Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-50-50-440-001-C00 Turbine Exhaust Case (TEC) Assembly - Assemble The TEC Assembly, Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment face of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to the SPM TASK 70-44-01-400-501.

After assembly apply CoMat 07-012 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to the SPM TASK 70-38-06-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must be removed immediately before the installation of the components.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10041 TEC lift adapter | 0AM53 | IAE 1F10041 | 1 | |

| IAE 1F10042 Engine lift eye rear bare | 0AM53 | IAE 1F10042 | 1 | |

| IAE 1P16376 Locating pin | 0AM53 | IAE 1P16376 | 4 | |

| IAE 1F10178 Storage and Turnover adapter | 0AM53 | IAE 1F10178 | 1 | |

| IAE 1M14110 Turnover stand | 0AM53 | IAE 1M14110 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-012 AIR DRYING ENAMEL | 0AM53 | CoMat 07-012 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 | ||

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Oil seal | 1 | |||

| Packing | 1 | |||

| Packing | 1 | |||

| Thrust wire | 1 | |||

| Thrust wire | 1 |

Safety Requirements

NONEProcedure

Install IAE 1F10178 Storage and Turnover adapter 1 off on the trunnion plate of IAE 1M14110 Turnover stand 1 off. Attach with the bolts. Put the trunnion plate in vertical position.

Install IAE 1F10042 Engine lift eye rear bare 1 off on IAE 1F10041 TEC lift adapter 1 off. Attach with the bolts.

SUBTASK 72-50-50-440-068 Install the Turbine Exhaust Case on the Build Stand

Refer to Figure.

