Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 24-21-43-300-002 IDG Power Cables - Replace One Cable, Repair-002 (VRS2791) - SBN 70-0736

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Strap Wrench | LOCAL | gripping diameter 2.0 to 4.0 in. (50.8 to 101.6 mm) | ||

| IAE 1R18201 Torque spanner | 0AM53 | IAE 1R18201 | 32 lbfin. (3.6 Nm) | |

| IAE 1R18201 Torque spanner | 0AM53 | IAE 1R18201 | 70 lbfin. (7.9 Nm) | |

| Pneumatic crimp tool | LOCAL | PICO 500D-1 | ||

| Die set | LOCAL | PICO 514DA-2/0-D | ||

| Locator | LOCAL | PICO 5402-1 | ||

| Locator | LOCAL | PICO 5520-3 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-153 FELT TIP MARKER, RAPID DRYING | LOCAL | CoMat 06-153 |

Spares

NONESafety Requirements

NONEProcedure

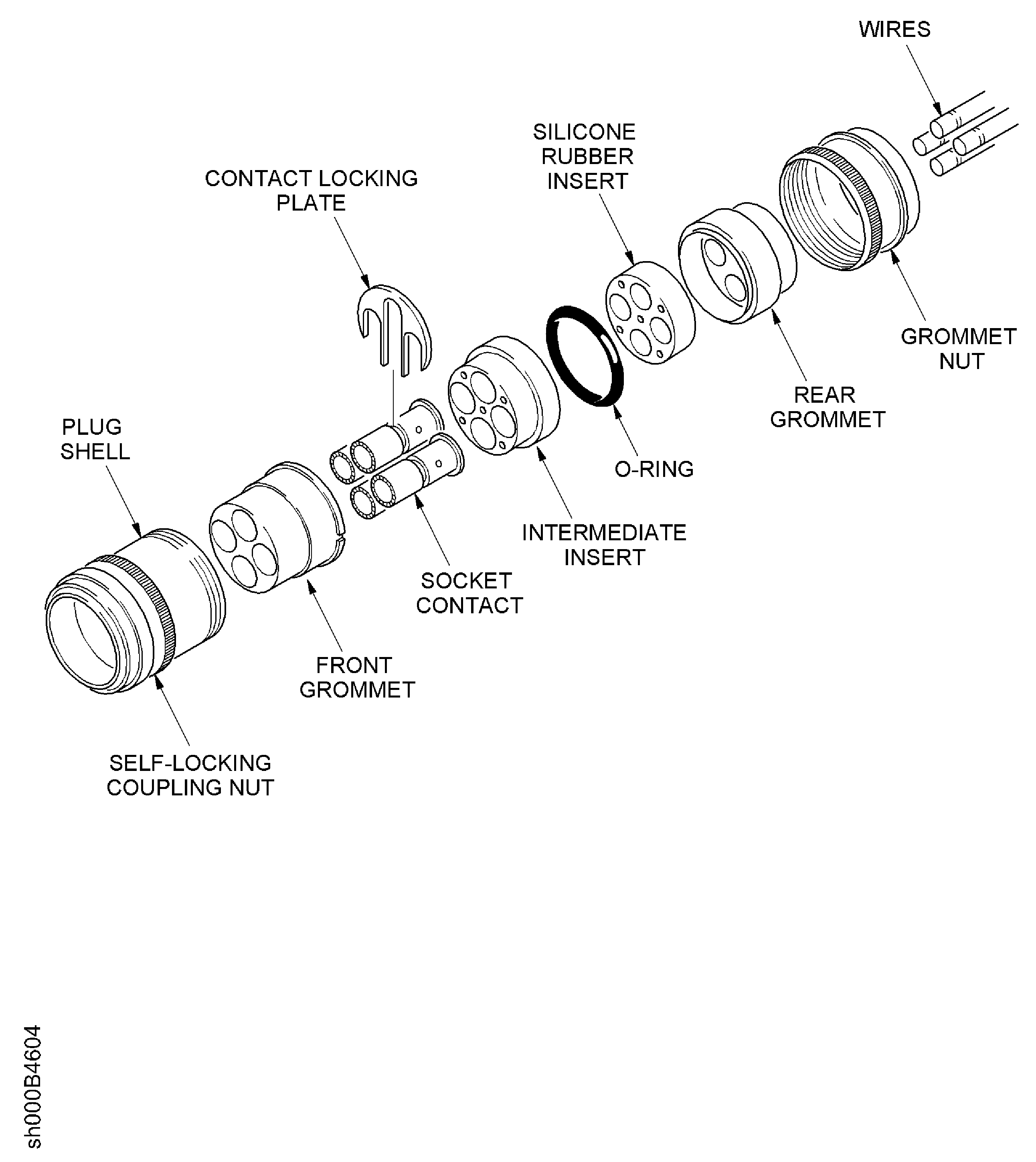

Refer to Figure.

Make sure you make a note of the position of the lacings, clamp and orientation of the cables at each position. (It is recommended to cut the lacings one at a time to help keep the controlled twist of the cables in the harness).

If the cables are not replaced and laced in the same controlled twist, they can foul with other engine parts and become damaged.

CAUTION

MAKE A NOTE OF THE POSITION OF THE LACINGS AND CLAMP, THE CONTROLLED TWIST AND PROFILE (SHAPE) OF THE CABLES AT EACH POSITION. IF THE CABLES ARE NOT REPLACED AND LACED IN THE SAME CONTROLLED TWIST AND PROFILE (SHAPE) THEY CAN FOUL WITH OTHER ENGINE PARTS AND BECOME DAMAGED.Remove the lacings and clamp from the cable harness.

