Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-00-02-400-028 (A1/A5-PPBU) - Install The Thermal Anti-Ice (TAI) Valve, Installation-028

General

Fig/item numbers in parentheses in the procedure agree with those used in the EIPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the EIPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Transportation covers/blanks must be removed immediately before installation of the components.

For the torque tightening procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

Special torque data and assembly tolerances are included in this procedure.

Special torque data is identified with the symbol * after the torque value.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 |

Spares

NONESafety Requirements

NONEProcedure

Clean the surface of the E-seals with a clean cloth made moist with CoMat 01-076 METHYL ETHYL KETONE.

SUBTASK 71-00-02-110-001 Clean the Seals

WARNING

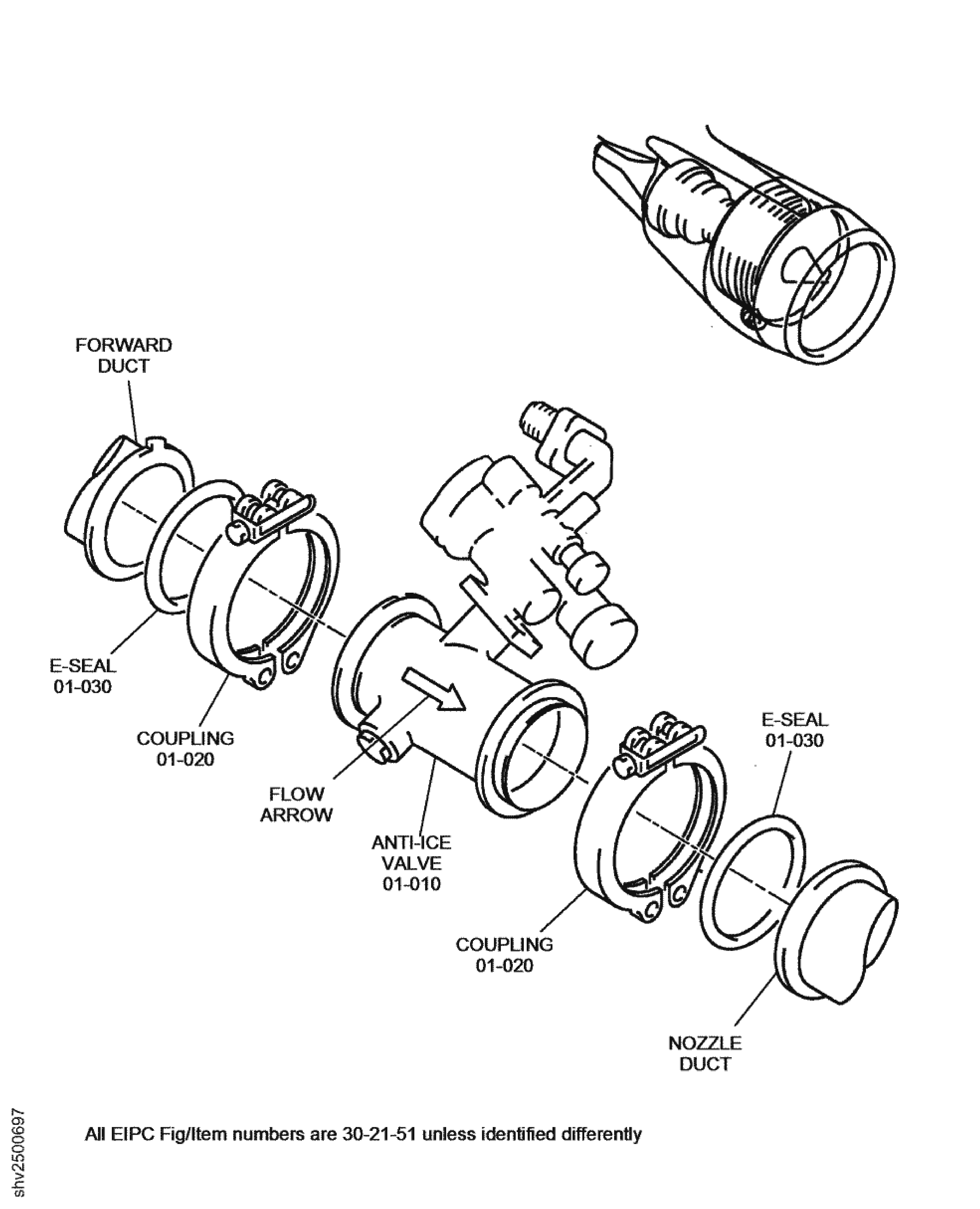

CLEANING FLUID IS CLASSIFIED AS A HAZARDOUS MATERIAL WHICH CAN CAUSE INJURY OR ILLNESS IF NOT PROPERLY USED. THIS PRODUCT MUST BE USED ONLY IN ACCORDANCE WITH THE MANUFACTURER'S SPECIFIC HEALTH AND SAFETY RECOMMENDATIONS. PRIOR TO USE OF THIS PRODUCT, CAREFULLY READ THE APPLICABLE "MATERIAL SAFETY DATA SHEET" AND OBEY ALL LISTED SAFETY AND HEALTH PRECAUTIONS.Put the anti-ice valve ENGINE-AIR INTAKE ANTI ICE VALVE (30-21-51,01-010) between the forward duct and the nozzle duct. Make sure that the flow arrow on the valve points to the nozzle duct and the index mark is aligned with the forward duct.

CAUTION

MAKE SURE THE SMOOTH CIRCULAR SURFACE OF THE COUPLING IS RADIALLY OUTBOARD FROM THE ENGINE. DO NOT LET THE COUPLING TOUCH THE ENGINE COMPONENTS OR STRUCTURE. DAMAGE TO THE COMPONENTS OR STRUCTURE COULD OCCUR.Install the E-seal on the anti-ice valve. Attach the anti-ice valve to the ducts with the couplings.

Attach the anti-ice valve ENGINE-AIR INTAKE ANTI ICE VALVE (30-21-51,01-010) to the ducts:

Install the Valve ENGINE-AIR INTAKE ANTI ICE VALVE (30-21-51,01-010).

SUBTASK 71-00-02-420-151 Install the Thermal Anti-Ice (TAI) Valve

Figure: Install the Thermal Anti-Ice Valve (TAI)

Install the Thermal Anti-Ice Valve (TAI)