Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-11-18-300-503 Carbon Seal Handling - (Cleaning, Lapping And Checking)

General

This procedure gives the instructions for handling new carbon seals and used carbon seals, during engine overhaul. It also gives the procedures used to clean and lap the carbon seals, and the procedure used to measure if the seals are flat.

The procedure makes sure that the necessary quality of V2500 new and used carbon seals is kept; when the engine is disassembled and assembled. It also makes sure that the serviceable life of each carbon seal is not decreased, when the module is disassembled.

To identify the consumable materials, refer to the Consumable Materials Index.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Lap plate | LOCAL | Lap plate | ||

| Lapmaster machine | LOCAL | Lapmaster machine | Supplier Code 71724 | |

| Optical flat and monochrome light | LOCAL | Optical flat and monochrome light |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-228 METAL CUTTING COMPOUND(OIL TYPE) | 0AM53 | CoMat 01-228 | ||

| CoMat 01-313 LAPPING VEHICLE | 71724 | CoMat 01-313 | ||

| CoMat 05-116 LAPPING COMPOUND | 71724 | CoMat 05-116 | ||

| CoMat 05-117 COMPOUND, LAPPING - GRAIN ONLY | V065V | CoMat 05-117 | ||

| CoMat 05-118 DIAMOND LAPPING COMPOUND,SLURRY, SPRAY, OR SUSPENSION | 4S8W0 | CoMat 05-118 | ||

| CoMat 05-120 POLISHING CLOTH | 06565 | CoMat 05-120 | ||

| CoMat 06-087 COMPOUND LAPPING | 71724 | CoMat 06-087 | ||

| CoMat 10-008 DEWATERING OIL (HOT) | LOCAL | CoMat 10-008 | ||

| CoMat 10-009 DEWATERING FLUID (COLD) | LOCAL | CoMat 10-009 | ||

| CoMat 10-010 DEWATERING FLUID (COLD) | LOCAL | CoMat 10-010 | ||

| CoMat 10-011 DEWATERING FLUID (COLD) | K6835 | CoMat 10-011 | ||

| CoMat 10-012 DEWATERING FLUID (COLD) | LOCAL | CoMat 10-012 | ||

| CoMat 10-013 DEWATERING FLUID (COLD) | LOCAL | CoMat 10-013 | ||

| CoMat 10-061 STODDARD SOLVENT | LOCAL | CoMat 10-061 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| CoMat 12-015 CORROSION PREVENTIVE, FINGERPRINT REMOVER | 0AM53 | CoMat 12-015 | ||

| CoMat 12-016 CORROSION PREVENTIVE THIN FILM | 2H517 | CoMat 12-016 | ||

| CoMat 12-027C CORROSION PREVENTIVE COMPOUND | LOCAL | CoMat 12-027C |

Spares

NONESafety Requirements

WARNING

Procedure

Used seals, that look dirty must be cleaned after removal as specified in SPM TASK 70-11-18-100-501, SUBTASK 70-11-18-100-002.

Lap and examine the used seals, after removal, as specified in Step.

NOTE

It is not necessary to heat-treat the carbon seals, after they are cleaned, when the lubricant is applied.Clean the carbon seal surfaces again, with a clean cloth made moist with CoMat 10-077 APPROVED ENGINE OILS so that the tacky compound will not occur again.

Dry the carbon seal surfaces, with a clean cloth, to remove the remaining water.

When the seals are removed from their protective covers, they must be touched very carefully; to make sure that their carbon faces do not become damaged. Do not put the seals on top of each other. All seals coated, before storage, must be cleaned before they are assembled into the engine. Initially, the coating is a tacky compound, which can become white crystals on the carbon surface. This compound, which is made from the material used to apply the carbon, can change the seal vacuum and air checks. Remove this compound as follows:

To keep the seals in a serviceable condition, obey the recommended handling instructions; during the procedures to disassemble.

SUBTASK 70-11-18-300-001 Basic Handling Instructions

Soak seals in CoMat 10-061 STODDARD SOLVENT for up to four hours.