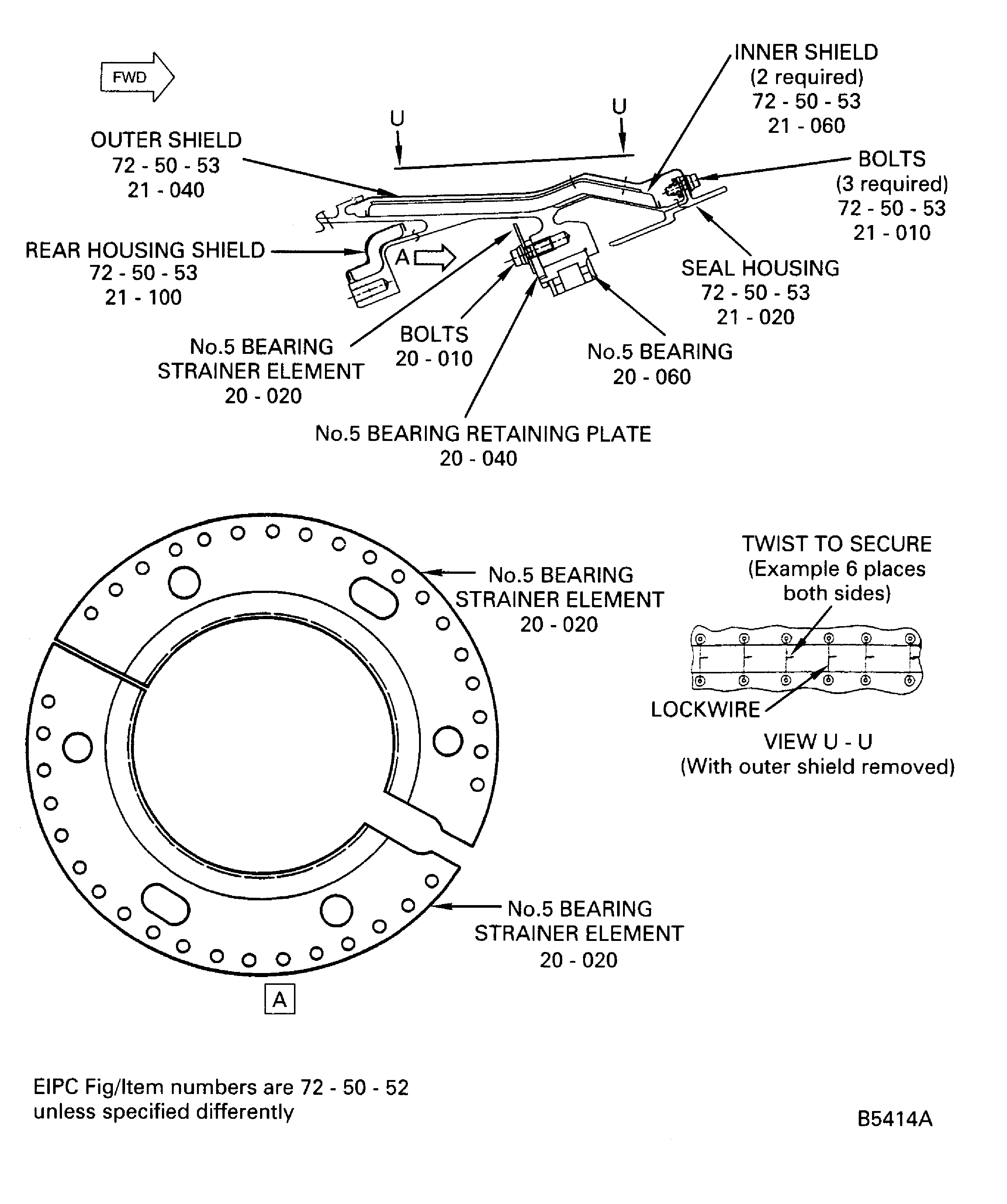

Install the retaining plate ENGINE-NO.5 BEARING PLATE AND OIL DEFLECTOR (72-50-52,20-040) over the outer race of the No. 5 bearing ENGINE-NO.5 BEARING PLATE AND OIL DEFLECTOR (72-50-52,20-060). Put the lugs on the rear flange of the outer race into the slots on the front flange of the retaining plate.

Install IAE 1P16376 Locating pin 4 off through the holes of the retaining plate and put them into the bolt holes on the rear flange of the No. 5 bearing housing.

Install the two No. 5 bearing strainer elements ENGINE-NO.5 BEARING PLATE AND OIL DEFLECTOR (72-50-52,20-020) on the retaining plate. Align the holes with the cutout on ends over the oil feed port.

Install the six bolts ENGINE-NO.5 BEARING PLATE AND OIL DEFLECTOR (72-50-52,20-010) which attach the strainer elements and the retaining plate to the flange of the turbine exhaust case while removing the locating pins. Torque the bolts to 85 to 105 lbfin (10 to 12 Nm).

SUBTASK 72-50-50-440-069 Install the Outer Race of the No. 5 Bearing

Refer to: Figure

Install the rear housing shield Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,21-100) to the exhaust case. Align the cutouts with the pressure and scavenge ports.

