Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Description

How To Use (Engine Manual)

General

This manual provides overhaul/repair information for the IAE V2500 engine, power plant and thrust reverser. The A.T.A. chapters covered in this manual are:

Chapter 05 - Group A Parts Lives

Chapter 71 - Power Plant

Chapter 72 - Engine

Chapter 78 - Exhaust (including thrust reverser)

The overhaul/repair information for the other A.T.A. chapters is included in the component maintenance manuals detailed in Paragraph 'Related Publications'. Standard Practices and Processes are issued as a separate manual (Standard Practices Manual - SPM) and contain policy requirements for cleaning, inspection and repair topics together with other essential information associated with the engine manual.

Manual Instructions

The IAE originated instructions for overhaul and repair of the engine/power plant/thrust reverser contained in this manual have been devised to preserve the integrity of the parts during their service lives; it is important that these instructions are observed. Refer to the SPM TASK 70-01-00-000-501 for further details.

Related Publications

Other V2500 publications associated with this manual are listed below:

Standard Practices Manual (SPM) (Formerly referred to as Standard Practices and Processes)

Component Maintenance Manuals:

Tubes, Hosees and Ducts - CMM-THD

Electrical Harnesses - CMM-EHC

Fuel Nozzle and Support Assembly - CMM-FN

Miscellaneous Mechanical Components - CMM-MMC

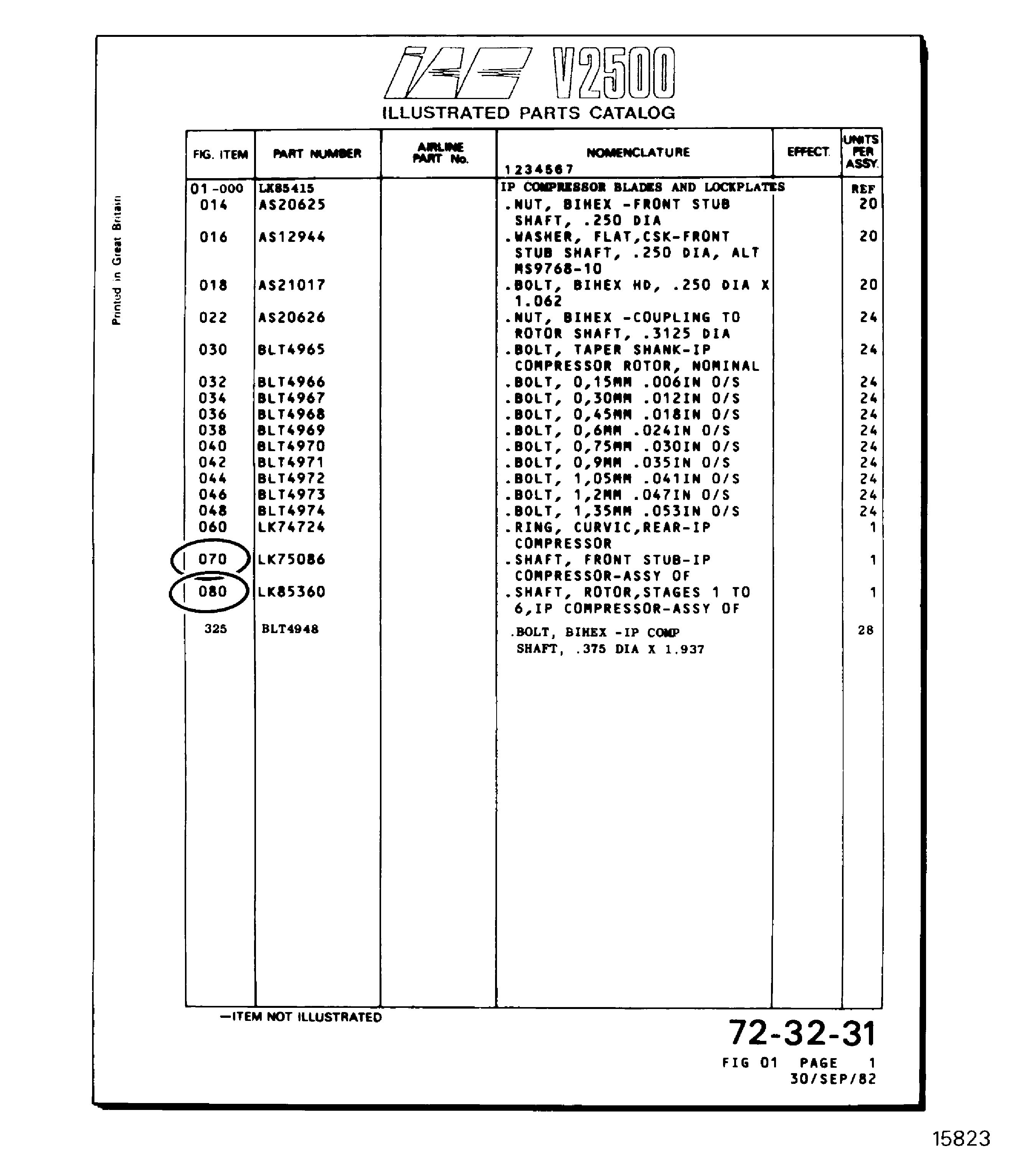

Engine Illustrated Parts Data - IPD (formerly referred to as Engine Illustrated Parts Catalogue)

NOTE

The Engine Illustrated Parts Data (IPD) includes accessory manufacturers units and their attaching parts together with vendor codes and addresses.Illustrated Tool and Equipment Manual - ITEM-V2500

Facilities Planning Manual - FP-V2500

Facilities Equipment Manual - FE-V2500

Overhaul Processes and Consumables Index - PCI-V2500

Support Equipment Numerical Index - SEI-V2500

Manual Structure

The structure of this data follows the ATA 100 specification. This specification gives a 'three element' (six number) method of identification. The first element is the chapter number, the second element is the section number and the third element is the subject number. The subsequent steps give an example of this method of identification.

Chapter 72 = Engine

Each chapter is sub-divided into Sections. For example - 72-41-00 is the HP compressor assembly.

Chapter 72 = Engine; Section 41 = HP compressor assembly.

Each section can be divided in to Subjects. For example - 72-41-11 is the stages 3 to 8 H.P. compressor disks.

Each Section or Subject is divided in to Topics. For example 'Description and Operation', 'Disassembly', 'Cleaning' etc.

The full range of topics are as follows:

Description and Operation

Fault Isolation

Special Procedures

Removal

Installation

Disassembly

Cleaning

Unassigned

Inspection

Repair

Assembly

Servicing

Storage

Testing

Rework

Fits and Clearances

Dimensional information contained in piece part Inspection only relates to the specific piece part in question, i.e., only the min/max values for each dimension measured are given. Only at the various assembly and installation levels will the relationship, or Fits and Clearances, between mating parts be considered. Thus, the Fits and Clearance tables are included in ASSEMBLY and INSTALLATION.

Topic Break-Outs

Additional to the configuration defined in A.T.A.100 Specification Section 2-13-3 and to provide for major technical changes required within a work topic, eg Service Bulletin introduction, engine rating differences, further sub-divisions of material may be made using topic breakouts.

The ATA numbering structure is also designed to enable work on a module ON the engine (removal and installation) and work on a module OFF the engine (disassembly and assembly) to be identified.

In all topics except Fault Isolation, Cleaning and Inspection, the first break-out is 01. For example:

ASSEMBLY-01 72-41-10

ASSEMBLY-02 72-41-10

Only when there is more than one topic break-out is the first break-out numbered -01. If all the technical data is contained in one breakout then that breakout is not numbered.

Fault Isolation

In the Fault Isolation topic, each Fault Isolation procedure is given a break-out. The first break-out within this topic is numbered -00 and is in the form of a look up table. This look up table identifies the break-out number for each Fault Isolation procedure.

Cleaning and Inspection

Each piece part item is covered by a separate break-out in the applicable Chapter/Section/Subject. When the technical criteria of a piece part item differs due to an engineering change, a new configuration to the break-out is included.

The first break-out within these topics is numbered -00 and is in the form of a look up table, where the EIPD Fig/item numbers, the part numbers and their locations relative to break-out and configuration are given.

Repairs

As agreed by A.T.A. and identified by a sequential repair number and a unique IAE repair number:

VRS1234 UNIQUE IAE REPAIR NUMBER VRS2345

72-51-51 72-51-51

REPAIR 001 SEQUENTIAL REPAIR NUMBER REPAIR 002

Once the unique IAE repair number (VRS) and sequential repair number have been allocated to a repair within a Chapter/Section/Subject the two numbers are retained with the repair.

If a repair is not applicable to the engine variant(s) contained in this Manual, then the repair will be omitted from the sequence of repair numbers.

Configuration Usage

For all topics except for CLEANING, INSPECTION, REPAIR OR REWORK, where significant differences occur due to Service Bulletin Standards, Method differences or Engine Variants, two TASKS are required and identified by CONFIGURATION differences. For example CONFIG-1 would contain the original, or first, information data; CONFIG-2 would contain the data for the new CONFIGURATION at Service Bulletin Standard, method difference or Engine Variant. The same criteria would apply to further changes to make CONFIG-3 and so on.