Remove the grommet nut from the connector and pull it away from the plug shell. Pull the rear grommet and the rubber insert from the plug shell.

Move the rear grommet carefully to prevent damage to the O-ring.

Carefully remove the plug shell from the intermediate insert, the contact locking plate and the front grommet.

Remove the front grommet and the contact locking plate from the socket contact.

Cut the socket contact from the applicable wire.

Pull the cable through the intermediate insert, the O-ring, the rubber insert, the rear grommet and the grommet nut.

Remove the cable from the connector.

Remove the two nuts, the two washers and the two bolts that attach the cable clamp around the harness.

Remove the cable from the harness.

Remove the cable from the cable clamp.

SUBTASK 24-21-43-050-051 Remove the Cable from the Harness

Cut the new wire to the correct length.

It is important the length is the same as the cable to be replaced.

Cut the new wire.

Remove approximately 0.8 in. (20 mm) of the insulation from around the cut end of the cable.

Remove the cable into the terminal lug.

Make sure that the insulation touches the barrel all around.

Make sure that you can see the end of the conductor at the ring end of the lug.

Use the Pneumatic crimp tool with the Locator and crimp the lug to the cable.

Put a 0.75 in (19 mm) HTMS sleeve on the barrel of the lug and shrink in position.

Install the terminal lug(s).

SUBTASK 24-21-43-350-001 Prepare the New Cable

Clean inside of the connector sockets with filtered clean, dry compressed air and install a dust cap to the front face of the connector. Use the filtered air at a pressure of 30 psig (206.8 KPa) maximum discharge pressure. Refer to SPM TASK 70-10-00-100-501.

WARNING

WEAR APPLICABLE PROTECTIVE EQUIPMENT (PPE) WHEN YOU DO THIS TASK. BEFORE YOU USE PPE, READ, UNDERSTAND AND OBEY ALL INSTRUCTIONS FOR IT'S USE. THESE INSTRUCTIONS INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, YOUR EMPLOYER AND GOVERNMENT REGULATIONS. YOU CAN GET INJURED IF YOU DO NOT USE PPE. GET INSTRUCTIONS FROM YOUR EMPLOYER ON WHICH PPE IS NECESSARY.

CAUTION

USE ONLY FILTERED AIR TO CLEAN THE CONNECTOR SOCKETS.Clean inside of the connector.

SUBTASK 24-21-43-110-053 Clean the connector

Examine all the connector components for the correct condition.

Replace as necessary any components that are not of the correct conditions.

Examine the connector for the correct condition.

SUBTASK 24-21-43-220-004 Examine the Connector

If necessary, refer to the Wiring Diagram Manual 24-21-43 and carefully push the wire through the correctly identified hole in the rear grommet, the rubber insert and the intermediate insert.

Make sure that the keyway on the intermediate insert will align with the keyways on the front grommet and the contact locking plate.

Push the cable through the grommet nut.

Remove 0.9 in. to 1.1 in. (23 mm to 28 mm) of the insulation from the cut end of the wire.

Push the conductors into the contact crimp pot.

Make sure that the conductors are visible through the inspection hole and the insulation touches the socket contact all round.

Push the conductors into the Contact crimp pot.

Use the Pneumatic crimp tool with the Locator to crimp the socket contact to the wire.

Crimp the socket contact to the Wire.

Refer to the Wiring Diagram Manual 24-21-43 and insert each numbered contact/wire assembly into the correctly identified hole in the front grommet.

NOTE

The identification marks are on the front face of the grommet.

Push the wire into the front grommet.

Make sure that the machined shoulder of each contact is flush with the rear face of the front grommet.

Install the contact locking plate.

Make sure that the keyway on the contact locking plate is aligned with the keyway on the front grommet.

Install the contact locking plate.

Push the intermediate insert along the wire to touch the contact locking plate.

NOTE

Make sure that the keyways on the intermediate insert, the contact locking plate and the front grommet are aligned.

Move the intermediate insert.

Align the key on the inside of the plug shell with the keyway on the front grommet.

Install the plug shell on the front grommet, the contact locking plate and the intermediate insert.

Push the rubber insert along the wires to touch the intermediate insert.

Push the rear grommet along the wires to enclose the rubber insert.

NOTE

Make sure that the O-ring is installed in the recess on the front face of the rear grommet.Push the grommet nut along the wires and hand tighten on the plug shell.

Install the plug shell and assemble the connector.

Use the Strap Wrench and IAE 1R18201 Torque spanner and torque tighten the grommet nut to 70 lbfin. (7.9 Nm).

Torque the grommet nut.

SUBTASK 24-21-43-350-002 Install the Cable in the Connector

Do a continuity and insulation test. Refer to TASK 24-21-43-700-001.

Test the connector.

SUBTASK 24-21-43-220-054 Test the Connector.

Install the 27 lacings no more than 2.0 in. (50.8 mm) apart on the cable harness. Refer to SPM TASK 70-43-02-400-501.

NOTE

Make sure that the lacings and the controlled twist are in the same position noted in Step after installation.

Install the lacings on the cable harness.

SUBTASK 24-21-43-350-055 Install the Lacings on the Cable Harness

Put the cable into the cable clamp in the correct position for installation.

Safety the cable clamp closed with the two bolts, the two washers and the two nuts.

Use the torque spanner and torque tighten the bolts to 32 lbfin. (3.6 Nm).

Install the cable into the cable clamp.

SUBTASK 24-21-43-350-056 Install the Cable into the Cable Clamp

Put the repair scheme number VRS2791 on the harness, adjacent to the part numbers.

SUBTASK 24-21-43-850-001 Put the Repair Scheme Number on the Harness

Figure: Repair Details And Dimensions

Repair Details And Dimensions