SUBTASK 72-50-50-440-070 Install the Rear Housing Shield

Refer to: Figure

SUBTASK 72-50-50-440-071 Install the No. 5 Bearing Seal Housing

Refer to: Figure

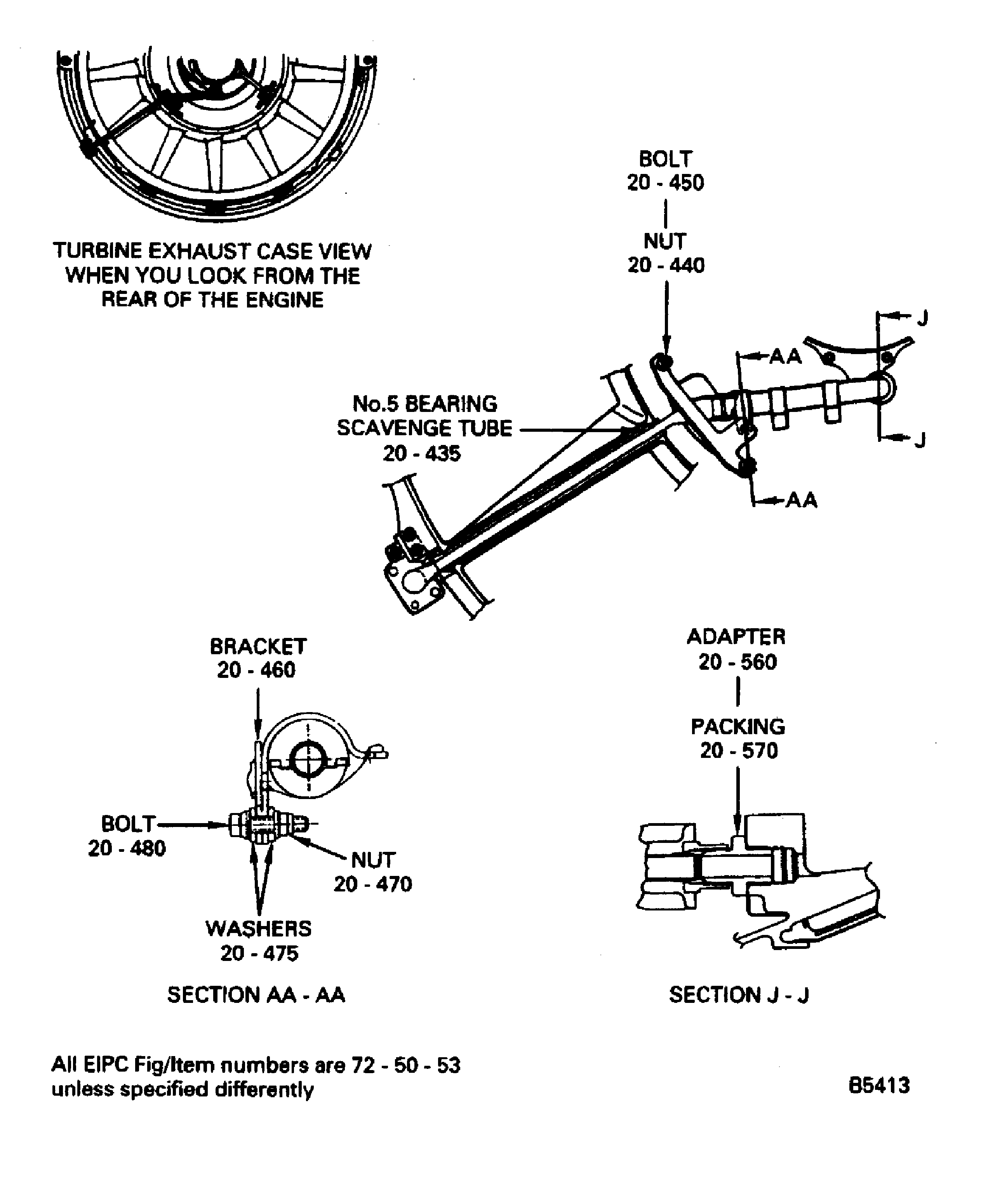

Install a new packing Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-570) 1 off to the adapter Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-560). Install the adapter to the scavenge port on the exhaust case housing. Torque the adapter to 150 to 170 lbfin (16.948 to 19.207 Nm).

Install the No. 5 bearing scavenge tube Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-435) into the exhaust case strut and attach the tube nut to the adapter hand tight only.

Attach the tube nut Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-433) to the scavenge tube with thrust wire Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-432) where tube comes out of case.

Install the bracket Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-350) and secure with two bolts Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-370) and nuts Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-360) hand tight only to the external flange of the case.

Install the elbow Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-320) to the scavenge tube hand tight only. Attach the other end of the elbow to the bracket with the bolt Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-340) and nut Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-330) hand tight only.

NOTE

When you do the next steps you should make sure the tube is in the center of the exhaust case opening.Install the bracket Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-460) onto the inner support of the case. Install the two bolts Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-450) and the two nuts Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-440). Torque the nuts to 85 to 95 lbfin (9.604 to 10.734 Nm).