CLEANING AND INSPECTION data initially appears in the manual as CONFIG-1. Differences in method or Technical Criteria resulting from new Part Number Standards cause a new CONFIGURATION to be created.

CONFIGURATIONS are not utilized in the REPAIR and REWORK Topics.

Effectivity

The basic standard of engine covered in this manual is the V2500.

EFFECTIVITY: V2500/ALL - Applicable to all engine mark numbers listed on the manual title page

In non-cleaning inspection or repair topics a service bulletin could have a significant change upon the procedure causing the pre service bulletin and the service bulletin information to become separate TASKS.

EFFECTIVITY: V2500/PRE SBE72-1234 - the information for the pre SBE information

EFFECTIVITY: V2500/SBE72-1234 - the information for the SBE information

Application of Task Numbering System

The task numbering system used in the manual is in accordance with the "Jet Engine Maintenance Task Oriented Support System" (J.E.M.T.O.S.S.) requirement defined in A.T.A.100 Specification, Section 2-13-4.

The system uses an expansion of the 'Three Element' (six digit) numeric identity described in Paragraph, to which fourth, fifth, sixth and seventh elements can be added. This provides a numbering system giving a unique numerical identity for those TASKS normally accomplished in an overhaul/repair facility. A TASK is a work requirement, its incremental work steps being known as SUBTASKS. The TASK and SUBTASK numbers are included to enable the data to be used in an electronic data processing environment. However, control of data by fixed identities such as TASKS and SUBTASKS makes it eminently suitable for use on job work cards etc.

These TASKS and SUBTASKS are allocated a code which defines their function and the addition of a sequential identifier makes them unique.

Work Function Definitions (Element No. 4)

WORK FUNCTION

DESCRIPTION

000

REMOVAL AND DISASSEMBLY

010

Remove Engine

020

Remove Engine Module Sections

030

Disassemble Engine Modular Sections

040

Disassemble Engine Subassemblies

050

Remove Accessory Components

060

Disassemble Accessory

070

Disassemble Accessory Subassembly

080

Remove Engine Test Equipment

090

Disassemble Support Equipment

100

CLEANING

110

Chemical

120

Abrasive

130

Ultrasonic

140

Mechanical

150

Unassigned

160

Miscellaneous

170

Unassigned

180

Unassigned

190

Unassigned

200

INSPECTION

210

Check

220

Visual/Dimensional

230

Penetrant

240

Magnetic

250

Eddy Current

260

X-Ray

270

Ultrasonic

280

Special

290

Unassigned

300

REPAIR

310

Welding and Brazing

320

Machining (See NOTE)

330

Stripping and Plating

340

Plasma and Flame Spraying

350

Miscellaneous Repairs

360

Bonding and Moulding

370

Heat Treating

380

Surface Treating

390

Machine Riveting and Flaring

400

ASSEMBLY AND INSTALLATION

410

Install Engine

420

Install Engine Modular Sections

430

Assemble Engine Modular Sections

440

Assemble Engine Subassemblies

450

Install Accessory Components

460

Assemble Accessory

470

Assemble Accessory Subassembly

480

Install Engine Test Equipment

490

Assemble Support Equipment

500

MATERIAL HANDLING

510

Shipping

520

Receiving

530

Packing

540

Unpacking

550

Storage

560

Marshalling and Turning

570

Engine Ferry/Pod Maintenance

580

Unassigned

590

Unassigned

600

SERVICING/PRESERVING/LUBRICATING

610

Servicing

620

Preserving

630

Depreserving

640

Lubricating

650

Unassigned

660

Unassigned

670

Unassigned

680

Unassigned

690

Unassigned

700

FUNCTIONAL TESTING

710

Oil Flow

720

Air Flow

730

Fuel Flow

740

Water Flow

750

Electrical

760

Engine

770

Accessory

780

Pressure Check

790

Leak Check

800/990

MISCELLANEOUS

810

Fault Isolation

820

Adjusting/Aligning/Calibrating

830

Rigging

840

Service Bulletin Incorporation

850

Unassigned

860

Unassigned

870

Unassigned

880

Approved Vendor Processes

890

Airline Maintenance Program

900

Unassigned

910

Special Equipment Maintenance

920

Standard Equipment Maintenance

930

Tool Fabrication

940

Unassigned

950

Unassigned

960

Unassigned

970

Unassigned

980

Unassigned

990

Illustrations, Tables, etc.

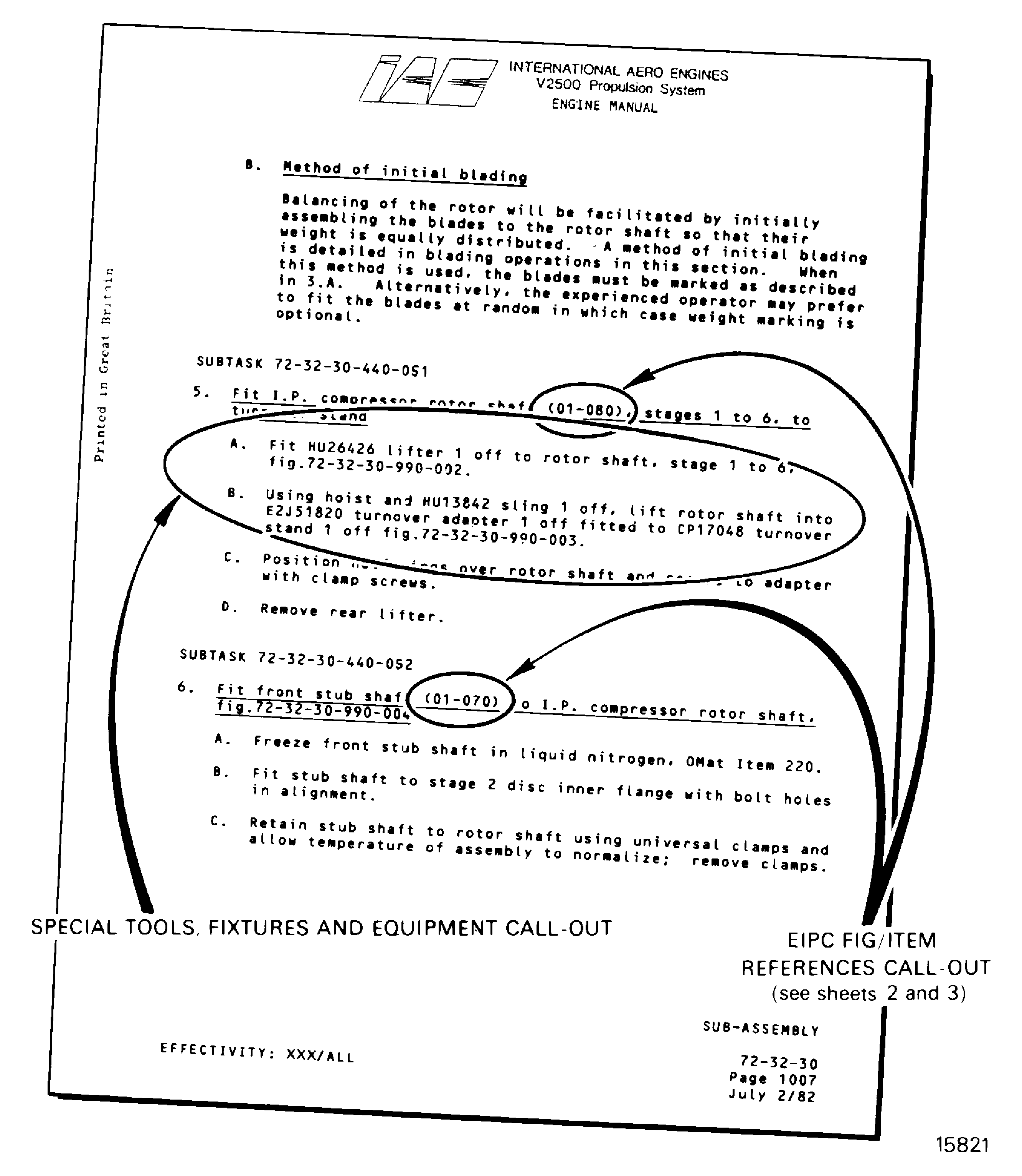

Each element of the numbering system and how it performs its specified function is described below. The structure of a JEMTOSS Task number is detailed in Figure.

Elements 1, 2 and 3:

These are the existing A.T.A. numbers as described previously in Paragraph used as hardware identifiers.

Element number 4:

The fourth element numerically defines the function being performed. See Figure and para. 9.D. at TASK level the function is represented by the appropriate functional code, i.e., 020 Removal, 030 Disassembly.

Element number 5:

The fifth element is provided to create unique numbers (sequential identifiers) for all TASKS and SUBTASKS which are similarly numbered through the first four elements (type of work function sequential identifier).