If necessary, you can remove particles of coke with a blunt-edge tool or spray with CoMat 10-061 STODDARD SOLVENT. Be careful not to cause scratches, chips, or other damage to the carbon surface.

CAUTION

DO NOT CLEAN THE SEALS WITH A DIRTY CLOTH. DO NOT CLEAN WITH CARBON SOLVENT OTHER THAN CoMat 10-061 STODDARD SOLVENT. THESE MATERIALS WILL REMOVE THE CARBON SEAL COMPOUNDS, WHICH WILL CAUSE INCREASED SURFACE POROSITY AND HIGHER WEAR RATES.Use subsequent procedure to clean the V2500 carbon seals.

SUBTASK 70-11-18-300-002 Procedure to Clean the Used Carbon Seals

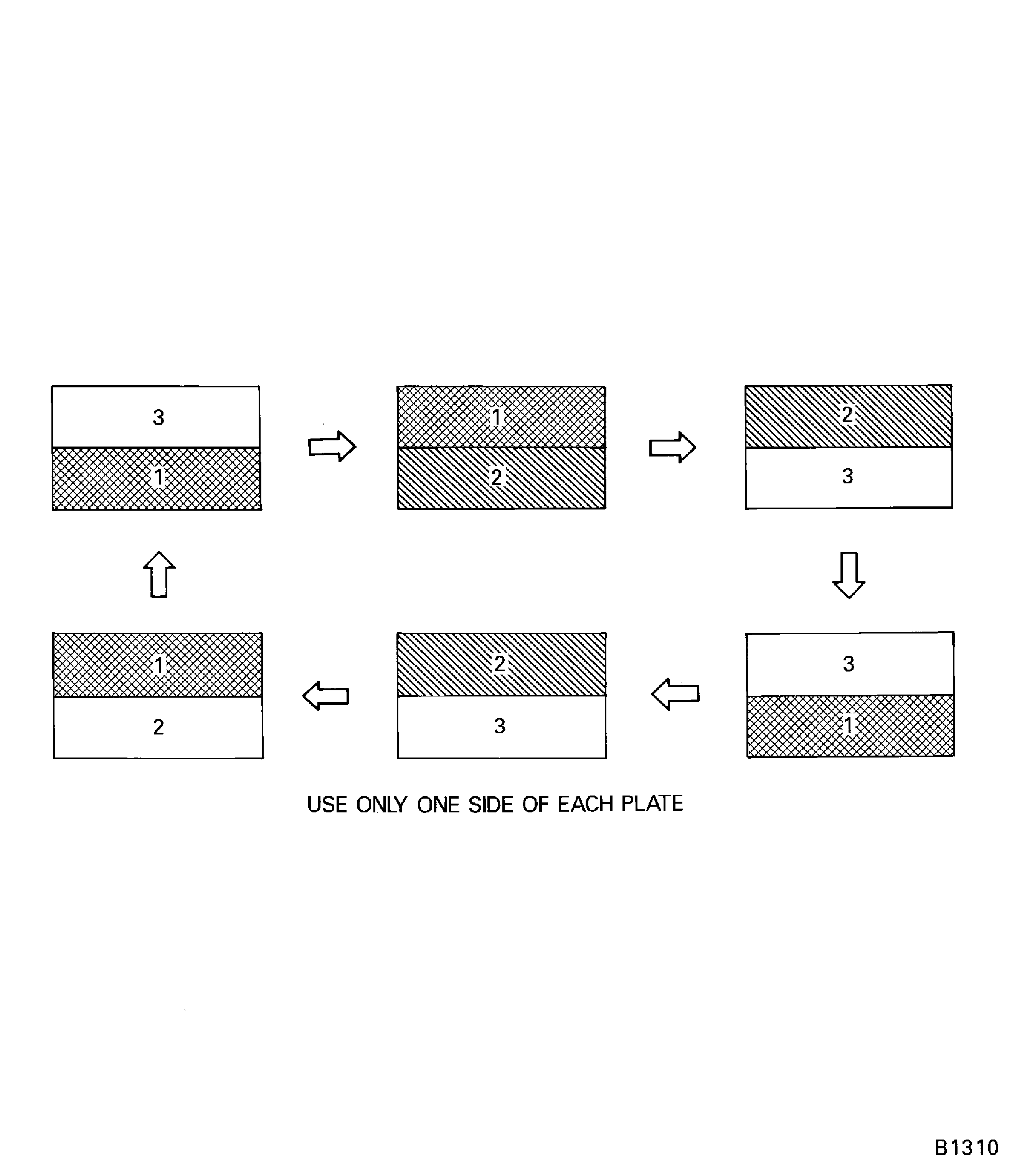

Use three flat glass plates, with CoMat 05-116 LAPPING COMPOUND, or an equivalent.

NOTE

Use only one side of each plate. The other side must touch the bench.Make one surface of each plate flat, by lapping one against the other as shown in Figure, with the lapping compound.

Lap each carbon seal on one plate. Use a metal fixture, with a sponge-rubber pad, to help keep a constant pressure; which will give a smooth satisfactory finish, to the carbon seal.

Glass plate lapping:

CAUTION

DURING THE LAPPING PROCEDURE, DO NOT DECREASE THE TOTAL WIDTH OF THE SEALS TO BELOW THE MINIMUM DIMENSIONS GIVEN FOR EACH SEAL.THE LAPPING EQUIPMENT MUST BE CORRECTLY USED. ALWAYS OBEY THE MANUFACTURERS INSTRUCTIONS. MAKE FREQUENT FLATNESS CHECKS ON THE LAP SURFACE.Lap the main bearing carbon seals.

Use a Lapmaster machine, made by Lapmaster International (Supplier Code 71724), or its equivalent.

NOTE

The lapping time for new parts is less than that for parts repaired by chromium plating.Obey the manufacturers instructions, to operate the lapping machine.

Use a lapping solution of 4 oz (113 g) of CoMat 06-087 COMPOUND LAPPING or CoMat 05-117 COMPOUND, LAPPING - GRAIN ONLY to 1 gal (3.8 l) of CoMat 01-313 LAPPING VEHICLE, or CoMat 01-228 METAL CUTTING COMPOUND(OIL TYPE).