Install the upper heatshield Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-402) and lower heat shield Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-394) or upper heatshield Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-420) and lower heatshield Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-412) over the inner end of the scavenge tube.

Install the bolt Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-480), washers Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-475) and nut Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-470) to secure the upper heatshield to the bracket on the inner housing. Torque the nut to 36 to 40 lbfin (4.067 to 4.519 Nm).

Safety the upper and lower heatshields to each other with CoMat 02-141 LOCKWIRE.

SUBTASK 72-50-50-440-072 Install the No. 5 Bearing Scavenge Tube

Refer to Figure.

Install a new packing Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-300) 1 off to the adapter Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-290). Install the adapter to the scavenge port on the exhaust case housing. Torque the adapter to 110 to 120 lbfin (12.4 to 13.6 Nm).

Install the No. 5 bearing pressure tube Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-176) into the exhaust case strut and attach the tube nut to the adapter hand tight only.

Attach the tube nut Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-172) to the pressure tube with the thrust wire Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-170) where tube comes out of case.

Install the bracket Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-020) and secure with two bolts Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-040) and nuts Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-030) hand tight only to the external flange of the case.

Install the No. 5 bearing pressure tube elbow Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-010) to the pressure tube hand tight only. Attach the other end of the elbow to the bracket with clamp Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-016), bolt Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-017) and nut Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-015) hand tight only.

NOTE

When you do the next steps you should make sure the tube is in the center of the exhaust case opening.Install the bracket Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-200) onto the inner support of the case. Install the two bolts Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-190) and the two nuts Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-180). Torque the nuts to 85 to 95 lbfin (9.604 to 10.734 Nm).

Install the upper heatshield Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-142) and lower heat shield Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-134) or upper heatshield Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-160) and lower heatshield Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-152) over the inner end of the pressure tube.

Install the bolt Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-220), washers Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-215) and nut Turbine Exhaust Case (TEC) Assembly And Related Parts (72-50-53,20-210) to secure the upper heatshield to the bracket on the inner housing. Torque the nut to 36 to 40 lbfin (4.067 to 4.519 Nm).

Safety the upper and lower heatshields to each other with CoMat 02-141 LOCKWIRE.