Element number 6:

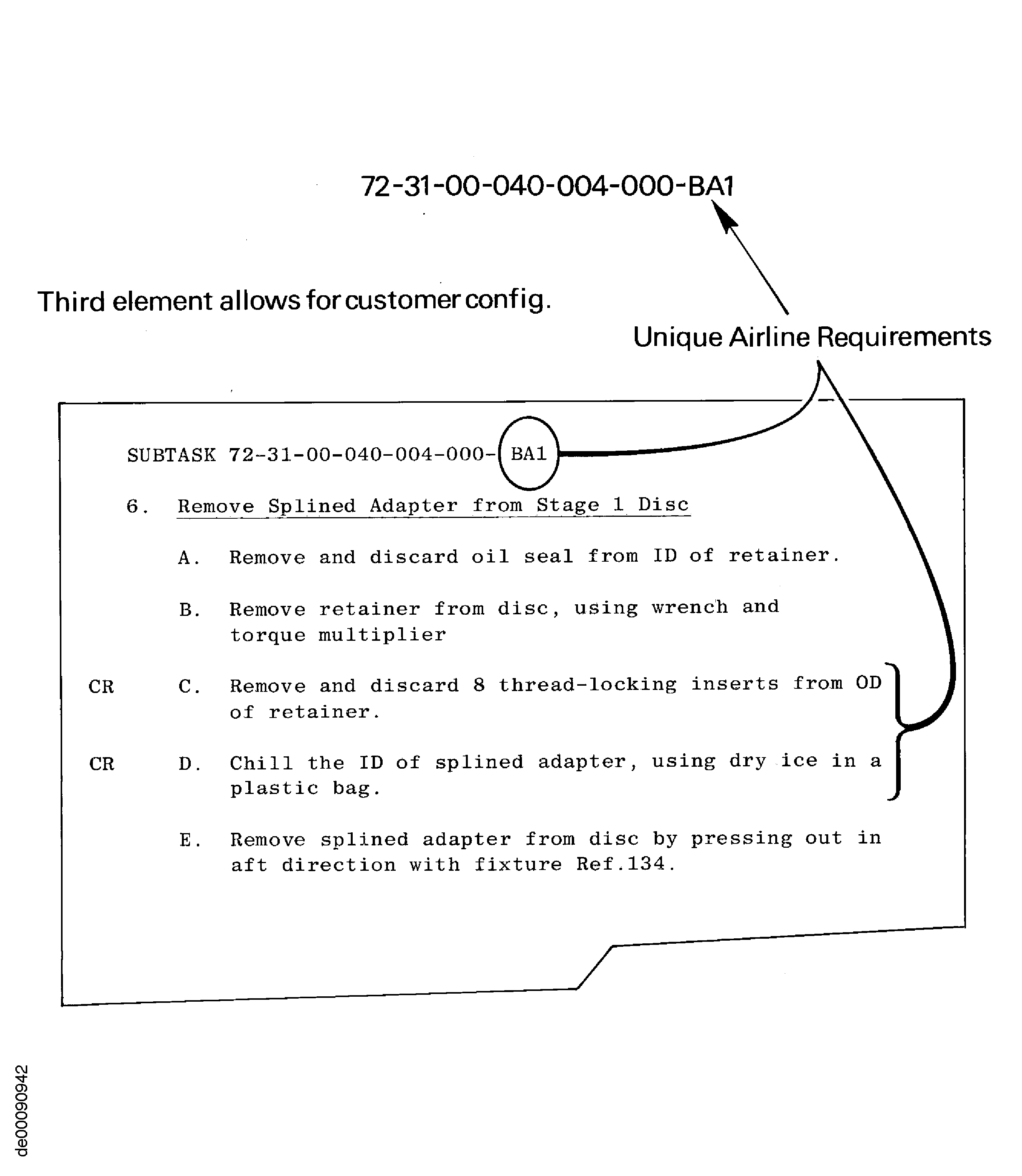

A three-position alpha/numeric sixth element allows for identification of technical differences in configurations methods/techniques at TASK or SUBTASK level. See Figure and Figure.

Alpha prefix AXX, BXX - this is used to denote configurational (hardware) differences, for example A00 is the first hardware standard and B00 is the second hardware standard.

Numeric suffix XX1, XX2 - this is used to denote alternative method differences, for example 001 is the first method and 002 is the second (alternative) method.

Config and method differences are identified using the alpha prefix to identify the hardware and the numeric suffix the method alternatives. For example A01 is the first hardware standard, first method; A02 is the first hardware standard, second method; B01 is the second hardware standard, first method and B02 is the second hardware standard, second method.

Element number 7:

The seventh element allows for coding those TASKS or SUBTASKS that have been changed by the customer in cases where a customer has the contractual facility to input customer originated data. See Figure.

Cross-reference data

Figure provides an example of a cross-reference. Cross references are of great assistance in the preparation and subsequent reliability of job cards.

Illustrations are numbered in sequential order, identified as Fig 1, Fig 2, Fig 3, etc. Tables are numbered in sequential order, identified as Table 1, Table 2, Table 3, etc.

Data Location

The Chapter/Section/Subject breakdown, previously described in Paragraph, uses a module dominant, three element number which enables the user to easily identify the path required to accomplish a work sequence on a particular module.

The following example shows how the module number is moved from the third to the second element dependant on the work sequence. At module removal/installation and associated work activities the module number is identified in the third element. At the subsequent work activities: disassembly/assembly etc. the module identity is moved from the third to the second element.

First

Second

Third

element

element

element

CHAPTER

SECTION

SUBJECT

WORK IDENTITY

71

00

3X

Procedures on power plant to gain access to module 3X

72

00

3X

Module removal/installation and interface inspections

72

3X

00

Module disassembly/assembly

72

3X

10

Overhaul procedures for module parts

11 etc.

The coverage for parts that do not belong to a module i.e. power plant, engine and thrust reverser, are as follows:

CHAPTER

SECTION

SUBJECT

WORK IDENTITY

71

00

00

Procedures for power plant related items

71

1X

XX

Overhaul procedures on power plant related items

72

00

00

Procedures for complete engine, eg engine test schedule

72

X1

XX

Overhaul procedures on engine related, but not module related items

78

00

00

No procedural coverage under this identifier, all done under second element identifier

78

3X

XX

Overhaul procedures on thrust reverser related items

Call-outs and Cross Reference

Repair schemes are self-contained and have individually assigned VRS numbers. If the VRS number is known, the manual location of the repair can be found by utilizing the Index of Repairs Scheme Order or Repair Number Order cross reference list located behind the Index of Repairs, Rework and SBs divider card. Each Chapter/Section/Subject has a List of Repairs which lists the repairs by number and description contained within that Chapter/Section/Subject.

In all topics, the equipment, consumable materials and special tools required to accomplish the TASK are listed under the TASK number.

To locate a particular item requiring a specific work topic, the following technique should be used (as in this example):

If the Inspection procedure is required for the stages 3 to 8 HP compressor disks then:

Using the Manual Contents, determine the A.T.A. number for the stages 3 to 8 HP compressor disks, eg 72-41-11.

