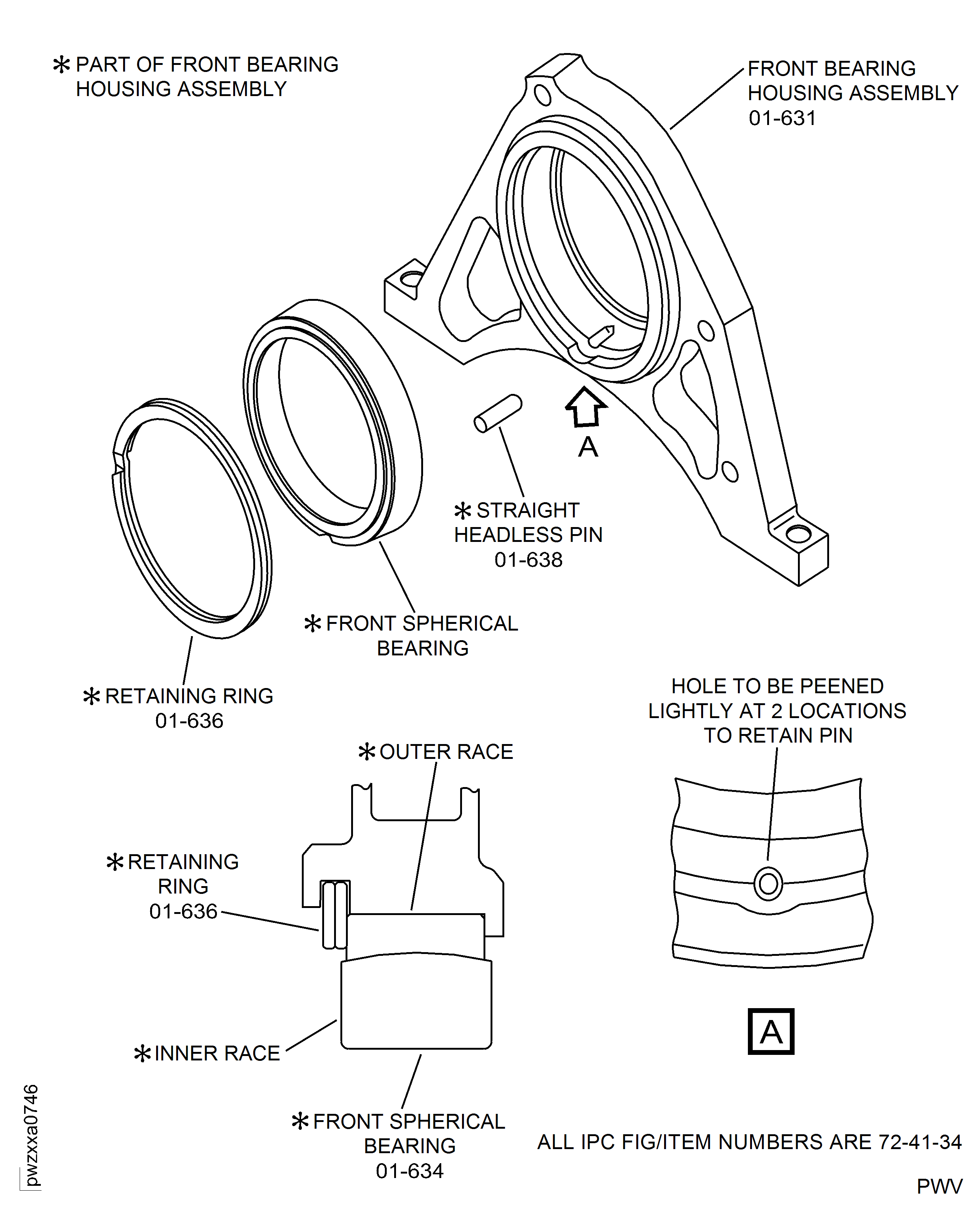

Figure: Install The Front Spherical Bearing Into The Front Bearing Housing Assembly