SUBTASK 72-50-50-440-073 Install the No. 5 Bearing Pressure Tube

Refer to: Figure

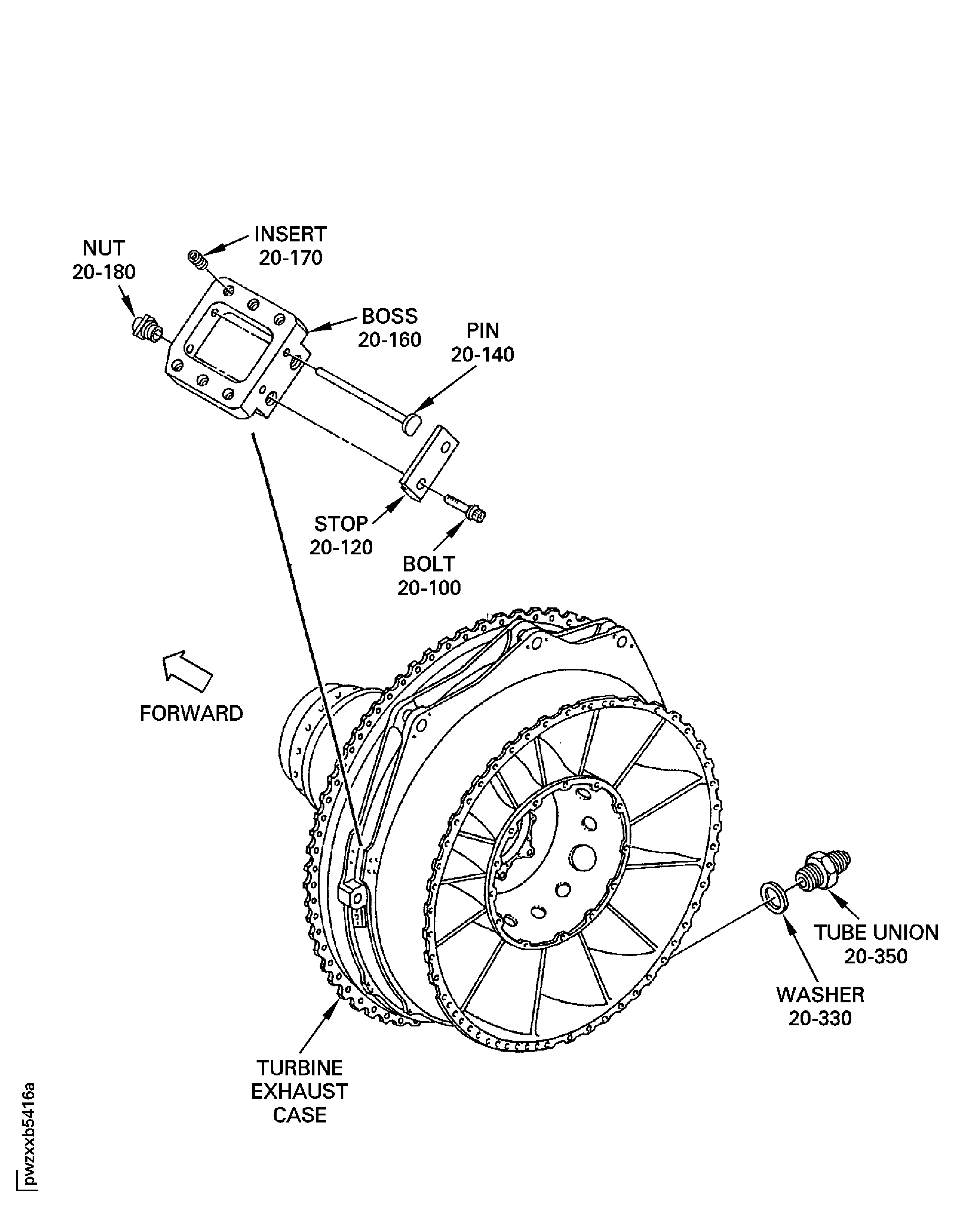

Install the ENGINE-TURBINE EXHAUST CASE ASSEMBLY (72-50-50,20-330) washer 1 off on the tube union.

Install the tube union ENGINE-TURBINE EXHAUST CASE ASSEMBLY (72-50-50,20-350) into the turbine exhaust case. Torque the tube union to 221 to 239 lbfin (25.00 to 27.00 Nm).

SUBTASK 72-50-50-440-074 Install the Tube Union

Refer to: Figure

Put the boss ENGINE-TURBINE EXHAUST CASE ASSEMBLY (72-50-50,20-160) in position between mounting flanges on turbine exhaust case.

Install the pin ENGINE-TURBINE EXHAUST CASE ASSEMBLY (72-50-50,20-140).

Apply CoMat 10-077 APPROVED ENGINE OILS to the threads of two bolts ENGINE-TURBINE EXHAUST CASE ASSEMBLY (72-50-50,20-100).

Install the stop ENGINE-TURBINE EXHAUST CASE ASSEMBLY (72-50-50,20-120) to the boss with two bolts and nuts ENGINE-TURBINE EXHAUST CASE ASSEMBLY (72-50-50,20-180).

SUBTASK 72-50-50-440-075 Install the Bosses

Figure: Install the Outer Race of the No. 5 Bearing

Install the Outer Race of the No. 5 Bearing

Figure: Install the No. 5 Bearing Scavenge Tube

Install the No. 5 Bearing Scavenge Tube

Figure: Install the No. 5 Bearing Pressure Tube Assembly

Install the No. 5 Bearing Pressure Tube Assembly

Figure: Install the Tube Union and the Bosses

Install the Tube Union and the Bosses