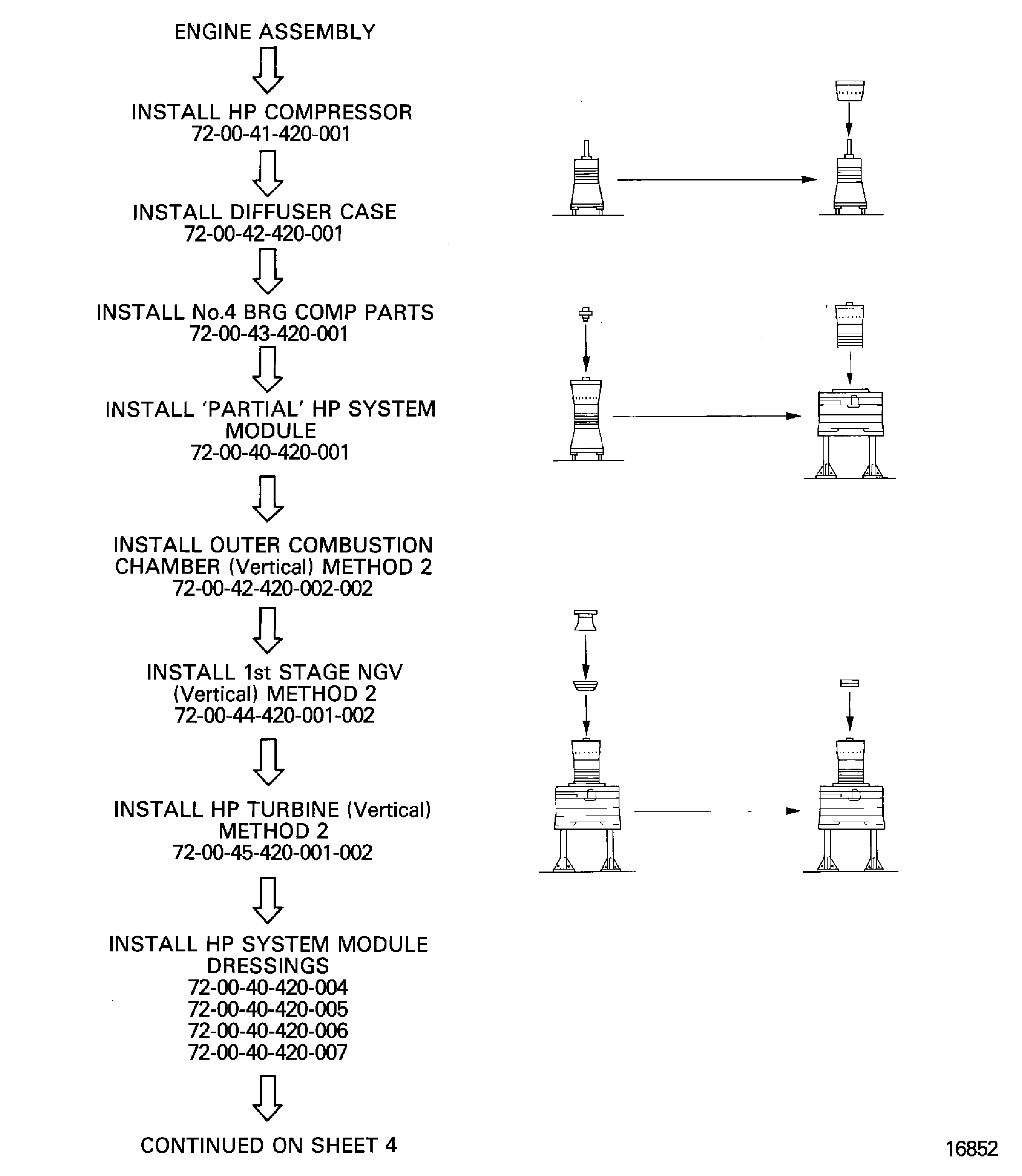

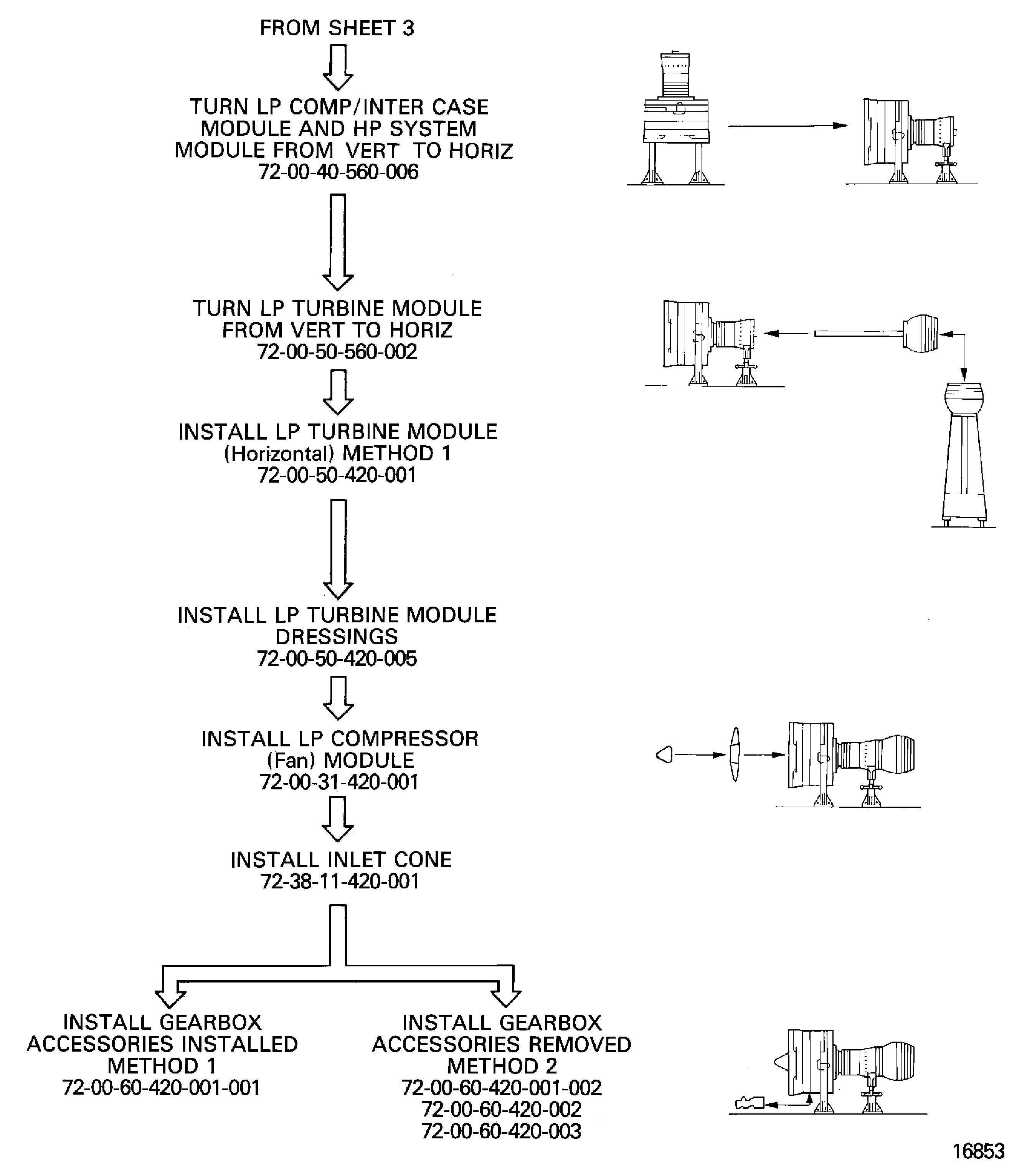

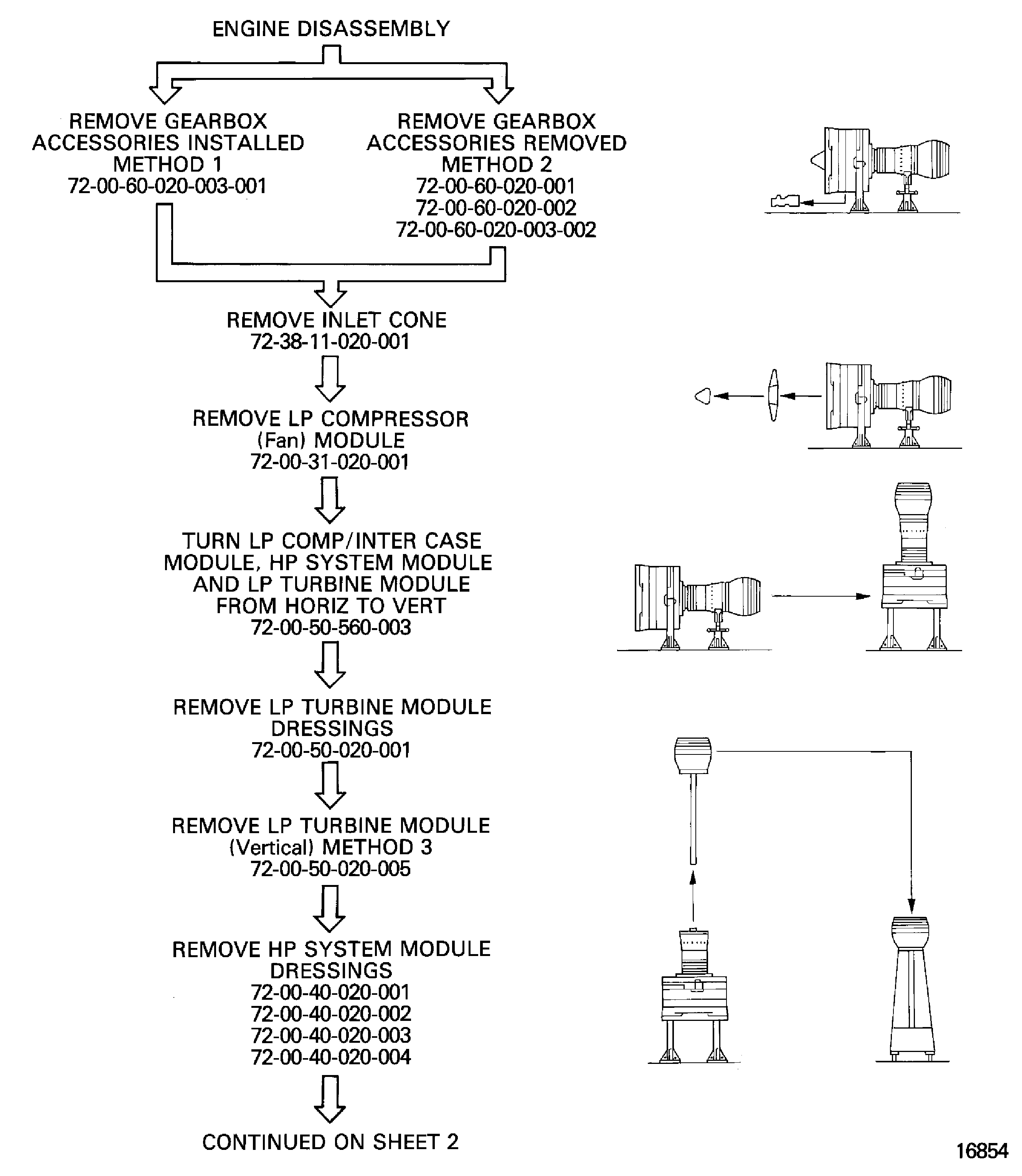

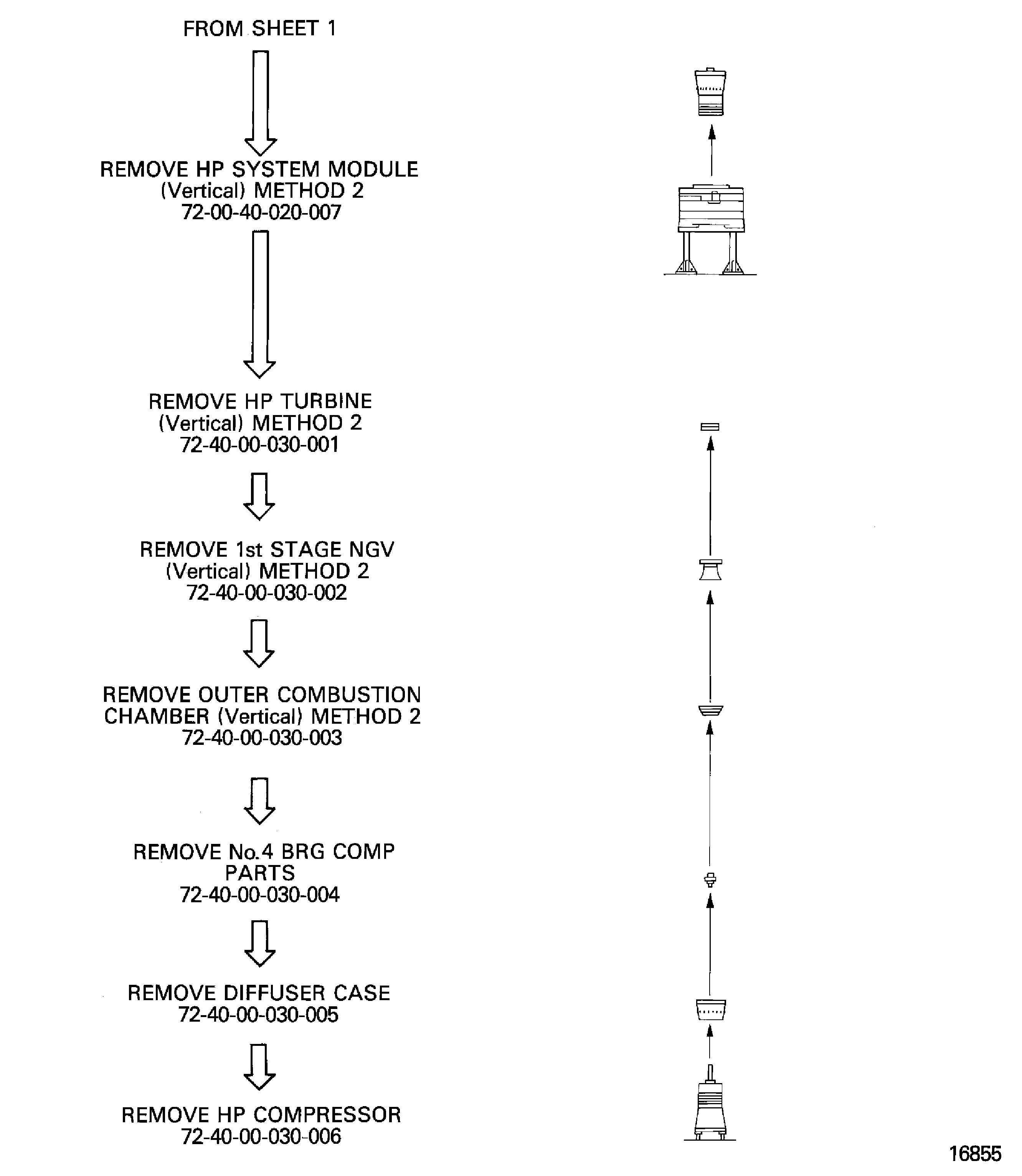

Engine Sectionalization

The engine sectionalization has been developed to provide a comprehensive guide to engine disassembly/assembly to suit the operators individual needs and requirements. The alternative methods by which the engine can be disassembled and assembled have been identified and allocated a unique OPTION number. For example, the maximum horizontal method of engine disassembly/assembly, including the work required to effect hot section inspection, is identified as OPTION 1. Where any variation occurs in how a particular step within an option can be achieved, each variation is further identified as a METHOD. For example, (in OPTION 1), to remove/install the LP turbine module can be achieved in two ways - horizontal as a complete module, (METHOD 1), or horizontal in two stages, (METHOD 2).

There are a total of four OPTIONS:

OPTION 1 - Maximum Horizontal Method

OPTION 2 - Major Module Replacement Method

OPTION 2 - Major Module Replacement Method

OPTION 4 - Maximum Vertical Method

The choice of OPTION will depend on the operators requirements and facilities.

Once the OPTION has been chosen the operator should follow the sequence, TASK by TASK, to achieve the work required.

For the purposes of clarity, the module and mini-module pack and unpack data has not been included on the illustrations. However, this data can be found in the applicable Chapter/Section/Subject. For example, the data to pack the LP compressor (Fan) module can be found in TASK 72-31-00-530-001.

Component Quantity

The use of the word 'off' in connection with special tools new or expendable parts means the quantity required for the operation. For example; 'install IAE 1R18088 bolt 20 off in to the .....', means 20 bolts are required.

Tools and Equipment