Machine lap areas without surface protection and chromium-plated areas:

Use a lap plate made of gray cast-iron or Meehanite - GA50. The lap surface must contain serrations or grooves, with a 90 degree shape. The grooves must have a width of 0.030 to 0.060 in. (0.8 to 1.6 mm) and a depth of 0.030 to 0.060 in. (0.8 to 1.6 mm) and be approximately 0.500 in. (12.7 mm) apart. A relief, at least 25 percent as large as the outer diameter of the lap plate, must be supplied in the lap center.

The diamond lapping compound must be fully included in the lap. Push the CoMat 05-118 DIAMOND LAPPING COMPOUND,SLURRY, SPRAY, OR SUSPENSION, or an equivalent, into the lap: by lapping with a hard steel, or linde flame plated disk which has a weight of approximately 20 psi. The disk must be put in the conditioning rings, the same as the part.

Apply a thin coating of CoMat 10-061 STODDARD SOLVENT to the lap. Run the lap almost dry, until its surface looks iridescent. The lap must have a matt finish and not look wet, as when too much solvent is used. The lap surface must be very dark, when fully charged.

It is only necessary to charge the lap again, when the lap time has increased by more than 50 percent; of that used for a fully charged lap. When the correct load is applied to the part (Refer to Step above), the necessary finish will be completed in less than 25 minutes; if all the operational conditions are satisfactory.

Examine the lapped surface - (Refer to Step).

Clean the part (Refer to Step or SPM TASK 70-11-03-300-503). Parts put into storage before they are cleaned must be kept wet with CoMat 10-061 STODDARD SOLVENT so that the lapping compound will not become dry.