Install The Front Spherical Bearing Into The Front Bearing Housing Assembly

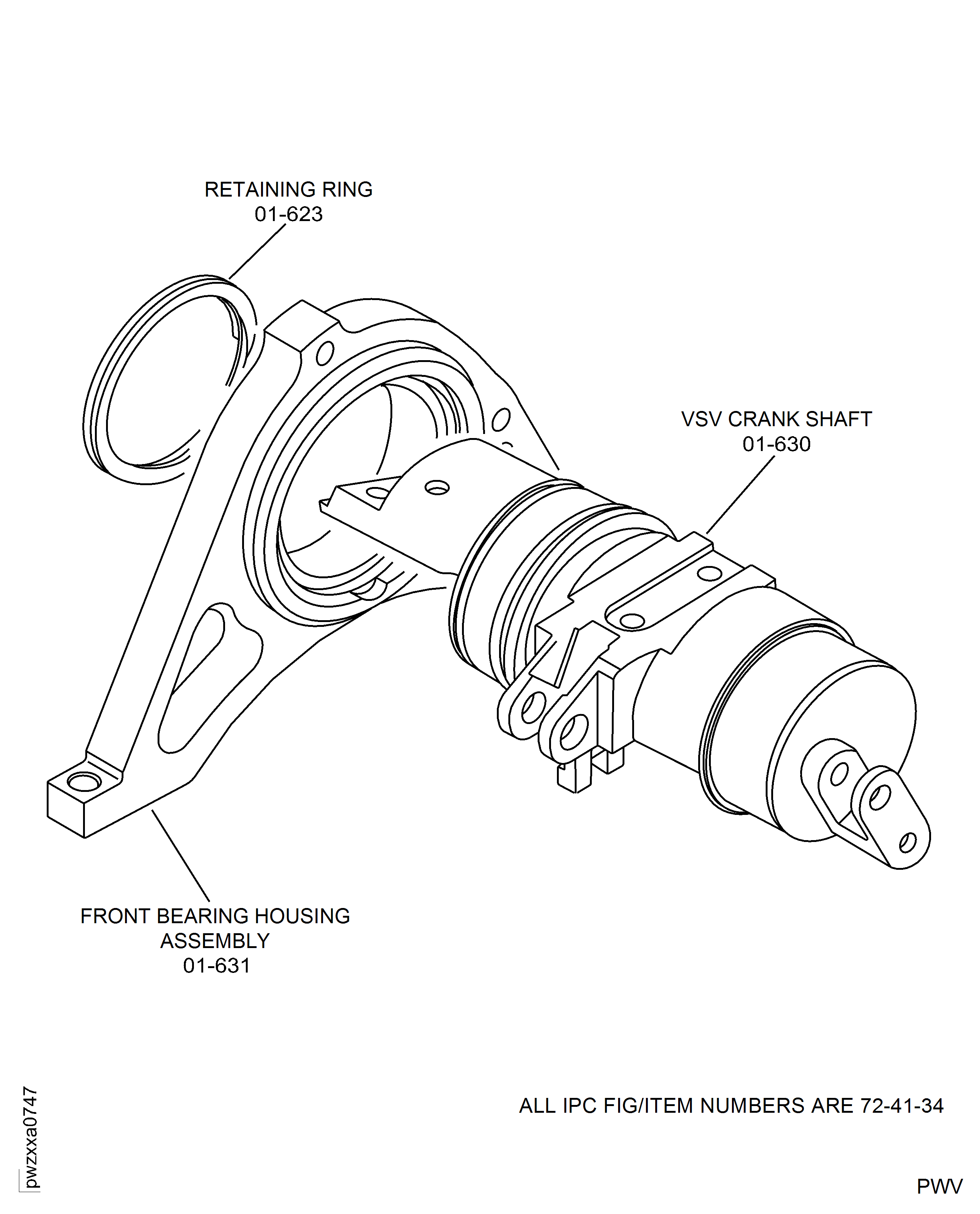

Figure: Install The Front Bearing Housing Assembly

Install The Front Bearing Housing Assembly