In order to overhaul the V2500 certain tools and equipment are essential. These fall into two classifications.

Standard Tools - these tools or equipment have three categories:

Facilities equipment - these tools or equipment are detailed in the Facilities Equipment Manual, FE-V2500-1IA and are tools or equipment used within a particular functional environment for a specific application within the overhaul facility. An example of which would be vernier gage used within an inspection environment. These tools or equipment are not necessarily identified in the Engine Manual.

Other standard tools - these tools or equipment are not special tools Paragraph nor tools or equipment identified in Paragraph and Paragraph. These can be tools or equipment of a general nature which can be purchased or manufactured locally, or can be tools or equipment used outside their normal environment. Examples of which would be a container to drain fluid into or a balancing machine used during assembly. These tools or equipment are identified in the Engine Manual under Equipment and Material.

It is imperative that all measuring equipment, torque wrenches and calibration tooling are regularly checked for accuracy in accordance with the manufacturers instructions. It is incumbent upon the operator to ensure that this is accomplished in a manner that is in compliance with the applicable Regulatory requirements.

Overhaul Components - Removal/Installation Data

Listed below are the removal and installation Engine Manual TASK details for all overhaulable components contained in the V2500 List of Overhaulable Components (V2500 TPI/LOC/VIM).

The ATA Ref.No. is the Chapter/Section/Subject of the component. Nomenclature is the description of the component. Component Removal/Installation Location is the TASK in which the component is removed/installed, the first TASK being removal, the second TASK installation. Where the component is removed or installed in more than one TASK then the preferred method is the first group.