Machine lap Praxair (was Linde) flame plated areas:

NOTE

Use only one side of each plate. The other side must touch the bench.Make one surface of each plate flat, by lapping one against the other as shown in Figure, with the lapping solution given above.

NOTE

Repair the surface of each cast-iron or Meehanite - GA50 plate, when necessary (Refer to Step above), to get a satisfactory optical flatness check.Lap each seal plate or spacer, with all three plates, approximately the same. Apply an equal pressure, to make sure that the lap is smooth.

Use three flat cast-iron or Meehanite - GA50 plates; with a lapping solution of 4 oz (113 g) of CoMat 06-087 COMPOUND LAPPING lapping aluminum oxide, or CoMat 05-117 COMPOUND, LAPPING - GRAIN ONLY, to 1 gal (3.8 l) of CoMat 01-313 LAPPING VEHICLE, or CoMat 01-228 METAL CUTTING COMPOUND(OIL TYPE).

Lap with cast-iron or Meehanite - GA50 plates:

CAUTION

THE LAPPING EQUIPMENT MUST BE CORRECTLY USED. ALWAYS OBEY THE MANUFACTURERS INSTRUCTIONS. MAKE FREQUENT FLATNESS CHECKS ON THE LAP SURFACE.Lap the main bearing seal plates and spacers.

NOTE

The polishing cloth must be pulled tight over the flat surface, to make sure its edges are flat, to get a smooth finish.To help with this check, carefully polish each part with CoMat 05-120 POLISHING CLOTH, or equivalent, attached to flat plate.

Examine the carbon seal, seal plate or spacer, for flatness; with an optical flat and monochrome light. The flatness is measured in helium light bands and one band (That is, from the center of a dark area to the center of an adjacent dark area) is equal to 11.6 millionths of an inch (0.29 micrometers).

NOTE

An optical flatness check of the main bearing carbon seals, seal plates and spacers, is not necessary; if a satisfactory air pressure check is done, on the seal "stack-up" parts used in the engine. If a simulated seal plate or spacer is used, during a different air pressure check, an optical flatness check will be necessary. All repaired carbon seals, seal plates and spacers, must be examined by this procedure.Optical flatness check for main bearing carbon seals, seal plates and spacers.

SUBTASK 70-11-18-300-003 Procedure to Lap the Carbon Seals, Seal Plates and Spacers

NOTE

This step is optional.Preclean (Refer to SPM TASK 70-11-03-300-503).

Apply the steps that follow, when specified in the V2500 procedures given above.

Soak the part in an alkaline rust remover (Refer to SPM TASK 70-11-13-300-503 for data on the approved rust removers, concentrations and tests), at 180 to 200 deg F (82 to 93 deg C), for 30 to 90 minutes.

If the water on the part surface does not flash off when the part comes out of the hot water, then the time interval that the part stayed in the hot water was too short to increase the part temperature sufficiently.

Put the part fully in hot water, 150 to 200 deg F (66 to 93 deg C). until the temperature of the part increases sufficiently to flash dry.

When necessary, momentarily put the part into one of the rust inhibitors or dewatering agents that follow: CoMat 10-008 DEWATERING OIL (HOT), CoMat 10-009 DEWATERING FLUID (COLD), CoMat 10-010 DEWATERING FLUID (COLD), CoMat 10-011 DEWATERING FLUID (COLD), CoMat 10-012 DEWATERING FLUID (COLD), CoMat 10-013 DEWATERING FLUID (COLD), CoMat 12-015 CORROSION PREVENTIVE, FINGERPRINT REMOVER, CoMat 12-016 CORROSION PREVENTIVE THIN FILM, CoMat 12-027C CORROSION PREVENTIVE COMPOUND or Solution Code 80 corrosion inhibitor solution (Refer to SPM TASK 70-11-18-100-501, SUBTASK 70-11-18-100-002 and SUBTASK 70-11-18-100-003).

SUBTASK 70-11-18-300-004 Special Procedure to Clean the Carbon Seal Plate and Spacer

Figure: Glass plate lapping

Glass plate lapping