Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 77-21-43-300-001 EGT Harness - Wire Braid Repair, Repair-001 (VRS3862) (Post SB 77-0015)

General

This TASK gives the repair procedure for the damaged Wire Braid of EGT Harness.

Fig/item numbers in parentheses in the procedure agree with those given in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

All the parts must be cleaned before they are examined and repaired. Refer to the TASK 71-52-45-100-301.

All the parts must be visually examined for damage, corrosion, and wear. Any defects that are not identified in the procedure must be referred to IAE.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-119 LOCKWIRE | LOCAL | CoMat 02-119 | ||

| CoMat 02-391 ADHESIVE TAPE (ELECTRICAL) | LOCAL | CoMat 02-391 | ||

| CoMat 02-408 GROUNDING STRAP, TINNED COPPER | 92194 | CoMat 02-408 |

Spares

NONESafety Requirements

WARNING

Procedure

CAUTION

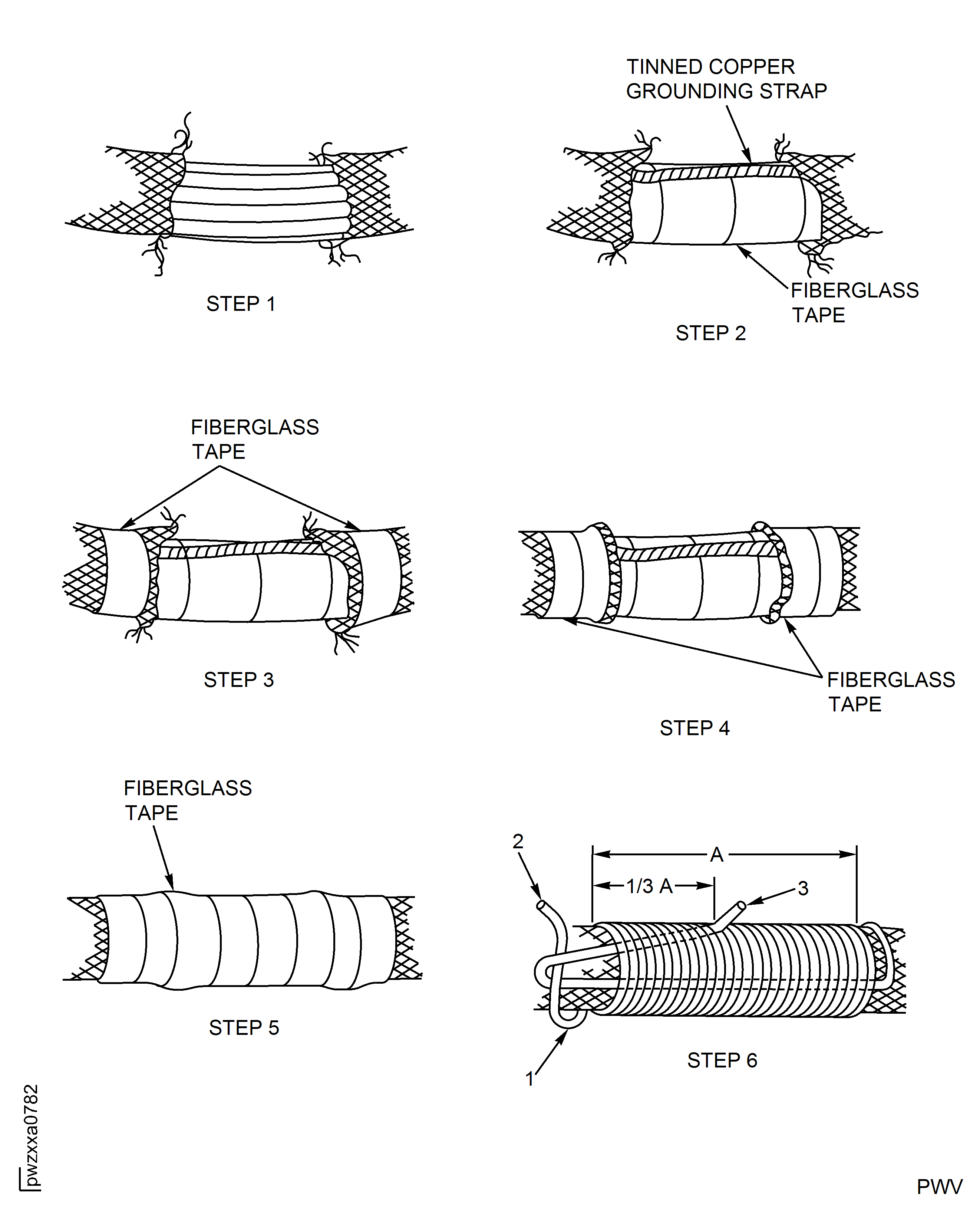

LOOSE WIRES AT THE ENDS OF THE BRAID CAN MAKE HOLES IN THE INSULATION AND CAUSE AN ERRATIC OR ERRONEOUS INDICATION.Cut away the wire braid all around the cable in the damaged area with a pair of scissors. Make sure to cut away all loose strands from the ends of the wire braid. Move the two cut ends of the braid apart.

Put two layers of CoMat 02-391 ADHESIVE TAPE (ELECTRICAL) around the wire bundle in the damaged area. Put a piece of CoMat 02-408 GROUNDING STRAP, TINNED COPPER (or equivalent) across the taped area in a longitudinal direction. Push the ends of the braid over the grounding strap as close together as possible.

Put two layers of CoMat 02-391 ADHESIVE TAPE (ELECTRICAL) around and over the braid 0.25 in. (6.35 mm) before each cut braid end.

Move the loose ends of the braid apart and carefully fold them back and over the tape that you applied in the step above. Put two layers of CoMat 02-391 ADHESIVE TAPE (ELECTRICAL) over the ends of the folded braid.

Fill the space between the braid ends with CoMat 02-391 ADHESIVE TAPE (ELECTRICAL) so that the repaired area has a constant diameter. Wind all the area with CoMat 02-391 ADHESIVE TAPE (ELECTRICAL).

WARNING

USE GOGGLES WHEN YOU REMOVE OR INSTALL LOCKWIRE. EACH TIME YOU CUT LOCKWIRE, REMOVE AND DISCARD IT IMMEDIATELY. LOOSE LOCKWIRE CAN CUT YOU OR MAKE YOU BLIND, AND/OR CAN CAUSE DAMAGE.Cut a sufficient length of wire. Make a loop at one end and pull the wire tight across the length of the damaged area. Make sure that you touch the wire braid at both ends of the repair.

Start at the opposite end and wind the wire tightly and smoothly over the cable braid and the repaired rear as shown in the figure. Make sure that the wire overlaps the fiberglass tape.

Wind approximately 2/3 of the length and leave the short end of the loop open. Continue to wind until the remaining 1/3 of the length is wound. The maximum repair length must not be more than 4.0 in. (101.6 mm).

When you have made the last turn with the wire, put the end through the loop. Pull both ends of the wire tight. Cut away the extra wire so that the ends are not sticking out and will not come into contact with any part of the case or nacelle.

Wind the repaired area with stainless steel CoMat 02-119 LOCKWIRE 0.030 in. - 0.034 in. (0.76 mm - 0.86 mm).

Refer to Figure.

SUBTASK 77-21-43-750-001 Repair of the Worn or Damaged Wire Braid

Figure: EGT Wiring Harness - Wire Braid Repair (VRS3862) Post SB 77-0015

EGT Wiring Harness - Wire Braid Repair (VRS3862) Post SB 77-0015