COMPONENT REMOVAL/

ATA REF NO

NOMENCLATURE

INSTALLATION LOCATION

24-21-15

IDG Oil Temperature Thermocouple

72-00-32-050-015

72-00-32-450-015

24-21-42

Fuel Cooled IDG Oil Cooler

72-00-32-020-004

72-00-32-420-002

26-12-15

Accessory Zone Fire Detector

72-00-60-020-001

72-00-60-420-003

26-12-17

Core Zone Fire Detector

72-00-50-020-001

72-00-50-420-005

29-11-17

Hydraulic Low Pressure Warning Switch

72-00-32-020-004

72-00-32-420-002

29-11-49

Hydraulic Couplings and Flexible Hoses

72-00-32-020-001

29-13-49

72-00-32-420-005

30-21-51

Anti-Ice Valve

Data to be issued

36-11-57

HP Compressor Stages 7 and 10 Solenoid Valve

72-00-32-050-012

72-00-32-450-012

Or

72-00-32-020-004

72-00-32-420-002

71-13-12

Fan Cowl Door Hold Open Rod

Data to be issued

71-13-13

Fan Cowl Door Support Latches

71-13-11-040-001

71-13-11-440-001

71-13-14

Latches

Data to be issued

71-13-17

Latches

Data to be issued

71-51-49

Ignition and Probe Heater Relay Unit

72-00-32-050-002

72-00-32-450-002

Or

72-00-32-020-004

72-00-32-420-002

72-32-18

Fan Speed Probe Trim Balance Probe

72-32-00-030-001

72-32-00-430-001

73-11-48

Flexible Fuel Tubes

72-00-32-020-003

72-00-60-420-002

73-12-41

LP/HP Fuel Pump

72-00-60-050-008

72-00-60-450-008

73-13-42

Fuel Diverter and Return Valve

72-00-32-050-013

72-00-32-450-013

Or

72-00-32-020-004

72-00-32-420-002

73-13-43

Fuel Distribution Valve

72-00-40-020-004

72-00-40-420-004

73-22-11

P2/T2 Sensor

71-11-00-050-001

71-11-00-420-001

73-22-34

Electronic Engine Control

72-00-32-050-001

72-00-32-420-001

Or

72-00-32-020-004

72-00-32-420-002

73-22-38

Dedicated Alternator Sensor

72-00-60-050-001

72-00-60-450-001

73-22-48

P2/T2 Air Tubes

71-11-00-050-001

71-11-00-400-001

73-22-52

Fuel Metering Unit

72-00-60-050-002

72-00-60-450-002

Or

72-00-60-020-003

72-00-60-420-001

73-31-17

Fuel Flow Transmitter

72-00-32-050-006

72-00-32-450-006

73-34-15

Fuel Filter Differential Pressure Switch

72-00-32-050-021

72-00-32-450-021

73-35-15

Fuel Temperature Thermocouple

72-00-32-050-003

72-00-32-450-003

74-11-38

Ignition Exciter

72-00-40-020-002

72-00-40-420-006

74-21-41

Ignitor Plug

72-00-40-050-004

72-00-40-450-004

Or

72-00-40-020-004

72-00-40-420-004

74-21-43

Ignition Lead

72-00-40-020-003

72-00-40-420-005

75-22-41

No.4 Bearing Compartment Air Cooler

72-00-50-050-003

72-00-50-450-003

Or

72-00-50-020-001

72-00-50-420-005

75-23-51

HPT Air Valve

72-00-40-050-005

72-00-40-450-005

Or

72-00-40-020-004

72-00-40-420-004

75-23-52

Stage 10 Air Solenoid Valve

72-00-32-050-010

72-00-32-450-010

Or

72-00-32-020-004

72-00-32-420-002

75-24-51

Active Clearance Control Actuator

72-00-40-020-001

72-00-40-420-007

72-00-60-450-002

75-24-52

Active Clearance Control Actuator

72-00-40-050-002

72-00-40-450-002

Or

72-00-40-020-002

72-00-40-420-006

75-28-48

Hoses

72-00-32-020-001

72-00-32-420-005

75-31-42

LP Compressor Bleed Master Actuator

72-00-40-020-002

72-00-40-420-006

75-31-43

LP Compressor Bleed Slave Actuator

72-00-40-020-002

72-00-40-420-006

75-32-41

VSV Actuator

72-00-40-050-001

72-00-40-450-001

Or

72-00-40-020-002

72-00-40-420-006

75-32-51

HP Compressor Stage 7 Solenoid Valve

72-00-32-050-009

72-00-32-450-009

Or

72-00-32-020-004

72-00-32-420-002

75-32-52

HP Compressor Stage 7 Bleed Valve

72-00-40-020-003

72-00-40-420-005

75-32-53

HP Compressor Stage 10 Solenoid Valve

72-00-32-050-011

72-00-32-450-011

Or

72-00-32-020-004

72-00-32-420-002

75-32-54

HP Compressor Stage 10 Bleed Valve

72-00-40-020-004

72-00-40-420-004

75-41-15

Nacelle Temperature Sensor

72-00-40-020-082

72-00-40-420-104

77-21-15

EGT Thermocouple

72-00-50-050-001

72-00-50-450-001

Or

72-00-50-020-001

72-00-50-420-005

77-21-43

EGT Harness and Junction Box

72-00-50-050-002

72-00-50-450-002

Or

72-00-50-020-001

72-00-50-420-005

77-32-15

Vibration Transducer

72-00-32-020-002

72-00-32-420-004

78-31-15

Proximity Switch

78-32-40-030-001

78-32-40-430-001

78-32-41

Thrust Reverser Manual Drive Mechanism

78-32-40-030-001

78-32-40-430-001

78-32-43

Thrust Reverser Actuator - Non Locking

78-32-40-030-001

78-32-40-430-001

78-32-44

Thrust Reverser Flexible Drives and Tubes

78-32-40-030-001

78-32-40-430-001

78-32-48

Thrust Reverser Actuator - Non Locking

78-32-40-030-001

78-32-40-430-001

78-32-50

C-Duct Hold Open Rod - Aft

78-32-40-030-001

78-32-40-430-001

78-32-51

C-Duct Hold Open Rod - Forward

78-32-40-030-001

78-32-40-430-001

78-32-52

C-Duct Auxilary Latch

78-32-40-030-001

78-32-40-430-001

78-32-53

Lower Bifurcation Latches

78-32-40-030-001

78-32-40-430-001

78-32-54

Translating Sleeve Latch

78-32-46-030-001

78-32-46-430-001

78-32-55

Translating Sleeve Keeper

78-32-76-030-001

78-32-76-430-001

78-36-49

Thrust Reverser Opening Tubes and Manifold

78-32-70-030-001

78-32-70-430-001

78-36-51

Thrust Reverser Opening Actuator

78-32-70-030-001

78-32-70-430-001

79-21-42

Air Cooled Oil Cooler

72-00-32-020-004

72-00-32-420-002

79-21-43

Fuel Cooled Oil Cooler

72-00-32-050-022

72-00-32-450-022

Or

72-00-32-020-004

72-00-32-420-002

79-21-44

Pressure Oil Filter Element

72-00-60-050-011

72-00-60-450-011

79-21-51

Oil Cooler Air Modulating Valve

72-00-32-050-007

72-00-32-450-007

Or

72-00-32-020-004

72-00-32-420-002

79-22-45

Magnetic Chip Detector

72-00-00-200-008

79-23-51

No.4 Bearing Compartment Scavenge Valve

72-00-60-050-004

72-00-60-450-004

79-31-15

Oil Quantity Transmitter

Data to be issued

79-32-15

ACOC Oil Temperature Thermocouple

72-00-32-050-004

72-00-32-450-004

79-32-16

Oil Scavenge Temperature Thermocouple

72-00-60-050-006

72-00-60-450-006

79-33-15

Oil Pressure Transmitter

72-00-32-020-004

72-00-32-420-002

Or

72-00-32-050-017

72-00-32-450-017

79-33-16

No.4 Bearing Pressure Transducer

72-00-32-020-004

72-00-32-420-002

79-34-15

Oil Low Pressure Switch

72-00-32-020-004

72-00-32-420-002

79-35-16

Oil Scavenge Filter Differential Pressure Switch

72-00-32-050-019

72-00-32-450-019

Or

72-00-32-020-004

72-00-32-420-002

80-13-41

Pneumatic Starter

72-00-60-050-009

72-00-60-450-009

Or

72-00-60-020-003

72-00-60-420-001

80-13-51

Pneumatic Starter Valve

72-00-32-050-008

72-00-32-450-008

Substances of Very High Concern and Safe Use Information

Article 33 of the REACh (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires the communication of safe use information for Substances of Very High Concern (SVHC). This requirement becomes necessary whenever the SVHC content of an article (eg. part number) is above 0.1 percent of its total weight.

For Pratt & Whitney impacted part numbers and their SVHC safe use documents, refer to the "MRO Information" in the link below:

https://www.pw.utc.com/company/EHS-and-sustainability/reach-and-materials-of-concern

For further information or questions, please contact:

Reach.Compliance@pw.utc.com

Figure: Task number structure

Task number structure

Figure: Use of sixth element configuration/method

Use of sixth element configuration/method

Figure: Use of customer configuration/seventh element

Use of customer configuration/seventh element

Figure: Cross reference

Cross reference

Figure: Deleted figure

Deleted figure

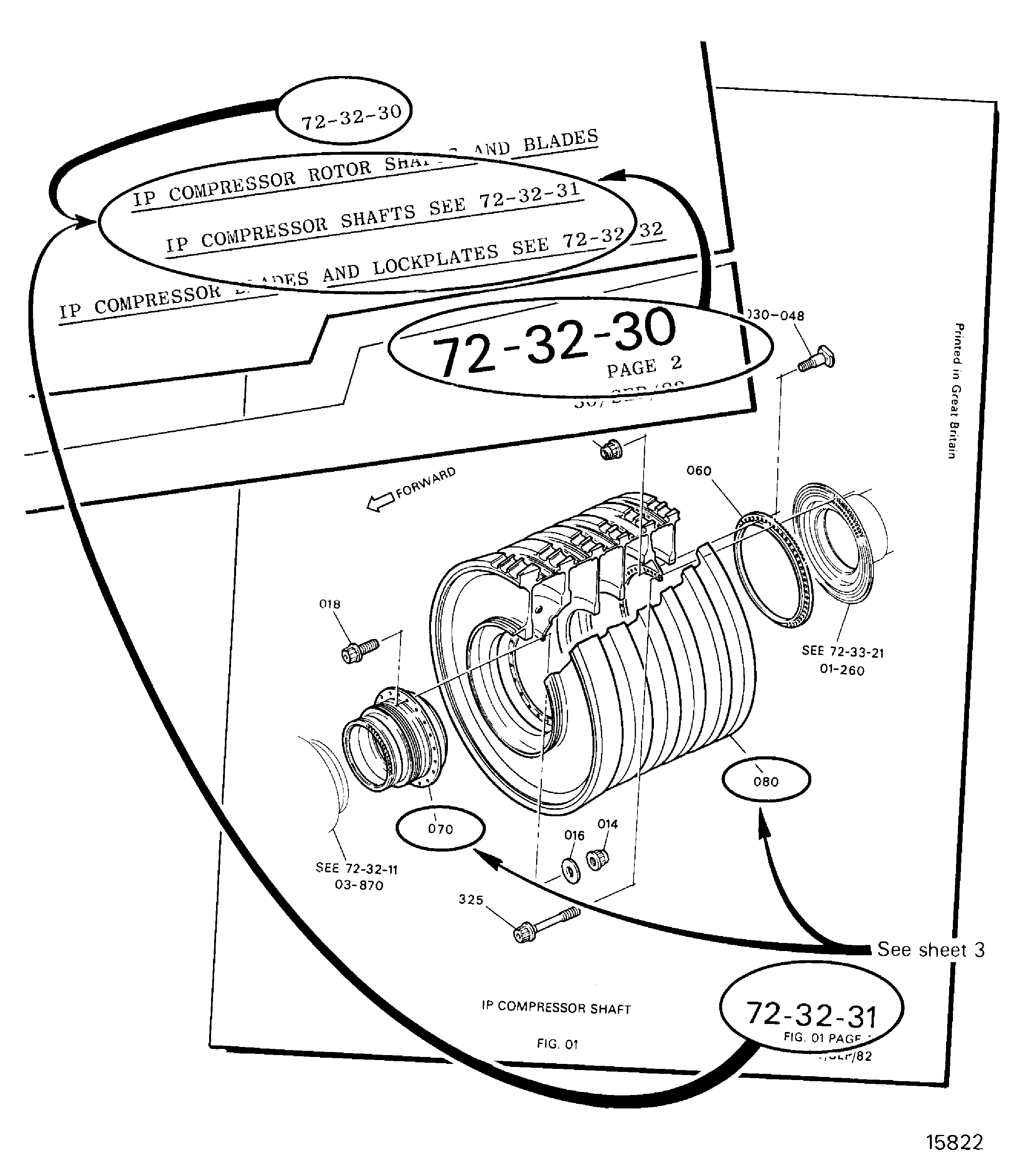

Figure: Sample EIPD and Special Tools, Fixtures and Equipment call-outs

Sample EIPD and Special Tools, Fixtures and Equipment call-outs

Sample EIPD and Special Tools, Fixtures and Equipment call-outs

Sample EIPD and Special Tools, Fixtures and Equipment call-outs

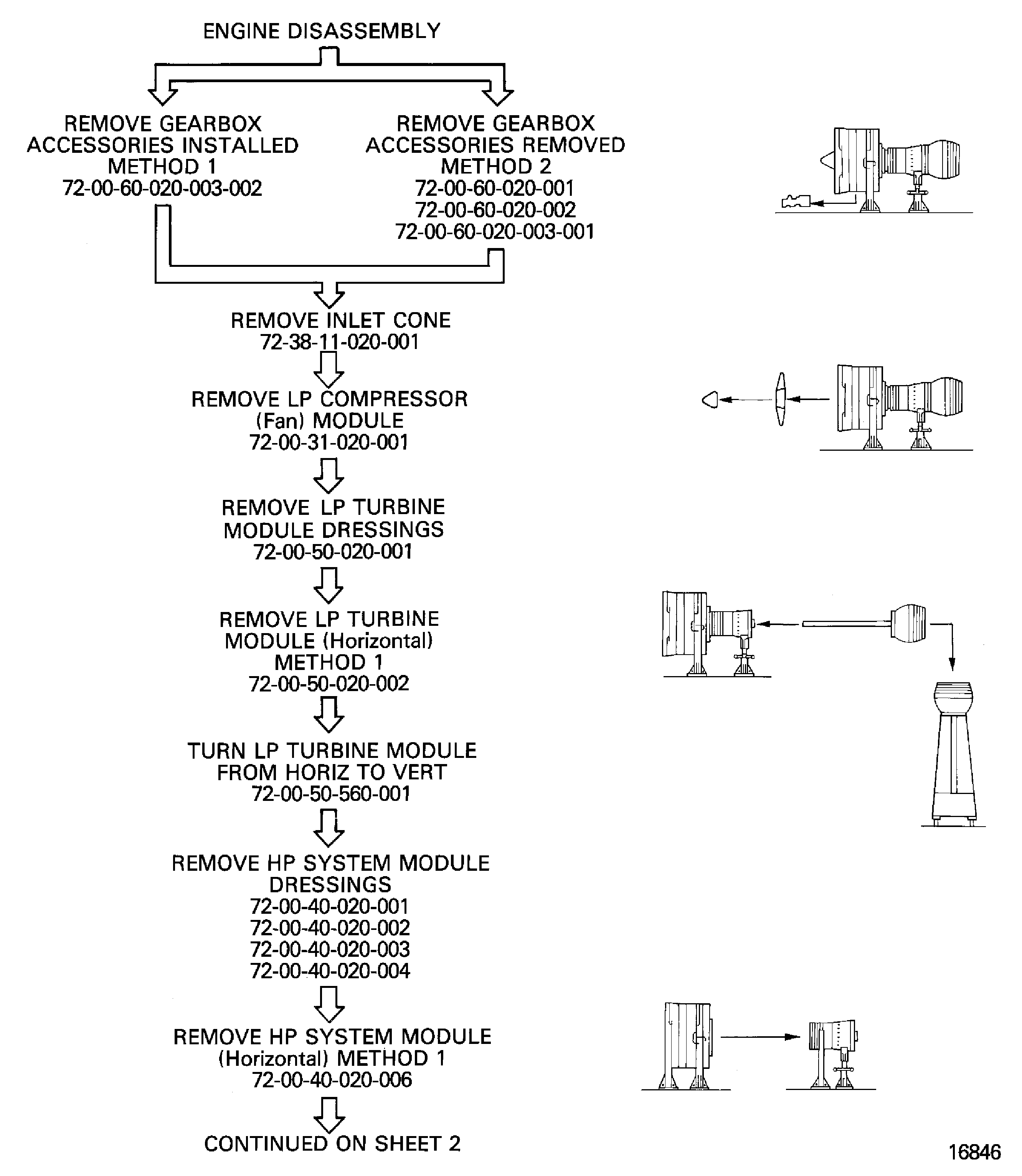

Figure: Option 1 - engine disassembly

Option 1 - engine disassembly

Option 1 - engine disassembly

Option 1 - engine disassembly

Option 1 - engine disassembly

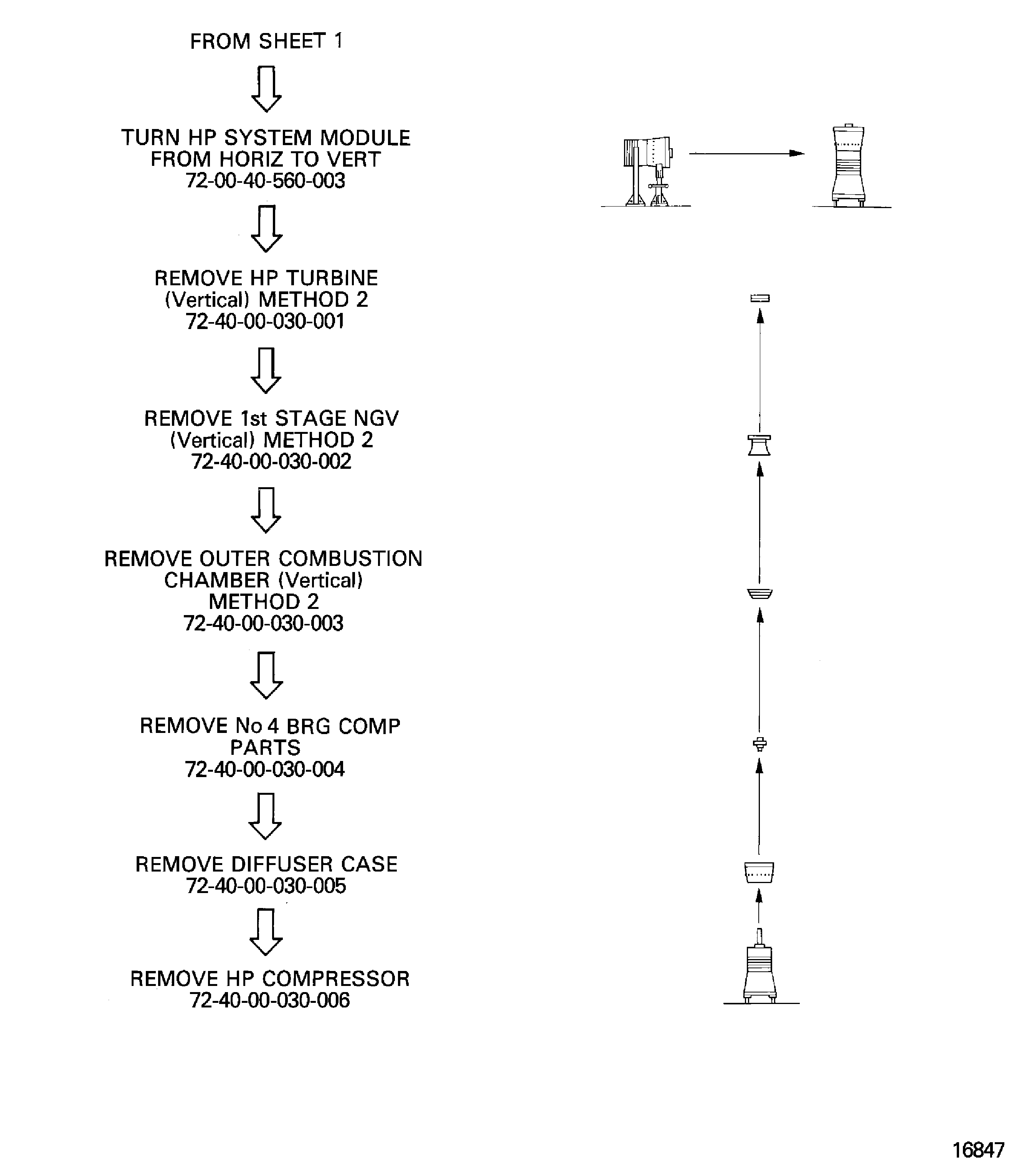

Figure: Option 2 - engine disassembly

Option 2 - engine disassembly

Option 2 - engine disassembly

Option 2 - engine disassembly

Option 2 - engine disassembly

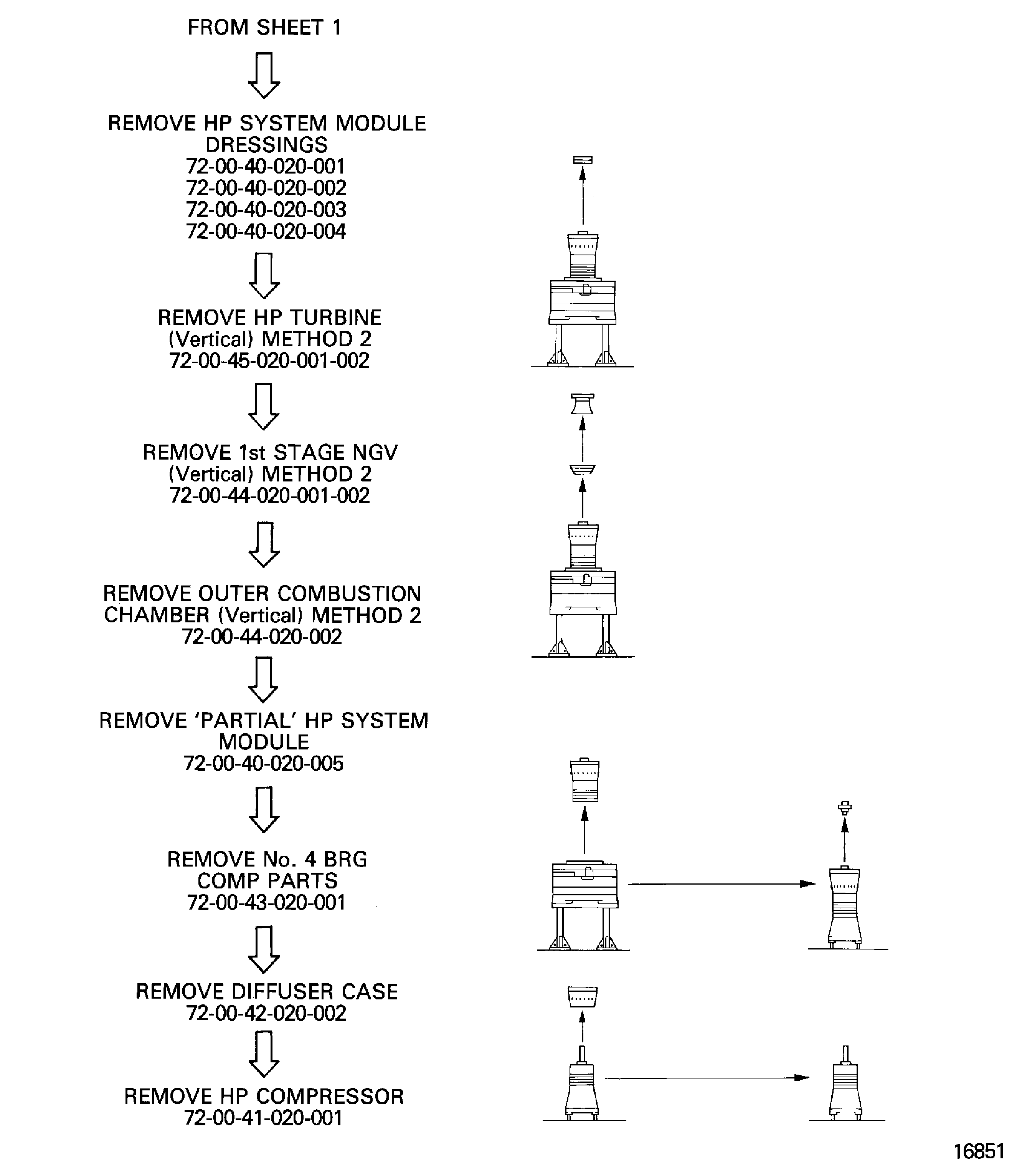

Figure: Option 3 - engine disassembly

Option 3 - engine disassembly

Option 3 - engine disassembly

Option 3 - engine disassembly

Option 3 - engine disassembly

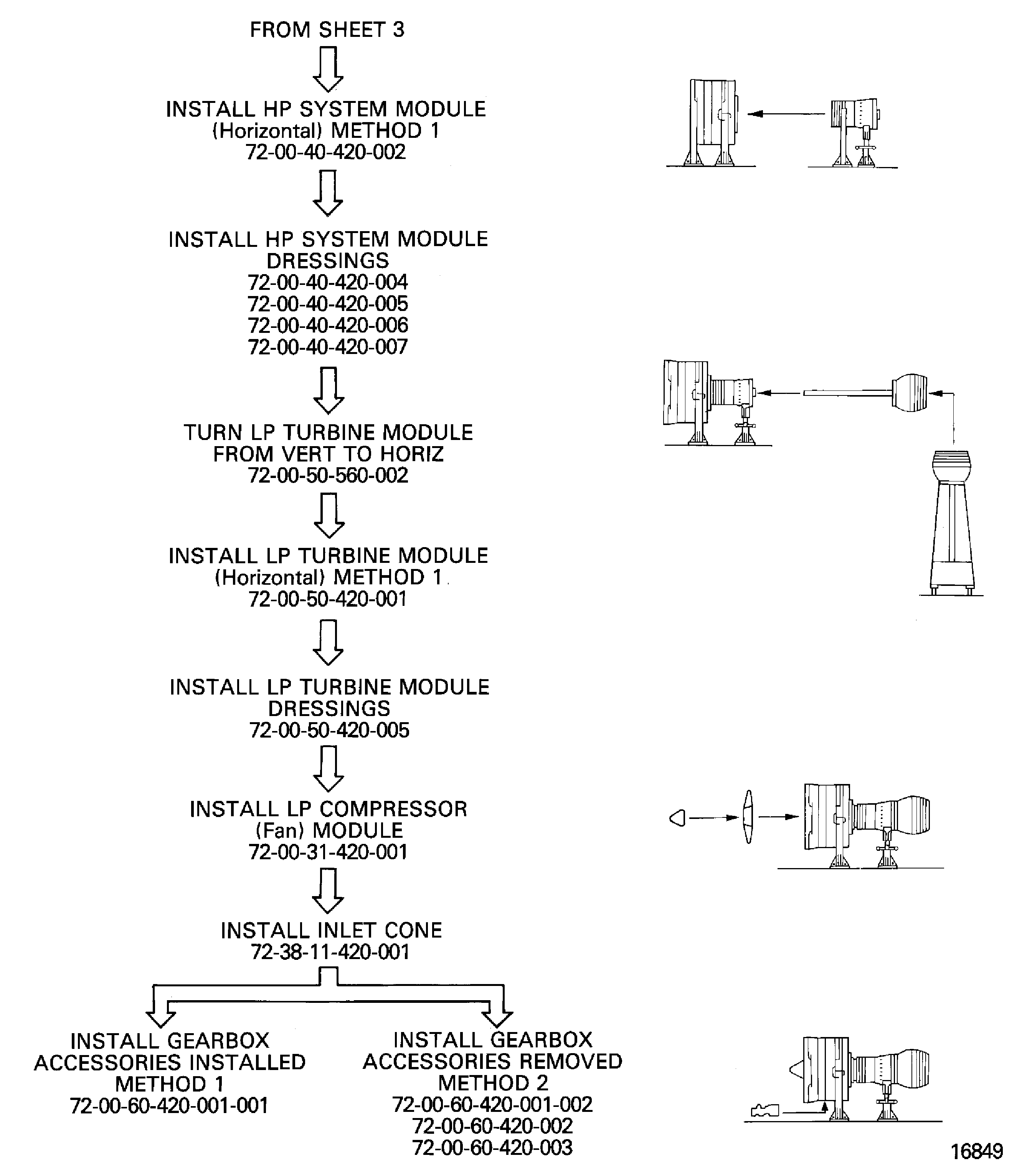

Figure: Option 4 - engine disassembly

Option 4 - engine disassembly

Option 4 - engine disassembly

Option 4 - engine disassembly

Option 4 - engine disassembly